PPSTinc 12.5-135/400 User manual

Induction Power Supplies

12.5KW; 135 – 400 KHz

LCD Display

(Integral Heat Station)

User’s Guide

Model 12.5-135/400

05/08

Rev D

1. Specifications and features...................................................................................... 3

2. Getting started........................................................................................................... 6

3. Connections .............................................................................................................. 8

4. Front panel description and operation.................................................................. 10

5. Programming and Status monitor ......................................................................... 16

6. Load station tuning. ................................................................................................ 22

7. APPENDIX A: USER INTERFACE........................................................................... 25

8. Layout.………………………………………………………………………………………27

9. Finding dew point…………………………………………………………………………28

2

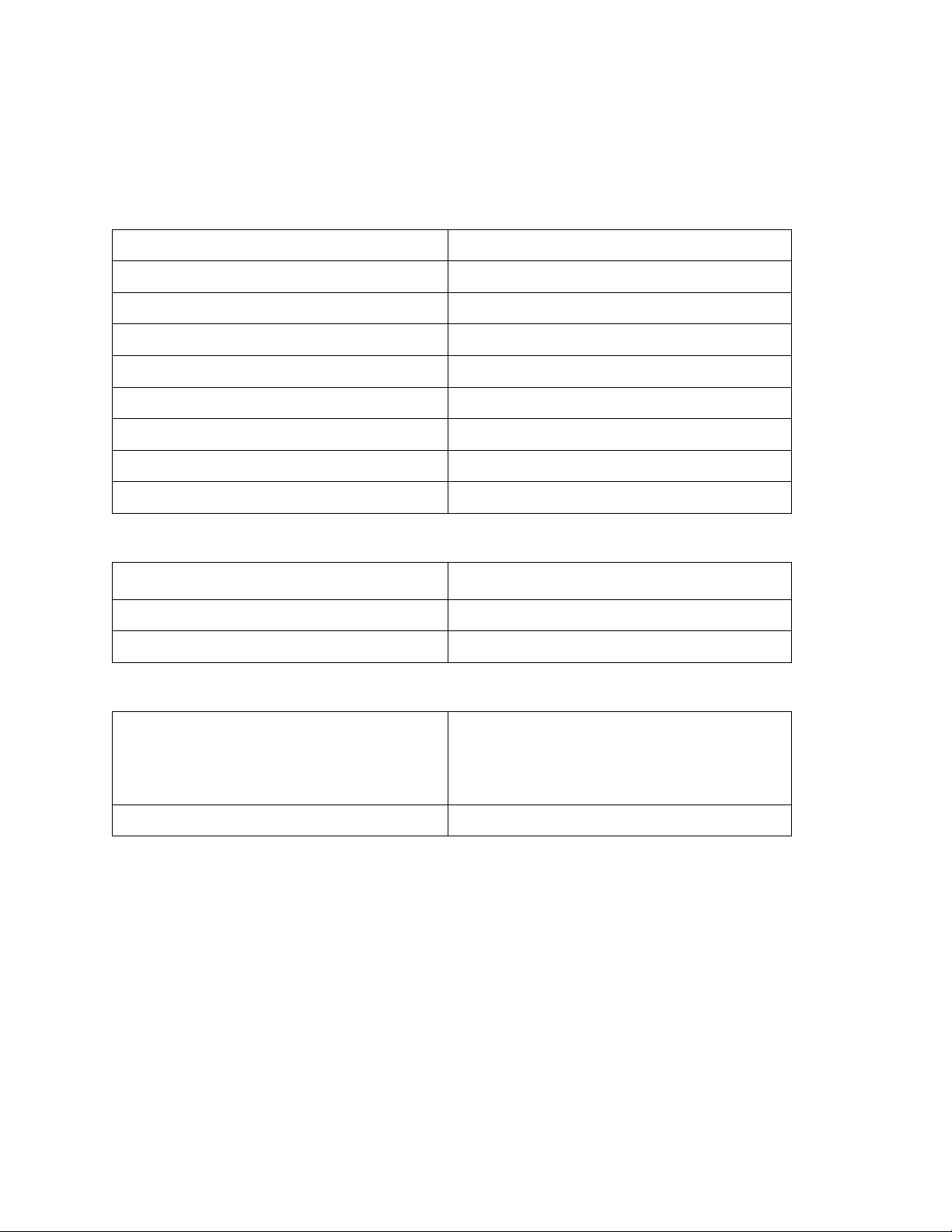

1. Specifications and features

1.1. Output

Maximum Power 12.5kW1

Maximum Apparent Power 25kVA @ 240V input

Minimum Power Factor 0.5 @ 480V input

Duty Cycle 100%

Maximum Voltage 500V 2

Power Transformers (6) 2 :1

Frequency Range 135kHz to 400kHz

Maximum response time 0.1s3

Minimum Allowed OFF-Time 0.5s

1.2. Input

AC line-to-line voltage 240V 10%, 3

, 50 to 60Hz

AC line current 35A @ 240V

AC power 14.5kVA

1.3. Physical

Dimensions: Depth

Width

Height

16in (41cm)

20in (51cm)

43.75in (111cm)

Weight 275lb (125kg) approximately

1 Inverter output power i.e. includes power losses in heat station.

2 Mainly limited by the rating of resonant capacitors. Consult manufacturer for operating

at output voltages above 500V rms.

3 When using the adjustable start-frequency feature.

3

1.4. Front panel controls and indicators

LED Indicators

Yellow indicator for limit.

Red indicators for fault and trip.

Red indicator for fault.

Yellow and Green indicators for heat

on and off.

Numeric Displays Run time read-outs for:

Job and Step for Programmed mode

Elapsed time for heat period

power meter (0-100%)

LCD Display Working mode and Messages for fault,

trip and limit

Run time read-outs for:

Power demand, operating frequency,

capacitor voltage and inverter current

Controls – Switch and knob Push button switch for Heat ON/OFF.

Single turn knob for power level.

(Manual mode)

Pushbutton to reset trips.

Emergency stop button.

Program keys 21 keys for Program and monitoring

command

4

1.5. Internal heat station

Resonant capacitors Mounting space provided for sixteen

capacitors. Eight 210nF, 500V or 8

200nF, 700V capacitors supplied.

330nf available

Series Parallel Capacitor Rail Kit available (optional)

Series inductor Adjustable for load matching

1.6. Protection

Power Limited to 12.5kW in any feedback

configuration

Inverter output current Limited to 250A peak. Short circuit

protected.

Resonant capacitor voltage Limited to 500V rms

Line current 50A Circuit breaker

DC link current 80A Semiconductor fuse

Temperature and cooling water Temperature switch on inlet water.

Differential pressure switch between

water inlet and outlet.

Safety Interlocks Emergency stop button or door switch

opens the main circuit breaker.

1.7. Load

Quality factor of load Will operate with any load Q (including

resistive loads), provided that the

output frequency and voltage is within

the specifications.

Connection Selectable between left and right.

Custom output connection provided.

1.8. Cooling water

Maximum pressure 100PSI (690kPa)

Minimum differential pressure 30PSI (207kPa)

Minimum water flow 2GPM (0.126l/s)

Maximum inlet water temperature 110F (43.3C)

Minimum inlet water temperature Approx. 90º F (32ºC)**

Minimum water resistivity 590.in (1500.cm)

Supply hose location Selectable between left or right

** must be set above dew point (see page 29)

5

2. Getting started

2.1. Safety Warnings

HIGH FREQUECY RADIATION can interfere with radio navagation, safety

services, computers and communication equiptment.

Have only qualified person familiar with electronic equiptment perform this

installation.

The user is responsible for having a qualified electrician promptly correct any

interference problem resulting from the installation.

Any modifications performed on this power supply may void warranty.

Contact manufactor for approval before any modifications are performed.

Have the installation regularly checked and maintained.

Keep high-frequency source door and panels tightly shut.

1. Read this operation manual completely before using the power supply.

2. Induction heating can be dangerous. Obey all warnings on unit and in

manual.

3. Do not touch live electrical parts. In operation, this means the output

connectors, the work coil, the work piece, and any bus work or cabling

connecting them.

WARNING: These symbols, placed at the outputs of the

power supply, warn of the electric shock hazard there and

RF burn hazard at the outputs when the unit is operating.

Disconnect input power before installing or servicing this

unit. The input AC voltage is live at the top of the main circuit

breaker and the control power circuit breaker. The door

interlock will prevent the main breaker from being closed when

the door in opened, but the control power breaker can be on

and 240VAC can be live inside the cabinet.

6

2.2. Set-up

The following is a list of steps describing the required actions to get the power supply

set up.

1. Check for any visual damage that could have happened during shipment. Check all

plug-in connectors on PCBs.

WARNING: Make sure that the

power is locked out before

connecting the input power.

2. Ensure that both the circuit breakers, located on the door of the unit, are in the OFF

position. Wire the power supply to the supply voltage as described in section 0

3. Connect the heating coil and load to the output of the unit (see section 4.).

4. Connect and test the cooling water supply, as described in section 0

5. Read section 0to become familiar with the front panel controls.

6. Do initial setups of the internal heat station, as described in section 6.1.

7. Do the tuning of the heat station, as described in section 6.2 The power supply will

not operate if the emergency stop button is pressed in or the door is not closed.

8. The unit is now ready for operation, and can be controlled by the front panel.

9. The unit is programmed for power control. For inverter current, load voltage or

auxiliary control see section 5.1.

7

3. Connections

3

This section gives a description of the required steps to connect the supply voltage,

load, cooling water and remote loader to the unit. 3

3.1 Three phase input voltage

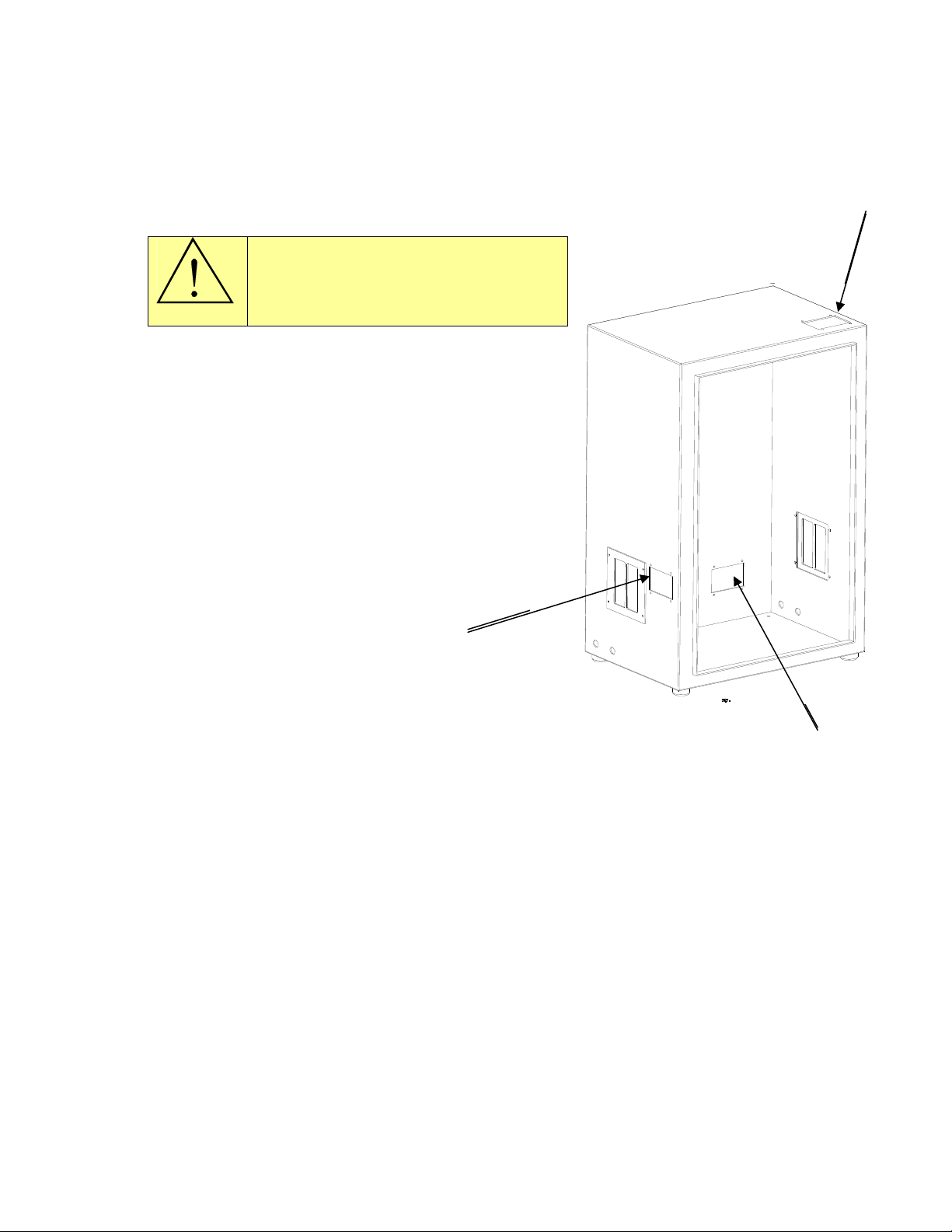

WARNING: Make sure that the

power is locked out before

connecting AC power to the unit.

Connect only 220-240V, 3~.

A hole needs to be punched in the cabinet of the

power supply for the supply voltage cable. It can

be done in one of two recommended locations.

The primary location (1) is on the left side of

cabinet next to left blank cover. The second

location (2) is at right side rear. Cut-outs in

cabinets will be available and cover plates will

be removable to make it easy for drilling holes

for power cables.

1

(3) A third cutout is provided for control

wiring.

2

3.2 Load

The load can be connected to the left or right side of the power supply. The unit is

shipped with the output on the right hand side. To change the output to the left hand

side, exchange the copper output blocks and covers between the two sides. The load or

cables connect to the output blocks. Ensure o-rings are used to avoid water leakage.

See Figure 2.

8

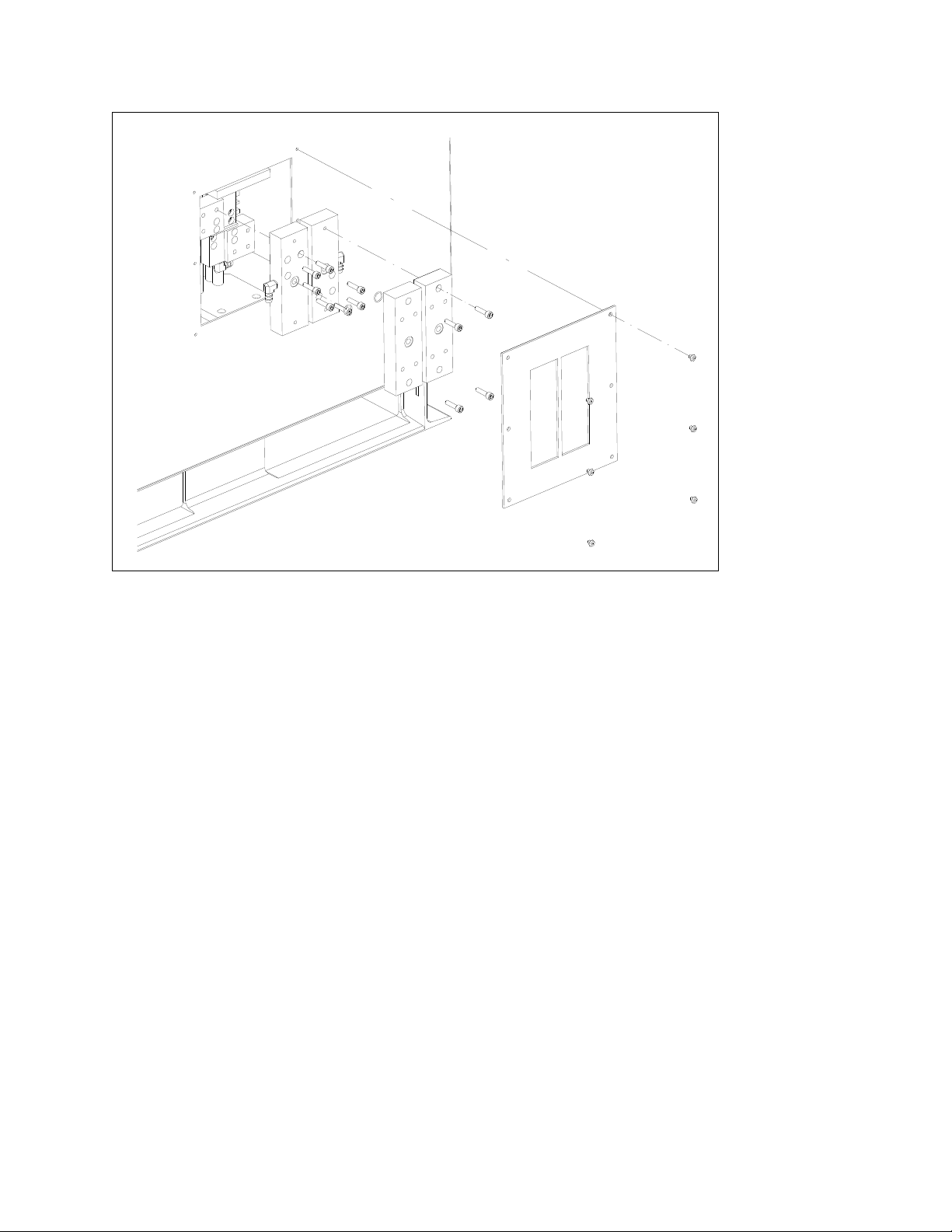

Figure 2: Output blocks mounting.

3.3 Cooling water

The cooling water can be connected to the left or right side of the power supply. The

unit is shipped with the water inputs on the left hand side. Two female ¼” NPT

connections are provided. If required, move the water fittings to the right hand side.

Keep the input towards the back of the unit and output towards the front of the unit

location. The unit will not operate if the water flow is reversed.

Turn on the cooling water flow and verify that it meets the minimum requirements as

given in section 1.8. on page 5. Check for any water leaks on the inlet, outlet and

heating coil. Tighten connections if necessary. Also check for any water leaks inside the

unit that could have been caused by shipping, and tighten any hose clamps if

necessary.

9

4. Front panel description and operation

4.1 Front panel description

This section identifies and describes the various parts of the front panel.

1 2

3 5

6

7 8 9

4

10

1) Fault, Trip and Limit LEDs

2) Heat On/Off LEDs

3) Program Indicator

4) Time Indicator

5) Power Indicator

6) LCD display

7) Reset button

8) Heat switch

9) Power Knob

10) Program Buttons

Figure 3: Front panel layout.

10

4.1.1 Fault, Trip and Limit indicators

Identified by --in Figure 3.

Fault indicator: This indicator is red in color and is lit if the unit gets any faults. No

power is being delivered to the load and the heat OFF indicator will be lit.

There are six fault statuses displayed on LCD:

E-STOP: Indicates that the unit is in Emergency stop status.

AUX INT: An auxiliary interlock wired to the unit has tripped it.

DOOR OPEN: Indicates that the door of the unit is not closed.

WATER PRESS: Indicates that there is inadequate differential water pressure.

WATER TEMP: Indicates that the temperature of the inlet water has exceeded the

allowable level. (see 5.2.)

PARAMETER: Indicates that the wrong parameters have been set. (see 5.2.)

Trip indicator: This indicator is red in color and is lit when the unit has been tripped. No

power is being delivered to the load and the heat OFF indicator will be lit.

There are three trip statuses displayed on LCD:

SW/THRU TRIP: The inverter circuit failed or swing through signal missing due to a

short in the load, heat station component or poor tuning of the heat station

components.

RES TRIP: The circuit momentarily operated below the resonant frequency due to

e.g. a short in the load or heat station component or poor tuning of the heat station

components.

I.C TRIP: The inverter current momentarily exceeded the set maximum peak value

due to e.g. a short in the load or heat station component of poor tuning of the heat

station components.

Limit indicator: This indicator is yellow in color and is lit when the heat station is not

properly tuned. The power output of the unit is limited below the desired level set by the

power knob or remote input. There are four limit indicators:

POWER LIMIT: If lit the power is being limited at 12.5kW.

FRQ LIMIT: If lit the circuit is being limited at the resonant frequency of the

resonant tank.

C.V LIMIT: If lit the capacitor voltage is being limited at 500V or 700V rms.

I.C LIMIT: If lit the inverter current is being limited at 250A peak. (Note: The load

coil current could be much higher than 250A peak).

C.V, I.C and FRQ limit can occur simultaneously and those limit messages can be

displayed together e.g. if C.V limit and FRQ limit occur at once “FRQ/C.V LIMIT” will

display.

If any limit indicators are lit, the heat station components needs to be adjusted to obtain

the required power (see section 6.2).

11

4.1.2. Heat ON/OFF indicators.

These LEDs show whether the power supply is generating output or is off. (identified

by -- in Figure 3.).

4.1.3. Program status indicator.

Identified by -- in Figure 3. This read-out displays the programs status when using

the PROGRAMMED mode. Selected JOB profile number and STEP order will display

as like “1-12”

4.1.4. Time display indicator.

Identified by -- in Figure 3. This read-out displays elapsed heating time as seconds

4.1.5. Power display indicator

Identified by -- in Figure 3. This read-out displays the power output when the power

supply is operating.

4.1.6. LCD display

Identified by -- in Figure 3. Details information display on LCD display.

MANUAL [T=2.5S] LOC

>> POWER LIMIT

P.S=50% C.V=500V

I.C=320A FRQ=370KHz

Figure 4: LCD display layout.

1st line: Displays Control mode.

MANUAL [CONT]: Indicates power supply working in manual continuous mode.

MANUAL [T=0.0S]: Indicates power supply working in manual timed mode.

PROGRAMMED: Indicates power supply working in programmed mode.

Selected job number display on Program status indicator.

LOC: Indicates Local control mode.

EXT: Indicates External control mode.

REM: Indicates Remote control mode.

2nd line: Alert status like fault, trip or limit. (See 4.1.1.)

3rd line: Indicates requested power level (manual mode) or number of heat cycles in

auto repeat (programmed mode) and capacitor voltage.

P.S: Percentage of requested power level.

REP: Number of cycles in auto repeat.

Operating frequency

4th line: Indicate capacitor voltage C.V: and inverter current I.C.

12

4.1.7. Reset button

Identified by -- in Figure 3. This button is used to clear the fault and/or trip

indicators if a run-time or interlock trip has occurred. Depressing the button will clear

the latch for the fault and trip indicators. If the LED does not go out, then the reason for

the fault is still present.

4.1.8. Heat switch

Identified by -- Figure 3. When the power supply is energized, and no fault

indicators are lit, pressing the START button will start the power supply delivering heat.

When moved back to the STOP position, the heating will be terminated. While in

PROGRAMMED mode, the ON position initiates the heat cycle. Pressing the STOP

button will terminate the heat cycle.

4.1.9. Power Pot

Identified by --in Figure 3. The power pot sets the requested power level indicated

as P.S on LCD display. The level of power output is indicated by the percentage on the

POWER indicator LED. This pot is disabled during PROGRAMMED mode operation.

4.1.10. Program buttons

Identified by -- in Figure 3. The program buttons are used to program and display

jobs for the power supply to run automatically. See section 5 for a description of how to

program the power supply.

4.2. Operation

4.2.1. Manual mode operation

Turn on the control breaker, and then LCD display shows as below. Operation mode

and heat control mode displayed on the 1st line.

Select Manual mode in the programming if current mode is programmed. (see

section 5.1.)

MANUAL [CONT] LOC

>> POWER LIMIT

P.S=50% C.V=500V

I.C=300A FRQ=370KHz

MANUAL [T=2.5S] LOC

>> POWER LIMIT

P.S=50% C.V=500V

I.C=300A FRQ=370KHz

There are two selections in Manual mode.

13

When Manual is in continuous mode: “MANUAL [CONT]” displays on 1st line of LCD,

When Manual is in timed mode: “MANUAL [T=0.0S] displays on 1st line of LCD.

1) Operation in Manual continuous mode.

Press START switch to heat on and press STOP switch to heat off.

If current mode is in manual timed, you can change the mode by pressing

RIGHT (►) key for 1 sec. or more to manual continuous mode.

2) Operation in Manual timed mode.

Press START switch to heat on and unit will stop after the set time has ended.

If current mode is manual continuous, you can change the mode by pressing

LEFT (◄) key for 1 sec. or more to manual timed mode and the LCD [T=0.0S]

will blink. You can enter the time you want to change with numeric keys and then

press ENT key to save.

4.2.2. Programmed mode operation

Select Programmed mode in the programming if current mode is manual. (see

section 5.1.)

PROGRAMMED LOC

>> POWER LIMIT

P.S=50% C.V=500V

I.C=300A FRQ=370KHz

Press START switch to start process, the unit follows the selected job profile

and then stops.

See section 5.1., for programming job profile.

5. Programming & Status monitor

5.1. Programming

The power supply can be programmed to control the functions below through the menu.

1) Control mode :

Operating mode

Heat control mode

External heat control

External reset control

External emergency stop

14

Aux. interlock control

Power control mode

Feedback control mode

2) Job select: Selecting job to proceed under Programmed mode.

3) Job order: Setting Job parameters in each profile.

4) System parameters: Setting control parameters.

Power limit

Capacitor voltage limit

Inverter current limit

Shutdown water inlet temperature (Does not apply for 25kW)

Restart water inlet temperature (Does not apply for 25kW)

Communication address

Communication baud rate

Operating frequency range

Capacitor rail configuration

5) Start frequency: Setting start frequency.

6) Pass word: Changing password.

5.1.1. Entering a program

1. Turn on the power supply.

2. Enter the program mode by pressing the “PROG” button for 1 second, to display

“password=” on LCD, enter password, and press “ENT” key to display

“PROGRAM menu”. (Default password=0000)

3. Use UP (▲) and DOWN (▼) key to move object item to program and select the

item with ‘ENT” or “SEL” key to enter into the item.

4. Press “ESC” key to exit program mode

5.1.2. Control mode

1. Select the item “CONTROL MODE” in PROGRAM menu.

2. Use UP (▲) and DOWN (▼) key to move object item to program and select the

item.

3. Select each value with LEFT (◄) and RIGHT (►) key and press “SAVE” key to

save the new values and return to PROGRAM menu.

4. Press “ESC” key, to return to PROGRAM menu without saving the changed

values

OPER MODE: Setting operating mode.

MANUAL: Operate heat on/off or power level by switches or knob on the panel

or external signal.

PROGRAMMED: Operate process by programmed job profile.

HEAT CONT: Setting Heat control mode.

LOCAL: Heating on or off by START/STOP switch on the panel.

EXT: Heating on or off by external heat contact input connected to E- HEAT

terminal of TB2 on EXT-TERM board.

REMOTE: Operate by control command from remote loader or PC.

15

EXT HEAT: Selecting External heat control mode.

(only when unit is in “HEAT CONT = EXT” mode.

MOMENT: On or off by contact of E- HEAT terminal of TB2 on EXT-TERM

board (close=On, open=Off)

LATCH: Latch On or latch off alternately by contact close triggering of E-

HEAT terminal of TB2 on EXT-TERM board.

EXT RESET: Selecting external reset function: enable or disable.

DISABLE:

ENABLE:

EXT E.STOP: Selecting external emergency stop function: enable or disable.

DISABLE:

ENABLE: In this case, E- STOP terminal of TB2 on EXT-TERM board should

be closed in normal operation.

AUX INT: Selecting auxiliary interlock: enable or disable.

DISABLE:

ENABLE: In this case, AUX-INT terminal of TB2 on EXT-TERM board should

be closed in normal operation.

POWER CONT: Selecting source for output power control under manual mode.

LOCAL: Output power controlled by panel knob.

EXT 0-5V: Output power controlled by Voltage level of P-DEMD terminal of

TB1 on EXT-TERM board (5V=100%)

EXT 4-20mA: Output power controlled by current level of P-DEMD terminal of

TB1 on EXT-TERM board (4mA=0%, 20mA=100%)

(Terminated with 250 ohm internal)

When EXT 0-5V or EXT4-20mA selected, SW2 must be set as same name on

EXT-TERM board.

FBK MODE: Selecting source of object control power.

POWER:

CAP.V:

INV.C:

AUX 0-5V:

AUX 4-20mA:

(When EXT 0-5V or EXT4-20mA selected, SW3 must be set as same name on

EXT-TERM board.)

In this mode the operator can select which function to control on the power

potentiometer, provided the load does not change. Example: Selecting POWER:

when the potentiometer is set to 50% the power supply will try to deliver 50%

power or 12.5kW. If selected CAP.V, 50% demand will result in 50% of 500volts

or 250V. For INV.C, 50% demand will display 250A. (Given no limits are

reached). If the load changes accuracy is around 15%.

5.1.3. Job select

Selecting job profile: enter PROGRAMMED mode operation. Selected job number

displayed on the Program status indicator.

1. Select “JOB SELECT” in the PROGRAM menu.

2. Enter a job number(1~15) with numeric keys and press “ENT” key to select the

16

3. Press “ESC” key to return to PROGRAM menu without setting change.

5.1.4. Job order

Setting job parameters to operate the power supply in “PROGRAMMED” mode. The

power supply can be programmed for 15 separate heating profiles or jobs. Each profile

can contain up to 29 steps.

1. Select “JOB ORDER” in the PROGRAM menu.

2. Enter a job number (1~15) with numeric keys and press “ENT” key to select the

job profile. If a heating profile has previously been entered in a Job, then the

values will be displayed.

3. Enter value for each item and press “ENT” key to change and move the cursor to

the next item.

4. Use UP (▲) and DOWN (▼) key to move the cursor only without changing value.

5. Press “SAVE” key to save all the changed values and return to “JOB ORDER”

menu.

6. Press “ESC” key to return to “JOB ORDER” menu without saving changes.

REPEAT: Setting numbers of auto repeat (1~100 times)

Each Job has an auto repeat function, which enables a selected job to be

repeated up to 100 times. (If 0 set, proceed as 1).

PAUSE: Pausing time must set when auto repeat times is over 1.

(Input range=0.1~6399sec. but must set 1sec. or more).

STEP 1~29: Enter the values of power level & time for each step.

POWER: (0~100 %,). The power level will ramp from the last power level to

the power level requested.

TIME: (0.1~6399sec).

Note: Enter “0” for the values of power level & time both at a step to stop the job

process. Other steps after this step shall be ignored even they contained any values.

5.1.5. System parameters

Setting system functions

1. Select “SYSTEM” in the PROGRAM menu.

2. Enter values or select menu with numeric keys or LEFT (◄) and RIGHT (►) key

and press “ENT” key to change values and move cursor to next item.

3. Press “SAVE” key to save all the changed values and return to PROGRAM menu

4. Press “ESC” key to return to PROGRAM menu without setting change.

POWER LIMIT: Set the percentage of output power to limit level (0~100%).

100% of POWER LIMIT is 25kW, If 50% is set power output shall be limited to 12.5kW.

CAP.V LIMIT: Set the percentage of capacitor voltage to limit level (0~100%).

100% of capacitor voltage is 500V

INV.C LIMIT: Set the percentage of inverter current to limit level (0~100%).

100% of inverter current is 300A.

SHDN W/TEMP: Set the temperature of inlet water to shutdown power supply as

centigrade (0~40℃). If the water temperature increase over this value, then the power

supply gets a fault state and stops heating

17

HS TEMP: HS TEMP must be set to 50℃ always.

REST W/TEMP: Set the restart-able inlet water temperature as centigrade (0~ SHDN

W/TEMP). Power supply can restart after water temperature has gone down to this

setting value. This value must be lower then SHDN W/TEMP value (37℃).

COMM ADDR: When the RS485 port is being used to control or monitor the power

supply, a unique ID for the machine can be entered (1~255).

BAUD RATE: The communications baud rate for an RS485 connection can be set here

(4.8, 9.6, 19.2, 38.4 kbps).

FREQ: Set operating frequency range. (Must be “135-400”) power supply can’t work

properly or can cause damage with the wrong value set.

C.RAIL: Setting configuration of capacitor rail.

Set “PARL” for parallel configuration and “SER/PARL” for series-parallel configuration.

In case of this setting is C.RAIL = SER/PARL, capacitor voltage limit should be higher

by 2 times; the display on LCD will be twice.

5.1.6. Start frequency

Setting start frequency (135~440 kHz).

1. Select “START FREQ” in the PROGRAM menu.

2. Enter frequency of start and press “ENT” key to save the start frequency and

return to PROGRAM menu.

3. Press “ESC” key to return to PROGRAM menu without setting change.

5.1.7. Pass word

Changing password (0000~9999), Default Password is”0000”

1. Select “PASSWORD” in the PROGRAM menu.

2. Enter 4 digit password and press “ENT” key to save change and return to PROG

RAM menu.

3. Press “ESC” key to return to PROGRAM menu without setting change.

5.2. Status monitoring

5.2.1. Entering a monitoring

1. Turn on the power supply.

2. Pressing the FUNC button for a second until “FUNCTION menu” sign displays

on the LCD display window.

3. Select an item to monitor, use UP (▲) and DOWN (▼) keys and press “ENT” or

“SEL” key to display.

4. Press “ESC” key to exit the monitoring mode.

5.2.2. Parameter status

Show status of each parameters setting “OK” or “FAIL”

SYS: Display system parameter setting.

CONT: Display control parameter setting.

JOB: Display job parameter setting. If there is a “FAIL” parameter, power supply

will not start heating in PROGRAMMED mode.

18

CAL: display status of control board calibration. If this shows “FAIL”, it has lost

the calibration data and you need to call Tech Support.

5.2.3. Inverter status

No function for this power supply.

5.2.4. Auxiliary status

W/IN TEMP: Displays water inlet temperature as centigrade (℃).

5.2.5. Date/Time display and Setting

Display or setting date & time

To set date and time, move cursor to the item use UP (▲), DOWN (▼), LEFT (◄)

and RIGHT (►) key and enter value with numeric keys and press “ENT” key to

change and move cursor to next item.

Press “SAVE” key to save changes and return to FUNCTION menu.

5.2.6. History

Display history events of Power supply.

Stores and displays the numbers of failed events that occurred in the heating

process.

TURN ON: Stores time of power on of power supply. (hour, minute)

HEATING: Stores time of Heat on. (hour, minute)

PRESS FAIL: Stores failure of differential pressure of cooling water.

TEMP FAIL: Stores if exceeding temperature of cooling water.

INV FAIL: Not activated for this power supply.

SW/TH FAIL: Number of swing thru fail count.

SHORT COIL: Number of resonant trips.

INV.C TRIP: Number of inverter current trips.

DOOR OPEN: Number of door opens.

E-STOP: Number of emergency stops.

AUX-INT: Number of auxiliary interlocks.

5.2.7. Version

Display firmware and PLD version of Control board and display board.

(CONT = control board, DISP = display board, S000 = firmware version, P000 = PLD

version)

19

6. Load station tuning.

WARNING: Always ensure that

both the power supply’s circuit

breakers are turned OFF when

adjusting heat station

components.

This section describes the

procedures for tuning the heat

station so that full power will be

obtained at the desired frequency.

6.1 Initial setup.

The following are the steps to be taken for the initial setup of the load station for a new

heating coil and/or load:

1. Install all twelve the load station capacitors.

2. Install the turns-bar in the 12 turns position and remove the two shorting bars.

Section 6.3 describes the procedures for changing heat station components.

6.2 Tuning.

WARNING: Never run the power

supply with an open coil. Doing

so may damage the inverters.

This section provides the procedures required for the tuning of the heat station for a

specific heating coil and load. It is assumed that the initial setup of the heat station has

been completed as described in section 6.1

The aim of this exercise is to have the unit operating at full power (25kW) at the desired

frequency (user specified between 135 kHz and 400 kHz) without any indicators lit.

1. Ensure that the heat switch on the front panel is OFF state, that the program

“POWER CONT=LOCAL” and that the power level knob is turned completely

counter clockwise. Check that the cooling water is turned on. The unit will not deliver

power if the minimum differential water pressure specification is not met, a flow trip

will occur.

2. Turn on the control breaker. The green OFF indicator should light up and the LCD

display should indicate that the control circuitry is powered up. Press the reset

button if any trip (red) indicators are lit. Ensure the emergency stop button is not

pressed in and the door is closed. Turn on the Main circuit breaker.

3. Press the ON button of the HEAT switch. Turn the POWER knob until the unit

delivers approximately 10% power. If the frequency of the unit is not slightly above

the desired (user specified) frequency, adjust the capacitance of the heat station and

return to step 1. The required capacitance change is inversely proportional to the

square of desired frequency change. Example: To increase the frequency by 40%,

20

Table of contents