Stora Enso CLT Instruction Manual

Version: 2021.06.02 Pages: 16

CLT Lifting Guideline

Lifting devices for

Cross Laminated Timber

2 (16) CLT Lifting Guideline

Publishing info

Stora Enso

Division Wood Products

www.storaenso.com/woodproducts

Building Solutions

Product Development

wilhelm.polster@storaenso.com

Subject to typographical and printing errors.

This document is valid until further notice and invalidates all previous lifting device guidelines.

Content

Introduction .................................................................................................................................................. 3

Overview lifting devices................................................................................................................................ 5

Lifting sling – one hole.................................................................................................................................. 6

Lifting sling – two holes ................................................................................................................................ 7

Lifting sling – with blind-hole and dowel........................................................................................................ 8

Lifting screw with anchor............................................................................................................................ 10

Floor .................................................................................................................................................... 10

Wall...................................................................................................................................................... 11

RAMPA insert with lifting loop..................................................................................................................... 12

RAMPA lifting gear..................................................................................................................................... 13

Sihga Pick.................................................................................................................................................. 14

Floor .................................................................................................................................................... 14

Wall (on request).................................................................................................................................. 14

Power Clamp.............................................................................................................................................. 15

Floor .................................................................................................................................................... 15

Wall (on request).................................................................................................................................. 15

Appendix.................................................................................................................................................... 16

3 (16) CLT Lifting Guideline

Introduction

“Safety first” is one of Stora Enso’s most important principles and we constantly try to improve safety within our company and where it concerns

our collaboration with suppliers and customers. This document is a general guideline and it only can point out the core items needed for planning

of lifting devices delivered by Stora Enso. Therefore, it is necessary that users of lifting devices also know and apply original instructions for use

(manuals, technical data sheets). This also includes a preceding validation of applicability by the customer, according to national and own safety

standards.

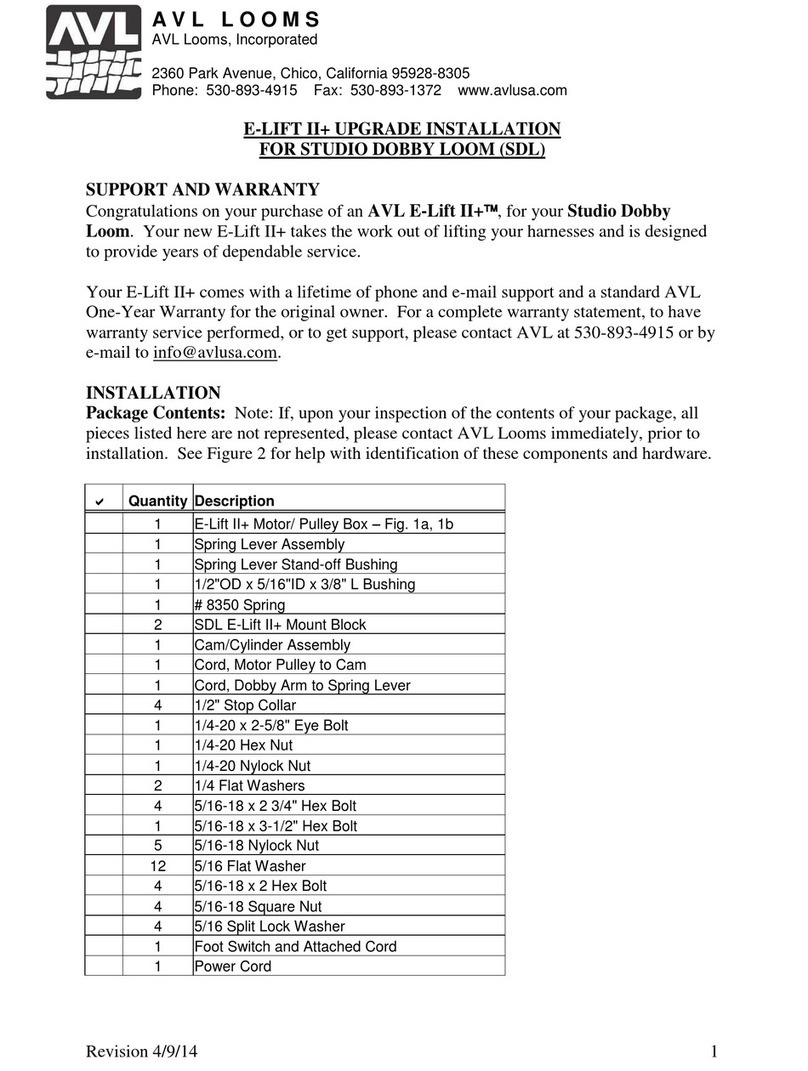

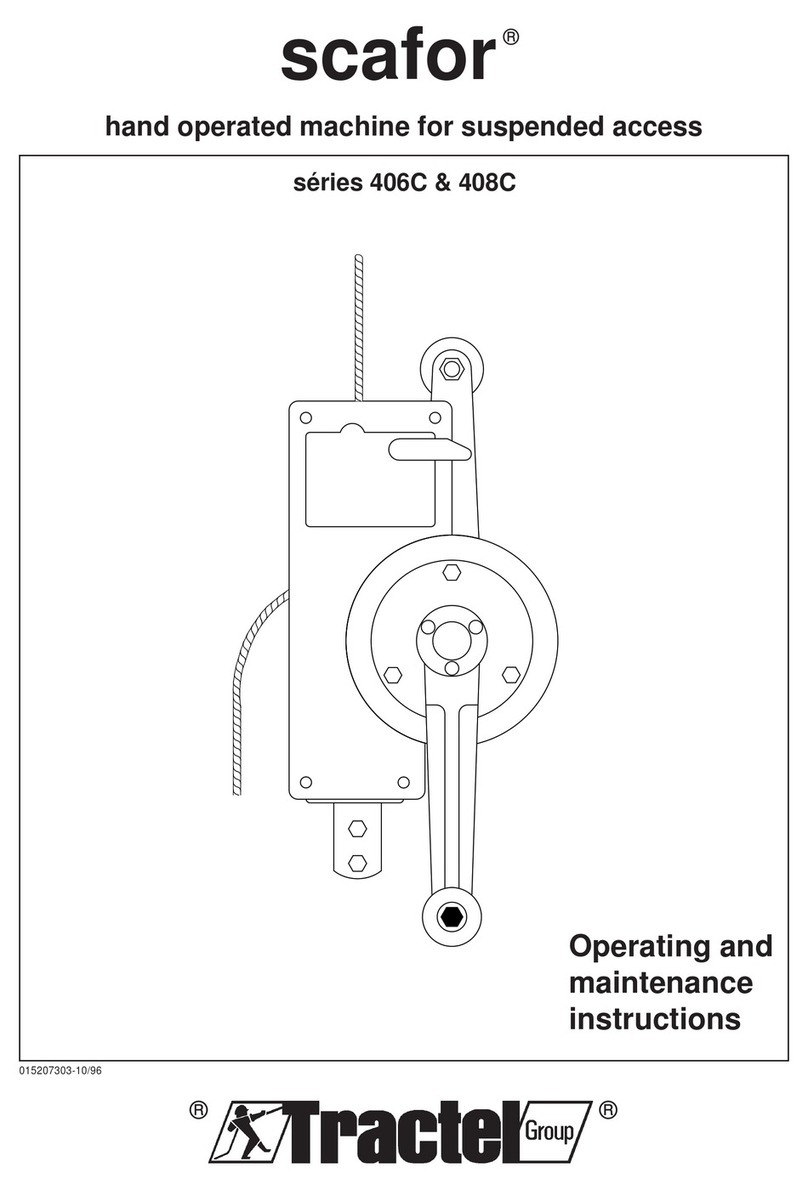

The lifting angle (β) has a significant influence on the load-bearing

capacity of each lifting system:

F

v

L

oad

>

vertical

share

F

d

Load

>

diagonal share

(chain/

anchor/sling

)

F

h

Lo

ad

>

horizontal

share

An increase of the lifting angle decreases the load-bearing capacity

(F

v

) of a lifting system, as you can see in the force diagram below:

If Stora Enso has to plan number and position of lifting points,

we have to assume that the lifting angle is not higher than 30°.

Required exceptions have to be verified and formally agreed:

•Higher lifting angles increase the risk and load-bearing capacity of

lifting devices is reduced. In any case lifting angles higher than

45° are not supported by Stora Enso.

•There is a simple rough-and-ready rule to secure that 30° in

practice is not exceeded: Chain length has to be equal or ideally

longer than the maximal distance between lifting points (D).

•The lifting points have to be aligned symmetrically regarding

center of gravity and lifting direction. Deviations are allowed if load

per lifting point is not increased more than 10 %.

If Stora Enso has to plan number and position of lifting points,

we have to assume a symmetric system and that all lifting points

are loaded equally. Required exceptions have to be verified and

agreements have to be formally confirmed.

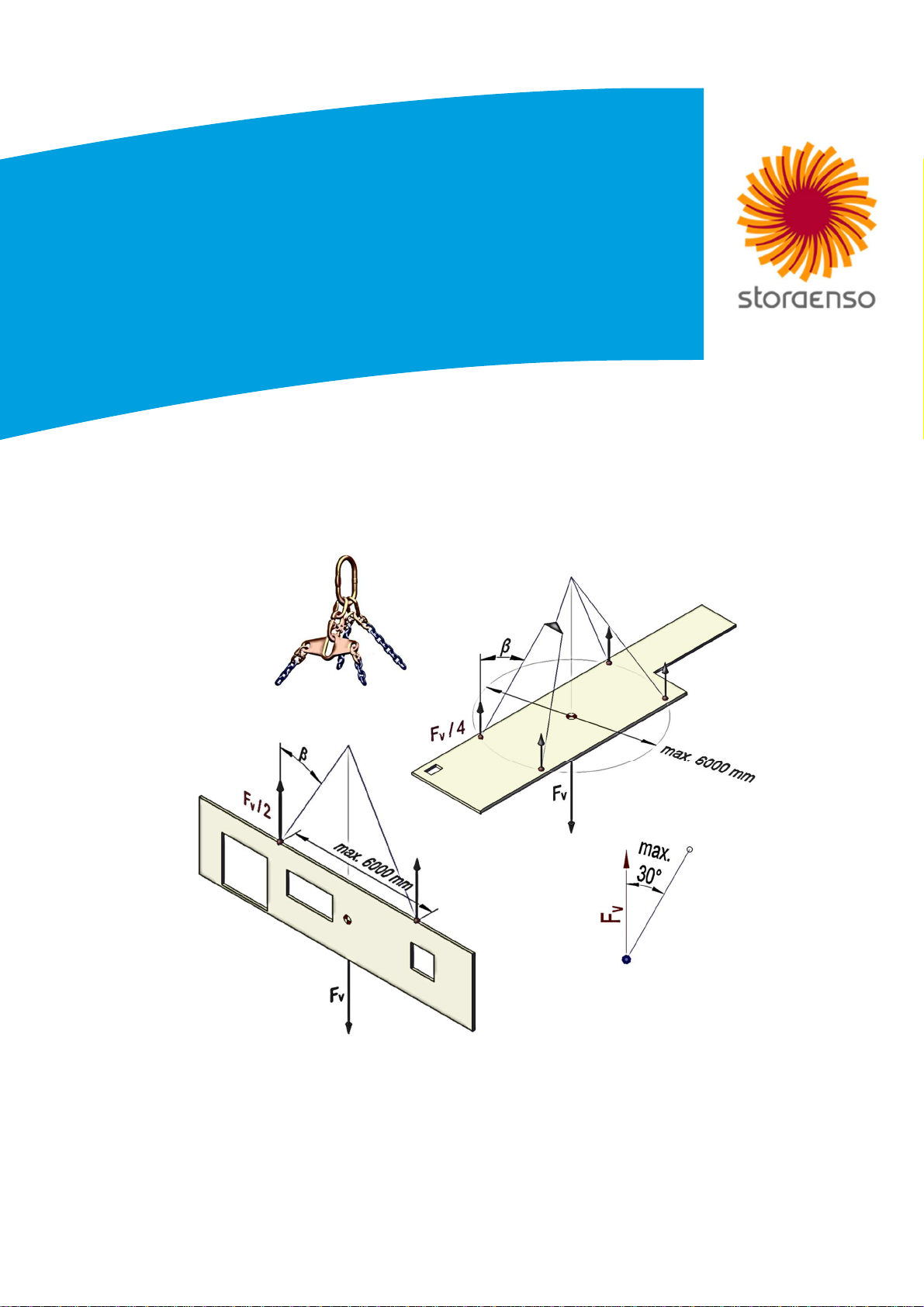

Load distribution

If no load distribution gear is used, load-bearing capacity has to be

reduced at least by 25 %.

Symmetry

If lifting points regarding …

•chain lengths

•lifting angles

•center of gravity

…cannot be lifted symmetrically, then the load-bearing capacity has

to be verified by an expert and on demand to be reduced up to 50 %.

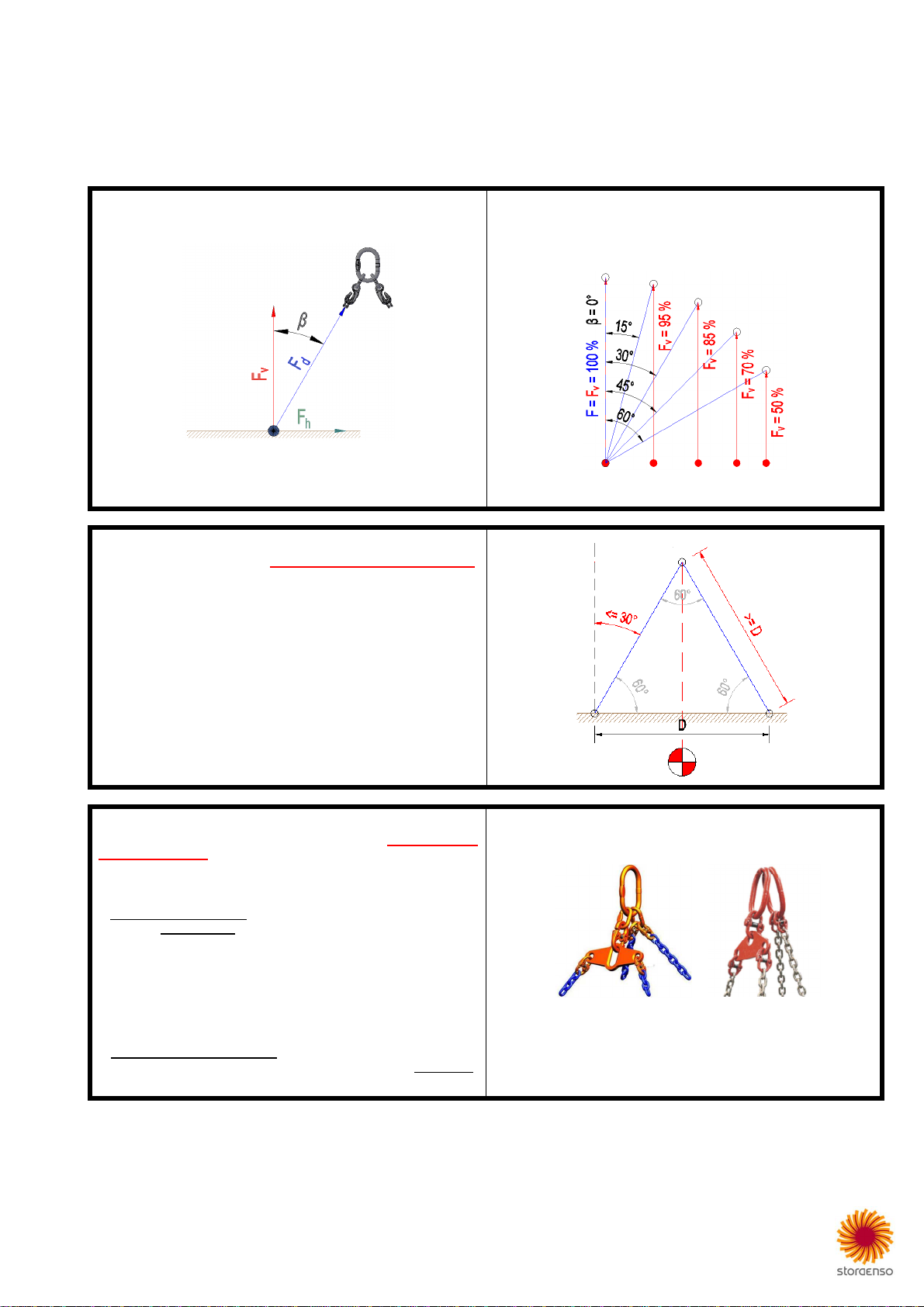

Examples: “balancing rocker”. It is an affordable and

very effective load distribution

gear

for

floor panels

.

4 (16) CLT Lifting Guideline

4-leg gear with a load distributor:

(examples)

Each lifting point is loaded equally with 1/4 of the total load if

center of gravity and lifting points are lifted symmetrically.

In other cases, load-bearing capacity has to be reduced at

least

by

25

%.

4-leg gear without a load distributor:

(example)

* Despite symmetrical alignment the total load is not

distributed equally to all 4 lifting points. Therefore load-

bearing capacity has to be reduced at least by 25 %.

This can be reasoned because not always each chain has

exactly the same length and because there are also always

small distance

respectively

symmetry deviations.

3-leg gear:

There are two conditions to distribute the total load equally to all

3 lifting points:

•All lifting points must have the same distance from center of

gravity.

•The angle between lifting points must be always 120°.

The lifting points are aligned within a relatively small area.

Having long panels this will cause higher deflection during

lifting. Therefore, three lifting points are only useful for quadratic

or small panels.

Wall panels are delivered in most cases horizontally. To upright such panels it has to be checked whether the load-bearing capacity of the

selected

lifting device works in both directions.

5 (16) CLT Lifting Guideline

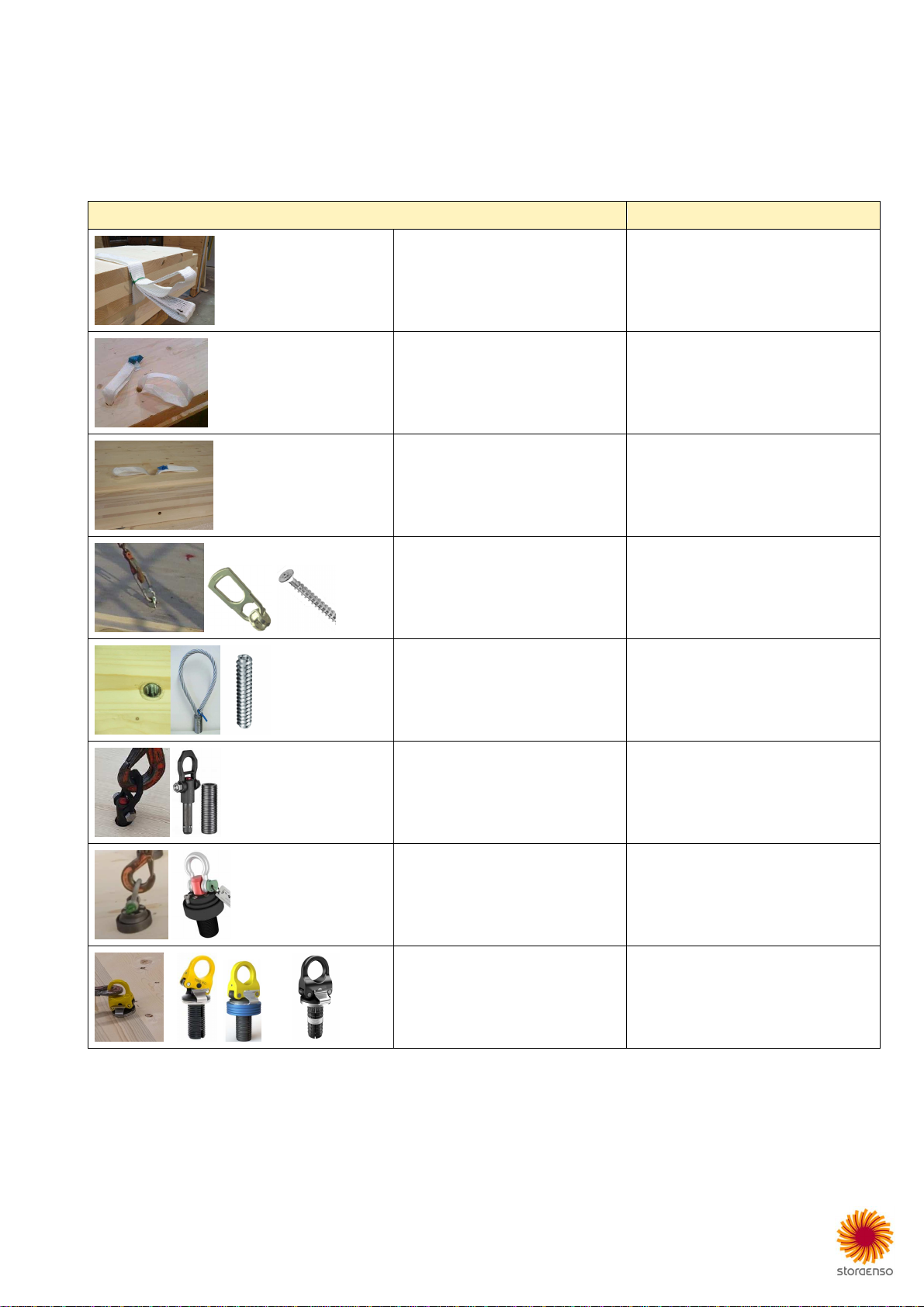

Overview lifting devices

The lifting of CLT panels is a very important and responsible topic to be considered in the early planning phase. There are different lifting devices

supported by Stora Enso, but not all can be used because of different national and/or own safety standards. It is the responsibility of the customer

to verify the lifting devices that are permitted for their projects.

Panel thickness, surface quality, building part type, mode of loading and most of all the load-bearing capacity (WLL = Working Load Limit) are

also important criteria that influence the choice of the proper lifting device.

Lifting

Device

B

uilding

P

art

T

ype

Lifting sling - one hole Wall: installed

Lifting sling - two holes Floor: installed

Lifting sling with blind-hole and dowel Floor: installed

Lifting screw with anchor Floor: not installed; blind-hole on demand

Wall: not installed; blind-hole on request

RAMPA insert and lifting loop Floor: installed

RAMPA Lifting:

•ball-lock pin

•insert type-X

Floor: installed

Sihga Pick – blind-hole Floor

Wall: on request

Power Clamp – blind-hole Floor

Wall: on request

6 (16) CLT Lifting Guideline

Lifting sling – one hole

Wall

EC

–

declaration of conformit

y:

P

lease see

Appendix.

This lifting device is based on a webbing sling made of 100 % Polyester (PES). Standard length is 1 meter, width is 50 mm and thickness is

about 3 mm. On request special lengths like 2 or 4 meters are available.

The sling is installed in a hole with D35 mm and it is for single-use only. “Single-use” means maximal 6 lifting cycles with the same panel. It is

not allowed to remove slings to use them for other panels.

All slings must always be checked for damages before each lifting cycle.

The standard lifting method must be “Basket”. The sling is pre-mounted and delivered this way by Stora Enso and it is not allowed to

choke afterwards. On demand exceptions are possible. But this must be clarified with Stora Enso and finally formally confirmed.

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

≤30°

Lifting

Method

F

v

(kg)

“Basket”

(standard) 1000 (1400) *

“Choked”

(on request) 400 (560) *

*

As an exception

to be formally confirmed,

values in brackets can be

used.

The drilling diameter is 35 mm. Depending on the load, the sling can cause localised crushing of the timber around the hole. The lifting hole can

be plugged when lifting is complete, using D35x10 mm timber plugs, or D35x1000 mm wooden poles that can be delivered:

7 (16) CLT Lifting Guideline

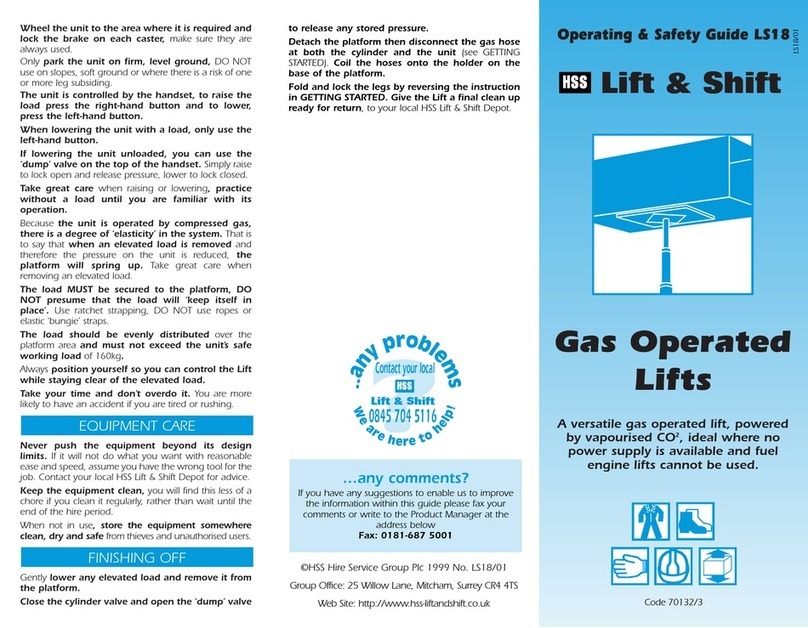

Lifting sling – two holes

Floor

EC

–

declaration of conformity

:

P

lease se

e Appendix.

This system is based on a webbing sling made of 100 % Polyester (PES). Standard length is 1 meter, width is 50 mm and thickness is about 3

mm. On demand special lengths like 2 or 4 meters are available.

The sling is installed in two holes with D35 mm and it is for single-use only. “Single-use” means maximal 6 lifting cycles with the same panel, but

you are not allowed to remove slings to use them for other panels.

All slings must always be checked for damages before each lift.

The standard lifting method must be “Basket”. The sling is pre-mounted and delivered this way by Stora Enso and it is not allowed to

choke afterwards. On demand exceptions are possible. But this must be clarified with Stora Enso and finally formally confirmed.

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for

hoisting velocity up to 36 m/min = 0.6 m/s.

≤30°

Lifting Method

with load distributor *

F

v

(kg)

“Basket”

(standard) 1400

“Choked”

(on request) 560

*

Without

load distributor

(

or something

equivalent

)

indicated loads have to be

reduced

at least

by

25 %.

The drilling diameter is 35 mm. Depending on the load, slings can cause localized crushing of the timber:

8 (16) CLT Lifting Guideline

Lifting sling – with blind-hole and dowel

Floor

EC

–

declaration of conformity

Please see

Appendix.

Expert Opinion No. GU20-403-3-01 Graz University of Technology

Lignum Test Center (LTC)

The webbing sling is made of 100 % Polyester (PES). Standard length is 1 meter, width is 50 mm and thickness is about 3 mm. On demand

special lengths like 2 or 4 meters are available.

The sling is installed in a blind-hole with D68 mm and it is for single-use only. “Single-use” means maximal 6 lifting cycles with the same panel,

but you are not allowed to remove slings to use for other panels.

The sling is fixed by a steel dowel and is stuffed into the blind-hole for easy stacking and transport.

All slings must always be checked for damages before each lift.

The standard lifting method must be “Basket”. The sling is pre-mounted and delivered this way by Stora Enso and it is not allowed to

choke afterwards. On demand exceptions are possible. But this must be clarified with Stora Enso and finally formally confirmed.

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

≤30°

Lifting Method

with load distributor *

“Basket”

(standard)

CLT (mm) F

v

(kg)

80 - 90 500

100 - 150

1000

> 150 1250

“Choked”

(on request) max. 560

“Inline”

(on request) max. 700

* Without

load distributor

(

or something

equivalent

)

indicated loads

have

to be reduced

at least

by

25 %.

9 (16) CLT Lifting Guideline

Below parameters for drillings and load-bearing capacities of our standard CLT panels styles. If a panel style is not listed, then parameters for

blind-hole and steel dowel must be done according to the following basic two rules:

•t1 … The blind-hole should be as deep as possible but can be maximal 160 mm.

•t2 … The steel dowel has to be 20 mm less deep than t1 and dowel axis should be aligned perpendicular under the layer above.

Steel dowel (d):

•diameter: 16 mm

•length: 300 mm

•depth (t2): see table below

•steel grade: S235

Blind-hole (D):

•diameter 68 mm

•depth (t1): see table below; max. 160 mm

Edge distance (y):

•min = 200 mm

•max = 340 mm

Webbing PES sling: 50x1000 mm; blue label

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

Product

Thickness

Structure

Blind-hole

t1

Steel dowel

t2

with load

distributor *

F

v

(kg)

CLT

60

L3s

not

possible

CLT

80

L3s

70

50

500

CLT

90

L3s

80

60

500

CLT

100

L3s

90

70

1000

CLT

120

L3s

110

90

1000

CLT

100

L5s

90

70

1000

CLT

120

L5s

100

80

1000

CLT

140

L5s

110

90

1000

CLT

160

L5s

130

110

1250

CLT

180

L5s

140

120

1250

CLT

200

L5s

-

2

150

130

1250

CLT

160

L5s

-

2

140

120

1250

CLT

180

L7s

160

140

1250

CLT

200

L5s

160

140

1250

CLT

240

L7s

160

140

1250

CLT

220

L7s

-

2

160

140

1250

CLT

240

L7s

-

2

160

140

1250

CLT

260

L7s

-

2

160

140

1250

CLT

280

L7s

-

2

150

130

1250

CLT

300

L8s

-

2

160

140

1250

CLT

320

L8s

-

2

160

140

1250

*

With

out

load distributor

(

or something

equivalent

)

indicated loads have to be reduced

at least

by

25 %.

10 (16) CLT Lifting Guideline

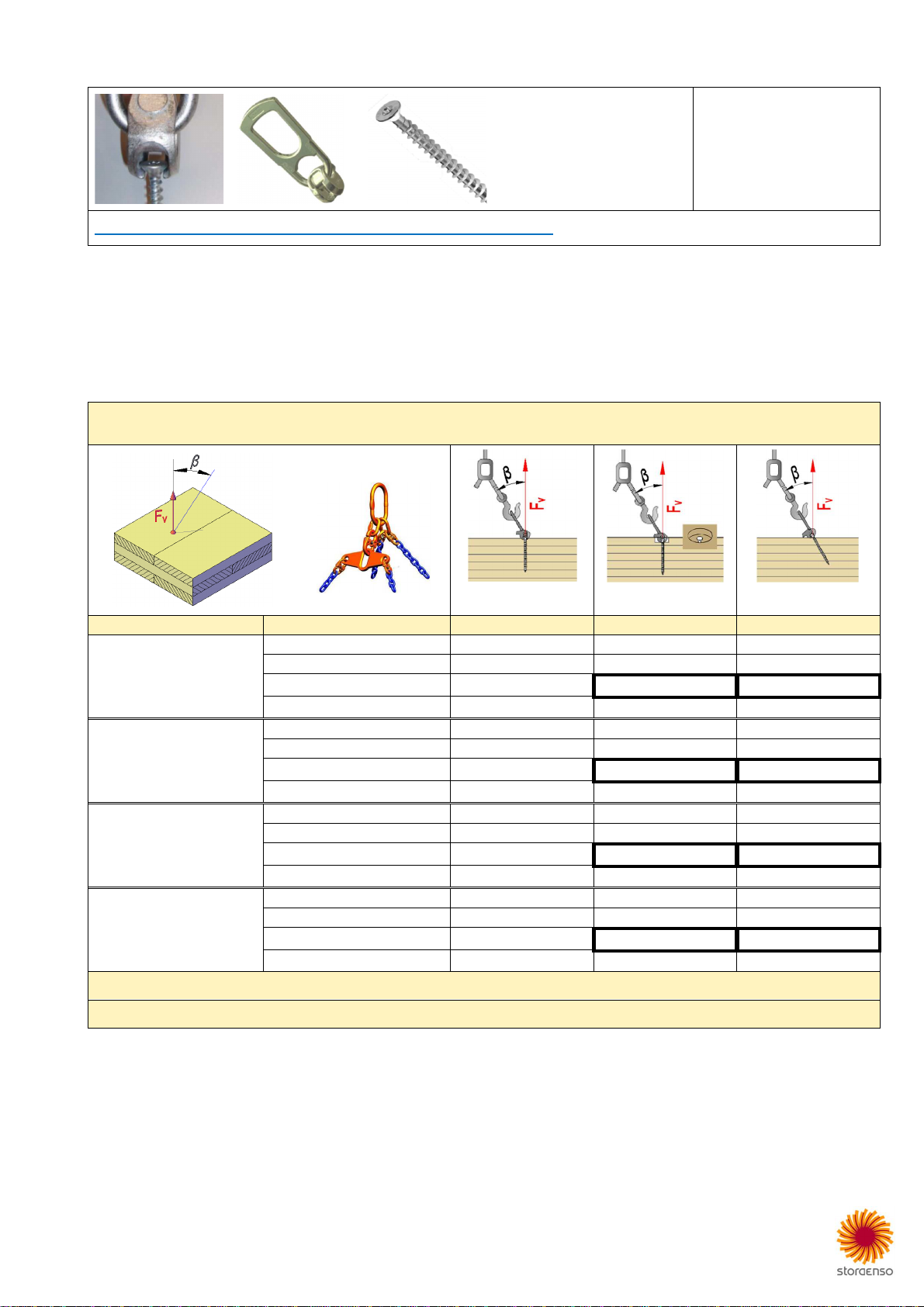

Lifting screw with anchor

Floor

Wall

https://www.rothoblaas.com/products/machines-and-tools/transport-and-lifting/wasp

Use must be done according to the original instructions for use (technical data sheets). To always get the latest documents, we ask you to visit

the homepage of supplier and/or contact their technical support. Please inform Stora Enso if here indicated links do not work correctly or if there

is a relevant discrepancy with summarized info below.

This lifting system is not installed by Stora Enso. On demand we can deliver required material (anchors and screws).

Floor

On demand lifting device location mark drillings D10x10 mm (small drill hole) or blind-holes D55x30 mm (large drill hole) can be done to allow

accurate positioning of lifting screws on site:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for

hoisting velocity up to 36 m/min = 0.6 m/s.

with load distributor *

perpendicular **

perpendicular

with

blind

-

hole

inclined

Screw

…

β

(

°

)

F

v

(kg)

***

F

v

(kg)

F

v

(kg)

VGS Ø11

100

0

430

430

430

15

350

430

410

30

240

430

370

45

150

430

300

VGS Ø11

150

0

710

710

710

15

570

710

690

30

380

710

620

45

240

450

500

VGS Ø11

200

0

1000

1000

100

0

15

760

980

970

30

470

780

870

45

290

450

710

VGS Ø11

250

0

10

10

1010

1010

15

860

980

980

30

500

780

880

45

300

450

720

* Without

load distributor

(

or something

equivalent

)

indicated loads have to be reduced

at least

by

25 %.

**

Not recommended.

11 (16) CLT Lifting Guideline

Wall

On request lifting device location marks D10x10 mm (small drill hole) or blind-holes D55x30 mm (large drill hole) can be done to allow accurate

positioning of lifting screws on site:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

perpendicular *

perpendicular

with blind-hole

inclined

Screw

…

β

(

°

)

F

v

(kg)

F

v

(kg)

F

v

(kg)

VGS Ø11

200

0

630

630

630

15

420

630

610

30

240

630

550

45

150

450

440

VGS Ø11

250

0

790

790

790

15

530

790

770

30

300

780

690

45

180

450

560

s Please note that screws may not be inserted parallel to grain direction.

T

hickness of concerned layer

can be 20, 30 or 40 mm.

*

Not recommended.

12 (16) CLT Lifting Guideline

RAMPA insert with lifting loop

Floor

https://www.rampa.com/service/wp

-

content/uploads/2021/03/RAMPA_Lasttabelle_BL

-

SKL

-

D25M16

-

2021.pdf

Use must be done according to the original instructions for use (technical data sheets). To always get the latest documents, we ask you to visit

the homepage of supplier and/or contact their technical support. Please inform Stora Enso if here indicated links do not work correctly or if there

is a relevant discrepancy with summarized info below.

The insert is installed and on demand required lifting loops can be delivered.

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only

valid for hoisting velocity up to 36 m/min = 0.6 m/s.

with load distributor *

Minimal panel thickness: 60 mm

Blind-hole: D22x45/65/85/105 mm

RAMPA-Insert Type …

F

v

(

β)

kg (0°) ** kg (30°)

BL

D25 x 40 mm

330

290

BL/SKL

D25 x

60 mm

475

410

BL/SKL

D25 x

80 mm

640

550

BL/SKL

D25 x

100 mm

810

700

* Without

load distributor (or something equivalent)

indicated loads have to be reduced

at least

by

25 %.

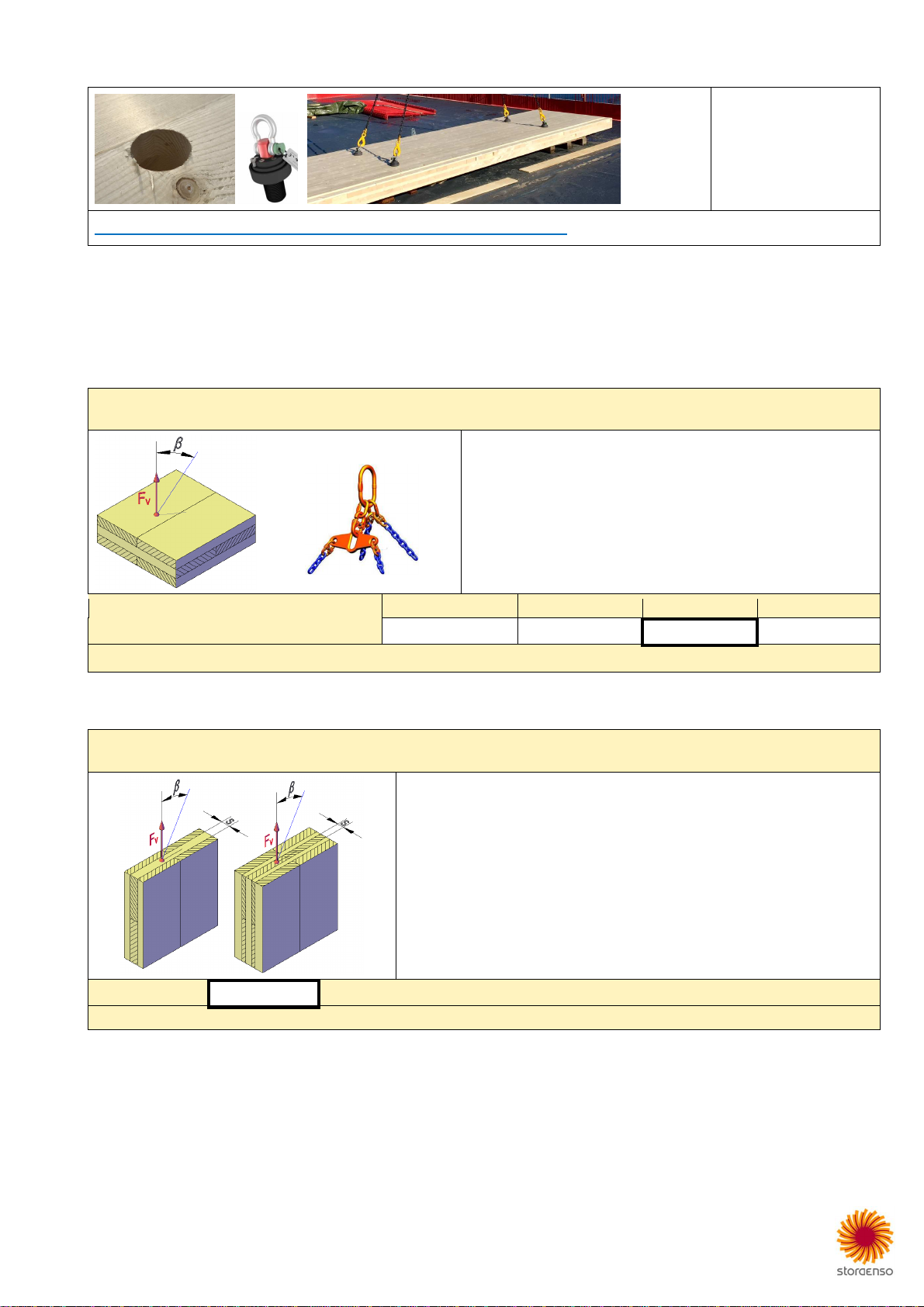

13 (16) CLT Lifting Guideline

RAMPA lifting gear

Floor

https://www.rampa.com/service/en/products/wood-applications/lifting_gear/

Use must be done according to the original instructions for use (technical data sheets). To always get the latest documents, we ask you to visit

the homepage of supplier and/or contact their technical support. Please inform Stora Enso if here indicated links do work correctly or if there is a

relevant discrepancy with summarized info below.

Regarding insert type-X is installed and on demand ball-lock anchor (load suspension type-X) can be delivered.

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

with load distributor *

Minimal panel thickness: 80 mm

Blind-hole: D34x75 mm

RAMPA-Insert: Type-X D36x73 mm

β

0°

30°

45°

60°

**

F

v

(kg)

900

770

620

440

* Without

load distributor (or something equivalent)

indicated loads have to be reduced

at least

by

2

5 %.

**

Not recommended

.

14 (16) CLT Lifting Guideline

Sihga Pick

Floor

Wall (on request)

https://www.sihga.com/ecommerce/product?category_id=153948&product_id=546961

Use must be done according to the original instructions for use (technical data sheets). To always get the latest documents, we ask you to visit

the homepage of supplier and/or contact their technical support. Please inform Stora Enso if here indicated links do not work correctly or if there

is a relevant discrepancy with summarized info below.

Stora Enso does not sell this product but we can produce the required drillings under the following conditions:

Floor

Number and position of lifting points can be planned by Stora Enso:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

with load distributor *

Minimal panel thickness: 80 mm

Blind-hole:

•D50x75 mm

•Tolerance diameter: -0.0 / +1.0 mm.

•Edge distance: 250 mm

β

(mini

mal

= 5°)

5°

15°

30°

45°

F

v

(kg)

**

1100

1000

900

800

* Without

load distributor (or something equivalent)

indicated loads have to be reduced

at least

by

25 %.

Wall (on request)

On request number and position of lifting points can be planned by Stora Enso:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

Minimal panel thickness: 90 mm

Minimal edge distance: 20 mm

Blind-hole:

•D50x75 mm

•Tolerance diameter: -0.0 / +1.0 mm

Please consider that the blind-hole may not be positioned parallel to grain direction

within a zone where the end grain share is more than 40 mm.

F

v

(kg)

*

260

More d

etails according to original instructions for use (technical data sheet).

* Indicated load

s

are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

15 (16) CLT Lifting Guideline

Power Clamp

Floor

Wall (on request)

PowerClamp III D40x90(70*) https://www.pitzl-connectors.com/en/products/product-list/55890.1000

* 70 mm

:

with

spacer ring (blue)

PowerClamp II D40x90 https://www.pitzl-connectors.com/en/products/product-list/55860.1000

N

o longer available

, but still in use. Replaced by Power

Clamp III

D

40

x

90

.

Use must be done according to the original instructions for use (technical data sheets). To always get the latest documents, we ask you to visit

the homepage of supplier and/or contact their technical support. Please inform Stora Enso if indicated links do not work correctly or if there is a

relevant discrepancy with basic info below.

Stora Enso does not sell this product but we can produce the required drillings under the following conditions:

Floor

Number and position of lifting points can be planned by Stora Enso:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

with load distributor *

Minimal panel thickness:

•100 mm – Standard

•80 mm – with spacer ring

Blind-hole:

•D40x95 mm – standard

•D40x75 mm – with spacer ring

•Tolerance diameter: -0.0 / +1.0 mm

•Edge distance: 200 mm

PowerClamp …

F

v

(

β)

kg

(

0°

-

45°)

***

kg

(

45°

-

60°

)

**

III D40/90

1050

750

II D40/90

700

525

* Without

load distributor (or something similar)

indicated loads have to be reduced

at least

by

25 %.

**

Not recommended by Stora

E

nso.

Wall (on request)

On request number and position of lifting points can be planned by Stora Enso:

The lifting angle (β) is assumed to be maximal 30°.

Indicated loads are only valid for hoisting velocity up to 36 m/min = 0.6 m/s.

Panel thickness:

•minimal: 80 mm

•edge distance: 20 mm

Use of spacer ring is not allowed for walls.

Blind-hole:

•D40x95 mm

•Tolerance diameter: -0.0 / +1.0 mm

F

v

(kg)

PowerClamp III D40/90

PowerClamp II D40/90

525

350

More d

etails according to original instructions for use (technical data

sheet).

16 (16) CLT Lifting Guideline

Appendix

Table of contents

Popular Lifting System manuals by other brands

Tractel Group

Tractel Group scafor 408C Series Operating and maintenance instructions

HSS Hire

HSS Hire 70132/3 Operating & safety guide

morse

morse 520-114 Operator's manual

EZ-ACCESS

EZ-ACCESS PATHWAY Classic Series Instructions for use

Ravaglioli

Ravaglioli S1140A4 Translation of the original instructions

WITTUR

WITTUR WSG09 Operating and maintenance manual

Kelley

Kelley HK-S user manual

Haklift

Haklift VAK6 Translation of the original instructions

iCONNECT

iCONNECT TVL-RH installation instructions

Bravi Platforms

Bravi Platforms SPRINT LUI MINI T.L. Use and safety

Rotary

Rotary SM122-100 Series owner's manual

Harmar Mobility

Harmar Mobility AL100-DE owner's manual