Powr-Kraft PK30235L Operation instructions

12-16-13 Revision

1-Stage Snow Thrower

Operator’s Manual

MODEL NUMBER : PK30235L

SERIAL NUMBER :

Both model number and serial number may be found on the main

label. You should record both of them in a safe place for future use.

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE

Save This Manual for Future Reference

Original Instruction

12-16-13 Revision

1-STAGE SNOW THROWER

2

GB TABLE OF CONTENTS

ENVIRONMENTAL

Specifications

INTRODUCTION

Introduction 2

Environmental 2

Symbols 3

Safety 3

General Safety Rules 3

Specific Safety Rules 6

Contents supplied 7

Assembly 8

Know your machine 9

Features & Controls 9

Adjustments 12

Operation 13

Starting and Stopping the Engine 13

Snow Throwing Tips 14

Unclogging Discharge Chute 14

Traveling 15

Transport 15

Maintenance 15

Engine 15

Lubrication 15

Off-Season Storage 15

Service 16

Auger Belt Replacement 16

Auger Paddles Replacement 16

Trouble Shooting 17

Parts Schedule 19

Your new snow thrower will more than satisfy

your expectations. It has been manufactured

under stringent quality standards to meet

superior performance criteria. You will find it

easy and safe to operate, and with proper care, it

will give you many years of dependable service.

Carefully read through this entire

operator’s manual before using your

new snow thrower. Take special care

to heed the cautions and warnings.

Recycle unwanted materials instead

of disposing off them as waste. All

tools, hoses and packaging should

be resorted, taken to the local

recycling center and disposed off in

an environment-friendly safe way.

Your snow thrower has many features that

will make your job faster and easier. Safety,

performance, and dependability have been

given to top priority in the development of this

machine, making it easy to maintain and operate.

The Engine manufacturer is responsible

for all engine-related issues with regards to

performance, power rating, specifications,

warranty and service. Please refer to the Engine

Manufacturer’s owner’s/operator’s manual,

packed separately with your unit, for more

information.

Item No. 30235

Clearing Width 57.5cm

Intake Height 33.2cm

Auger Dia. 24.0cm

Speed 1F

Snow Engine Model LC168FD 196cc

Engine is a made by Loncin and

warranty support is through

www.awsglobal.net. 1-866-393-3968

12-16-13 Revision

1-STAGE SNOW THROWER 3

GB

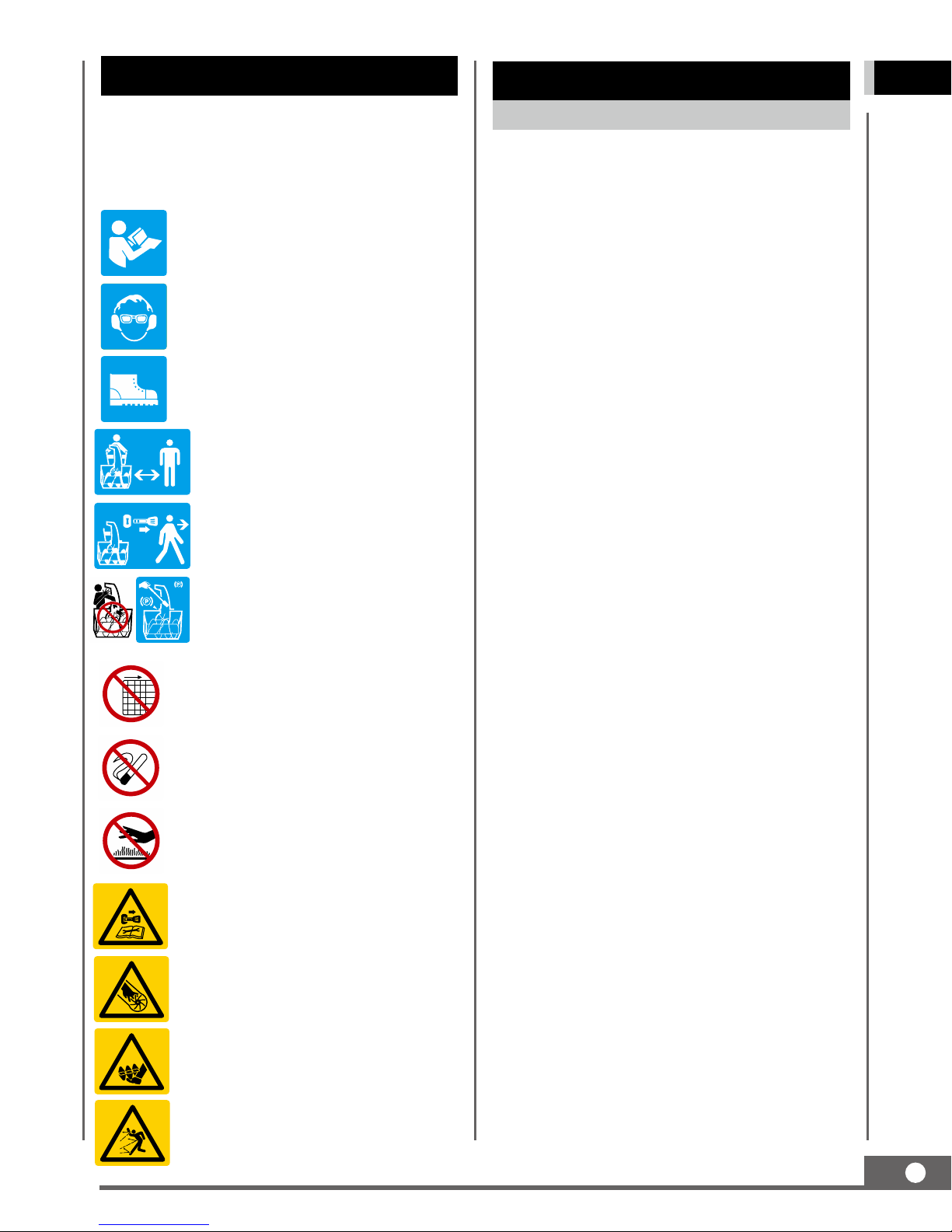

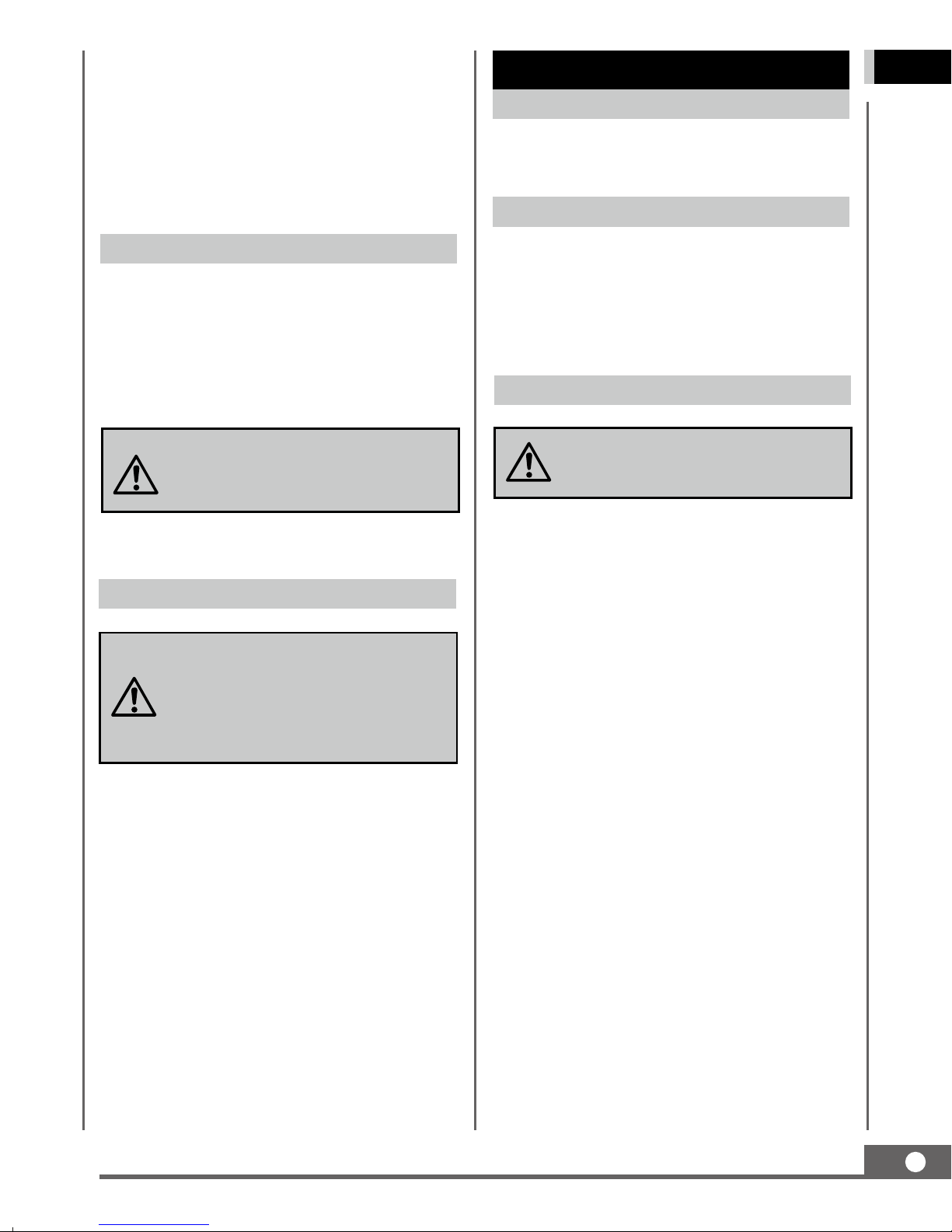

SYMBOLS

The rating plate on you r m a c h i ne may

show symbols. These represent important

information about the product or instructions

on its use.

SAFETY

General Safety Rules

Understand your machine

Allow operation only by properly trained adult,

never children.

Read and understand the operator’s manual

and labels affixed to the machine. Learn its

application and limitations as well as the

specific potential hazards peculiar to it.

Be thoroughly familiar with the controls and

their proper operation. Know how to stop the

machine and disengage the controls quickly.

Make sure to read and understand all the

instructions and safety precautions as outlined

in the Engine Manufacturer’s Manual, packed

separately with your unit. Do not attempt to

operate the machine until you fully understand

how to properly operate and maintain the

Engine and how to avoid accidental injuries

and/or property damage.

Work area

Never start or run the engine inside a closed

area. The exhaust fumes are dangerous,

containing carbon monoxide, an odorless and

deadly gas. Operate this unit only in a well

ventilated outdoor area.

Never operate the machine without good

visibility or light.

Never operate the machine on a steep slope.

Personal safety

Do not operate the machine while under the

influence of drugs, alcohol, or any medication

that could affect your ability to use it properly.

Dress properly. Wear heavy long pants, boots

and gloves. Do not wear loose clothing, short

pants, and jewelry of any kind. Secure long

hair so it is above shoulder level. Keep your

hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

Read these instructions for use

carefully.

Wear eye protection.

Wear hearing protection.

Wear safety footwear.

Keep bystanders away.

Stop engine and remove ignition

key prior to leaving the operator’s

position.

Only use clean-out tool to clear

blockage. Never use your hands.

It is forbidden to remove or tamper

with the protection devices and

safety devices.

Do not smoke or have open flames.

Do not touch a hot muffler, gear

housing or cylinder.

Stop engine, remove key, read

manual before making any repairs

or adjustments.

Keep hands out of the inlet and

discharge openings while machine

is running.

Stay away from rotating augers.

Never direct discharge towards

persons or property.

12-16-13 Revision

1-STAGE SNOW THROWER

4

GB Use safety equipment. Always wear eye

protection. Safety equipment such as a dust

mask, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

Check your machine before starting it. Keep

guards in place and in working order. Make

sure all nuts, bolts, etc. are securely tightened.

Disengage all clutches and shift into neutral

before starting the engine.

Never operate the machine when it is in need

of repair or is in poor mechanical condition.

Replace damaged, missing or failed parts

before using it. Check for fuel leaks. Keep the

machine in safe working condition.

Never tamper with safety device. Check their

proper operation regularly.

Do not use the machine if the engine’s throttle

control does not turn it on or off. Any gasoline

powered machine that can not be controlled

with the engine throttle control is dangerous

and must be replaced.

Form a habit of checking to see that keys

and adjusting wrenches are removed from

machine area before starting it. A wrench or

a key that is left attached to a rotating part of

the machine may result in personal injury.

Stay alert, watch what you are doing and use

common sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or

similar lightweight footwear. Wear protective

footwear that will protect your feet and

improve your footing on slippery surfaces.

Keep proper footing and balance at all times.

This enables better control of the machine in

unexpected situations.

Avoid accidental starting. Be sure the engine’s

throttle control is off before transporting the

machine or performing any maintenance or

service on the unit. Transporting or performing

maintenance or service on a machine with its

throttle control on invites accidents.

Fuel safety

Fuel is highly flammable, and its vapors can

explode if ignited. Take precautions when

using to reduce the chance of serious personal

injury.

When refilling or draining the fuel tank, use

an approved fuel storage container while in

a clean, well-ventilated outdoor area. Do not

smoke, or allow sparks, open flames or other

sources of ignition near the area while adding

fuel or operating the unit. Never fill fuel tank

indoors.

Keep grounded conductive objects, such as

tools, away from exposed, live electrical parts

and connections to avoid sparking or arcing.

These events could ignite fumes or vapors.

Always stop the engine and allow it to cool

before filling the fuel tank. Never remove

the cap of the fuel tank or add fuel while the

engine is running or when the engine is hot.

Do not operate the machine with known leaks

in the fuel system.

When practical, remove the machine from the

truck or trailer and refuel it on the ground. If

this is not possible, then refuel the machine on

a trailer with a portable container, rather than

from a fuel dispenser nozzle.

Loose the fuel tank cap slowly to relieve any

pressure in the tank.

Keep the nozzle in contact with the firm of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lock-

open device.

Never over fill fuel tank. Fill tank to no more

than 12.5mm (1/2”) below the bottom of the

filler neck to provide space for expansion as

the heat of the engine and/or sun cause fuel

to expand.

Replace all fuel tank and container caps

securely and wipe up spilled fuel. Never

operate the unit without the fuel cap securely

in place.

12-16-13 Revision

1-STAGE SNOW THROWER 5

GB

Avoid creating a source of ignition for spilled

fuel. If fuel is spilled, do not attempt to start

the engine but move the machine away

from the area of spillage and avoid creating

any source of ignition until fuel vapors have

dissipated. Serious personal injury can occur

when fuel is pilled on yourself or your clothes

which can ignite. Wash your skin and change

clothes immediately.

Store fuel in containers specifically designed

and approved for this purpose.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

Store fuel in a cool, well-ventilated area.

Safely away from sparks, open flames or other

sources of ignition.

Never store fuel or machine with fuel in the

tank inside a building where fumes may

reach a spark, open flame, or other sources

of ignition, such as a water heater, furnace,

clothes dryer and the like. Allow the engine to

cool before storing in any enclosure.

Machine use and care

Never pick up or carry a machine while the

engine is running.

Do not force the machine. Use the correct

machine for your application. The correct

machine will do the job better and safer at the

rate for which it was designed.

Do not change the engine governor settings

or over-speed the engine. The governor

controls the maximum safe operating speed

of the engine.

Do not put hands or feet near rotating parts.

Avoid contact with hot fuel, oil, exhaust fumes

and hot surfaces. Do not touch the engine or

muffler. These parts get extremely hot from

operation. They remain hot for a short time

after you turn off the unit. Allow the engine

to cool before doing maintenance or making

adjustments.

After striking a foreign object, stop the

engine, remove the wire from the spark

plug, thoroughly inspect the machine for

any damage, and repair the damage before

restarting and operating the machine.

If the machine should start to make an unusual

noise or vibration, immediately shut off the

engine, disconnect the spark plug wire, and

check for the cause. Unusual noise or vibration

is generally warning of trouble.

Us e o nly a t t ach m ents a n d ac c ess o ries

approved by the manufacturer. Failure to do

so can result in personal injury.

Maintain the machine. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

machine’s operation. If damaged, have the

machine repaired before use. Many accidents

are caused by poorly maintained equipment.

Keep the engine and muffler free of grass,

leaves, excessive grease or carbon build up to

reduce the chance of a fire hazard.

Never douse or squirt the unit with water or

any other liquid. Keep handles dry, clean and

free from debris. Clean after each use.

Observe proper disposal laws and regulations

for gas, oil, etc. to protect the environment.

Store idle machine out of the reach of children

and do not allow persons unfamiliar with

the machine or these instructions to operate

it. Machine is dangerous in the hands of

untrained users.

Service

B e fo r e c l ea n i n g , r ep a i r , in s p e c t i ng , o r

adjusting shut off the engine and make certain

all moving parts have stopped. Always make

sure the engine’s throttle control is in its STOP

position. Disconnect the spark plug wire, and

keep the wire away from the plug to prevent

accidental starting.

Have your machine serviced by qualified repair

personnel using only identical replacement

parts. This will ensure that the safety of the

machine maintained.

12-16-13 Revision

1-STAGE SNOW THROWER

6

GB Specific Safety Rules

Do not operate without wearing adequate

winter outer garments.

Do not use the machine on a roof.

Always check overhead and side clearances

carefully before operation. Always be aware of

traffic when operating along streets or curbs.

Thoroughly inspect the area to be worked.

Keep the working area clean and free of toys,

doormats, newspapers, sleds, boards, wires and

other foreign objects, which could be tripped

over or thrown by the auger/impeller. Check

for weak spots on docks, ramps or floors.

Plan your snow-throwing pattern to avoid

discharge toward people or areas where

property damage can occur.

Do not operate near drop-offs, ditches, or

embankments. Machine can suddenly turn

over if a wheel is over the edge of a cliff or

ditch, or if an edge caves in.

Keep all bystanders, children, and pets at least

23m (75 feet) away. If you are approached,

stop the unit immediately.

Use a grounded three-wire extension cord and

receptacle for all machines with electric start

engines.

Check clutch and brake operation frequently.

Adjust and service as required. The auger must

stop quickly when control lever is released.

Let engine and machine adjust to outdoor

temperature before starting to clear snow.

Stay alert for hidden hazards or traffic.

Do not overload machine capacity by attempting

to clear snow at too fast of a rate.

Do not throw snow any higher than necessary.

Adjust auger housing height to clear gravel

or crushed rock surfaces. Exercise extreme

caution when operating.

Exercise caution to avoid slipping or falling,

especially when operating in reverse. Never

operate machine at high transport speeds

on slippery surfaces. Always look down and

behind before and while backing.

Do not operate on steep slopes. Do not clear

snow across the face of slopes. Keep all

movement on slopes slow and gradual. Do not

make sudden changes in speed or direction.

Use a slow speed to avoid stops or shifts on

slopes. Avoid starting or stopping on a slope.

Disengage power to the auger when transporting

or not in use.

Disengage all control levers and stop engine

before you leave the operating position

(behind the handles). Wait until the auger

comes to a complete stop before unclogging

the chute assembly, making any adjustments,

or inspections.

Hand contact with the rotating parts inside

the discharge chute is the most common

cause of injury associated with snow throwers.

Do not unclog chute assembly while engine

is running. Shut off engine and remain behind

handles until all moving parts have stopped

before unclogging. Never put your hand in

the discharge or collector openings. Always

use the clean-out tool provided to unclog the

discharge opening.

12-16-13 Revision

1-STAGE SNOW THROWER 7

GB

The snow thrower comes partially assembled and is shipped in carefully packed carton. After all

the parts have been removed from the carton, you should have:

1. Snow Thrower Unit

2. Discharge Chute

3. Chute Crank Lever

4. Handle

5. Operator’s Manual & Engine Manual

6. Engine Hardware Bag

CONTENTS SUPPLIED

7. Snow Thrower Hardware Bag, Including

63

1

2

74

5

M10 X 45 X 4 A

M5 X 25 X 1 B

ST6.3 X 25 X 3 C

12-16-13 Revision

1-STAGE SNOW THROWER

8

GB

Following the assembly directions below,

you will assemble the snow thrower in a few

minutes

Handle

Install the handle to the lower handle using

four M10X45 screws, washers and nuts. Be

sure not to pinch or kink the auger clutch

cable in the process.

Slowly pull the recoil starter handle up

towards the eye bolt.

Place the chute crank lever onto the chute

rotation rod and secure with the screw and

nut.

Align the holes in the chute base with the

holes in the lower chute and secure with

three screws.

Slip the recoil starter rope into the eye bolt

from the back of the snow thrower.

2.

3.

1

1

2.

ASSEMBLY

Discharge Chute

M10 X 45 X 4 A

M5 X 25 X 1 B

ST6.3 X 25 X 3 C

Do not overtighten the screws;

otherwise you may damage the

discharge chute and prevent it from

turning freely.

12-16-13 Revision

1-STAGE SNOW THROWER 9

GB

KNOW YOUR MACHINE

Features and Controls

Chute Deflector

Fuel Filler Cap

Auger Clutch

Cable Adjuster Link

Recoil Start Handle

Discharge Chute

Auger

Scraper Blade

Belt Cover

Chute Crank Lever

Engine Oil Fill Cap w/Dipstick

Safety Ignition Switch

Electric Start Botton

Primer

Choke

Power Cord Plug

Oil Drain Plug

12-16-13 Revision

1-STAGE SNOW THROWER

10

GB

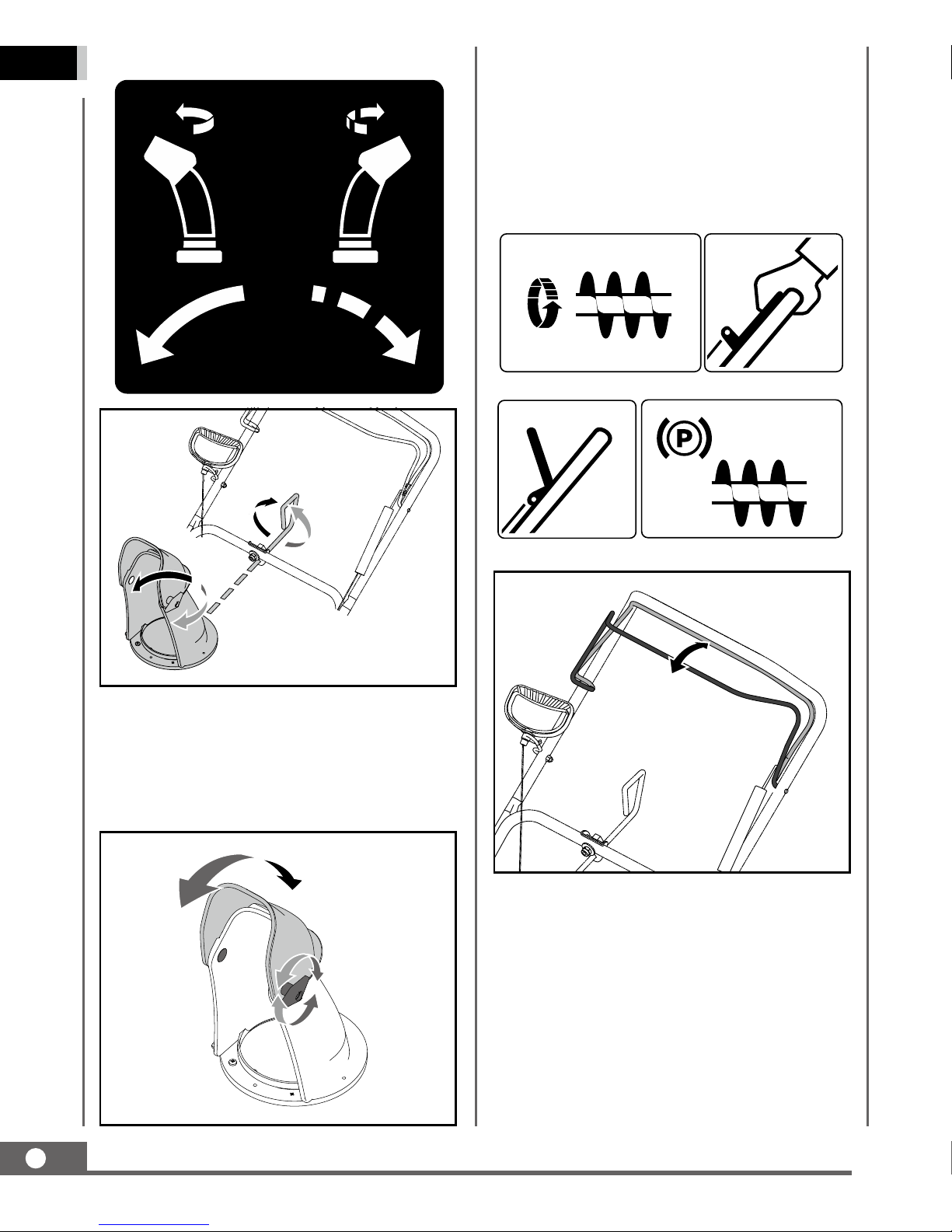

Rotate the discharge crank lever clockwise

to move the discharge chute to the right;

counterclockwise to move the chute to the

left.

Loosen the deflector wing knob and adjust

the chute deflector up or down to control the

snow discharge height and distance. Tighten

the wing knob securely to hold the desired

deflector adjustment once the desired position

have been achieved.

Chute Crank Lever

Chute Deflector

Auger Clutch

To engage the auger and start throwing snow,

hold the auger clutch against the handle.

To disengage the auger, release the auger

clutch.

Auger & Scraper Blade

When engaged, the auger rotates and draws

snow into the auger housing and throws it out

the discharge chute. Rubber paddles on the

auger also aid in propelling the snow thrower

as they come in contact with the pavement.

12-16-13 Revision

1-STAGE SNOW THROWER 11

GB

The scraper blade maintains contact with the

pavement as the snow thrower is propelled,

allowing snow close to the pavement’s surface

to be discharged.

The auger and the scraper blade are subject

to wear and damage. They should be checked

periodically. Adjust or replace when necessary.

During initial break-in period of

the auger, i t is normal for the

auger to build up excessive heat if

not operated in the snow. Do not

operate without snow or water for

lubricating the auger. This will cause

excessive heat build up in the auger

which could cause damage to the

auger and scraper blade.

Do not use the primer if the engine

h a s b e e n r u n n i n g a n d i s h o t .

Excessive priming may flood the

engine and prevent it from starting.

Use an extension cord recommended

for outdoor use that is not longer

than 15m (50 feet)

Thoroughly inspect the electrical

cord before using the machine. If

the cord is damaged, do not operate

the machine. Replace or repair the

damaged cord immediately.

Connect exten sion cord to the

electric starter plug-in first and

then to a power outlet; disconnect

the extension cord from the power

ou t le t fi r s t an d t hen f r om th e

machine.

To prevent damaging the electric

starter, do not run it more than

5 continuous seconds each time

you try to start. Wait 10 seconds

between each attempt.

Unplug the power cord whenever

yo u a re no t st ar t i ng t h e sn o w

thrower.

D u r i n g i n i t i a l o p e r a t i o n t h e r e

may be wear between the auger

and the scraper blade. Maximum

performance, both snow throwing

and driving, occurs when there is

zero clearance between these two

parts.

Firmly push in the primer with your

thumb, holding the primer in for a

second before releasing it each time.

Remove your glove when you push

in the primer so that air can not

escape from the primer hole.

Choke

Engage choke by rotating lever to FULL

position whenever you are starting a cold

engine. As engine warms up, gradually rotate

the choke to the OFF position.

Recoil Starter

The recoil starter is on the back side of the

engine. Pull the recoil starter handle to start

the engine.

Safety Ignition Switch

Insert the safety ignition key for engine to

start and run. To stop the engine, remove the

key.

Electric Starter & Start Button (if so equipped)

The electric starter will start a properly choked

and cranked engine when start button is

pushed.

To start the machine, connect the electric

starter to an electric power source with an

approved extension cord and press the start

button.

Do not use choke to start a warm

engine.

Never use choke to stop engine.

Primer

Press the primer to pump additional fuel from

the carburetor to the cylinder for improved

cold weather starting.

12-16-13 Revision

1-STAGE SNOW THROWER

12

GB

Scraper Blade

When place the snow thrower on a level

surface, the wheels, scraper blade and auger

should all contact the lever surface. If the

scraper blade is adjusted too high, snow may

blow under the housing. If the scraper blade

wears out excessively, or the snow thrower

does not self-propel, the scraper blade may be

too low and needs to be adjusted.

Auger Clutch

The auger must not turn unless the auger

clutch is engaged. The auger must stop within

5 seconds after the auger clutch is released.

If the auger no longer turns when the auger

clutch is engaged or if the belt slips under

load, the auger cable or belt may have

stretched. This can be compensated for by

adjusting the auger clutch cable.

The upper hole in auger clutch lever provides

for an quick adjustment method. To adjust,

unhook and move the clutch cable to the

upper position. Insert the cable from the

outside.

The cable adjuster link on the auger clutch

ca b l e provi d e s the m et h o d for v erni e r

adjustment:

To adjust the scraper blade proceed as

follows:

Adjustments

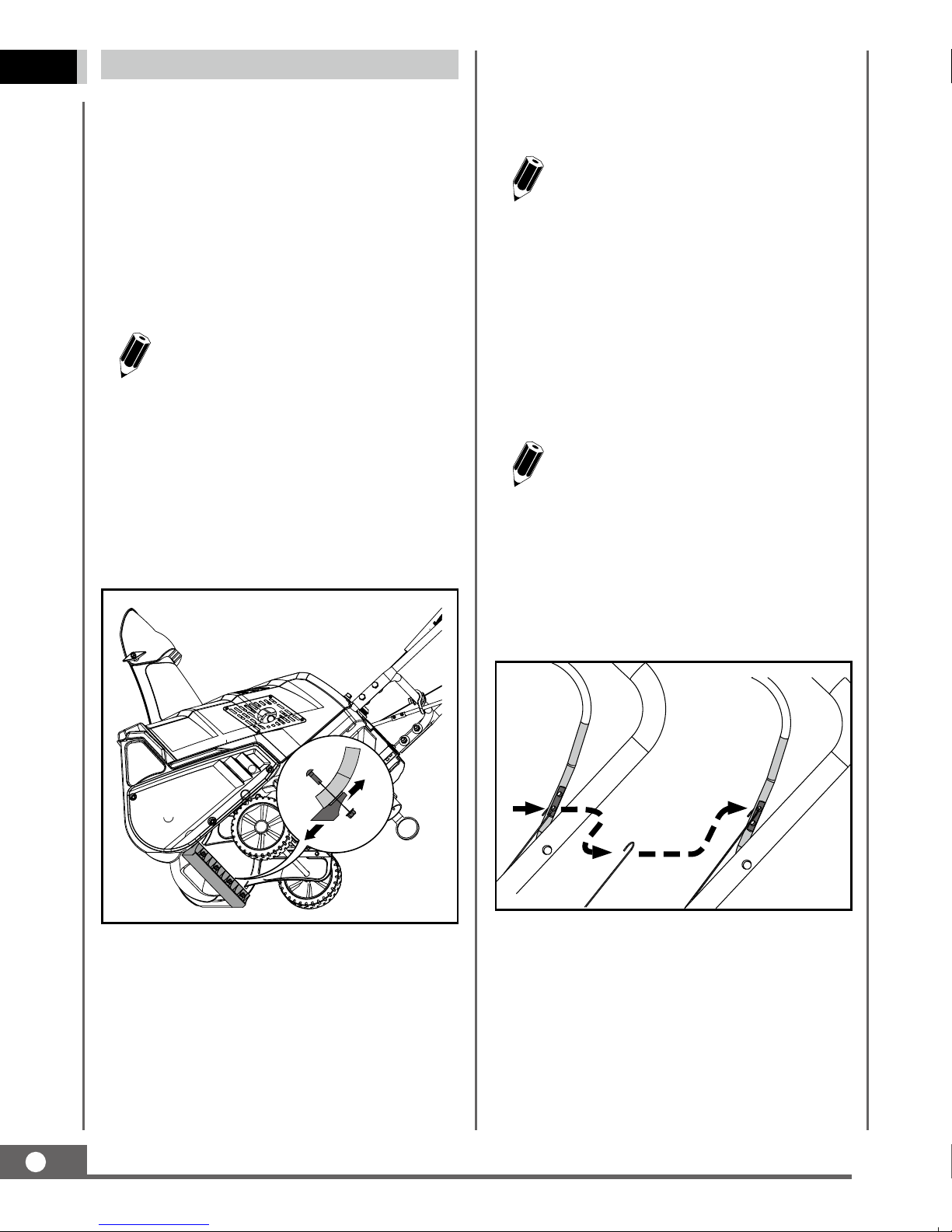

Run the snow thrower until the fuel tank is

empty.

Pull the recoil starter handle until resistance

is felt. Then tip the snow thrower back until

it rest on the handle.

Loosen the four flange lock nuts and

carriage screws which secure the scraper

blade to housing. Move the scraper blade

to the desired position and retighten the

nuts and screws securely.

T i p t h e s n o w t h r o w e r b a c k t o t h e

operating position and pull the starter

handle a few times to see if it is difficult to

pull.

If the starter is difficult to pull, remove

the spark plug and pull the handle several

times to ensure that any oil trapped in the

head is removed.

Inspect the spark plug. If it is wet, clean off

any oil before re-installing.

1

2.

3.

5.

6.

4.

On new snow throwers with a new

scraper blade installed, the auger

may be slightly off the ground.

Oil may come out of the spark plug

hole when it is removed and the

starter handle is pulled.

The clutch cable must contain some

slack when you disengage the clutch

lever for the auger to stop properly.

12-16-13 Revision

1-STAGE SNOW THROWER 13

GB

Test the snow thrower to see if there is a

noticeable difference. If after the adjustment

to the control cable the auger still hesitates

when rotating, replace the auger belt.

Slide up the spring cover and unhook the

spring from the adjuster link.

Move the Z-bend to a higher or lower hole

on the adjuster link as needed to obtain

proper auger clutch adjustment.

Hook the spring to the adjuster link and

slide the spring cover over the adjuster

link.

1

2.

3.

You can pull up the adjuster link and

cable to make unhooking the spring

easier.

Z-bend

Spring Hook

Spring Cover

Adjuster link

OPERATION

Starting and Stopping the Engine

The engine is equipped with both electric

starter and a recoil starter. The electric starter

is equipped with a three-wire power cord and

plug and is designed to operate at the voltage

shown in the label.

Cold Start – Electric Starter (if so equipped)

Before starting the engine, check

engine oil level and ensure the

engine is served as described in

the Engine Manual with the snow

thrower.

Do not use the electric starter if

your household voltage different

from the one shown on the electric

starter.

Insert safety ignition key into ignition slot

until it clicks. Do not turn the key.

Move choke control to FULL position.

Push the primer 2 or 3 times. When temperature

is below -25oC (15oF), additional priming may

be needed. When temperature is above 10oC

(50oF), priming is not necessary.

Connect the extension cord to the engine.

Plug the other end of the extension cord

into a three-wire grounded receptacle.

Push starter button until engine starts.

1

4.

5.

6.

2.

3.

Over priming may cause flooding,

preventing the engine from starting.

If you do flood the engine, wait a

few minutes before attempting to

start and do not push the primer.

To prevent damaging the electric

starter, do not run it more than

5 continuous seconds each time

you try to start. Wait 10 seconds

between each attempt.

12-16-13 Revision

1-STAGE SNOW THROWER

14

GB 7. When the engine starts, release the starter

button and slowly move the choke control

to the OFF position.

8. Disconnect the extension cord from the

receptacle first, then from the engine.

Insert safety ignition key into ignition slot

until it clicks. Do not turn the key.

2. Rotate choke control to FULL position.

3. Pu s h t h e prime r 2 or 3 times. Wh en

t e m pe r a t u r e i s b e l o w - 2 5 oC ( 1 5 oF ) ,

additional priming may be needed. When

temperature is above 10oC (50oF), priming

is not necessary.

Grasp recoil starter handle and pull rope

out slowly until it pulls harder. Let rope

rewind slowly.

Pull rope with a rapid continuous full arm

stroke. Do not allow starter rope to snap

back.

Repeat steps 4 and 5 until engine starts.

When the engine starts, release the recoil

starter handle and slowly move the choke

control to the OFF position.

Follow the steps above, keeping the choke

control in the OFF position and do not use

primer.

1

5.

6.

7.

4.

Cold Start – Recoil Starter

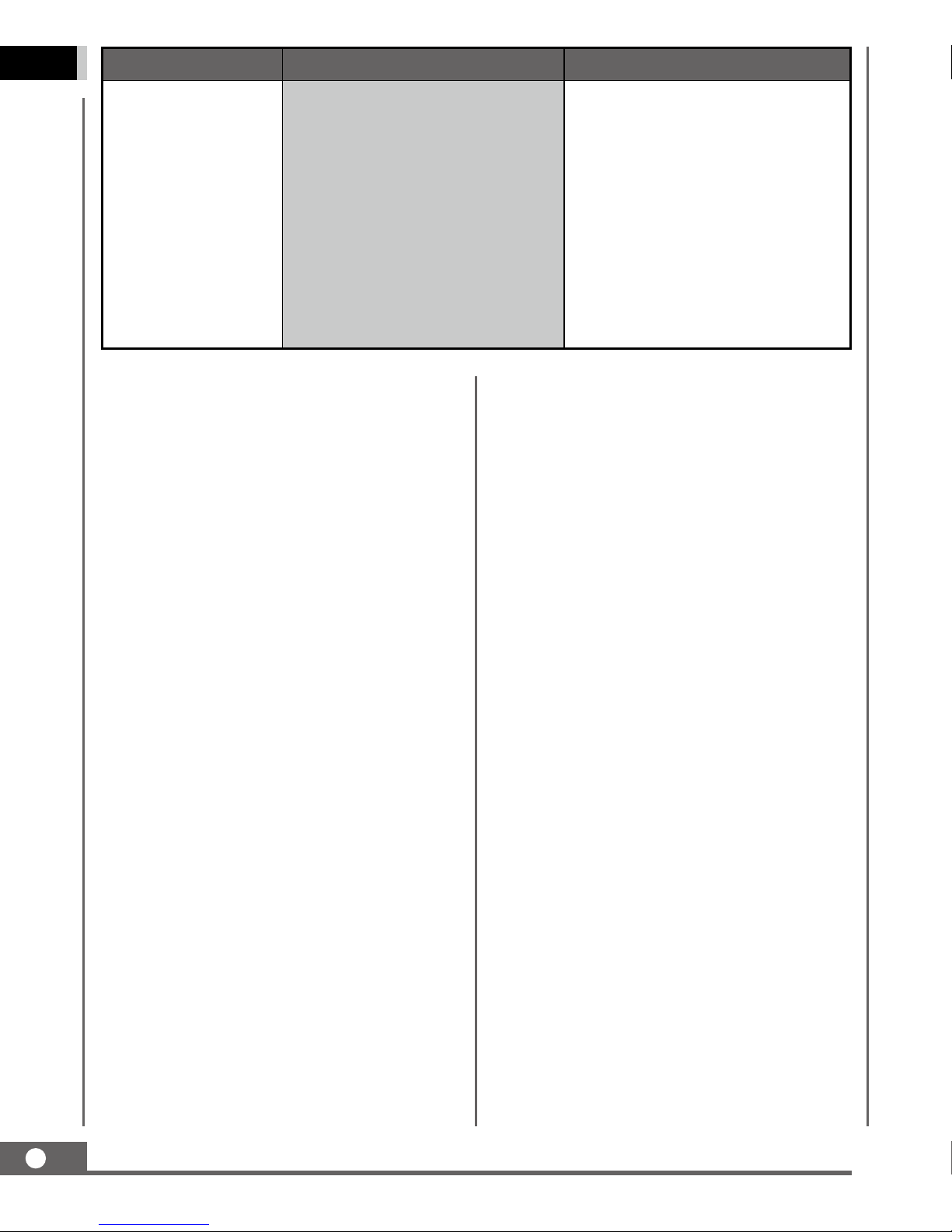

It is easier and more efficient to remove snow

immediately after it falls.

The best time to remove snow is the early

morning. At this time the snow is usually dry

and has not been exposed to the direct sun

and warming temperatures.

Slightly overlap each successive path to

ensure all snow will be removed.

For large areas, start in the middle and throw

snow to each side, so snow is not cleared

more than once.

For extremely heavy snow, reduce the width

of snow removal by overlapping previous path

and moving slowly.

Throw snow downwind whenever possible.

On gravel or crushed rock surfaces, push

down slightly on the handle to avoid ingesting

rocks. Do not allow rocks and gravel to be

picked up and thrown from snow thrower.

Keep engine clean and clear of snow during

use. This will help air flow and extend engine

life.

After snow-throwing is completed, let the

engine run for a few minutes to help dry

off the moisture on the engine and prevent

moving parts from freezing. Engage the auger

to clear any remaining snow from inside

the housing. Rotate the discharge chute to

prevent it from freezing. Stop the engine, wait

for all moving parts to stop, and remove all

ice and snow from the snow thrower. With

the engine off, pull the recoil starter handle

several times to prevent the recoil starter from

freezing up.

Warm Start

Over priming may cause flooding,

preventing the engine from starting.

If you do flood the engine, wait a

few minutes before attempting to

start and do not push the primer.

Allow the engine to warm up for a

few minutes, engine will not develop

full power until it has reached normal

operating temperature.

I n s n o w y a n d c o l d c o n d i t i o n s ,

some controls and moving parts

may freeze. Do not use excessive

force when trying to operate frozen

con t r o l s . I f y ou have diffic ul t y

operating any control or part, start

the engine and let is run for a few

minutes.

Unclogging Discharge Chute

Never use your hands to clear a

clogged discharge chute. Shut off

engine and remain behind handle

until all moving parts have stopped

before unclogging.

12-16-13 Revision

1-STAGE SNOW THROWER 15

GB

Tip the handle forward slightly to allow the

rubber paddles on the auger to contact the

pavement and propel the snow thrower

forward. Pushing downward on the handle

will raise the auger off the ground and stop

forward motion.

Traveling

Excessive upward pressure on the

handle will result in premature wear

on the rubber auger paddles.

Always shut off engine, remove

key, and close fuel shut-off valve

when transporting unit on a truck

or trailer. Do not transport machine

while engine is running.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle. Never

secure from rods or linkages that could be

damaged.

Transport

MAINTENANCE

Engine

Lubrication

Refer to the Engine Operator’s Manual.

Lubricate the pivot points on the auger clutch

lever and the spring at the end of the clutch

cable with a light oil once every season before

off-season storage.

At the end of the season or if the snow

thrower will not be used for 30 days or longer,

follow the storage instructions below.

Refer to the Engine Manual for

information on storing your engine.

Off-Season Storage

Run the engine until the fuel lines and

carburetor are empty and it stops due to

lack of fuel.

Remove the safety ignition key and allow

the engine to cool.

Lubricate the machine as instructed.

Clean the exterior of the engine and the

snow thrower thoroughly.

Touch up all rusted or chipped paint

surfaces; sand affected areas before

painting, and use a rust preventative to

prevent the metal parts from rusting.

Tighte n a l l loose s c r e w s, bol ts , and

locknuts. Repair or replace any damaged

parts.

Cover the machine and store it in a clean,

dry place out of the reach of children.

1.

2.

3.

4.

5.

6.

7.

12-16-13 Revision

1-STAGE SNOW THROWER

16

GB

Remove the screws that hold the belt

cover in place and set the cover aside.

Remove the existing rubber paddles by

unthreading the hex washer screws which

secure them to the auger.

Secure the replacement rubber paddles

to the auger using the hardware removed

earlier.

Route the end of the new belt around the

auger pulley and slide the pulley back on

to the auger shaft. It may be necessary to

push down on the idler pulley to get the

auger pulley under the belt keeper.

Replace the screw and washer and tighten

securely.

Reinstall the belt cover removed earlier.

Route the new belt around the drive pulley

and under the idler pulley.

Remove the auger pulley and the belt.

1

1

3.

4.

5.

6.

2.

2.

SERVICE

Auger Belt Replacement

If the auger belt becomes worn, oil-soaked,

or otherwise damaged, proceed as follows to

replace the belt.

The snow thrower auger’s rubber paddles are

subject to wear and should be replaced if any

signs of excessive wear are present.

Auger Paddles Replacement

Do not allow the auger’s rubber

paddles to wear to the point where

portions of the metal auger itself

c a n c o m e i n c o n t a c t w i t h t h e

pavem ent. Doing so can result

in serious damage to the snow

thrower.

T h e a u g e r p a d d l e s s h o u l d b e

replaced one at a time so that the

auger still attached can be used as

an example for positioning and re-

installing the new auger.

12-16-13 Revision

1-STAGE SNOW THROWER 17

GB

TROUBLE SHOOTING

Problem Cause Remedy

Electric starter does

not turn(on models so

equipped)

1.Extension cord not connected.

2.The extension cord is worn,

corroded, or damaged.

3.The power outlet is not energized.

1.Connect the extension cord to the

outlet and/or the machine.

2.Replace the extension cord.

3.Have a qualified electrician

energize the outlet.

Engine fails to start

1.Choke not in CHOKE position.

2.Engine not primed.

3.Engine is flooded.

4.Spark plug wire loose or

disconnected.

5.Fuel tank empty or stale fuel.

6.Faulty spark plug.

7.Safety ignition key is not inserted.

8.The engine oil level in the engine

crankcase is too low or too high.

1. Move choke to CHOKE position.

2.Prime engine as instructed in this

manual.

3.Wait a few minutes before

restarting, do not prime.

4.Connect or tighten spark plug wire.

5.Fill tank with clean, fresh gasoline.

6.Clean, adjust gap, or replace.

7.Insert safety ignition key.

8.Add or drain oil to adjust the oil

level in the engine crankcase.

Engine idles or runs

roughly

1.Engine running on CHOKE.

2.Fuel tank is nearly empty or stale

fuel.

3.Contaminated fuel supply.

4.Carburetor out of adjustment.

5.Engine over-governed.

6.Spark plug wire loose.

7.Faulty spark plug.

8.The engine oil level in the engine

crankcase is too low or too high.

1. Move choke lever to RUN position.

2.Fill tank with clean, fresh gasoline.

3.Replace with clean fuel.

4.Contact a qualified repair

personnel.

5.Contact a qualified repair

personnel.

6.Tighten spark plug wire.

7.Clean, adjust gap, or replace.

8.Add or drain oil to adjust the oil

level in the engine crankcase.

Loss of power

1.Spark plug wire loose.

2.Gas gap vent hole plugged.

3.Dirty or clogged muffler.

1. Tighten spark plug wire.

2.Clean or replace fuel cap.

3.Clean or replace muffler

The engine overheats Carburetor not adjusted properly. Contact a qualified repair personnel.

Excessive vibration Loose parts or damaged parts. Tighten all fasteners or replace

damaged parts.

Snow thrower fails to

self-propel

1.Auger clutch cable out of

adjustment.

2.Auger belt loose or damaged.

1. Adjust auger clutch cable.

2. Replace auger belt.

Auger fails to stop

within 5 seconds

after auger clutch is

released.

Auger clutch cable out of

adjustment. Adjust auger clutch cable.

12-16-13 Revision

1-STAGE SNOW THROWER

18

GB Problem Cause Remedy

Snow thrower fails to

discharge snow

1.Discharge chute clogged.

2.Auger jammed.

3.Auger clutch cable not adjusted

properly.

4.Auger belt loose or damaged.

5.Auger rubber paddles worn or

damaged.

6.Throwing too much snow.

7.Trying to remove extremely heavy

or wet snow.

8.Auger is frozen in place.

1. Unclog discharge chute.

2.Remove debris or foreign object

from auger.

3.Adjust auger clutch cable.

4.Replace auger belt.

5.Replace rubber paddles.

6.Reduce width of swath.

7.Do not overload with extremely

heavy or wet snow.

8.Move unit to a warm place to

thaw.

12-16-13 Revision

1-STAGE SNOW THROWER 19

GB

PARTS SCHEDULE

12-16-13 Revision

Parts Request Form

Faxto541‐895‐2756orE‐mail

Name:

Address:

City State Zip:

Phone:

E‐mail:

Model Number:

Serial Number:

Purchased From:

Purchase Date:

Item No. Description Qty Price Amount

Comments:

Table of contents

Other Powr-Kraft Snow Blower manuals