Premier Mounts L180F User manual

INSTALLATION INSTRUCTIONS

L180F

Motorized Flat Panel Lift System*

*Enclosure Not Included

NORTH AMERICA

1321 S. State College Blvd.

Fullerton, CA 92831 USA

USA and Canada –

Phone: 800-368-9700

Fax: 800-832-4888

EUROPE

Unit 3, The Moorings Business Park

Channel Way, Longford,

Coventry, CV79JY, UK

Phone: +44 (0) 2476 644105

Fax: +44 (0) 2476 644165

Other Locations – Phone: (001)-714-632-7100; Fax: (001)-714-632-1044

©Premier Mounts 2013

9534-005-003-00

Page 2 Installation Instructions

L180F

Table of Contents

Preface 3

Warning Statements 3

Parts List 4

Installation Tools 4

Mounting Hole Layout 6

Wiring Instructions 6

Lift Operation 7

Support Bracket Installation 8

Lift Base Installation 8

Base Installation 9

Mount Installation 10

Thread Depth Indicator 11

Attaching the Mounting Brackets 12

Attaching the Mounting Plate 13

Securing the Display 14

Attaching the Floating Lid Bracket 15

Troubleshooting Procedures 16

Programming Lift Height (Optional) 16

Technical Specifications 17

Warranty 18

Installation Instructions Page 3

THE STRUCTURE MUST BE CAPABLE OF SUPPORTING AT LEAST FIVE TIMES THE WEIGHT OF THE DISPLAY AND

LIFT. IF NOT, THE STRUCTURE MUST BE REINFORCED. PROPER INSTALLATION PROCEDURE BY A QUALIFIED

SERVICE TECHNICIAN, AS OUTLINED IN THE INSTALLATION INSTRUCTIONS, MUST BE ADHERED TO. FAILURE TO

DO SO COULD RESULT IN SERIOUS PERSONAL INJURY, OR EVEN DEATH.

DO NOT PLACE DISPLAYS WEIGHING MORE THAN 175LBS. ON THIS MOUNT. IF THIS WEIGHT IS EXCEEDED, DAMAGE TO

THE MOUNT AND/OR LIFT UNIT MAY OCCUR.

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION INSTRUCTIONS SHOULD BE READ AND

COMPLETELY UNDERSTOOD. THE INSTALLATION INSTRUCTIONS MUST BE READ TO PREVENT PERSONAL INJURY AND

PROPERTY DAMAGE. KEEP THESE INSTALLATION INSTRUCTIONS IN AN EASILY ACCESSIBLE LOCATION FOR FUTURE

REFERENCE.

Warning Statements

Indicates that the power plug is to be disconnected

from the power outlet.

Safety precautions must be taken at all times.

Warning and Caution statements.

Do not install on a structure that is prone to vibration, movement or chance of impact. Failure to do so could result in damage to the flat panel

display and/or damage to the mounting surface.

Do not install next to any high heat sources. Failure to do so may result in damage to the flat panel display and could increase the risk of

fire.

Contact Premier Mounts with any questions.

In the interest of safety, it is recommended that two perform this installation. Injury and/or damage can result from dropping or mishandling

the flat panel display.

If there is visible damage to the product, it must not be

installed.

This unit is not intended for use by young children of

infirm persons without supervision.

Young children should be supervised to ensure that they

do not play with the unit.

Preface

We are delighted that you have chosen a product from Premier Mounts. Premier Mounts mounting systems are high-tech products that

are based on many years of experience in the manufacture and development plasma displays, LCD diplays and projector mounts. We are

also constantly improving our products to meet our family of customers particular requirements.

These installation instructions will assist and direct you in how to assemble, install and utilize your flat panel lift system.

We are sure that your display lift system will give you many years of problem-free operation. Before our products leave the factory they

undergo full function and quality testing. Should you, nevertheless, experience problems with your system, you are always welcome to

contact our Customer Service department.

Premier Mounts provides a warranty on all of our products. This warranty, however, is subject to correct use in accordance with the

specifications and procedures as set forth in the manual. Maintenance and repairs must be done by a certified technician.

Changes in installation and use of Premier Mounts products can affect their operation and durability. Changes must therefore only be

made at your own risk.

PREMIER MOUNTS DOES NOT WARRANT AGAINST DAMAGE CAUSED BY THE USE OF ANY PREMIER MOUNTS

PRODUCT FOR PURPOSES OTHER THAN THOSE FOR WHICH IT WAS DESIGNED OR DAMAGE CAUSED BY UNAUTHORIZED

ATTACHMENTS OR MODIFICATIONS, AND IS NOT RESPONSIBLE FOR ANY DAMAGES, CLAIMS, DEMANDS, SUITS,

ACTIONS OR CAUSES OF ACTION OF WHATEVER KIND RESULTING FROM, ARISING OUT OF OR IN ANY MANNER

RELATING TO ANY SUCH USE, ATTACHMENTS OR MODIFICATIONS.

L180F

Page 4 Installation Instructions

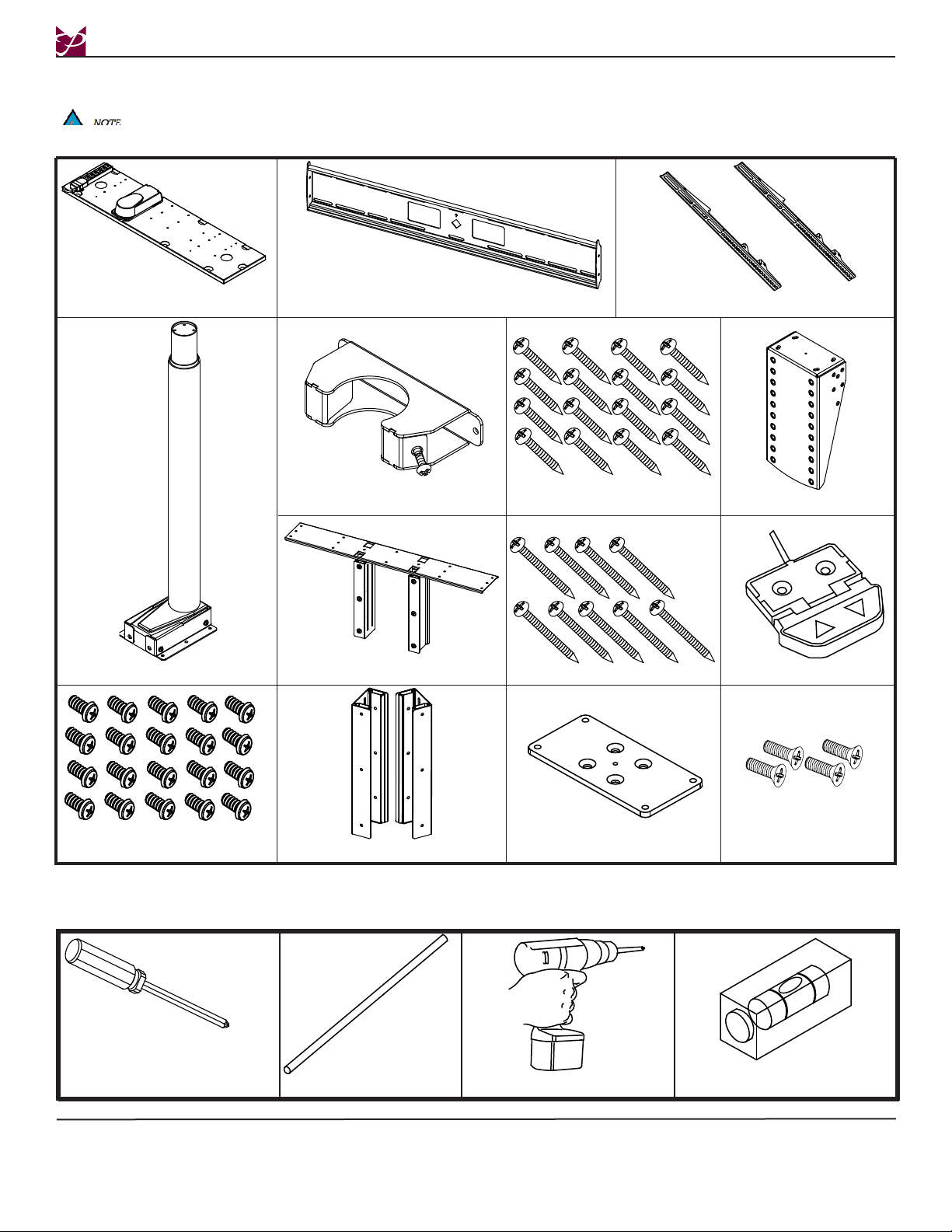

Installation Tools

Screwdriver Thread Depth Indicator Portable Drill

Parts List

This mount is shipped with the following installation hardware and components. Make sure that none of these parts

are missing and/or damaged before beginning installation. If there are parts missing and/or damaged, please stop the

installation and contact Premier Mounts (800-368-9700).

Steel Floor Board (Qty 1)

Manual Switch (Qty 1)

#10 x 3/4” Wood Screw (Qty 9)

Lift (Qty 1)

M6 x 12 Phillips Head

Screws (Qty 20)

Mounting Plate (Qty 1)

#8 x 1/2” Wood Screw (Qty 16) Display Mount (Qty 1)

Mounting Brackets (Qty 2)

Support Brace (Qty 1)

Level (Supplied)

L180F

Floating Lid (Qty 1)

Spacer (Qty 1)

M6 x 20mm Phillips Flat

Head Screws (Qty 4)

Slide Brackets (Qty 2)

Installation Instructions Page 5

The nylon spacers may be stacked to achieve proper spacing.

M8 x 40 (Qty 6)

M6 x 12 (Qty 8)

(Qty 8)

M4 x 25

M4 x 16

M5 x 25

M5 x 20

M5 x 16

M5 x 12

M5 x 50

M8 x 70

M8 x 35

M8 x 30

M8 x 25

M8 x 20

M6 x 20

(Qty 4)

(Qty 8)

(Qty 6)

(Qty 6)

(Qty 4)

(Qty 4)

(Qty 6)

(Qty 4)

(Qty 6)

(Qty 6)

(Qty 6)

(Qty 6)

1

4" Nylon Spacers

(Small)

(Qty 6)

1 Nylon Spacers

(Qty 6)

1

4" Nylon Spacers

(Large)

(Qty 6)

5

16" Nylon Sleeves

(Qty 4)

9

16" Nylon Spacers

(Qty 6)

5

16" Flat Washers

(Metal)

(Qty 6)

1

2" Nylon Spacers

(Large)

(Qty 12)

L180F

Page 6 Installation Instructions

Mounting Hole Layout

Mounting Hole Pattern

1. Single Lift Mounting Points

2. Dual Lift Mounting Points

3. Outlet Electrical Box Mounting Points

4. Steel Floor Board Mounting Points

5. Power Cord Outlet Holes

6. Display On/Off Control Box Mounting Points

7. Control Box Mounting Points

1

1

11

1

1

4444

4

44

4

4

4

33

33

2

2

22

2

22

2

22

2

2

6

66

6

5

5

77

77

Wiring Instructions

Prior to installing the base, the L180F must be wired.

Step 1. Locate the lift control

cable (pre-installed on

lift base)

Step 2. Insert control cable into

Slot #1 of control box.

Step 3. Locate manual

switch.

Step 4. Insert manual switch

cable into the RJ45 plug

on the control box.

Step 5. Attach the switch to the

inside wall of the cabinet

using two (2) #8 x 1/2”

screws.

Step 6. Locate extension power

cord and route through

(pre-cut) holes in base.

Install in an easily

accessible location and

away from moving parts.

L180F

Installation Instructions Page 7

Lift Operation

Console ON/OFF Box Functionality for Display Lift Applications

Systems utilizing the console ON/OFF box will automatically turn on and off a display connected to the system. Power is delivered to

the display when the lift is raised, and removed when the lift is lowered. The system is capable of running up to three lifts in parallel

with impulse functionality and always active Anti-Collision™.

Impulse Activation

When a key is pressed to drive the system up or down, the lift system will continue running after the key is released until it reaches the

stroke limit. If the system comes in contact with a rigid obstruction, Anti-Collision™ will be activated.

The user may also stop travel of the lift system by pressing a button opposite to the present travel direction. For example if the system

is being driven up, pressing the down button will stop the system.

Remote Activation (optional)

When used in conjunction with the IR sensor and remote, the lift system is capable of being operated remotely. To activate the system

in either the up or down direction wirelessly, simply point the remote at the receiver and press the respective button.

Depending on the furniture and screen size of the television, different stroke lengths are sometimes needed. Adjustments in the stroke

may be performed using the IR sensor. Remote activation is performed using the remote.

To set the stroke limit, move the lift to the desired position using the IR sensor. The lift will move on its own after a single button press,

so be sure to press the key opposite to the direction of travel to stop it at the preferred location. Where the lift stops will then be set as

the stroke limit. This stroke limit is only obeyed by the remote.

Anti-Collision™

The anti-collision function is always active when running the system. Anti-collision can limit material damages on a flat screen lift if a

collision with a solid object should occur.

Situations where the Anti-Collision™ does not work

There are situations where the anti-collision will not be activated. These situations are:

If the collision happens during the initialization phase

If the collision happens within the first 1000 msec or after the control button has been released

If the collision happens between the floor and the table and the load on the desk + the weight of the legs are lower than 40 kg

If the collision happens over too long time, e.g. if the collision is with a soft object

Initialization of the lift system

When a system is first assembled it is necessary that the system be initialized. The lift system is initialized by pressing the down button

once or twice and holding it down until the lift runs into end stop, it will then automatically run approximately 3mm out again hereafter,

slowly running in again. Only release the down button when the movement has completely stopped.

If the button is released before the sequence is complete then the initialization is interrupted and must be started again

from the beginning.

Because the lift can be in different modes when initialization starts, it is sometimes necessary to press the down button twice to start the

initialization. If an error situation occurs at the end stop positions, then the lift has to be initialized again.

L180F

Page 8 Installation Instructions

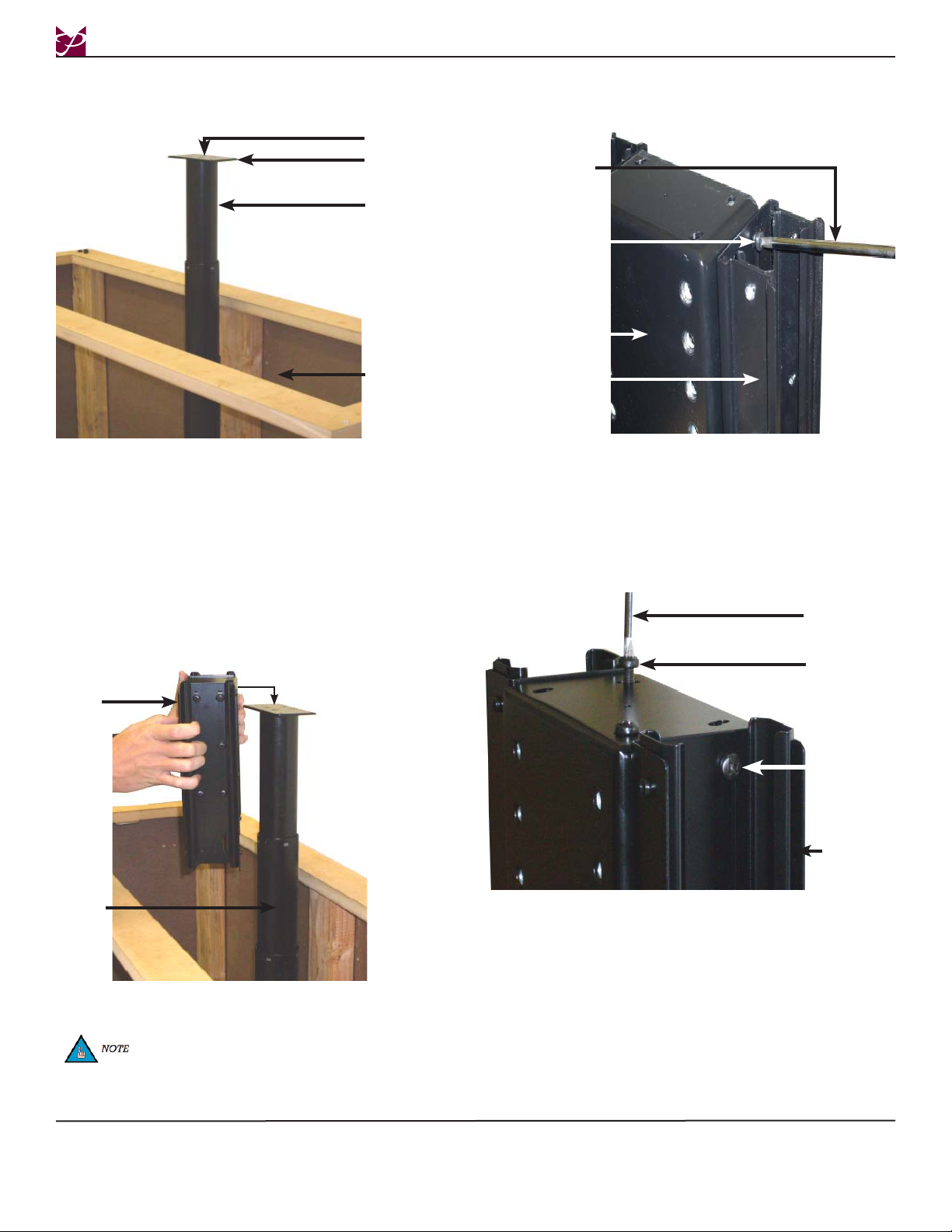

Lift Base Installation

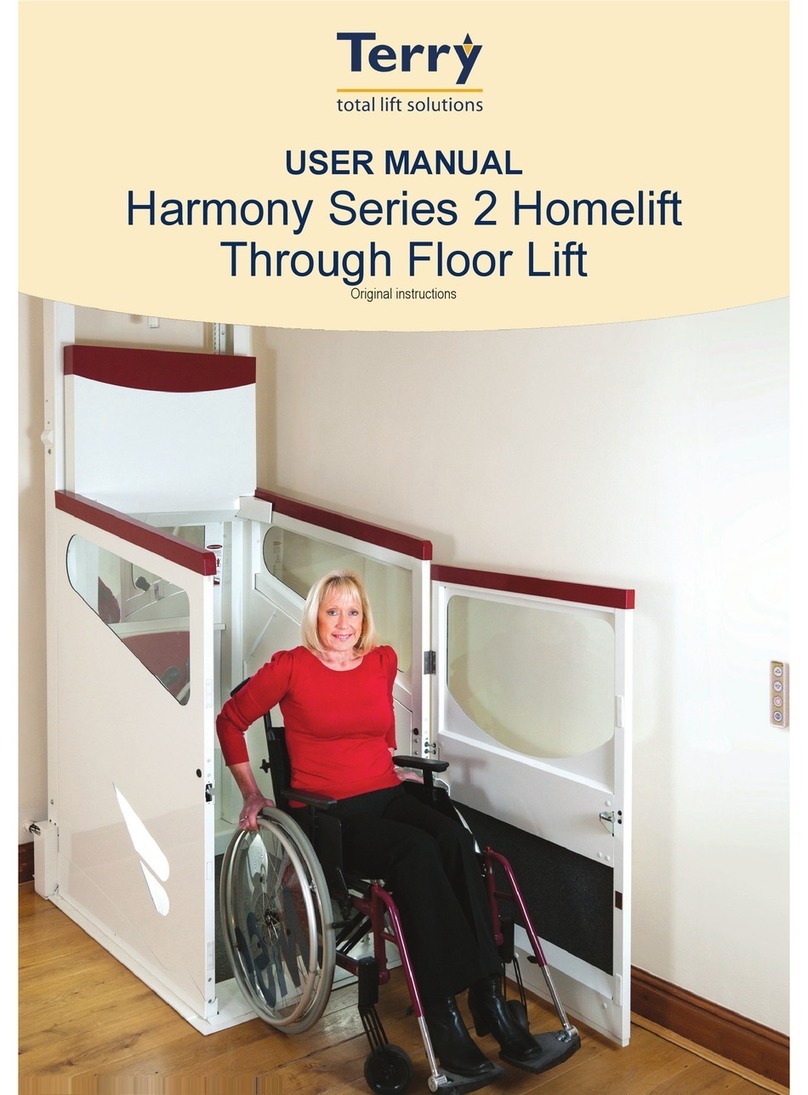

The lift assembly comes pre-assembled.

Step 1. Locate the six (6) mounting points that

are located on the lift base (three on each

side).

Step 2. Determine where the six (6) mounting points are

for the single base installation (see page 5).

Step 3. Place the lift base over the mounting points and

line up the holes.

Steel Floor Board

Lift Base

Step 4. Attach the lift base to the steel floor board using

six (6) M6 x 12 Phillips head screws (three on

each side).

Lift Base

Steel Floor

Base

Mounting Points

Support Bracket Installation

Step 1. Slide the support bracket down the lift

column about 3” from the top of the outer

lift tube.

Step 2. Use two (2) #8 x 1/2” Phillips head wood

screws to attach the support bracket to the

rear of the cabinet.

Step 3. Insert and tighten two (2) M8 x 35

Phillips head screws (one on each side) on

the back of the support bracket. Thread

these screws all the way in.

Wood Screw

Mounting Point

Support

Bracket

Lift

Column

M8 x 35mm

Screw

Tightening the screws will force the tabs

against the lift. Screw all the way in.

L180F

Installation Instructions Page 9

Base Installation

The following steps direct you only on how to attach the lift to a pre-existing mounting surface. These directions will

proceed on the assumption that you have already selected your mounting surface (i.e. furniture enclosure, plywood

base, concrete floor, etc.). Unpack the L180F and familiarize yourself with the components. Please take time before you

install the L180F to determine the location of where the L180F will be mounted. Please familiarize yourself with all

components contained herein.

Step 1. Place the steel floor board on the mounting surface inside the cabinet, making sure that the steel floor board is centered

right to left and positioned against the front inside wall of the cabinet.

Step 2. Locate the nine (9) mounting holes that are on the steel floor board.

Step 3. Using nine (9) #10 x 3/4” wood screws (supplied) and a portable drill, attach the steel floor board to the mounting surface.

All wiring must be completed prior to performing the following steps.

Steel Floor Board

Steel Floor Board

#10 x 3/4”Wood Screw

Drill

L180F

If mounting to concrete, please use commercially available concrete anchors.

Page 10 Installation Instructions

Step 1. Activate the remote and extend the lift

until the lift is in the fully raised position.

Step 2. Place the mounting spacer on top of the

lift.

Step 3. Use four (4) M6 x 20mm Phillips flat head

screws to secure the spacer to the lift.

Mount Installation

Cabinet

Lift

Mounting

Spacer

Step 5. Place the display mount on top of the lift

column.

Lift

Display

Mount

Screwdriver

M6 x 20mm

Mounting

Screw

Be sure to line up the holes on the

display mount with the threaded holes

that are located on the lift.

Side Slide

Bracket

L180F

Step 6. Loosen the six (6) M6 x 12 screws on the

inside of the sliding support bracket.

Step 7. Raise the bracket up to the desired height and

re-tighten.

Step 8. When the lid and slides are inserted, the lid

should be sitting no less then ¼” above the

top of the display.

Step 9. To gain extra height out of the slide support

bracket, use the top four (4) screws only.

This will allow the slide support brackets to

be raised higher.

M6 x 12mm

Mounting

Screw

M6 x 20mm Phillips

Flat Head Screws

Step 4. Attach the slide brackets to the display

mount using twelve (12 - six per side)

M6 x 12mm Phillips head screws.

Slide Bracket

Display Mount

M6 x 12mm Phillips

Head Screw

Screwdriver

Installation Instructions Page 11

/180F

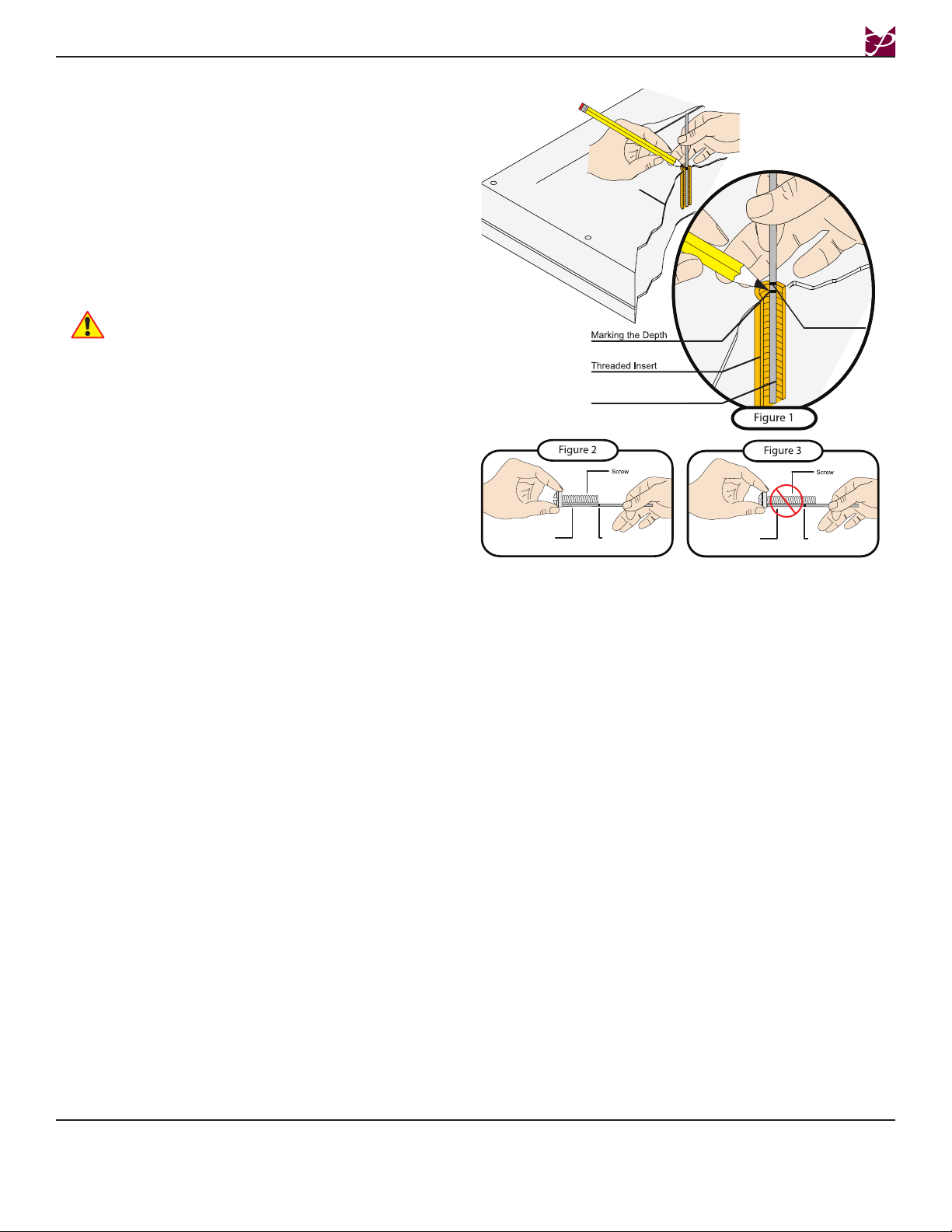

Selecting the Mounting Hardware

Insert a small straw or toothpick into the threaded

inserts found on the back of the flat panel.

® Use a pencil to mark the depth of the threaded insert

on the small straw or toothpick.

¯ Mark the straw or toothpick 1/8” above the depth of

the threaded insert, as shown in Figure 1.

° Insert the small straw or toothpick into the remaining

threaded inserts to compare and verify their depth

using the straw or toothpick’s 1/8” allowance mark.

± Locate the correct diameter screw for the threaded

insert.

If the screw you selected is longer than the 1/8”

allowance mark on the small straw or toothpick,

as shown in Figure 2 and Figure 3, do not use this

screw. The screw length must not bypass the mark.

² Test each size of the screws provided.

The correct screws should thread easily into the

mounting point and not pull out when tension is

applied.

Small Straw or Toothpick

Small Straw

or Toothpick

Small Straw

or Toothpick

Marking the 1/8”

Allowance

Depth Plus 1/8” Allowance

Mark

Depth Plus 1/8” Allowance

Mark

Page 12 Installation Instructions

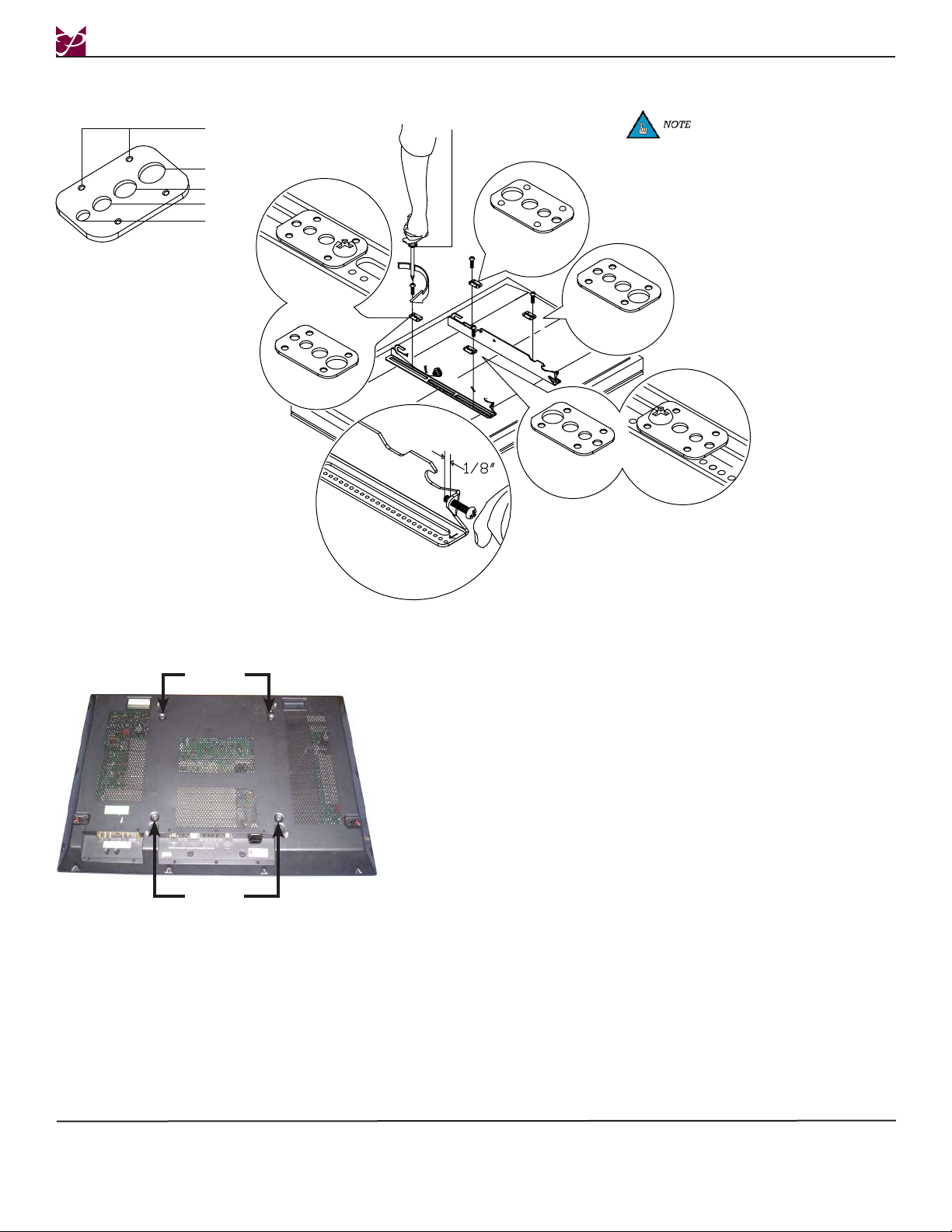

Attaching the Mounting Brackets

Step 1. Place the display on a soft, flat surface,

face-down.

Step 2. Determine where the mounting points are

located.

Step 3. Place the universal brackets over the

mounting points.

Step 4. Once the desired position has been

determined, place the mounting hardware

over each mounting point and secure them

using a screwdriver.

Mounting

Points

Mounting

Points

Phillips Head Screwdriver

DIMPLES

FACING UP

DIMPLES

FACING UP

DIMPLES

FACING DOWN

DIMPLES

FACING DOWN

Dimple

M4

M5

M6

M8

The Griplate™ have M4, M5

M6 and M8 hole patterns to

fit the hardware that your flat

panel requires.

L180F

Installation Instructions Page 13

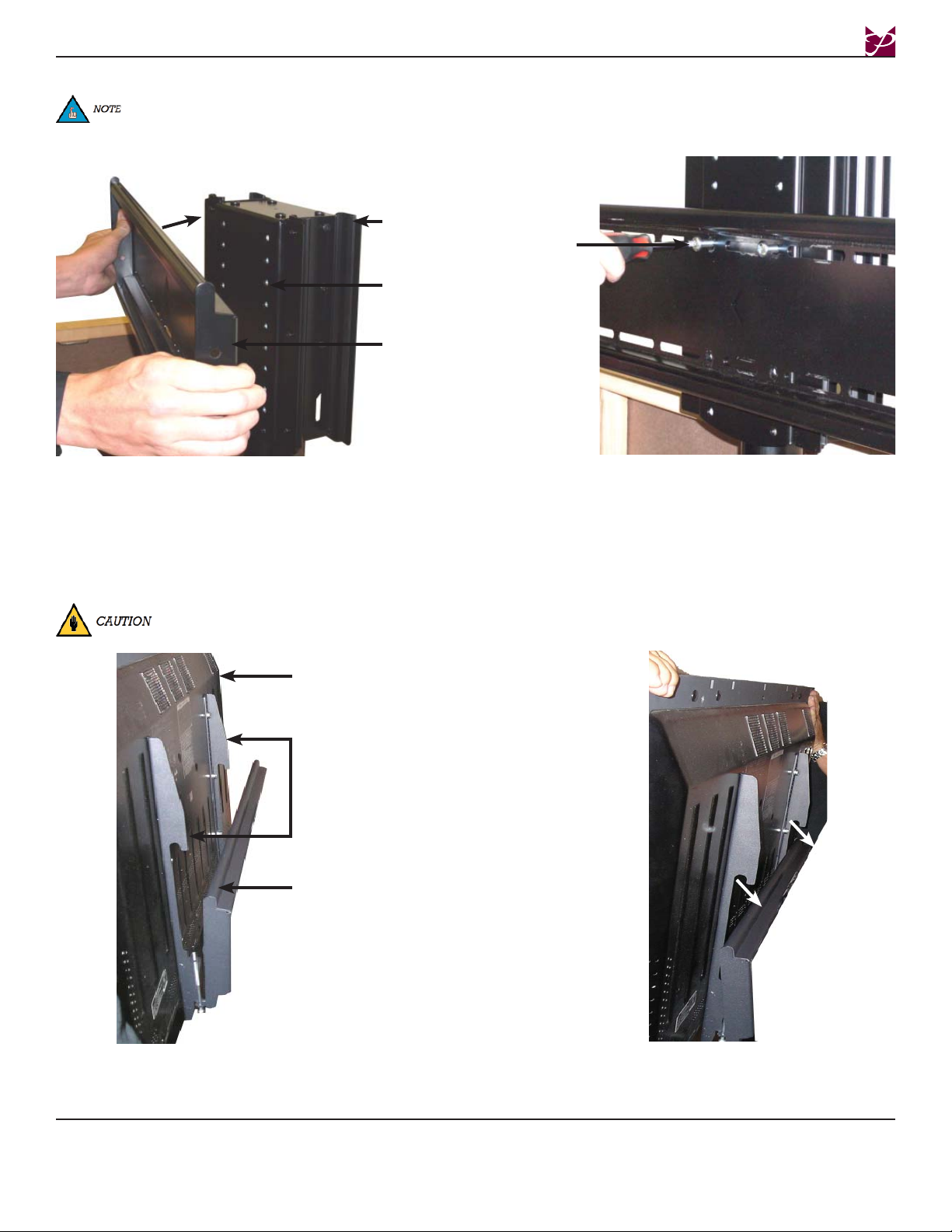

IT IS RECOMMENDED THAT TWO PEOPLE MOUNT THE DISPLAY, AS THE UNIT IS HEAVY AND, IF

DROPPED, WILL DAMAGE THE MOUNT, THE DISPLAY, AND/OR PERSONNEL.

Attaching the Display

Step 1. Place the universal brackets and the

display over the upper mounting rail of the

mounting back plate.

Display

Mounting Brackets

Mounting Rail

Step 2. Lower the universal mounting brackets

and display onto the mounting rail of the

mounting back plate.

Attaching the Mounting Plate

Step 1. Place the mounting back plate against the

display mount and line up the mounting

holes on the mounting back plate with the

mounting points on the display mount.

Step 2. Use four (4) M8 x 16 Phillips head screws

to attach the mounting back plate to the

display mount.

Step 3. Tighten the mounting hardware with a

Phillips screwdriver.

The mounting back plate comes with two vertical rows of mounting holes. These holes are all spaced evenly apart.

Determine which holes will be best for your application. These holes will help determine the overall height of your

display. Please refer to the Technical Specifications (page 17)

Display

Mount

Mounting

Points

Mounting

Back Plate

M8 x 16

Phillips

Screw

L180F

Page 14 Installation Instructions

Attaching Floating Lid Bracket

Step 1. Line up the track with the track receiver.

Step 2. Gently lower the floating lid track down

into the track receiver.

Floating

Lid

Track

Track

Receiver

Securing the Display

Once the brackets have been placed over the upper mounting rail on the mounting back plate, use a screwdriver to tighten the two bracket

security screws. This will secure the display to the mounting back plate and will also prevent any lateral shift (see NOTE:) movement.

The lateral shift adjustment allows

the user to center the display on the

mount. Once the display is attached,

slide the assembly left or right to cen-

ter the display.

Bracket Security Screw

Phillips Screwdriver

Mounting Back Plate

Display

Floating lid should be at least 1/4” above

the display.

L180F

Installation Instructions Page 15

Floating Top Installation

Step 1. Close the lift using the manual remote. Step 2. Insert the lid into the top of the cabinet.

Step 3. Raise the lift while at the same time

applying light pressure on the lid to keep it

from moving.

Step 4. Insert the #8 x 1/2” wood screws through

the lift mounting plate and into the bottom

of the cabinet top.

Use a clamp to hold the lid in place

during installation.

If the lid is installed crooked or off

alignment, the lift will not close

properly and may cause damage to the

lift and cabinet.

L180F

If using material other than wood,

secure with appropriate hardware

(commercially available).

Page 16 Installation Instructions

Troubleshooting Procedures

Symptom Check Try

The lift does not run.

Is the main connected to the control box?

Are all the plugs mounted correctly in the control box?

Is there any visible damage to the cables, controls, or

the control box?

Try to connect a lamp to the main power supply to check

that the supply voltage is functioning.

Check all connections.

Damaged parts must be exchanged (contact your vendor).

Is the lift in the fully extracted position?

Is there any load on the lift compared to when the lift

functions normally?

When the lift has reached its upper position it can only run

downwards.

Remove any load and try again.

The lift stops and can only

operate in the opposite

direction.

The lift will only run down-

ward even though the lift is not

overloaded.

Perform Basic Setting (see Owner’s Manual that came

packaged with the lift).

The lift does not run with full

stroke length upwards. It always

stops at the same position.

The system has set a new start/stop program.

Perform Basic Setting (see Owner’s Manual that came

packaged with the lift).

The lift does not run at all. No

movement is observed.

Defective handset or control box.

Poor connection.

Main cable has been disconnected.

No voltage on the main cable.

Check all connections. Check that there is voltage at the

main plug. Connect a handset that you know functions

correctly. If the lift runs, than the handset is defective. If

this does not work, than the control box is defective.

The lift is in the down position

and will not go up.

The lift is overloaded.

The cable between the lift and the control box is not

OK.

Remove some of the load from the lift.

Perform Basic Setting (see Owner’s Manual that came

packaged with the lift). If Basic Setting does not work,

exchange the cable.

L180F

Step 1. Once lift is completely installed, lower the lift to its closed position and release the down ( ) button.

Step 2. Press and hold the down ( ) button until the lift resets.

Step 3. Press the up ( ) button and monitor the lift as it moves up.

Step 4. Once the lift has reached the desired height, stop it by pressing the down ( ) button.

Step 5. Press the down ( ) button again to lower the lift.

Step 6. The programming phase is complete once the lift is in the lowered position.

Step 7. The lift should only be controlled by the remote at this point. If the buttons on the manual switch are pressed again, it will reset

the lift and the height setting will be lost. If this happens, run the previous steps again to re-program.

Programming Lift Height (Optional)

You can program the travel height of the lift using the optional remote. To do this, please refer to the following instructions.

Technical Specifications

All measurements are in inches(mm).

Installation Instructions Page 17

L180F

Page 18 Installation Instructions

Warranty

PREMIER MOUNTS

LIMITED WARRANTY

This Warranty covers the following products:

L180/L360 Series Flat Panel Motorized Safety Lift Systems

What and Who is Covered by this Limited Warranty and for How Long

Premier Mounts warrants this product to be free from defects in material and workmanship. All metal parts and

assemblies are covered for the life of the original owner. Electro-mechanical components are covered for three

(3) years from the date of purchase.

What Premier Mounts Will Do

At the sole option of Premier Mounts, we will repair or replace, free of charge, any product or component covered

by this Warranty if we determine that it is defective in materials or workmanship.

What is Not Covered; Limitations

PREMIER MOUNTS DISCLAIMS ANY LIABILITY FOR DAMAGE TO CABINETS, MOUNTS, ADAPT-

ERS, DISPLAYS, PROJECTORS OR OTHER PROPERTY, OR PERSONAL INJURY, RESULTING IN

WHOLE OR IN PART FROM IMPROPER INSTALLATION, MODIFICATION, USE OR MISUSE OF ITS

PRODUCTS.

PREMIER MOUNTS DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

PREMIER MOUNTS IS NOT RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN-

CLUDING BUT NOT LIMITED TO, INABILITY TO USE ITS PRODUCTS OR LABOR COSTS FOR RE-

MOVING AND REPLACING DEFECTIVE PRODUCTS, COMPONENTS OR PARTS. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THIS LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

How to Obtain Limited Warranty Service

If you wish to obtain warranty service please write to us at the address below. You must include proof of pur-

chase (e.g. an original sales receipt) and a description of the defect, the purchaser’s name, address, and telephone

number.

Premier Mounts

Attn: Warranty Claim

1321 S. State Collge Blvd.

Fullerton, CA 92831

General inquiries can be addressed to Premier Mounts Customer Service at 1-800-368-9700.

State Law

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE.

L180F

NOTWITHSTANDING ANYTHING TO THE CONTRARY IN THIS WAR-

RANTY, THIS WARRANTY IS LIMITED TO FIVE YEARS FROM THE DATE

OF PURCHASE IN THE EVENT THAT THE WARRANTED PRODUCT IS

COMMERCIALLY RENTED OUT.

Electrical products and components, such as amplifiers, speakers, motors, switches

remote controls and related electrical items, are backed by a 3-year warranty.

Table of contents