TC310VP Instruction Manual Powtier Controls Limited

TECHNICAL SPECIFICATION

INPUT

Thermocouple Standard ASTM E230, BS4937, DIN 43710.

Cold junction compensation Automatic.

Thermocouple break protection Upscale fitted as standard, display shows "bbb." (b:blank)

Downscale fitted as an option.

Resistance Thermometer 2 or 3 wire Any lead resistance error is automatically reduced by

using 3 wires.

RTD (Pt 100) BS 1904, DIN 43760.

VALVE POSITION OUTPUT

Motor supply voltage 24Vac to 240Vac (EXTERNAL STEP DOWN

TRANSFORMER REQUIRED).

Output twin triacs rating 2Arms, 24Vac to 240Vac.

Feedback potentiometer 100 to 1000 Ohms.

CONTROL

PID control Proportional, Integral and Derivative.

Proportional band Xp 2.5% to 15% of span.

Integral time ti Switching integral time 5 to 40 minutes.

Derivative time td Switching derivative time 0.5 to 5 minutes.

PD control (option) Proportional and derivative.

Proportional band Xp 2.5% to 15% of span.

Derivative time td 0.5 to 5 minutes.

Manual reset PD control only, 0 to 50% output power at span.

ON/OFF control (option) Hysteretic 0.5% of span.

ALARMS OUTPUTS (option)

Relay Normally energised and de-energised in alarm

conditions. 2Aresistive at 230Vrms.

Alarm LED Flashing LED at fascia.

Low deviation Adjustable +0.5% to -8% of span.

High deviation Adjustable -0.5% to +8% of span.

Band deviation Adjustable 1.5% to 8% of span.

RETRANSMISSION SIGNAL (option)

Analogue signal 5V, 5mA max.m signal linear to span.

ENVIRONMENTAL

Supply voltage 115/230V +/-15% 50/60Hz

100/200V +10% -15% 50/60Hz.

Operating temperature 0 to 50 °C.

Storage temperature -20 to +80 °C.

PERFORMANCE

Indication accuracy Better than 0.5% of span +/-1 digit.

Supply voltage variation Negligible effect within operating range.

GENERAL

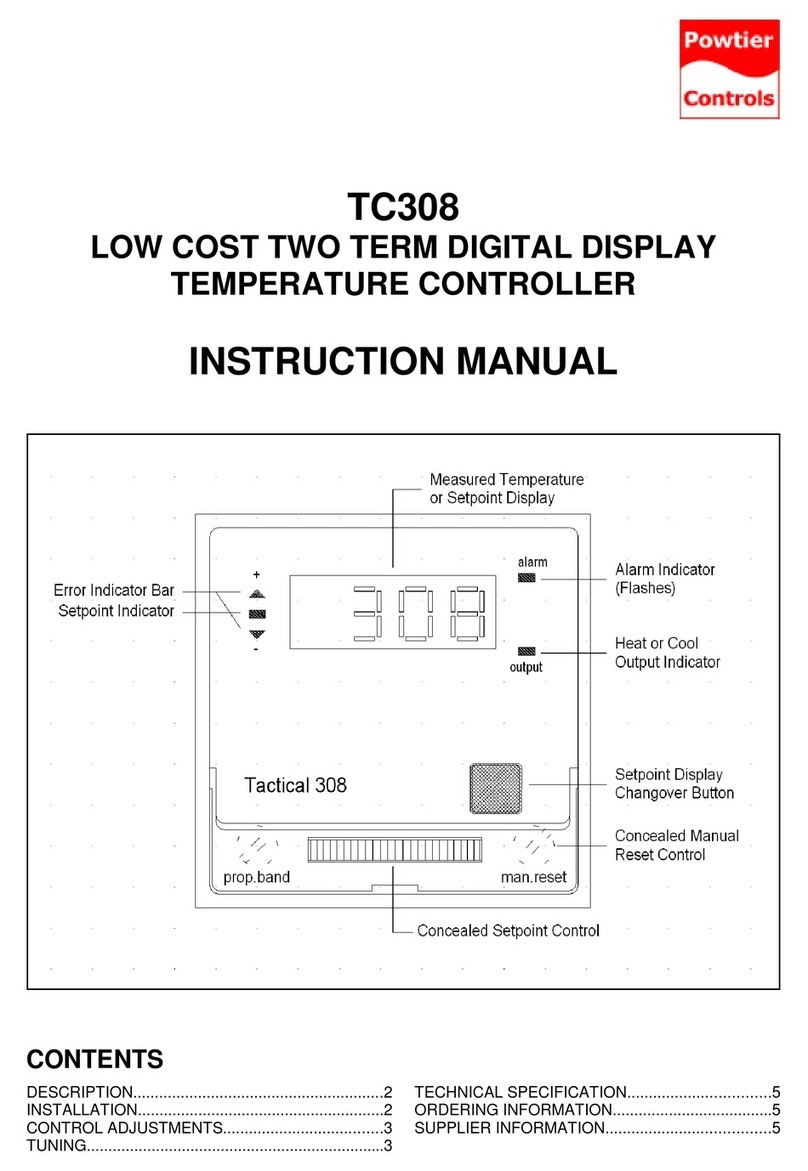

Display digit 3 digit 7 segment with negative sign display;

digit size 13mm height by 7.4mm width.

Error indication 9 LED display bar; central LED +/- 0.4% of span

+/-1 degree and +/-0.8% of span +/-1 degree

per LED above and below setpoint.

Dimensions 96x96x190mm.

Weight 2Kg maximum.

Power consumption 6VA maximum.

14 March 1995 - 7 - 310VPIM

Issue 2.0