Precision Digital Corporation SuperNova PD500 User manual

SuperNova PD500 PID Process & Temperature Controllers

Instruction Manual

PRECISION DIGITAL CORPORATION

233 South Street • Hopkinton MA 01748 USA

Tel (800) 343-1001 • Fax (508) 655-8990

www.predig.com

•1/16, 1/8, and 1/4 DIN Auto-Tuning PID Process & Temperature Controllers

•Thermocouple and RTD Inputs

•DC Voltage and Current Inputs (1-5 V, 0-5 V, 0-10 V, 0-50 mV, 0-100 mV; 4-20 mA with Resistor)

•250 Ω Resistor(s) Included Standard

•High Accuracy Auto-Tuning PID

•High Durability Front with Hard Plastic Pushbuttons

•Large Easy to Read 14-Segment PV Display up to 1.1" (29 mm)

•Input Power 100-240 VAC

•Heating, Cooling, and Heating & Cooling Control

•Primary Control Output Options: 4-20 mA (SCR), Voltage Pulse (SSR), or Relay

•Secondary Control Output Relay Standard on All Models

•Easily Switch Between Auto and Manual Control Modes

•Up to 2 Alarm Relays & 4-20 mA Retransmit Outputs

•Remote Set Value 1-5 V Input Option (4-20 mA with External Resistor)

•Digital Input Set Value Selection

•RS-485 Serial Communications Option

•Modbus® RTU/ASCII Communications

•Mini-USB Port Standard

•FREE Programming and Monitoring Software

•1/16, 1/8, 1/4 DIN Sizes Available

•Shallow Depth Case Extends Only 2.5" (63 mm) Behind Panel

•IP65 Fronts

•UL & C-UL Recognized Process Control Equipment, Electrical - Component

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

2

Disclaimer

The information contained in this document is

subject to change without notice. Precision Digital

makes no representations or warranties with

respect to the contents hereof and specifically

disclaims any implied warranties of

merchantability or fitness for a particular purpose.

See Warranty Information and Terms &

Conditions on www.predig.com for complete

details.

•Read complete instructions prior to installation

and operation of the controller.

•Risk of electric shock or personal injury.

•This product is not recommended for life support

applications or applications where malfunctioning

could result in personal injury or property loss.

Anyone using this product for such applications

does so at his/her own risk. Precision Digital

Corporation shall not be held liable for damages

resulting from such improper use.

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Operation & Care Notes

Limited Warranty

Precision Digital Corporation warrants this

product against defects in material or

workmanship for the specified period under

“Specifications” from the date of shipment from

the factory. Precision Digital’s liability under this

limited warranty shall not exceed the purchase

value, repair, or replacement of the defective unit.

See Warranty Information and Terms &

Conditions on www.predig.com for complete

details.

Registered Trademarks

All trademarks mentioned in this document are

the property of their respective owners.

© 2021 Precision Digital Corporation.

All rights reserved.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

3

Table of Contents

Introduction......................................................................................................... 6

Abbreviations ................................................................................................. 6

General Controller Term Descriptions.......................................................... 6

Range and Scale Descriptions..................................................................... 6

Engineering Unit Descriptions...................................................................... 7

Ordering Information.......................................................................................... 8

Enclosures...................................................................................................... 9

Accessories .................................................................................................... 9

Specifications ................................................................................................... 10

General.......................................................................................................... 10

Process Input ............................................................................................... 10

Temperature Input........................................................................................ 11

Control Outputs............................................................................................ 11

Alarm Relay Outputs.................................................................................... 12

4-20 mA Retransmit Output......................................................................... 12

Remote SV Process Input............................................................................ 12

USB Connection........................................................................................... 12

Digital Inputs ................................................................................................ 12

Modbus® RTU Serial Communications...................................................... 13

SuperNova TCS Software ............................................................................ 13

Compliance Information................................................................................... 14

Safety ............................................................................................................ 14

Electromagnetic Compatibility.................................................................... 14

Safety Information ............................................................................................ 14

Operation & Care Notes............................................................................... 15

Installation......................................................................................................... 15

Unpacking..................................................................................................... 15

Panel Mounting Instructions ....................................................................... 16

Controller Dimensions................................................................................ 17

Connections ................................................................................................. 18

Connectors Labeling .................................................................................. 18

Power Connections.................................................................................... 19

Signal Connections .................................................................................... 19

Relay Connections..................................................................................... 19

4-20 mA Output Connections..................................................................... 20

Digital Input Connections ........................................................................... 20

Remote SV Input Connections................................................................... 20

Modbus RTU Serial Communications ........................................................ 20

Digital Input Connections ........................................................................... 20

Controller Operation ........................................................................................ 21

Change Control Set Value (SP) ................................................................. 21

RUN/STOP Modes..................................................................................... 21

Menu Timeout ............................................................................................ 21

Front Panel ................................................................................................ 21

Front Panel Buttons and Status Indicators................................................ 22

Setup and Programming.................................................................................. 23

Overview ....................................................................................................... 23

Setting Up the Controller............................................................................. 23

Programming the Controller ....................................................................... 24

Set Value Group (G.SV) ............................................................................ 24

G.SV Parameter Details............................................................................. 24

Input Group (G.IN) ..................................................................................... 25

G.IN Parameter Details.............................................................................. 26

Output Group (G.OUT) .............................................................................. 27

Output Limit High (OL-H) and Low (OL-L).................................................. 28

G.OUT Parameter Details.......................................................................... 29

Settings Group (G.SET)............................................................................. 30

Power-On Operation Mode (POOM).......................................................... 30

G.SET Parameter Details........................................................................... 31

Communication Group (G.COM)................................................................ 32

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

4

G.COM Parameter Details ......................................................................... 33

Sub Relay Group (G.SUB)......................................................................... 34

G.SUB Parameter Details .......................................................................... 36

Transmit & Remote Group (G.TRS)........................................................... 37

G.TRS Parameter Details .......................................................................... 38

Alarm Group (G.ALM) ................................................................................ 39

G.ALM Parameter Details .......................................................................... 43

Control Group (G.CTL) .............................................................................. 44

G.CTL Parameter Details........................................................................... 47

SuperNova TCS Software ................................................................................ 49

Remote Programming.................................................................................. 49

Data Acquisition........................................................................................... 49

Monitoring..................................................................................................... 49

Monitoring with RS-485 Connection........................................................... 49

SuperNova TCS Installation ........................................................................ 49

Running SuperNova TCS the First Time......................................................... 50

SuperNova TCS Main menu ........................................................................ 50

Top Level Menus .......................................................................................... 50

Troubleshooting Tips....................................................................................... 52

Error Messages ............................................................................................ 53

Modbus Register Tables .................................................................................. 54

Fixed Modbus Tables................................................................................... 54

General Process and Indication, Address 0 - 99........................................ 54

Set Value Group (G.SV), Address 100 - 199 ............................................. 54

Control Group (G.CTL), Address 200 - 299 ............................................... 55

Alarm Group (G.ALM) Address, 300 - 399................................................. 56

Transmit Group (G.TRS), Address 400 - 499............................................. 56

SUB Relay Group (G.SUB), Address 500 - 599......................................... 57

Communication Group (G.COM), Address 600 - 699 ................................ 57

Set Value Group (G.SET), Address 700 - 799 ........................................... 57

Output Group (G.OUT), Address 800 - 899) .............................................. 58

Input Group (G.IN), Address 900 - 999 ...................................................... 58

User Defined Modbus Map .......................................................................... 58

Modbus Register Bit Information................................................................ 59

Register Bit Assignment............................................................................. 59

Bit Definitions............................................................................................. 59

EU Declaration of Conformity.......................................................................... 61

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

5

Table of Figures

Figure 1. Panel Cutout Dimensions ................................................................ 16

Figure 2. PD510 Mounting Bracket Installation.............................................. 16

Figure 3. PD520 and PD530 Mounting Bracket Installation .......................... 16

Figure 4. Controller Dimensions ..................................................................... 17

Figure 5. Recommended Terminal Connectors ............................................. 18

Figure 6. PD510 Connector Diagram .............................................................. 18

Figure 7. PD520 & PD530 Connector Diagram............................................... 18

Figure 8. PD510 Power Connection ................................................................ 19

Figure 9. PD520 & PD530 Power Connection................................................. 19

Figure 10. PD510 Signal Connection .............................................................. 19

Figure 11. PD520 & PD530 Signal Connection............................................... 19

Figure 12. PD510 Relay Connections ............................................................. 19

Figure 13. PD520 & PD530 Relay Connections.............................................. 19

Figure 14. PD510 4-20 mA Retransmit Connections ..................................... 20

Figure 15. PD520 & 530 4-20 mA Retransmit Connections........................... 20

Figure 16. PD510 Digital Input Connections .................................................. 20

Figure 17. PD520 & PD530 Digital Input Connections................................... 20

Figure 18. PD510 Remote SV Input Connections .......................................... 20

Figure 19. PD520 & PD530 Remote SV Input Connections........................... 20

Figure 20. PD510 RS-485 Connection............................................................. 20

Figure 21. PD520 & PD530 RS-485 Connection ............................................. 20

Figure 22. Front Panel Buttons and Indicators .............................................. 22

Figure 23. Input Type and Range Selection ................................................... 25

Figure 24. Heating & Cooling Hysteresis........................................................ 28

Figure 25. Alarm Operation when ON & OFF Time delays are Set............... 34

Figure 26. Alarm Type and Number Table...................................................... 39

Figure 27. Alarm Operation Description Table............................................... 40

Figure 28. High Absolute Alarm Operation .................................................... 41

Figure 29. High Absolute Alarm Operation without Standby........................ 41

Figure 30. High Absolute Alarm Operation with Standby ............................. 41

Figure 31. High Absolute Alarm with Latch Function ................................... 41

Figure 32. Loop Break Alarm (LBA) Operation in Reverse Action Mode..... 42

Figure 33. Standard and Low PV Auto-Tuning SV......................................... 45

Figure 34. Response Adjustment with Alpha................................................. 46

Figure 35. Set Value Ramp Up......................................................................... 46

Figure 36. Set Value Ramp Down.................................................................... 46

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

6

Introduction

The SuperNova PD500 Series of PID Process & Temperature Controllers is a complete line of PID and on/off

controllers. Available in popular 1/4, 1/8, and 1/16 DIN sizes, and with a shallow depth behind panel of only 2.5"

(63 mm) it is easy to fit into almost any panel, product, or enclosure.

Voltage, current (with external resistor), and direct temperature thermocouple and RTD inputs make it an excellent

choice for any control application requiring easy to change, visible set points.

This modern line of controllers shows the process variable (PV), set value (SV), and manipulated value (output

level%, MV) on a striking reverse polarity LCD screen. Indicators for units (˚C, ˚F,%, or none)

Auto and manual control modes can be easily changed by holding two buttons, and this is indicated on the front panel

to make it easy for operators to know how to use this feature.

Main control outputs can be 4-20 mA (SCR), voltage pulse (SSR), or relay outputs. A secondary relay control output

is standard, which allow for one or two direction SV control (i.e., heating and cooling).

Additional outputs may include two SPST alarm relays and a 4-20 mA retransmit output. Other options include a

secondary 4-20 mA input to remotely control the set point, and RS-485 for Modbus communication.

A mini-USB port may be used for a direct PC connection to run the SuperNova software for monitoring, programming,

and data logging. This USB port is located on the rear behind the panel for PD510 1/16 DIN models, and on the front

behind a rubber tab on PD520 and PD530 1/8 and 1/4 DIN models.

Abbreviations

The following abbreviations are used throughout this manual.

General Controller Term Descriptions

Abbreviation Full Meaning

PV Process value

SV Set value

MV Manipulated value (Output value %)

AT Auto-tuning

REM Remote set value

RET Retransmission 4-20 mA output

SUB1 SUB1 output (alarm relay 1)

SUB2 SUB2 output (alarm relay 2)

LBA Loop break alarm

EU Engineering unit

EUS Engineering unit, total span

Range and Scale Descriptions

FR.L Full Range Low: The temperature range is defined according to the thermocouple or RTD type selected.

The minimum temperature value of this range is referred to as the FR.L (full range, low).

Example: For a type K thermocouple, the FR.L is -200 °C.

FR.H Full Range High: The temperature range is defined according to the thermocouple or RTD type

selected. The maximum temperature value of this range is referred to as the FR.H (full range, high).

Example: For a type K thermocouple, the FR.H is 1370 °C.

SL.L Scale Limit Low: The scale range is used when the input is a process signal, voltage or current (with an

external sense resistor). The minimum scale value of the process input is referred to as the SL.L. This

value may be changed with the SL-L parameter to scale the process input to the desired engineering

unit.

Example: For a 1 to 5 VDC input, the default SL.L is -1999. To represent an input value of 0 to 100%,

the SL-L parameter would be changed to 0, making the SL.L 0.

SL.H Scale Limit High: The scale range is used when the input is a process signal, a voltage or current (with

an external sense resistor). The maximum scale value of the process input is referred to as the SL.H.

This value may be changed with the SL-H parameter to scale the process input to the desired

engineering unit.

Example: For a 1 to 5 VDC input, the default SL.H is 9999. To represent an input value of 0 to 100%,

the SL-H parameter would be changed to 100, making the SL.H 100.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

7

Engineering Unit Descriptions

During the programming of the controller, there are two types of engineering units referred to, EU, and EUS.

EU: The value in engineering units according to the input range.

EUS: The value in engineering units according to the full span of the input.

Engineering Units (EU)

A parameter or other value defined in EU is defined in the actual absolute engineering unit value of the input type (or

scaled engineering units for the case of voltage or current inputs).

This means the EU value takes on the actual engineering unit value, which may be negative in some cases.

In the example below, the controller has been programmed for a type J thermocouple. A type J thermocouple has a

range of -200°C (FR.L) to 1200°C (FR.H). Any parameter or value using EU unit definitions could be defined in values

from -200°C to 1200°C.

If the parameter or value is defined in EU, but listed as a percentage (EU %), 0% represents the value of -200°C and

100% represents a value of 1200°C.

Engineering Unit Span (EUS)

A parameter or other value defined in EUS is defined in the actual engineering units of the input type (or scaled

engineering units for the case of voltage or current inputs) but represents the span value in those engineering units.

This means the EUS value is defined in engineering units, but begins at 0, representing the low range of input (FR.L

or SL.L) and will not be a negative value, regardless of the actual input range.

In the example below, the controller has been programmed for a type J thermocouple. A type J thermocouple has a

range of -200°C (FR.L) to 1200°C (FR.H), but a span of 1400°C. Any parameter or value using EUS unit definitions

could be defined in values from 0°C to 1400°C.

If the parameter or value is defined in EUS, but listed as a percentage (EUS %), 0% represents the value of 0°C and

100% represents a value of 1400°C.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

8

Ordering Information

Model Number

DIN Size

Main Control Output

Additional Features

PD510-A

1/16

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays

PD510-A-CD

1/16

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 2 Digital Inputs

PD510-A-CTR

1/16

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 4-20 mA SV

Input

PD510-S

1/16

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays

PD510-S-CD

1/16

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 2 Digital Inputs

PD510-S-CTR

1/16

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 4-20 mA SV

Input

PD510-R

1/16

Relay (On/Off)

Relay Control Output, 2 Alarm Relays

PD510-R-CD

1/16

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 2 Digital Inputs

PD510-R-CTR

1/16

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 4-20 mA SV

Input

PD520-A

1/8 (V)

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays

PD520-A-CTD

1/8 (V)

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD520-A-CTDR

1/8 (V)

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

PD520-S

1/8 (V)

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays

PD520-S-CTD

1/8 (V)

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD520-S-CTDR

1/8 (V)

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

PD520-R

1/8 (V)

Relay (On/Off)

Relay Control Output, 2 Alarm Relays

PD520-R-CTD

1/8 (V)

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD520-R-CTDR

1/8 (V)

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

PD530-A

1/4

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays

PD530-A-CTD

1/4

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD530-A-CTDR

1/4

4-20 mA (SCR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

PD530-S

1/4

Voltage Pulse (SSR)

Relay Control Outputs, 2 Alarm Relays

PD530-S-CTD

1/4

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD530-S-CTDR

1/4

Voltage Pulse (SSR)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

PD530-R

1/4

Relay (On/Off)

Relay Control Output, 2 Alarm Relays

PD530-R-CTD

1/4

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs

PD530-R-CTDR

1/4

Relay (On/Off)

Relay Control Output, 2 Alarm Relays, RS-485, 4-20 mA Retransmit, 2 Digital

Inputs, 4-20 mA SV Input

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

9

Enclosures

Model/Series

Meters

DIN

Material

PDA2301-V

1

1/8 (V)

Plastic NEMA 4X

PDA2302-V

2

1/8 (V)

Plastic NEMA 4X

PDA2303-V

3

1/8 (V)

Plastic NEMA 4X

PDA2304-V

4

1/8 (V)

Plastic NEMA 4X

PDA2305-V

5

1/8 (V)

Plastic NEMA 4X

PDA2306-V

6

1/8 (V)

Plastic NEMA 4X

PDA2301-4

1

1/4

Plastic NEMA 4X

PDA2301-16

1

1/16

Plastic NEMA 4X

PDA3408 1 1/4

Plastic NEMA 4X

with Clear Cover

PDA2600 1-6 1/8 (V)

Stainless Steel

NEMA 4X

PDA2700 1-6 1/8 (V)

Painted Steel

NEMA 4

Need help selecting the right enclosure?

Go to www.predig.com/esu

Accessories

Model

Description

PDX-RES2

250 Ω0.1% Precision Resistor for

SuperNova 4-20 mA Input

PDA7485-I

RS-232 to RS-485 isolated converter

PDA8485-I

USB to RS-485 isolated converter

PD9501

Multi-function calibrator

PDA-LH

Light / horn accessory

MOD-LH

Light / horn / enclosure modification

PDA-

MINIUSB

USB Cable for SuperNova Series, Type

A Male to Type Mini-B Male

PDX6901

Snubber: 0.01 μF/470 Ω, 250 VAC

Signal Splitter & Conditioner Accessories

Model Description

PD659-1MA-1MA

Signal Isolator with One 4-20 mA

Input and One 4-20 mA Output

PD659-1MA-2MA

Signal Splitter with One 4-20 mA

Input and Two 4-20 mA Outputs

PD659-1V-1MA

Signal Conditioner with One 0-10

VDC Input and One 4-20 mA Output

PD659-1MA-1V

Signal Conditioner with One 4-20

mA Input and One 0-10 VDC Output

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

10

Specifications

Except where noted all specifications apply to

operation at +25°C.

General

Display Wide viewing angle reverse polarity

LCD; PV: white, SV: green, MV: amber

PD510: PV and SV display

PD520: PV, SV, and MV display

PD530: PV, SV, and MV display

Display Height inches (mm)

PV SV MV

PD510 0.60 (15.2) 0.29 (7.4) N/A

PD520 0.81 (20.5) 0.50 (12.8) 0.37 (9.3)

PD530 1.14 (29.0) 0.59 (15.0) 0.43 (11.0)

PV Display

Update Rate

4/second (250 ms)

Non-Volatile

Memory

Settings stored for a minimum of

10 years.

EEPROM life: 1 million writes

Included

Components

Controller with rubber gasket and

mounting bracket, 250 Ω resistor (1%),

and Quick Start Guide. Additional 250 Ω

resistor (1%) provided for models with

remote setpoint input option.

EEPROM Lock Programmable lock or unlock write

access to the EEPROM. When locked,

setting changes stored in RAM (not

saved on power down).

Power 100 - 240 VAC ±10%, 50 / 60 Hz

8.5 VA max.

Insulation

Resistance

20 MΩ minimum, 500 VDC

Dielectric

Strength

3,000 VAC; 50/60 Hz for 1 minute

across power terminals

Environmental

Operating temperature range:

-10 to 50°C (14 to 122°F)

Storage temperature range:

-25 to 65°C (-40 to 185°F)

Relative humidity:

35 to 85% non-condensing

Front Panel IP65

Depth Behind

Panel

Case extends 2.5 in (63 mm) behind

panel.

Required Fuse

UL Recognized, 250 VAC 0.5 A max,

slow-blow fuse.

Use fuses or circuit breakers compliant

with IEC60947-1 or IEC60947-3

Connections Fixed rear screw terminals and

mini-USB

Mounting 1/4, 1/8, or 1/4 DIN panel cutout

required: panel mounting bracket

assemblies are provided.

Weight PD510: 4.2 oz (120 g)

PD520: 7.1 oz (202 g)

PD530: 10.2 oz (290 g)

Warranty 1 year parts & labor. See Warranty

Information and Terms & Conditions on

www.predig.com for complete details.

Process Input

Process Input

Selection

Voltage or current (with external

resistor)

Process Input 1-5 V (4-20 mA), 0-5 V, 0-10 V,

0-50 mV, 0-100 mV

External 250 Ωresistor required to read

4-20 mA. Recommended accessory

PDX-RES2.

Decimal Point Up to 3 decimals.

Input Sampling 20 samples/sec (50 ms per sample).

For display update rate, see Display

Update Rate

Input Accuracy

Input Type

Prog.

No.

Display

Scale Range

Accuracy

4-20 mA*

30

1-5

-1999 to 9999

±0.2% of FS

± 1 digit

1-5 V

30

1-5

0-5 V

31

5V

0-10 V

32

10V

0-50 mV

33

0.05V

0-100 mV

34

0.1V

*To achieve the highest accuracy with a 4-20 mA input to the

controller, connect a 250 Ω(0.1% or higher precision) resistor across

the input terminals. The 250 Ω(1%) resistor included with the product

is not a precision resistor. For precision resistor, order PDX-RES2.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

11

Temperature Input

Temperature

Input Selection

Field programmable for thermocouple

or RTD

Thermocouple

Type

K, J, E, T, R, B, S, L, N, U, W, PLII

RTD Type JPT100, PT100

Cold Junction

Compensation

(RJC)

±1.5°C (-10 to 50°C)

RTD Max Line

Resistance

Three wire RTD with identical line

resistance up to 10 Ω

Input Sampling 20 samples/sec (50 ms per sample).

For display update rate, see Display

Update Rate

Input Accuracy

Input

Type

Prog.

No.

Display

Range

Accuracy

K 1 K0 -328 to 2498°F

-200 to 1370°C

±0.2% of FS

± 1 digit

2

K1

-148 to 932°F

-100.0 to 500.0°C

J 3 J0 -328 to 2192°F

-200 to 1200°C

4

J1

-328 to 1652°F

-199. To 900.0°C

E

5

E1

-328 to 1652°F

-199.9 to 900.0°C

T 6 T1 -328 to 752°F

-199.9 to 400.0°C

R

7

R0

32 to 3092°F

0 to 1700°C

B 8 B0 212 to 3272°F

100 to 1800°C

±0.2% of FS

± 1 digit

100 to 200°C:

±2.0% of FS

± 1 digit

S 9 S0 32 to 3092°F

0 to 1700°C

±0.2% of FS

± 1 digit

L

10

L1

-328 to 1652°F

-199.9 to 900.0°C

N 11 N0 -328 to 2372°F

-200 to 1300°C

U

12

U1

-328 to 752°F

-199.9 to 400.0°C

W

13

W0

32 to 4172°F

0 to 2300°C

PLII 14 PL0 32 to 2372°F

0 to 1300°C

JPt100

20

JPt0

-328 to 932°F

-200 to 500°C

21 JPt1 -328 to 932°F

-199.9 to 500.0°C

Pt100

22

Pt0

-328 to 1184°F

-200 to 640°C

23

Pt1

-328 to 1184°F

-199.9 to 640.0°C

Control Outputs

Control

Outputs

Each controller has a main control output

and a secondary control relay output for

two directions of control. The secondary

control relay output is always used for

On/Off operation.

Main Control

Output

4-20 mA output (SCR), voltage pulse

(SSR), or electromechanical relay (On/Off)

outputs available.

Control Type ON/OFF, PID control

Output

Operation

Programmable for reverse or direct action.

Current SCR

Output

4-20 mA linear current output

Load resistance: 600 Ω maximum

± 0.2% of FS ± 1 digit

Voltage Pulse

SSR Output

12 V ± 1 VDC

Load resistance: 600 Ω minimum

Recommended minimum cycle time: 1 sec

Relay Output Rated resistive load switching capacity:

5 A, 250 VAC; 5 A, 30 VDC

Max switching power: 750 VA, 90 W

Max switching voltage: 250 VAC, 110 VDC

Max switching current: 5 A

Mechanical life: 20 million cycles (at 180

CPM)

Recommended minimum cycle time: 20 sec

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

12

Alarm Relay Outputs

Function Programmable for 13 different alarm

types or off.

Number Two alarm relays standard on all

models.

Alarm Relay

Ratings

Rated resistive load switching capacity:

5 A, 250 VAC; 5 A, 30 VDC

Deadband 0-100% FS, user selectable

High or Low

Alarm

User may program any alarm for high,

low, or high-low range operation.

Absolute or

Deviation Alarm

User may program any alarm as an

absolute value alarm or a set value

deviation alarm.

Loop Break

Alarm

User may program any SUB alarm relay

as a loop break alarm.

Alarm Relay

Operation

•Automatic (non-latching)

and/or manual reset

•Latching (requires manual

acknowledge) with/without

clear

•Off (disable unused relays)

Relay Reset

(Acknowledge)

Automatic, front panel button, in setup

parameter menu, or through serial

communications

Time Delay

0 to 999 seconds, on and off delays;

programmable for each SUB relay.

Fail-Safe

Operation

Programmable, independent for each

alarm relay. Relay coils are energized in

non-alarm condition. In case of power

failure, relays will go to alarm state.

Standby

Operation

Programming, independent for each

alarm relay

Auto

Initialization

When power is applied to the controller,

relays will reflect the state of the input to

the controller unless standby mode is

enabled.

4-20 mA Retransmit Output

Function

4-20 mA linear current output

Scaling Range 0-100% of full scale

Output Loop

Resistance

600 Ω maximum load

Output Accuracy

±0.2% of full scale ± 1 digit

0-10 VDC Output The PD659-1MA-1V can convert the

optional 4-20 mA output to a 0-10 VDC

output

Remote SV Process Input

Function Process input to remotely change SV

Input Type &

Range

1-5 V, 4-20 mA

External 250 Ωresistor required to read

4-20 mA.

Input Accuracy

±0.2% of full scale ± 1 digit

USB Connection

Function

SuperNova software connection only

Location PD510: Top, behind panel

PD520 & PD530: Front mounted behind

rubber seal, accessible from front panel

Communication

UMS (USB Mass Storage) 2.0

Compatibility USB 2.0 Standard, Compliant

Connector Type Mini-USB receptacle

Cable

USB A Male to Mini-USB Cable

Protocol Protocol: PC-LINK

Baud rate: 38400 bps

Start bit: 1 bit

Data bits: 8 bits

Parity bit: None

Stop bit: 1 bit

Communication

Distance

16.4 ft (5 m) maximum

Digital Inputs

Function Digital Input 1: Select Run/Stop Mode

Digital Input 2: Select SV 1 or SV4/REM

Contacts DI1 and DI2, shared common

Logic Levels On: 1.5 V; Off: 0.1 V

Input Current

Approximately 2 mA each contact

Input

Impedance

On : 1 kΩ max, Off: 100 kΩ min.

Open Contact

Voltage

Open contact voltage approximately

5 VDC

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

13

Modbus®RTU Serial

Communications

Communica-

tion Method

EIA RS-485 standard, 2-wire half-duplex

with grounded, shielded cable

Slave Id 1 – 99 (Controller address); 31 maximum

bus connections

Max Range

3,937 ft (1.2 km)

Baud Rate Programmable for 4800, 9600, 14400,

19200, 38400, 57600 bps.

Start Bit 1 bit

Data Bits Programmable for 7 or 8 bits

Parity

Programmable for none, even, or odd.

Stop Bit Programmable for 1 or 2 bits

Protocol PC-LINK STD, PC-LINK SUM, MODBUS-

ASCII, MODBUS-RTU

Response

Time

Actual response time =

processing time + (response time x 50 ms)

SuperNova TCS Software

Availability

Download directly from

www.predig.com/download_software

Operating

System

Requirements

Microsoft

®

Windows

®

7/8/10

64-bit (x64) or 32-bit (x86)

Minimum

Hardware

Requirements

Pentium 1 GHz

512 MB RAM

1 GB available hard drive space (x86)

2 GB available hard drive space (x64)

Communications

USB 2.0 (single controller only)

(Standard USB A to Mini-B USB)

RS-232 to RS-485 converter or

USB to RS-485 converter

(programming, monitoring, and data

logging of multiple units)

Configuration

Configure parameters of all connected

controllers.

Data Log

Data log onto computer hard drive.

Data log files may be exported to

HTML, .xls, .xlsx, or .pdf format as

graphs or data tables. Graphs may

also

be exported as .bmp, .gif, .jpeg, or

.png. Data tables may also be exported

as .csv.

USB Powered

USB port provides power to the

controller for programming.

Apply normal power for general

controller operations.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

14

Compliance Information

Safety

UL & C-UL

Recognized

Component

USA & Canada

Process Control Equipment, Electrical –

Component

Process Control Equipment, Electrical

Certified for Canada - Component

UL File Number

E171428

Electromagnetic Compatibility

CE Marked

EN 55022

Class A ITE emissions requirements

Electrostatic

Discharge

KN61000-4-2

Electrical Fast

Transients

EFT(RS): KN61000-4-3

Surge

KN61000-4-5

Conductivity RF

(CS)

KN61000-4-6

Note:

Testing was conducted on controllers installed through

the covers of grounded metal enclosures with cable

shields grounded at the point of entry representing

installations designed to optimize EMC performance.

Safety Information

•Read complete instructions prior to installation

and operation of the controller.

•Install outdoors only with appropriate protection.

•Use it only in the ambient temperature and

humidity ranges indicated in this manual.

•Do not use in locations where corrosive and

flammable gases are present.

•Use it in places where vibrations and impacts are

not directly applied to the unit.

•Use it in places without liquids, oils, chemicals,

steam, dust, salt, iron, etc. (pollution degree 1 or

2).

•Avoid places where large amounts of inductive or

electromagnetic noise or static electricity are

generated.

•Avoid places with heat accumulation caused by

direct sunlight, radiant heat, etc.

•Use it in places with elevation below 2000 m.

•Installation Category II.

•Risk of electric shock or personal injury.

•The input/output terminals are subject to electric

shock risk. Never let the input/output terminals

come in contact with your body or a conductive

material.

•This product is not recommended for life support

applications or applications where malfunctioning

could result in personal injury or property loss.

Anyone using this product for such applications

does so at his/her own risk. Precision Digital

Corporation shall not be held liable for damages

resulting from such improper use.

•This controller is not equipped with a power

switch or fuse, install them separately (fuse

rating: 250 VAC, 0.5 A).

•Supply the rated power voltage to prevent

product damage or malfunction.

•To reduce risk of electric shocks, do not supply

power until all installation wiring is complete.

•Do not connect or disconnect any wiring while the

power terminal wires are live.

•The product has no hazardous area

classifications. Use only in safe areas.

•Never modify, repair, or disassemble this

controller. This may result in electric shock, fire,

or damage to the controller.

•Please use this controller only after installing it to

a panel to reduce risk of shock or injury.

•When used in equipment with a high risk of

personal injury or property damage, installing a

redundant fuse and other safety devices is

recommended.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

15

Operation & Care Notes

•Please do not clean the controller with organic

solvents such as alcohol, benzene, etc. Clean it

with neutral detergents.

•If water enters the unit, a short circuit or fire may

occur, so please inspect the product carefully.

•For thermocouple input, use the predetermined

compensating cable (temperature errors occur

when using ordinary cable).

•For RTD input, use a cable with small lead wire

resistance and without resistance difference

among the 3 wires (temperature errors occur if

the resistance value among the 3 wires is

different).

•Keep the input signal line away from power line

and load line to avoid the influence of inductive

noise.

•The input signal line and the output signal lines

should be separated from each other. If

separation is not possible, use shield wires for

the input signal line.

•Use a non-grounded sensor for thermocouple

(using a grounded sensor may cause

malfunctions).

•When there is a lot of noise from the input power

source, we recommend using an isolation

transformer and noise filter. Please install the

noise filter to a grounded panel or structure and

make the wiring of the noise filter output to the

controller power supply terminal as short as

possible.

•Tightly twisting the power cables helps prevent

noise.

•Be sure to program the alarm functions to behave

as desired in the case of abnormal operation.

Confirm this before operation.

•When replacing the sensor, be sure to turn off the

power to the controller.

•Use an intermediate relay when the frequency of

operation (such as proportional operation) is

high, because connecting the load to the output

relay directly may shorten the life of the

controller. In these cases, using the voltage

pulse/SSR drive output type is recommended.

•When using an electromagnetic relay for control,

set the proportional cycle to at least 20 sec.

•When using SSR output for control, set the

proportional cycle to at least 1 sec.

•Do not wire anything to unused terminals.

•Confirm all terminal polarities before wiring any

inputs or outputs to avoid damage.

•When you install this product to a panel, use

switches or circuit breakers compliant with

IEC60947-1 or IEC60947-3.

•Install switches or circuit breakers at close

distance for easy user accessibility.

•Specify on the panel that, since switches or

circuit breakers are installed, if the switches or

circuit breakers are open, the power will be cut

off.

Installation

There is no need to remove the controller from its

case to complete the installation, wiring, and

setup of the controller.

Unpacking

Remove the controller from box. Inspect the

packaging and contents for damage. Report

damages, if any, to the carrier.

If any part is missing or the controller

malfunctions, please contact your supplier or the

factory for assistance.

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

16

Panel Mounting Instructions

•Prepare the appropriate standard DIN panel

cutout. Refer to Figure 1. Panel Cutout

Dimensions below for more details.

•Clearance: allow at least 3.5" (88.4 mm) behind

the panel for wiring.

•Panel thickness: 0.04" - 0.28" (1.0 mm - 7.0 mm).

•Remove the mounting bracket(s) provided with the

controller.

•Insert controller into the panel cutout.

•Install mounting bracket(s) and tighten the

screws against the panel. To achieve a proper

seal, tighten the mounting bracket screws evenly

until controller is snug to the panel. DO NOT

OVER TIGHTEN, as the rear of the panel may be

damaged. See Figure 2. PD510 Mounting

Bracket Installation

•and Figure 3. PD520 and PD530 Mounting

Bracket Installation.

Panel Cutout

Units: in (mm)

Dimension

PD510

PD520

PD530

W11

45.0

45.0

93.0

H11

45.0

93.0

93.0

A

60.0

70.0

117.0

B

60.02

122.0

117.0

1.+0.5 mm tolerance applied.

2. Allow 3.9 in (100.0 mm) above controller for use of

a USB cable with PD510.

Figure 1. Panel Cutout Dimensions

Figure 2. PD510 Mounting Bracket Installation

Figure 3. PD520 and PD530 Mounting Bracket

Installation

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

17

Controller Dimensions

Controller Dimensions

Units: in (mm)

Dimension

PD510

PD520

PD530

W

48.0

48.0

96.0

H

48.0

96.0

96.0

D

63.0

63.0

63.0

D1

5.0

5.0

5.5

Figure 4. Controller Dimensions

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

18

Connections

All connections are made to non-removable

screw terminal connectors located at the rear of

the controller.

The mini-USB connector is located at the front of

the PD520/PD530 and at the top of the PD510.

•Use copper wire with 60°C or 60/75°C insulation

for all line voltage connections. Observe all safety

regulations. Electrical wiring should be performed

in accordance with all applicable national, state,

and local codes to prevent damage to the

controller and ensure personnel safety.

•Use spade or ring terminals to secure wires.

Figure 5. Recommended Terminal Connectors

Connectors Labeling

The connector labelling diagraph marked on the

controller shows the location of all connectors

available with requested configuration.

All options are shown in the diagrams below, though

only installed options will appear on a controller.

Figure 6. PD510 Connector Diagram

Figure 7. PD520 & PD530 Connector Diagram

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

19

Power Connections

Power connections are made to two terminals.

Figure 8. PD510 Power Connection

Figure 9. PD520 & PD530 Power Connection

Signal Connections

Signal connections are made to a group of three

terminals. Use the labeling appropriate to the desired

input.

Additional setup and programming is performed using

the SuperNova software or through the front panel

buttons.

Thermocouple

Connect the thermocouple with the positive side to

plus and the negative side (typically red) to minus.

RTD

For a three-wire RTD, connect the single lead to

terminal A. Connect the identical leads to terminal B

and B’ to compensate for lead resistance (typically

identical colors).

Voltage

Connect the positive and negative of the voltage

source device to the positive and negative terminals.

Current

To accept a 4-20 mA input, connect the positive

terminal to + and the negative, return, or common

wire to -. In addition, connect an external 250 Ω

resistor across the + and – terminals.

Figure 10. PD510 Signal Connection

Figure 11. PD520 & PD530 Signal Connection

Relay Connections

Each controller has 3 or 4 relay outputs, one or two

control relays and 2 alarm relays.

If the controller has a main control relay, OUT1 will be

labelled as a relay (RLY) output. Control output 2 is

always OUT2, and is always a relay (RLY) output.

The alarm relay connections are made to terminals

SUB1 and SUB2.

Each relay is a form A relay with a normally open

(NO) and common (COM) contact. OUT1 and OUT2

are isolated. SUB1 and SUB2 alarm relays share a

common COM contact.

Figure 12. PD510 Relay Connections

Figure 13. PD520 & PD530 Relay Connections

SuperNova PD500 PID Process & Temperature Controllers Instruction Manual

20

4-20 mA Output Connections

Connections for the 4-20 mA retransmit output are

made to the connector terminals labeled mA OUT.

The 4-20 mA output is an active output, powered by

an internal 12 VDC power supply.

Figure 14. PD510 4-20 mA Retransmit

Connections

Figure 15. PD520 & 530 4-20 mA Retransmit

Connections

Digital Input Connections

Connections to the optional digital inputs are made to

the connector terminals labeled DI1, DI2, and COM.

Closing DI1 or DI2 to COM will activate that digital

input. Both digital inputs share a single common.

Figure 16. PD510 Digital Input Connections

Figure 17. PD520 & PD530 Digital Input

Connections

Remote SV Input Connections

Connections to the remote set value input are made

to the connector terminals labeled REM+ and REM-.

This input accepts a 1-5 VDC input. Connect the

positive and negative of the voltage source device to

the positive and negative terminals.

To accept a 4-20 mA input, connect the positive

terminal to + and the negative, return, or common

wire to -. In addition, connect an external 250 Ω

resistor across the + and – terminals.

Figure 18. PD510 Remote SV Input Connections

Figure 19. PD520 & PD530 Remote SV Input

Connections

Modbus RTU Serial

Communications

Serial communications connection is made to two

terminals for RS-485 half-duplex communication.

Figure 20. PD510 RS-485 Connection

Figure 21. PD520 & PD530 RS-485 Connection

Digital Input Connections

Connections to the optional digital inputs are made to

the connector terminals labeled DI1, DI2, and COM.

Closing DI1 or DI2 to COM will activate that digital

input. Both digital inputs share a single common.

Other manuals for SuperNova PD500

2

Table of contents

Popular Temperature Controllers manuals by other brands

YOKOGAWA

YOKOGAWA UP150 user manual

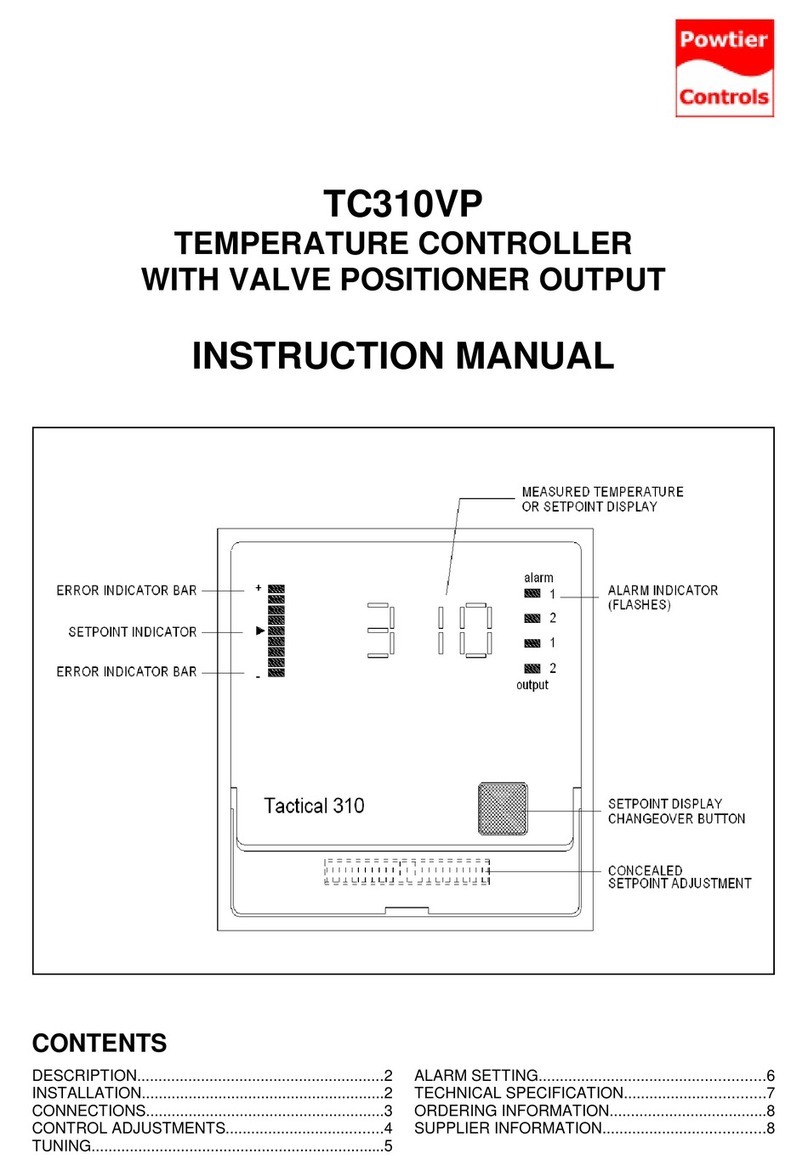

Powtier Controls

Powtier Controls Tactical 310 instruction manual

Viconics

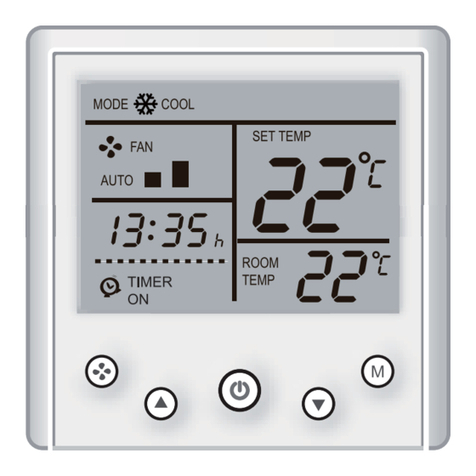

Viconics VT8300 Series installation guide

Novus

Novus N1050 instruction manual

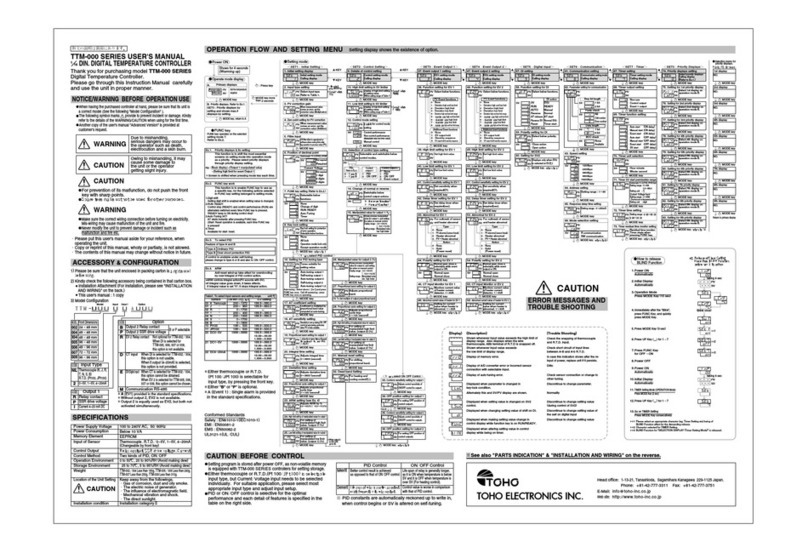

Toho Electronics

Toho Electronics TTM-000 SERIES user manual

Airtopia

Airtopia Control4 Installation and usage instructions

Lake Shore

Lake Shore 335 user manual

Shinko

Shinko RD-500 Series instruction manual

Eurotherm

Eurotherm 2108i Installing and operating instructions

Lowrance

Lowrance EP-80R TH Installation and configuration instructions

Tactical Controls

Tactical Controls 72TS instruction manual

Johnson Controls

Johnson Controls TM-11x1 series installation instructions