Preferred Utilities Quanta-Flame 5004-890 User manual

Quanta-Flame 5004-890

Quick Start Guide

For complete instruction manual, go to www.preferred-mfg.com

GN Electronics, a division of Preferred Utilities since 2007

E

N

G

I

N

E

E

R

E

D

5004-890 Quick Start Guide 5004-890 Quick Start Guide

DESCRIPTION

e Preferred Utilities 5004-890 controller is a direct replacement for the following Honeywell ame safe-

guard controllers:

RA890F-1031 RA890G-1047

RA890F-1056 RA890G-1062

RA890F-1072 RA890G-1112

RA890F-1262 RA890G-1120

RA890F-1288 RA890G-1179

RA890F-1346 RA890G-1197

RA890F-1510 RA890G-1260

is quick start guide will describe how to remove the existing RA890 controller, congure, install, and

test the new Preferred 5004-890 ame safeguard controller. Before starting work, de-energize power to the

existing ame safeguard controller. Close any fuel valves to the burner. Use lock out/tag out procedures

appropriate to the facility.

STEP 1. REMOVE THE EXISTING RA890 CONTROLLER

• Remove the cover from the existing RA890 exposing the ten (10) captive mounting screws.

• Unscrew the ten mounting screws and pull the RA890 controller away from the Q270A subbase.

• Inspect the pilot link jumper wire to determine if it is intact or if it has been cut. (Note only the RA890F

controllers have a pilot link jumper.

PILOT LINK JUMPER

STEP 2. CONFIGURE THE 5004-890 CONTROLLER

• Using the part number for the existing controller, set the four DIP switches and J2 according to the follow-

ing table. e DIP switches are located under the right side cover below the mounting screws. J2 is under

the le side cover below the mounting screws on the le side.

Pilot Trial for Ignition Timing

Recycle or

Non-Recycle

Mode

Intermittent or Continuous Pilot Flame Proving

Honeywell

Part Number DIP Switch 1 DIP Switch 2 DIP Switch 3 DIP Switch 4 J2 Position

RA890F-1288 OFF ON ON

For continuous pilot operation,

the pilot link on the existing

RA890F will be clipped. Set DIP

switch 4 to OFF.

If the pilot link on the existing

controller is intact, set DIP switch

4 to ON

Flame Rod

RA890F-1031 OFF ON ON Flame Rod

RA890F-1056 OFF ON ON Flame Rod

RA890F-1072 OFF ON ON Flame Rod

RA890F-1262 OFF ON ON Flame Rod

RA890F-1510 OFF ON ON Flame Rod

RA890G-1260 OFF ON ON

All RA890Gs are intended for

intermittent or interrupted pilot

only. DIP switch 4 to be set to ON

UV Scanner

RA890G-1047 OFF ON ON UV Scanner

RA890G-1062 OFF ON ON UV Scanner

RA890G-1112 OFF ON ON UV Scanner

RA890G-1120 OFF ON ON UV Scanner

RA890G-1179 OFF ON ON UV Scanner

RA890G-1187 OFF ON ON UV Scanner

e equipment covered in this manual is capable of causing property damage, severe injury, or death. It

is the responsibility of the owner or user to ensure that the dequipment described herein is installed and

commissioned in compliance with the requirements of all national and local codes, whichever may prevail.

e equipment covered in this manual is capable of causing property damage, severe injury, or death. It

is the responsibility of the owner or user to ensure that the dequipment described herein is installed and

commissioned in compliance with the requirements of all national and local codes, whichever may prevail.

5004-890 Quick Start Guide 5004-890 Quick Start Guide

STEP 3. INSTALL THE 5004-890 CONTROLLER

• Set the 5004-890 controller over the existing Q270A mounting base and tighten the ten mounting screws

securely.

• Restore power to the ame safeguard enclosure.

STEP 4. MINIMUM PILOT TEST

is test requires a digital multimeter capable of reading volts DC to measure ame signal strength. e

positive lead is plugged into the test jack labeled, “SIGNAL 0-5 VDC.” e negative lead is plugged into the test

jack labeled, “GND.”

e following test procedures ensures the ame sensor will not detect a pilot ame too small to

reliably light the main ame:

4.1 Manually shut o the fuel supply to the burner, but not to the pilot.

4.2 Start the system normally.

4.3 To enter the pilot test mode, press and hold the reset button for ten seconds on the front of the 5004

control.

4.4 e control will hold the operating sequence at the pilot ame step. Measure signal strength as

described above.

4.5 Reduce pilot fuel until the ame relay drops out. Increase pilot fuel until the ame signal is greater

than 1 VDC, and ame relay just manages to pull in. is is the minimum pilot. If you don’t think this

ame will be able to safely light the main burner, realign the sensor so that it requires a larger pilot

ame and repeat steps 4.2 through 4.5.

4.6 Push the reset button located in the lower right corner on the front cover to reset the control into the

normal and begin the normal start-up sequence again.

4.7 When the sequence reaches the main ame trial for ignition, smoothly restore the fuel supply to the

burner. If the main burner does not light within ve seconds, immediately shut o the burner supply to

shut down the system. Re-align the sensor so that it requires a larger pilot ame. Repeat steps 4.1

through 4.6 until the main burner lights o smoothly and reliably.

STEP 5. PILOT FLAME FAILURE TEST

• Manually shut o the fuel supply to the pilot and the main burner.

• Place system in pilot test mode

• Start the system normally. e controller should lock out; if it doesn’t, then the controller is detecting a

false ame signal. Find the problem and correct it before resuming normal operation.

STEP 6. MAIN FLAME FAILURE TEST

• Manually shut o the fuel supply to the main burner but not to the pilot.

• Start the system normally. is should ignite the pilot and lock out aer pilot interruption. If the

system does not lock out, the controller is detecting a false ame signal Find the problem and correct it

before resuming normal operation.

STEP 7. SPARK SIGHTING TEST

• Manually shut o the fuel supply to the pilot and the main burner.

• Start the system normally.

• Measure the ame signal.

• If a ame signal greater than 1 VDC is measured for more than three seconds during the trial for

ignition, then the sensor is picking up a signal from the spark plug.

Note: Periodically check all interlock and limit switches by manually tripping them during burner

operation to make sure they cause the system to shut down.

Warning: Never operate a system that is improperly adjusted or has faulty interlocks or limit

switches. Always replace faulty equipment with new equipment before resuming operation.

Operating a system with defective safety equipment can cause explosions, injuries, and property

damage.

e equipment covered in this manual is capable of causing property damage, severe injury, or death. It

is the responsibility of the owner or user to ensure that the dequipment described herein is installed and

commissioned in compliance with the requirements of all national and local codes, whichever may prevail.

e equipment covered in this manual is capable of causing property damage, severe injury, or death. It

is the responsibility of the owner or user to ensure that the dequipment described herein is installed and

commissioned in compliance with the requirements of all national and local codes, whichever may prevail.

Company Overview

Founded in 1920, Preferred

is an engineering,

manufacturing, technical,

and , mechanical services

rm based in Danbury,

Conneccut.

Preferred is a leader in

many diversied markets

with a focus on combuson,

control, instrumentaon,

fuel handling, mission

crical systems, steam/

power plant operaons,

and more. Preferred

delivers design-build,

program management, and

other professional services

packaged in innovave

alternave delivery methods

to government agencies as

well as private industrial

and commercial customers

worldwide.

For more about Preferred,

please visit www.preferred-

mfg.com.

E

N

G

I

N

E

E

R

E

D

31-35 South Street | 203-743-6741

Danbury, CT 06810

www.PREFERRED-MFG.com

MADE IN

THE USA

“People. Products. Results.”

Since 1920.

Popular Controllers manuals by other brands

LU-VE

LU-VE CBG 30AV instructions

Nice

Nice PLUTO PL 4000 Instruction manual and spare parts catalogue

Rain Bird

Rain Bird ESP-LXIVM Series Installation, programming & operation guide

cashco

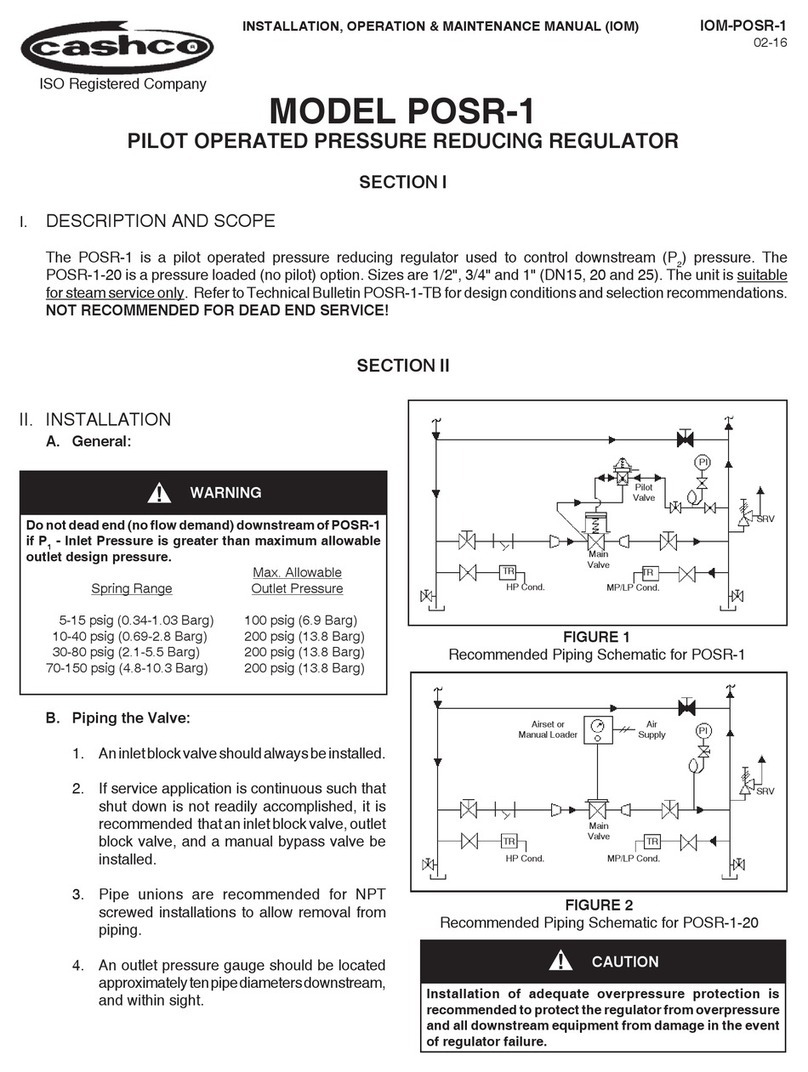

cashco POSR-1 Installation, operation & maintenance manual

Novusun CNC

Novusun CNC NVEMV2 manual

Daikin

Daikin BRC1H61W installation manual