IM 05C01F12-41E 1

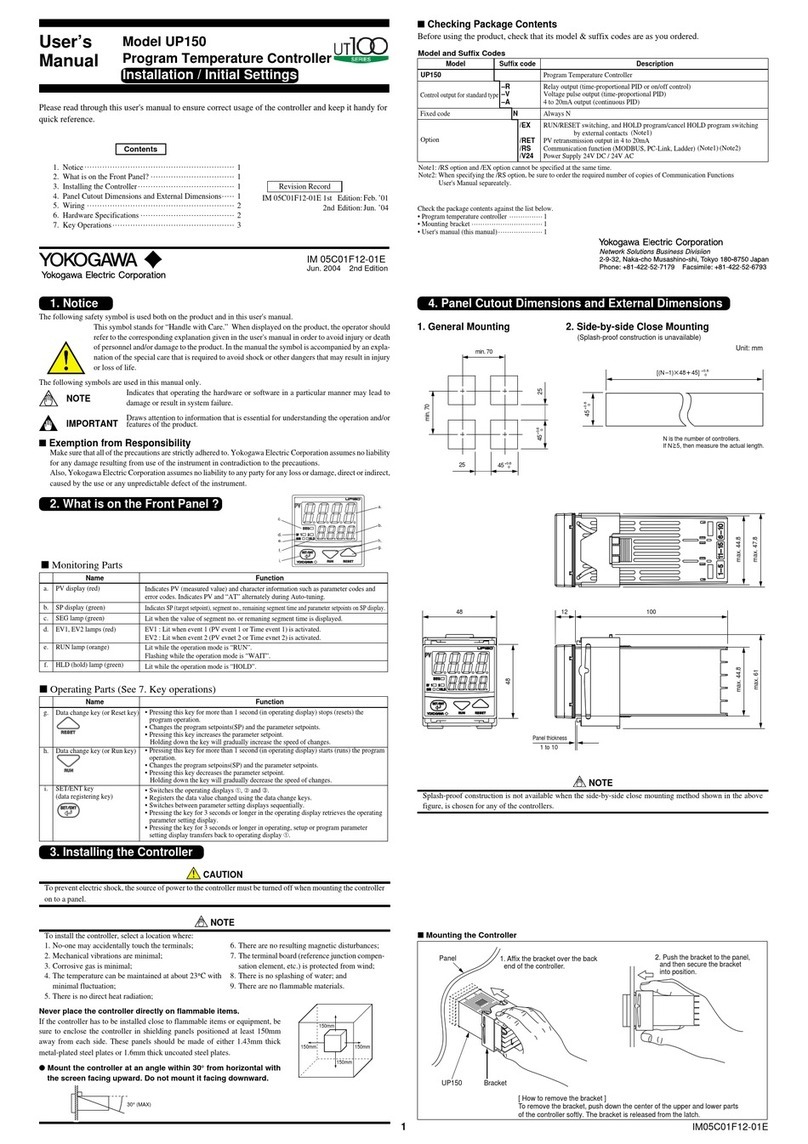

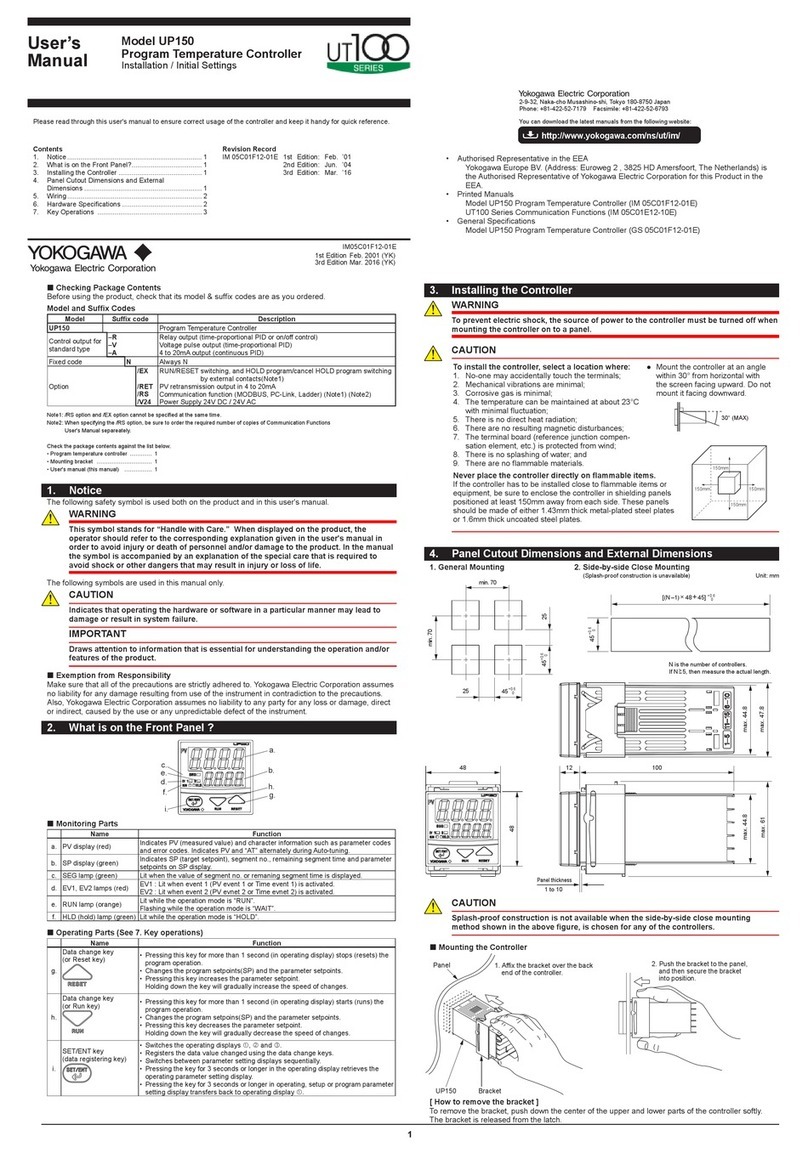

■Checking Package Contents

Before using the product, check that its model & suffix codes are as you ordered.

Please read through this user’s manual to ensure correct usage of the controller and keep it handy for quick

reference.

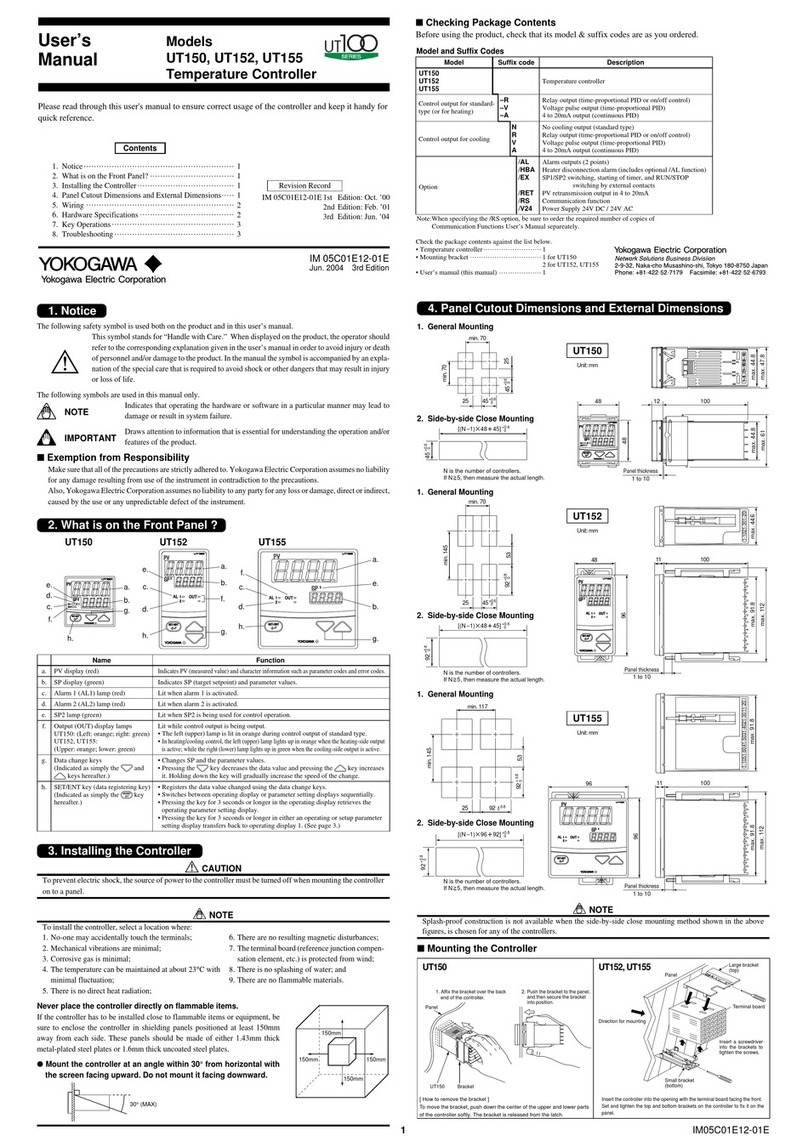

CONTENTS

1. Notice ............................................................................................................................... 2

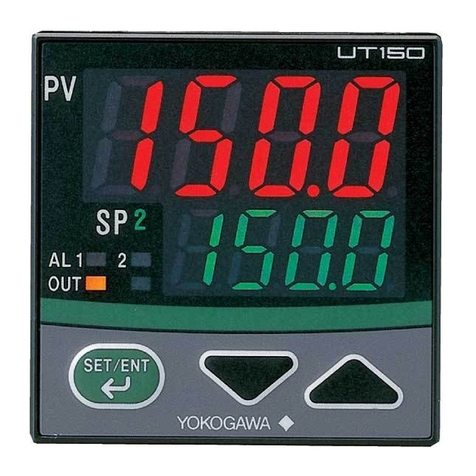

2. What is on the Front Panel?......................................................................................... 3

3. Installing the Controller ................................................................................................ 4

4. Panel Cutout Dimensions and External Dimensions.................................................. 5

5. Wiring.............................................................................................................................. 6

6. Hardware Specifications................................................................................................ 9

7. Key Operations............................................................................................................. 10

8. Programming ................................................................................................................ 19

9. Troubleshooting............................................................................................................ 19

Check the package contents against the list below.

•Program temperature controller

•Mounting bracket

•User's manual

1

1

1

...............

................................

....................................

Model

Model and Suffix Codes

Suffix code Description

UP150 Program Temperature Controller

–R

–V

–A

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID)

4 to 20mA output (continuous PID)

NAlways N

Option

/EX

/RET

/RS

/V24

RUN/RESET switching, and HOLD program/cancel HOLD program switching

by external contacts

PV retransmission output in 4 to 20mA

Communication function (MODBUS, PC-Link, Ladder)

Power Supply 24V DC / 24V AC

Control output for standard type

Fixed code

Note1: /RS option and /EX option cannot be specified at the same time.

Note2: When specifying the /RS option, be sure to order the required number of copies of Communication Functions

User's Manual separeately.

(Note1)

(Note1)(Note2)