PRD Fireball 125cc-TaG Operation manual

Courtesy of

1

INDEX

Page

GENERAL ENGINE DESCRIPTION

2

GENERAL ENGINE SPECIFICATIONS

3

1- Complete Engine Package

4

2- Engine Serial Numbers

6

3- Installation Instructions

7

3.1 Photo of Engine Mounted on Frame

7

3.2 Installing the Water Cooling System

8

3.3 Installing the Header

12

3.4 Engine Mount Preparation

13

3.5 Installing the Carburetor

14

3.6 Installing the Chain

16

3.7 Installing the Clutch Cover, Gear Plate Guard & Coil

17

3.8 Installing the Electrical System

19

3.9 Installing the Airbox and Exhaust

29

4- Fuel and Oil

32

5- Carburetor Specifications

32

6- Starting and Stopping the Engine

33

7- Engine Break In Procedure

33

8- Maximum RPM

34

9- Intake Silencer/Airbox

34

10- Exhaust System

34

11- Dry Centrifugal Clutch

35

12- Clutch Assembly & Maintenance

35

13- Battery

37

14- Electrical System Warnings

38

15- Spark Plug

39

16- Gear Ratio

40

17- Starter Removal and Assembly

41

18- General Maintenance Schedule

48

19- Recommended Engine Maintenance Schedule

49

20- Troubleshooting

50

21- Engine Storage

51

22- Engine Tightening Torque Settings

51

2

GENERAL ENGINE DESCRIPTION

The PRD 125cc Fireball engine is a “TaG” (Touch and Go) style engine. This engine is a

hobby engine and designed only for closed course racing on tracks built for this specific

purpose. The engine is a single cylinder 2-stroke.

Piston & Ring Single ring piston with an L-type cast iron & chrome plated ring.

Cylinder & Cast aluminum alloy.

Crank Case

Crank Case Liner The cast iron liner is fully machined then cast with an aluminum water

jacket creating a tamper proof locking system which ensures proper

alignment and stability.

Head The head is cast aluminum and fully machined on the combustion side

and attached to the cylinder with four (4) studs.

Crank Shaft Made of alloy steel machined, hardened and ground to exacting

specifications. The crank is supported in the case by C6305 ball bearings.

The connecting rod is investment forged for accuracy and durability.

Ignition Fully digital with a CDI ignition module, solid state relay and the rev

limiter preventing RPM’s in excess of 16,000. It is made for easy use and

great starting ability.

Bendix & Gear Engages the starter ring gear to start the engine.

Clutch The clutch is designed so the clutch gear may be easily changed to

achieve required gear ratios. The ring gear is part of the low stall dry

clutch that requires no adjustment. The ring gear/flywheel is part of the

clutch assy.

Carburetor HL-360A or HL-395A/HL-166 manufactured by Tillotson. Both are

diaphragm style with built in fuel pump, fully adjustable high and low

speed needles which can be set before starting the engine off the track.

3

GENERAL ENGINE DESCRIPTION (continued)

Battery 12 volt with a battery box to hold the battery.

Exhaust Pipe & Supplied with a connector tube to create the preferred tuned length.

Header

Complete Kit Includes all switches, radiator, radiator mount, radiator hoses, water pump

and more.

GENERAL ENGINE SPECIFICATIONS

Single Cylinder 2 stroke (2-cycle)

Volume of Cylinder 122.25cc

Maximum Bore 54.25mm

Stroke 54mm

Water Cooled 130°F +/- 15°

Carburetor Tillotson HL-360A or

Tillotson HL-395A/HL-166

Reed Valve Induction (2) Two petal reeds

Lubrication Fuel/Oil 10oz to 1 gallon

Electric Starter 12 volt

Clutch Dry, fixed-centrifugal

Max RPM’s 16,000 (built in rev limiter)

4

Section 1 COMPLETE ENGINE PACKAGE

Engine Box Engine

Header

Reed manifold & reeds (installed)

Dry clutch (installed)

Starter (installed)

Bendix (installed)

Accessory Box

Cooling System Radiator

Radiator hoses

Radiator mount

Water pump

Water pump pulley

(2) Water pump belts

Electrical System Battery

Battery box

Wiring harness

On/off switch

Starter button

Switch plate

Coil

Clutch cover/Coil mount

Relay

CDI ignition module

Spark plug

Spark plug boot

Exhaust System Pipe

Flex

Heat wrap

(4) Pipe Springs

(2) Pipe Cradle Springs

Induction System Tillotson Carburetor

Spec reeds (optional)

Filter Cup

Air box with hose clamp

5

ACCESSORIES

Exhaust

System

Battery and Box

Tillotson Carburetor

Easy Start Ignition System

Radiator and Mounting

Kit

Clutch Cover w/ Coil

Complete Water Pump

Intake Silencer

Spark Plug

Radiator Hose Kit

6

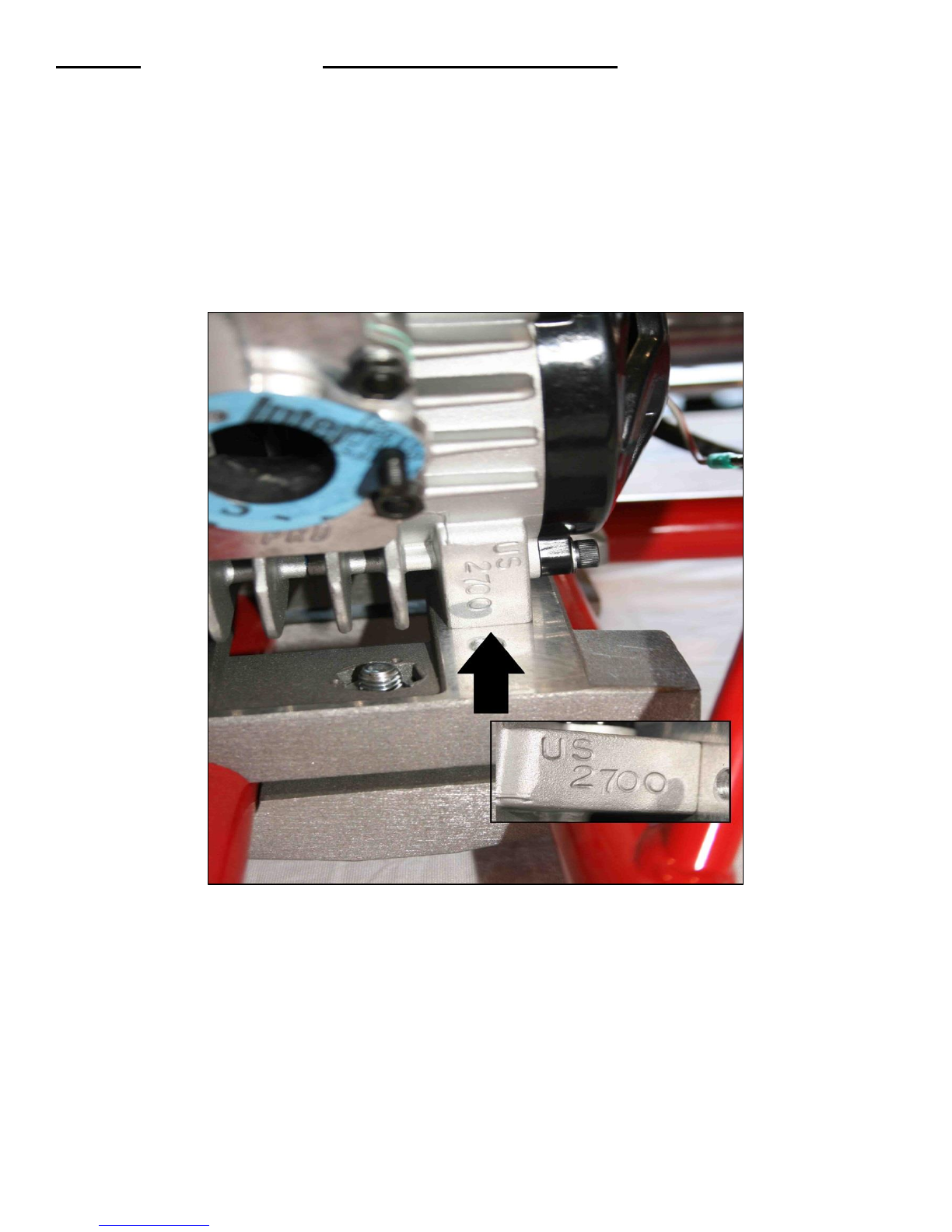

Section 2 ENGINE SERIAL NUMBERS

Each engine is stamped with a unique serial number. The serial number is displayed to the right

of the intake manifold at the base of the engine. This serial number will always start with US

and a four digit number “US 2700” as seen below. This serial number is referenced when

seeking support or information on your engine.

7

Section 3 INSTALLATION INSTRUCTIONS

Note: If your engine is already assembled and mounted on the chassis move to section 4.

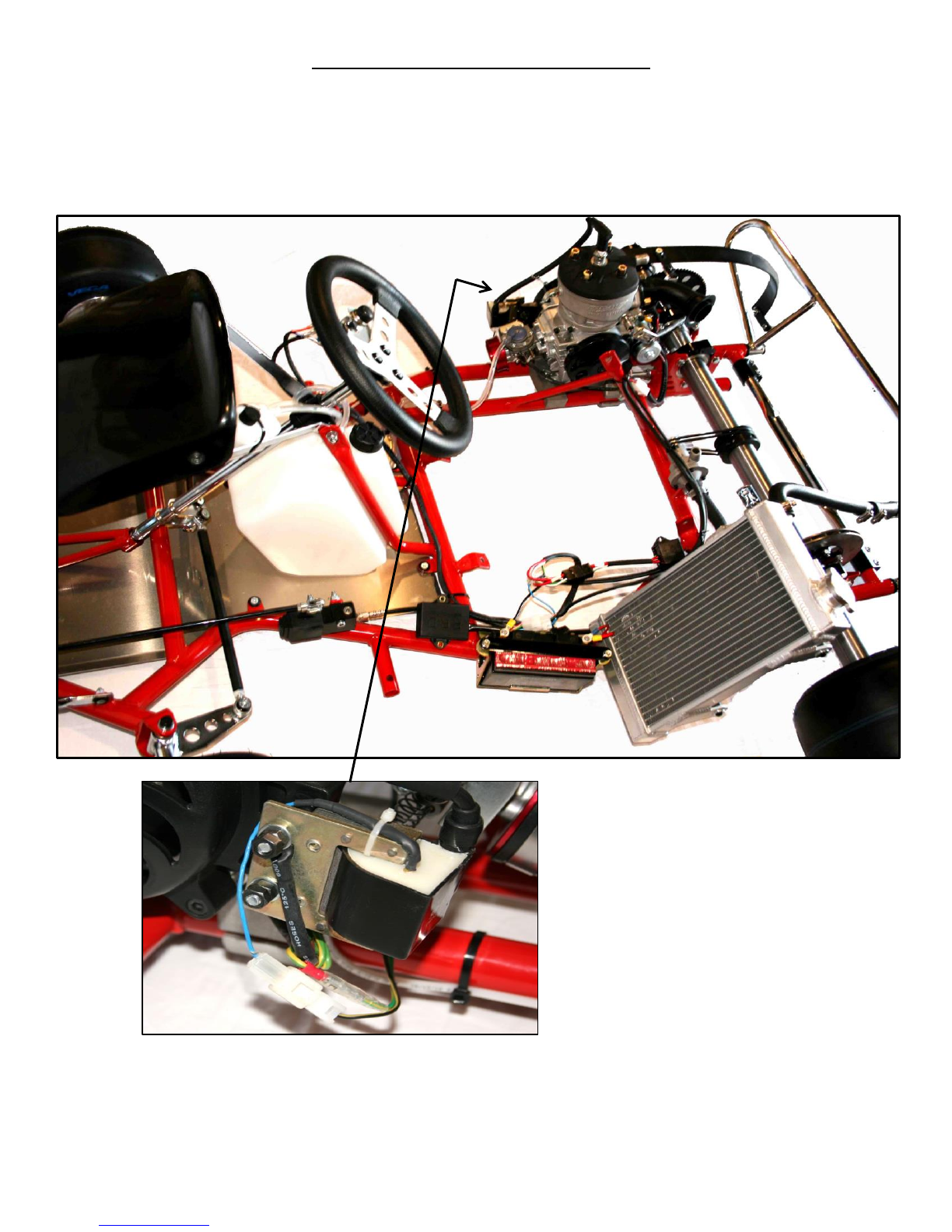

Section 3.1 General wiring layout of a kart frame with the engine mounted.

8

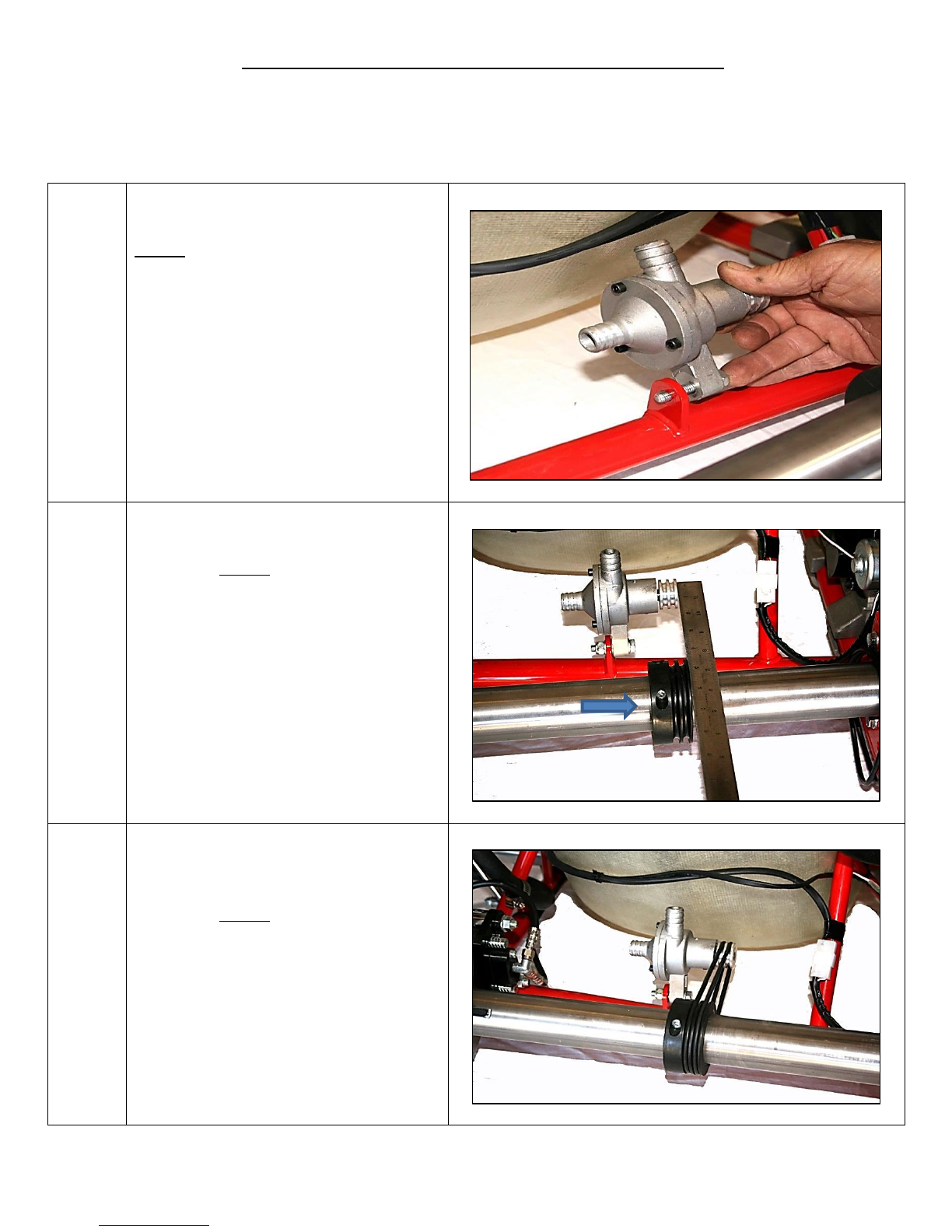

Section 3.2 INSTALLING THE WATER COOLING SYSTEM

Note: To install the belts it is necessary to remove the axle from one side of the kart. Once

done slide the belts over the axle and reinstall the axle. (Installing a spare set of belts

will eliminate removing the axle to replace a broken belt).

1

Install the water pump as shown in

Fig. 1. Use an M8x45 bolt and a

nylock nut (not included) to fasten

to frame.

Fig. 1

2

Install the water pump pulley as

shown in Fig. 2. Align the water

pump pulley with a straight edge

to the pump. Tighten the pulley to

the axel.

Fig. 2

3

Install the belts and tension, then

tighten the water pump in place as

shown in Fig. 3.

Fig. 3

9

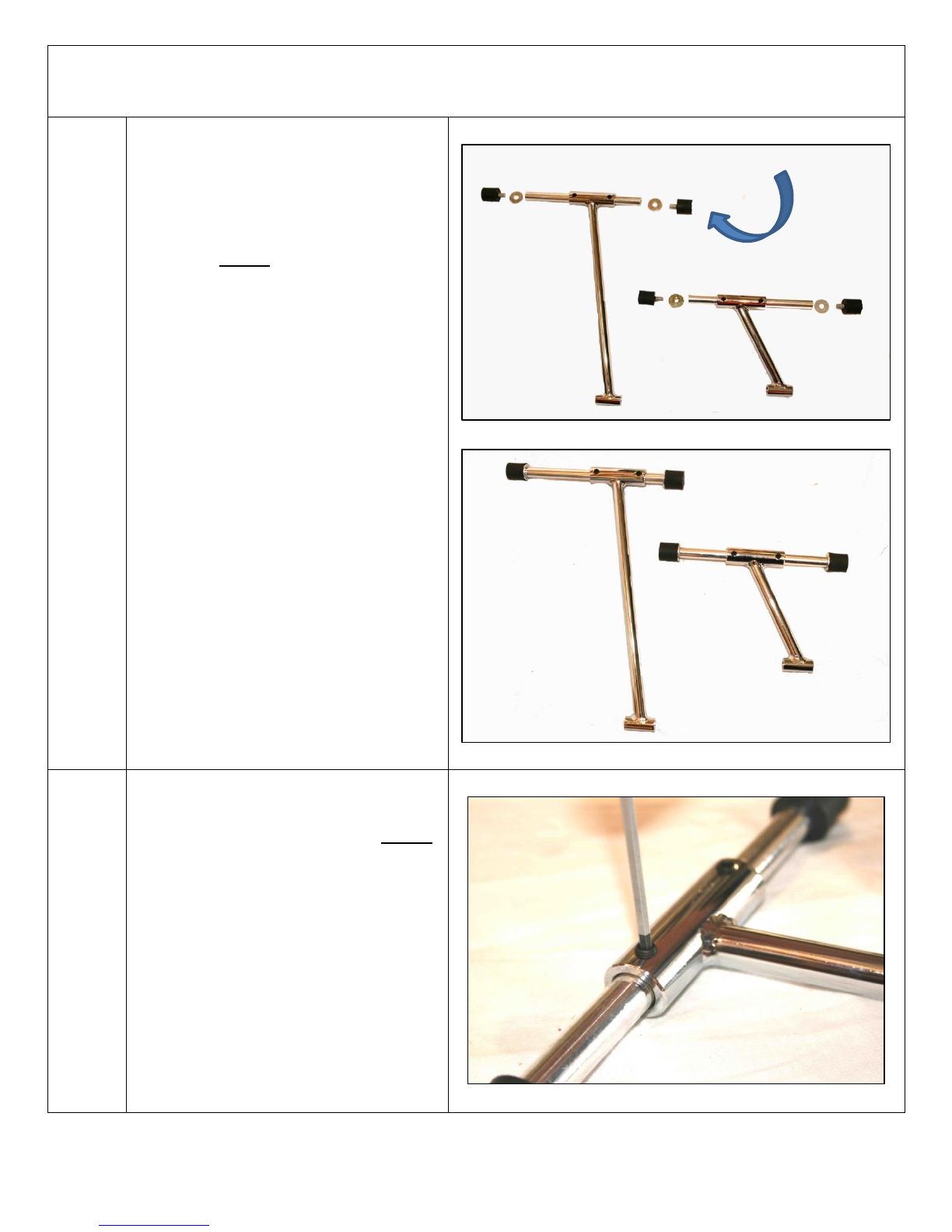

Before installing the radiator attach the mount brackets.

4

Slide mount bar through the upper

tube of each bracket. Add washer

and rubber isolators to the end of

each mount bar and tighten as

shown in Fig. 4.

Fig. 4

5

Install set screws in the upper tube

of each bracket as shown in Fig. 5.

Leave loose until mounted on the

kart.

Fig. 5

10

6

With set screws facing out install

the long bracket into the upper

tabs on the radiator. Use a washer

and M5x10 bolt as shown in

Fig. 6.

Fig. 6

7

Follow the instructions from Fig. 6

for the short bracket. Install them

into the lower tabs as shown in

Fig. 7.

Fig. 7

8

The radiator is now ready to install

on to the kart. Notice the angle of

the mount bars.

Fig. 8

11

9

Mount the lower bracket to the

chassis using an M6x70 bolt (not

included) as shown in Fig.9.

Leave loose for final positioning.

Fig. 9

10

Mount the upper bracket to the

bearing cassette or where best

suited using an M6x70 bolt (not

included) as shown in Fig. 10.

Leave loose for final positioning.

Fig. 10

11

Once the radiator is in position,

tighten set screws and bolts using

blue loctite as shown in Fig. 11.

Fig. 11

12

12

The kit includes 2 water hoses that

must be cut to fit.

Connect the first hose to the

top of the radiator and to the

top of the engine.

(Depending on the seat size

the hose may need to be cut

and coupled behind seat; see

red arrow).

Cut second hose and

connect to the bottom of the

radiator and inlet side of

water pump.

Use one of the residual

hoses to connect to the

water pump outlet (top) and

engine inlet.

Fig. 12

BEFORE THE FIRST START OF THE ENGINE:

Fill the radiator to the top and then rotate the rear axle to allow trapped air to escape.

Refill radiator and repeat this step until level stays full.

After the first run session check the water and top off as necessary.

Section 3.3 INSTALLING THE HEADER

1

Remove the exhaust nuts and

paper plug from exhaust port.

2

Install the header onto the three

studs of the cylinder as shown in

Fig.1. Tighten the header with

exhaust nuts.

Fig. 1

13

Section 3.4 ENGINE MOUNT PREPARATION

1

*If the engine mount is not drilled the engine bolt pattern is 102mm x 80mm.

2

Bolts should extend through the

mount ¾”. Turn the engine upside

down and install the engine mount

as shown in Fig. 2. Tighten bolts

in a cross pattern. (Length of bolt

is determined by your engine

mount. Bolt is an M8x1.25)

Fig. 2

3

Once mounted, place the engine

on the chassis and fasten with

lower clamps and bolts as shown

in Fig.3. Leave loose for chain

installment.

Fig. 3

14

Section 3.5 INSTALLING THE CARBURETOR

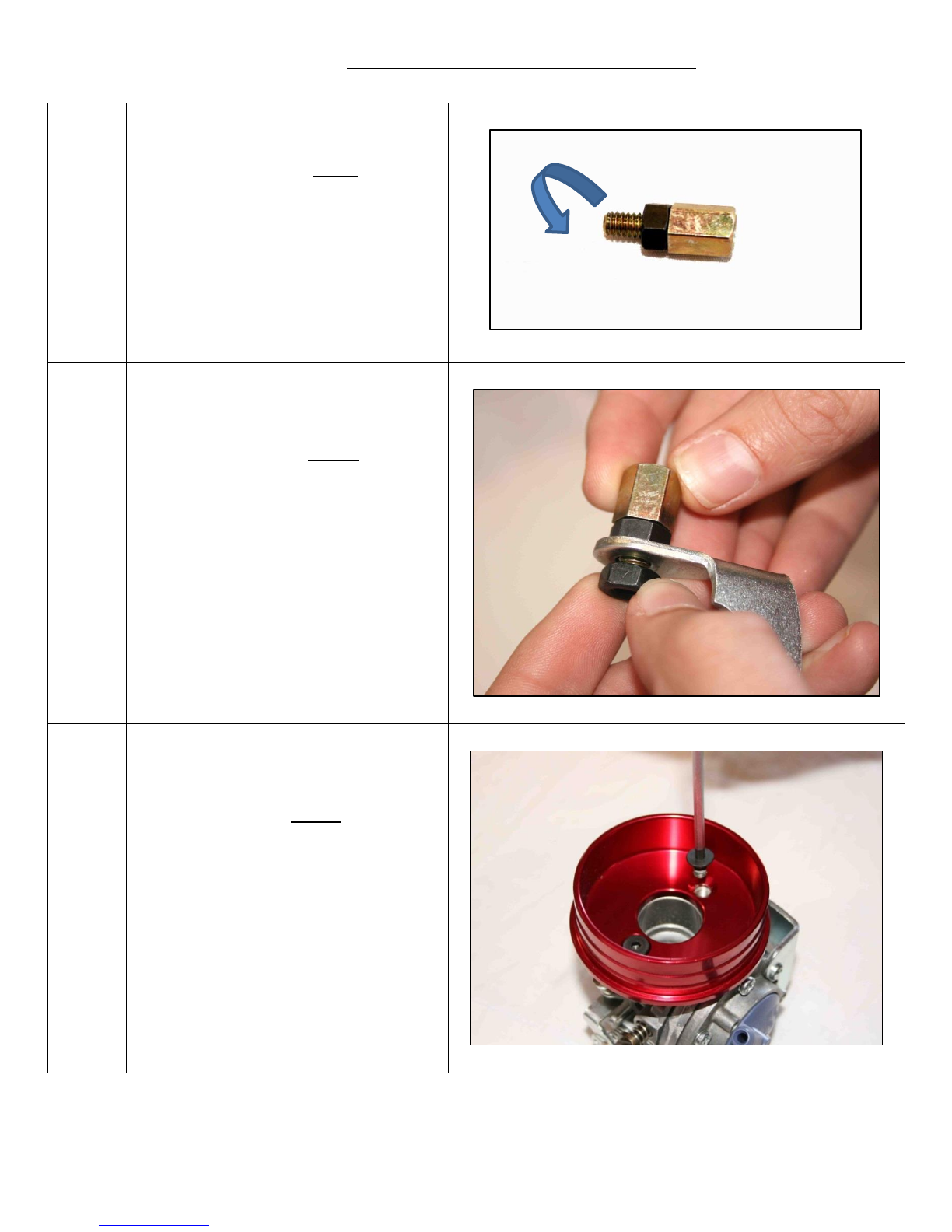

1

Install the nut on to the cable

adapter as shown in Fig.1.

Fig. 1

2

Insert cable adapter through the

throttle bracket and tighten with

the nut as shown in Fig. 2.

Fig. 2

3

Install the filter cup on to the front

of the carburetor and tighten with

bolts as shown in Fig. 3. (Blue

loctite on bolts is suggested)

Fig. 3

15

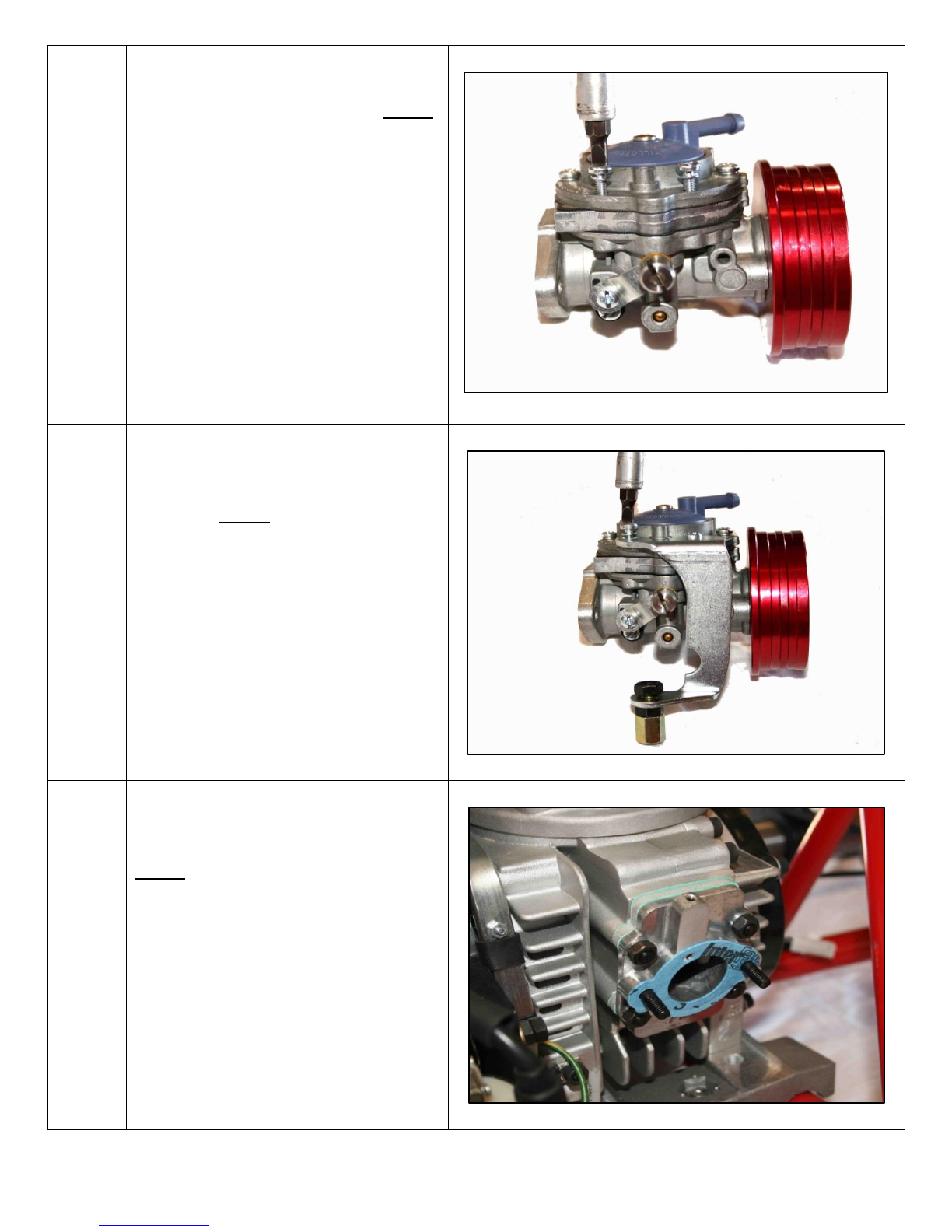

4

Remove the two top screws over

the throttle arm as shown in Fig. 4.

Fig. 4

5

Install the throttle bracket and

reinsert the two top screws as

shown in Fig. 5.

Fig. 5

6

Place the carburetor gasket over

the two intake studs as shown in

Fig. 6.

Fig. 6

16

7

Install the carburetor on to the two

intake studs as shown in Fig. 7.

Fasten with the two nuts provided.

Fig. 7

Section 3.6 INSTALLING THE CHAIN

1

Align the rear sprocket with the

clutch drum as shown in Fig. 1.

Fig. 1

2

Install #219 Xtreme Ultra

Performance chain from the clutch

drum to the rear sprocket as shown

in Fig. 2.

Fig. 2

17

3

Tighten the engine on to the

chassis leaving approximately ½”

free play as shown in Fig. 3.

Fig. 3

Section 3.7 INSTALLING THE CLUTCH COVER, GEAR PLATE GUARD & COIL

1

Add the medium silver washer to

the long side of the rubber isolator

and insert through the clutch

cover. Add the large washer as

shown in Fig. 1. Repeat this step

for the second hole on the clutch

cover.

Fig. 1

2

Secure each isolator with two nuts

as shown in Fig.2 and tighten.

Fig. 2

18

3

Place medium silver washers on

the other sides of the rubber

isolators as shown in Fig.3.

Fig. 3

4

Place the coil on to the isolators

then add the ground wire to the

top isolator. Add a small silver

washer to each of the isolators

followed by two nuts as shown in

Fig. 4 and tighten.

Fig. 4

5

Place the gear plate guard inside

of clutch cover as shown in Fig.5.

Fig. 5

19

6

Attach the clutch cover assembly

and fasten with bolts provided as

shown in Fig. 6.

Attach the ground wire from the

coil to the engine as shown in

Fig. 6.1.

Fig. 6

Fig. 6.1

Section 3.8 INSTALLING THE ELECTRICAL SYSTEM

1

Insert the two brackets into the

battery box as shown in Fig. 1.

Fig. 1

Table of contents

Other PRD Engine manuals