TRANZSPORTER LH4000 User manual

Red: 0-100-100-0 Blue: PMS 293

100-56-0-0

Color Logo use on white background only

Black Logo use on white background only

White Logo use on black background only

Instructions #08103

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

063010,E967

Owners Manual

LH4000

Lift Hoist 4000

Platform Hoist

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

1

Congratulations on your Purchase of the

TranzSporter Lift Hoist.

LH4000 - Series Specifications:

400 lb. MAXIMUM Hoisting Capacity

Power unit - (4 hp. Briggs & Stratton, 4 hp. Honda or High Torque Electric Motor)

Self-energizing brake, 4 ft. aluminum base section, 4, 8, and 16 ft. track sections.

The TranzSporter Lift Hoist - Series was designed to last.

Features include...

• Unitized Design - Fewer parts, stronger, less maintenance

• Non-Slip Carriage Deck - Safer operation

• Heavy Duty Aluminum Frame - Absorbs more punishment

• Spring Loaded Safety Latch - Keeps deck in place when transporting or when operator is away from

the hoist.

• Dual Brake System - Better control, longer brake life

• Hi-Impact Nylon Belt Guard - Safer operation

• Oven baked, Black Powder Coat Finish - Durable, long lasting

• Wide Foot Plate - Better control of lift operation

• Permanent Safety Information - Combination of stamped-in safety information and decal’s remind

your operator to use hoist in a safe manner

• Large Aluminum Foot Pads - Adds more stability, lasts longer

• Extended Brake Handle - Keeps operator away from hoist when raising or lowering materials

User Responsibilities

PERFORM THE FOLLOWING AT THE START AND END OF THE WORK DAY AND AFTER

4 HOURS OF OPERATION DURING THE DAY:

• Check oil level in engine and ll according to manufacturer’s specications.

• Check cable for smooth operation and for signs of wear.

• Check for loose bolts and tighten according to specications.

• Check track sections and all other moving parts for excessive wear or fatigue.

• Check general condition of equipment.

• Check operator’s understanding of the proper operation for this equipment.

• Check extension cords and connections for wear or damage.

• Check brake parts regularly for wear or damage.

• Check Cable Drum Bearings - they should run smoothly when brake is released. If there is any noise or if

the cable drum does not spin freely, replace immediately.

WARNING: DO NOT OPERATE THIS EQUIPMENT IF ANY UNSAFE CONDITIONS EXIST OR OCCUR

DURING OPERATION.

Remember: Safety First!!

NOTE: Platform speeds and capacities are average and are based on 7/16 inch cable. Lifting speed and

capacities decrease as cable builds up on drum assembly during lifting.

(404) 344-0000 • Fax (404) 349-0401 • www.tranzsporter.com 2

Safety instructions

CAUTION: Please read the safety warnings and Instructions contained in this manual before

operating the lift hoist. Failure to obey the warnings contained herein could result in personal

injury or damage to the equipment; however, this information should not be a substitute for routine

accident prevention, but rather an addition to routine accident prevention.

GENERAL SAFETY INSTRUCTIONS:

1. Transport and handle your lift hoist with care.

2. Unpack the TranzSporter carefully and inspect for any damage that may occur during transportation.

DO NOT USE THE HOIST IF ANY PART IS DAMAGED

3. Please observe all safety and warning labels attached to the hoist.

4. Use only replacement parts furnished by the manufacturer.

5. Always keep the area around the base section of the TranzSporter hoist clear to help prevent

slipping, tripping or falling against the hoist.

6. DO NOT ALLOW ANYONE TO OPERATE THE TRANZSPORTER HOIST WHO HAS NOT BEEN THOROUGHLY

AND PROPERLY TRAINED IN THE CORRECT OPERATION AND USE OF THIS HOIST.

7. This hoist is manufactured to lift materials only. Do not use the lift hoist for the purpose of

transporting personnel from one level to another.

8. Do not climb the lift hoist or use as a personnel ladder.

9. Do not overload - maximum lifting capacity for the LH4000 is 400 lbs. with a load capacity of 380 lbs.

10. Keep hands, feet and other body parts as well as clothing away from the track sections and moving or

rotating parts of the lift hoist when starting the engine or when operating the hoist.

11. Do not allow any persons to walk or work under or near the hoist while in operation.

12. Do not use this hoist to transport hot asphalt or any other hot molten substance from one

elevation to another.

13. Store all parts of the hoist in such a fashion as not to damage any of the components.

14. Do not operate indoors or in an area with poor ventilation.

Warning labels are attached to the LH4000

and are weather resistant. If you notice any

of these decal’s missing from your hoist,

please contact TIE DOWN ENGINEERING for a

replacement label.

Remember: Safety First!!

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

Assembly Instructions LH4000 Hoist

Congratulations on purchasing the TranzSporter LH4000 Hoist. The two boxes contain the ve assembled

parts plus the owner’s manual, making up the LH4000. Please read the following instructions completely before

starting assembly. Refer to the owner’s manual for further information on use and maintenance of the LH200.

Parts found in the two boxes are:

Track section base Carriage assembly

End cap Motor base

Brake handle Owner’s manual

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

3

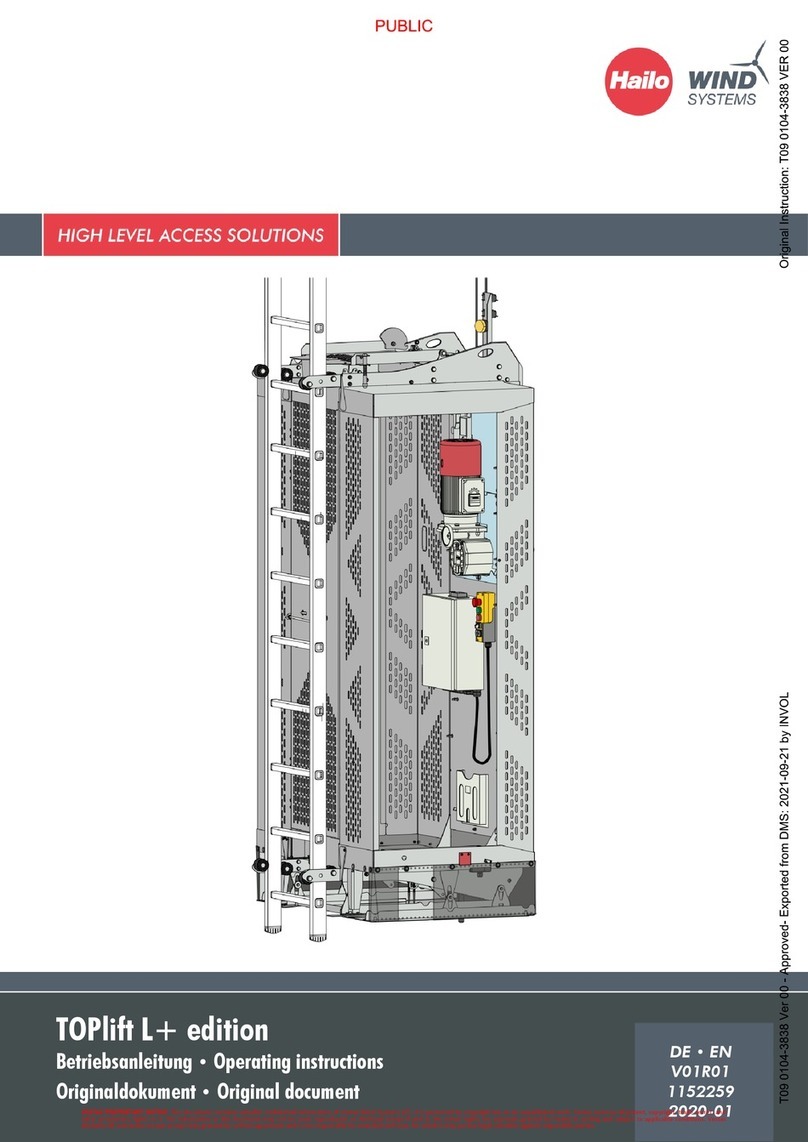

1. Remove all hoist parts from the two boxes and

place on a clean oor or assembly area. Lay one track

section on a flat floor with the “front” side up. This is

determined by the space between the track cross bar

and the track section edge as shown above.

3. Attach slice plates to the bottom section of the

track. Splice plates are mounted on the inside

track section. Slide the top section track into the

groves on the inside track section, attach with 2 nuts

and bolts per side. Pictures 4 & 5

2. Remove the end cap with a 7/16” wrench. Starting

at the top of the track section slide carriage assembly

onto track section so that the four rollers connect to

the top rail of the track section as shown in picture

2. “Roll” carriage assembly to the base. At this time

lock the base in place using the safety latch as shown

in picture 3.

Picture 1

Front

Back

Picture 2

Picture 3

Picture 4

Picture 5

Inside Track

Inside Track

(404) 344-0000 • Fax (404) 349-0401 • www.tranzsporter.com 4

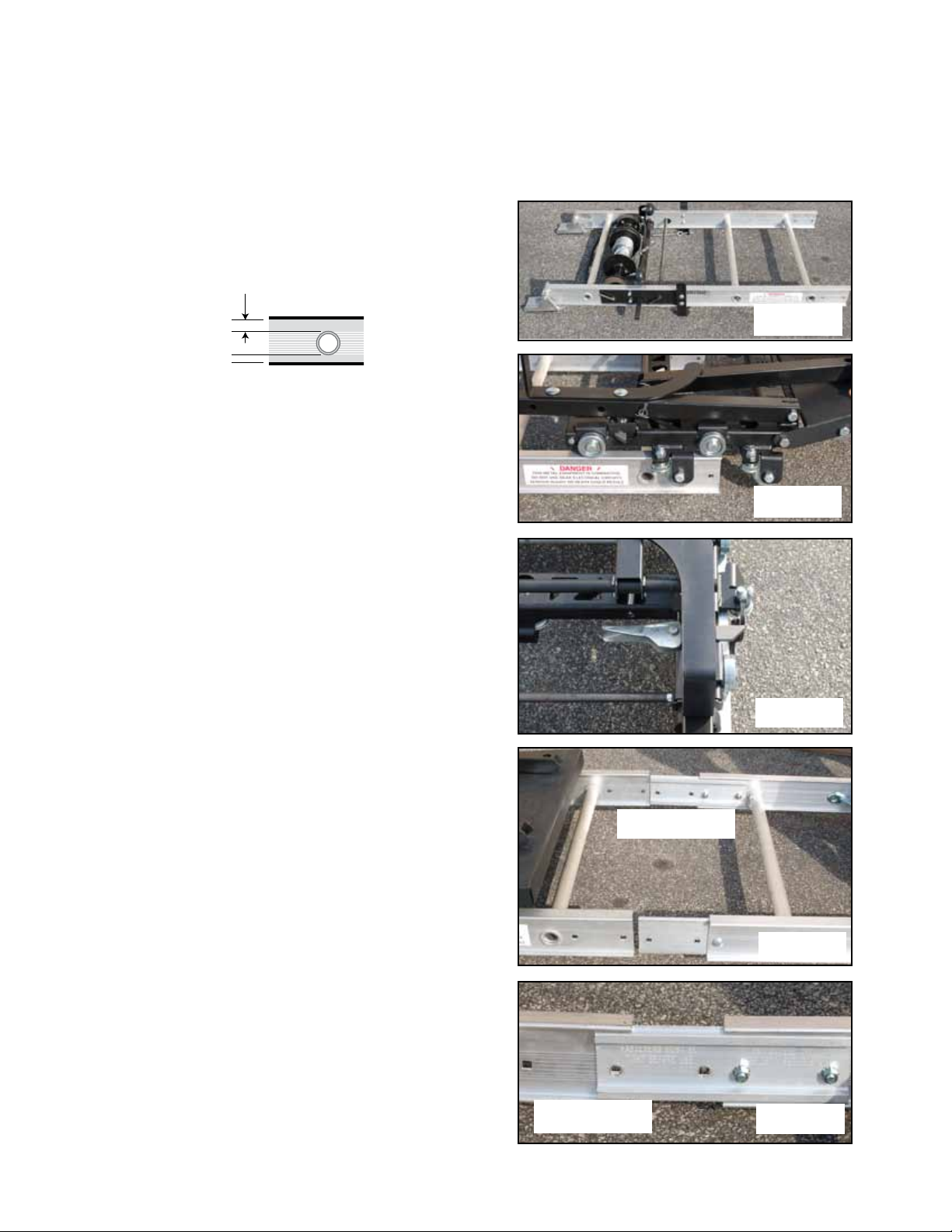

6. Remove the plywood/rolled goods brackets from both

sides of the lift platform (Picture 10, These are used to hold

down the loose platform arms during transporting.)

4. Reattach the end cap to the top end of the last section of

track section you intend to use. Assemble with two 3/8” x

3/4” hex head bolts with lock nuts provided. Make sure that

the top cap end slides into the inside of the track section.

5. From the back side of the hoist, remove the end of the

cable from the drum (picture 6a). It helps to attach the

brake handle, pulling back releases the brake drum. The

cable will will then easily unspool (picture 6b). Staying on

the outside (back) of the base section and track section,

take the cable to the top of the last track section where

the top cap pulley is attached. Feed the cable end through

the pulley as shown in picture 7, and down the front side

of the track section to the back of the carriage assembly.

Feed cable through the cable retainer assembly (picture 8)

attached to the carriage assembly, take the cable to the top

cap assembly and bolt it as shown in picture #9.

Picture 6a

Picture 7

Picture 8

Picture 10

Picture 9

Picture 6b

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

5

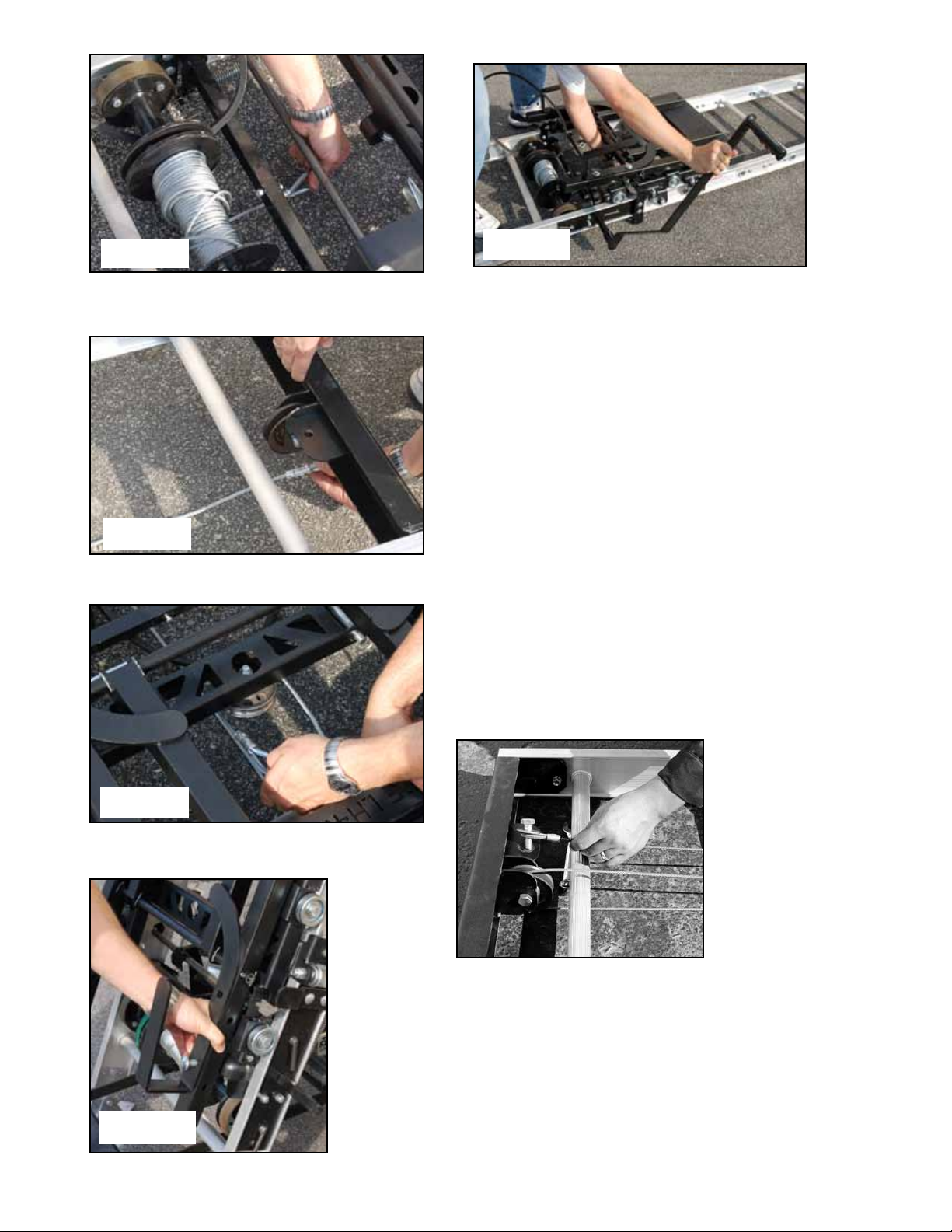

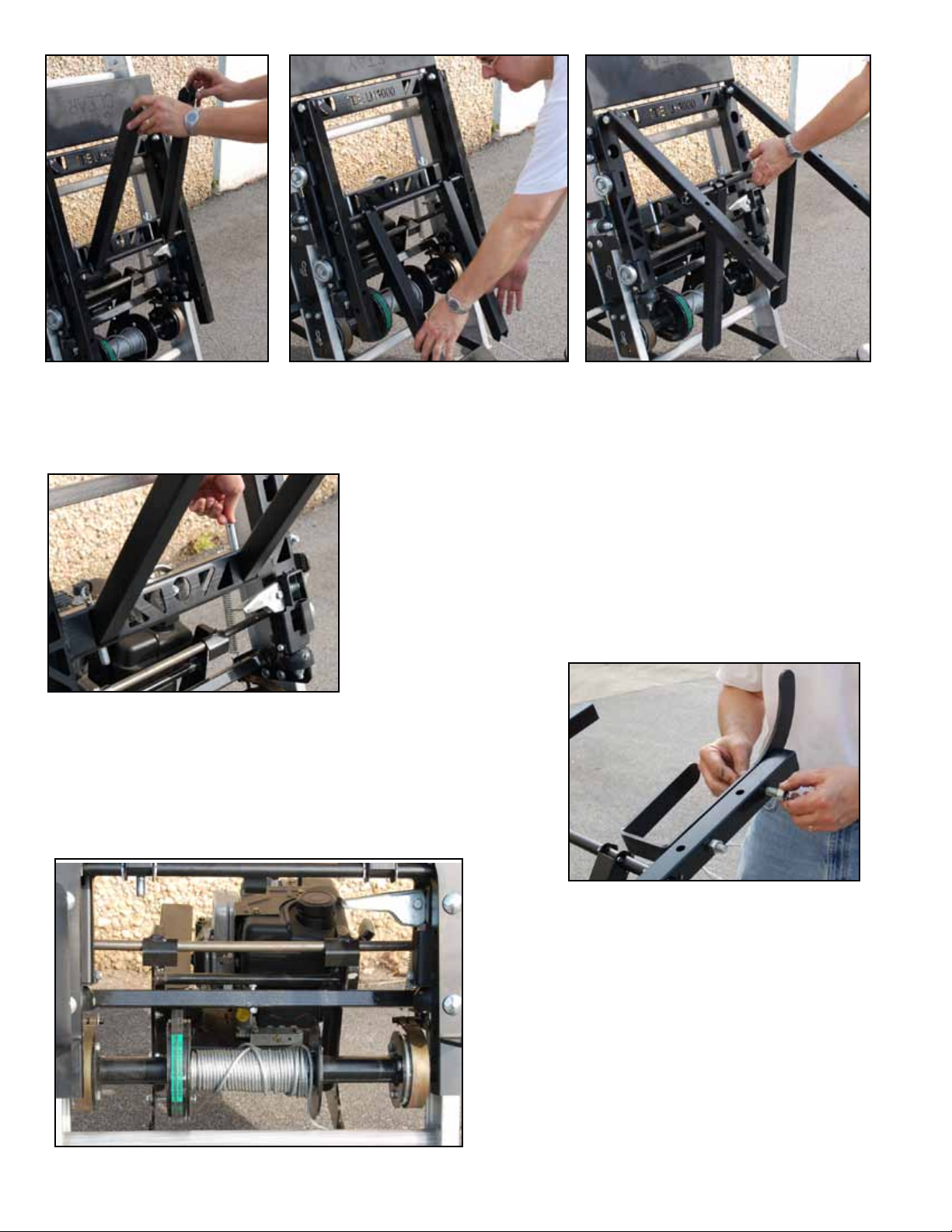

11. After the track section with base is properly

secured to the work site and properly braced,

the motor assembly can be attached to the

base unit. The foot pad of the motor base slides

under the track base section, while “hanging”

the motor base as shown right. Attach the “V”

belt to the large pulley (next to cable drum

assembly on track base), then to the small

pulley on the motor base.

7. Lower the platform supports 180 degrees. Lift the middle bar attached to the platform arms and support

(shown above). Remove the two quick release pins from the platform base.

8. Position/slide the two support arms into the mounting holes on

the cross bar of the platform base.

9. Insert the quick release pins through the platform base and

support arms. This locks the platform base into working position

(shown right).

10. Retach the plywood/rolled

goods brackets, if needed.

(404) 344-0000 • Fax (404) 349-0401 • www.tranzsporter.com 6

REPAIR INFORMATION

Your platform hoist is designed to provide years of service, however, when your lift hoist requires parts, service

or repairs, please contact your nearest authorized dealer, or call 1-800-241-1806, ext. 329 for information on

where to take your platform hoist.

Replaces all dated or undated limited warranties dated before May 1, 2001

Tie Down Engineering, Inc. will repair or replace, free of charge, any part, or parts of the TranzSporter

lift hoist that are defective in material or workmanship or both. The limited warranty is in effect for 90

days from date of purchase.Return the defective unit to the dealer or contact Tie Down direct at

800-241-1806, x329.

THERE IS NO OTHER EXPRESS WARRANTY IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO ONE YEAR FROM PURCHASE OR TO THE EXTENT

PERMITTED BY LAW AND ALL IMPLIED WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS

PERMITTED BY LAW. Some countries or states do not allow limitation on how long an implied warranty

lasts and some countries or states do not allow the exclusion or limitation of incidental or consequential

damages so the above limitation and exclusion may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary from country to country

and state to state.

Limited Warranty

for all models

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

GASOLINE POWER UNIT

1. Handle fuel with care. It is EXTREMELY ammable and explosive under certain conditions.

2. Do not smoke, allow open ames or sparks to be present during the refueling operation.

3. Use only an approved fuel container to transport fuel.

4. Do not fuel while engine is hot - allow to cool before attempting the refueling operation.

5. Replace all fuel tank caps securely and wipe the spilled fuel before restarting engine.

6. Do not operate the gasoline hoist in an enclosed area. The exhaust can be especially

hazardous in an enclosed area.

7. Stop the engine and lower the platform when leaving the vicinity of the lift hoist.

8. Always stop the engine, lower the platform, wait for all moving parts to stop, and allow the engine

to cool before disassembling or moving the hoist.

9. Disconnect the spark plug wire from the plug before disassembling or moving the hoist.

10. DO NOT store the engine in an enclosed area.

11. Allow engine to cool before storing.

12. DO NOT store engine where it might be subjected to ames, sparks, extreme heat or any other

source of combustion.

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

7

Raising the Track Section Assembly

WARNING: KEEP TRACK SECTIONS CLEAR OF ALL ELECTRICAL WIRES AND EQUIPMENT

BE AWARE OF OVERHEAD OBJECTS-NEVER CLIMB HOIST!

The hoist assembly is extremely top heavy and must be kept under control at all times.

Two alternate methods are suggested for raising the platform hoist to the operating position.

PROCEDURE “A”

This procedure requires two or preferably three men.

1. Lay the assembled track sections with the platform attached parallel to the building wall that is to

support the hoist.

2. Tie a rope to the head bracket and have the man on roof pull up the hoist while the other man on

the ground braces the shoes on the bottom section to prevent slippage of the hoist shoes. The

third man on the ground may aid in erecting by “walking” the hoist up hand over hand by

the rungs.

3. When the hoist reaches a vertical position, carefully turn the hoist 90 degrees with the platform

pointing away from the building. Move the bottom of the hoist away from the building, 1/4 of the

height of the building where the top of the hoist is to be supported. Make allowances for

overhang. See track section support chart for approximate distances of the base from the

bottom track.

ALTERNATE PROCEDURE “B”

1. Place track section assembly perpendicular to the building with the bottom shoes of the steel

bottom section resting against the building to prevent slipping.

2. Tie a rope to the head bracket and have the man on the roof pull up the hoist while the other man

on the ground braces the shoes on the steel bottom section to prevent slippage of the hoist shoes.

The third man on the ground may aid in erecting by “walking” the hoist up hand over hand

by the rungs.

3. When the hoist reaches a vertical position, carefully turn the hoist 180 degrees with the platform

pointing away from the building. Move the bottom of the hoist away from the building, 1/4 of the

height of the building where the top of the hoist is to be supported. Angle of track sections from

building should be between 18 and 20 degrees. Make allowances for an overhang. See track

section chart for approximate distances of the base from the building.

AFTER ERECTING THE HOIST USING PROCEDURE “A” OR “B”, CONTINUE AS FOLLOWS:

4. Tie the track section to the roof with a rope fastened to a cross tie on the top bracket to prevent

slippage of the track section. DO NOT TIE ROPE TO THE RAILS - THIS WILL PREVENT

THE PLATFORM FROM OPERATING PROPERLY.

5. Mount the power unit to the top rung of the steel bottom section. Attach the V-belt to the pulley

on the power unit.Slide the brake handle over the brake arm and install the pin provided.

6. Remove any ropes used to secure the platform during transportation.

7. Make certain the shoes on the steel bottom section are rmly resting on level ground. This will

help to prevent track section slippage or uneven loading of the track section which could cause

damage or injury to personnel and/or to equipment.

(404) 344-0000 • Fax (404) 349-0401 • www.tranzsporter.com 8

WARNING: BEFORE LOWERING THE TRACK SECTIONS, CAREFULLY CHECK FOR

OVERHEAD OBJECTS AND POWER LINES.

Raising the platform with or without load

WARNING: THE OPERATOR OF THIS HOIST UNIT SHOULD WEAR APPROPRIATE SAFETY EQUIPMENT

WHICH SHOULD INCLUDE APPROVED HAND PROTECTION, HEAD PROTECTION AND EYE PROTECTION.

To raise the platform on LH4000, face the platform and stand as far as possible from the hoist to operate.

Place your foot on the foot control brace to engage the motor to drum belt, permitting the platform to roll up

the track section. When the platform reaches the top, release foot IMMEDIATELY. This will apply the self

energizing brake. Move away from the hoist while the load is being removed from the platform.

Lowering the platform

To lower the carriage, stand to the right or left side of the hoist and grasp the brake handle. Lightly feather

the platform down by engaging and disengaing the brake to slow the carriage. Lower the carriage to the

ground at a slow speed (not to exceed 50 feet per minute). Continue to decelerate the platform as it nears

the ground to prevent damage to the platform or bottom brace stops.

CAUTION: NEVER APPLY THE BRAKE ABRUPTLY - BROKEN HOIST CABLES AND/OR SEVERE INJURY TO

PERSONNEL OR EQUIPMENT MAY OCCUR. MAKE CERTAIN PLATFORM DOES NOT STRIKE THE BOTTOM

BRACE STOPS UPON REACHING THE BOTTOM OF THE TRACK SECTION.

Lower and dismantle the platform hoist assembly in the reverse of the erection procedure, observing all

safety procedures.

Track Section Chart - Brace Support

Track lengths in excess of 28 feet require the use of the telescoping brace(#60005). The table below

provides the suggested information for the distance of the bottom track from the building and the

location of the track support for various conditions.

Building Length of Base of Track Track Brace Location

Height Track to Building Cross Tie from Bottom

42 44(max) 10’6” 25th and 27th

40 44 10’0” 26th and 25th

36 40 9’0” 19th and 21st

32 36 8’0” 14th and 16th

28 32 7’6” 11th and 13th

24 28 6’6” Not Required

20 24 6’6” Not Required

16 20 5’0” Not Required

12 16 4’6” Not Required

LH-4000 4 ft. Base Section

LH-4000 4 ft.

Base Section

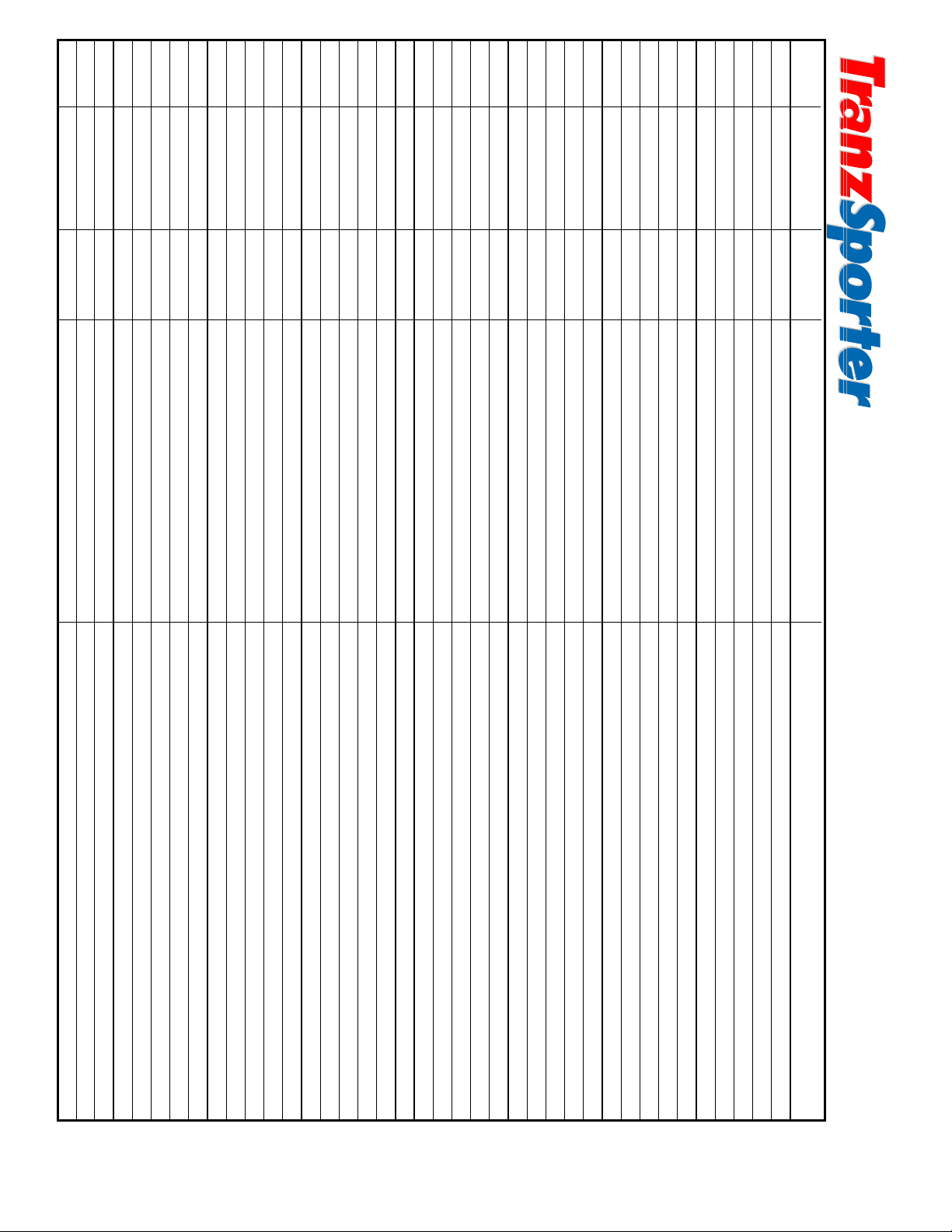

Parts List

1

2

11

19

19

4

15

15

15

17

17

30

28

17

15

15

13

29

29

31

37

30

33

12

16

16

33

33

17

5

8

9

7

6

14

14

14

10

10 18

18

3

21

20

22

23

23

35

36

35

26

24

26

24

24

24

25

25

32

32

25

31

Complete Drum

Assembly

#48491A

Number Kit Part # TDE Part # Description Kit Contains (Quanity-Part #)

1 10089 10089 4' Alum Platform with Safety Shoes

2 90033 48487 Right Carriage Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

3 90033 48488 Left Carriage Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

4 90032 48503-7R Right Carriage Lock Down 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

5 90032 48503-7L Right Carriage Lock Down 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

6 90002 48489R Drive support plate Right 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

7 90002 48489L Drive support plate Left 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

8 48525 48525 Cable Drum Shaft

9 90001 10057 Screw Collars 2-10057

10 90033 46434 Bumper Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

11 48524 48524 Brake Control weldment

12 90006 48564 Brake Control spacer 2-48564

13 48525 48525 Brake control shaft

14 90032 see also 90033 10916 Carriage Bolt 3/8-16 x 1.5" 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

15 90032 see also 90033 10627 3/8-16 Nyloc Nut 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

16 90002 10804 Carriage Bolt 3/8-16 x 1" 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

17 90032 see also 90033 48519 Guide Shim 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

18 90033 10806 1/2-13 x 1.5" Bolt 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

19 90033 10645 Nyloc Nut 1/2-13 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

20 90003 10946 1/4-20 Bolt 1-10946, 1-10027

21 90003 10027 1/4" nut 1-10946, 1-10027

22 See 48491A 48491 Cable Drum-400lb quick change

23 90009 11080 Bearing 2-10080

24 90007 10650 Nyloc Nut 5/16-18 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

25 13000 13000 Drum Brake

26 BBB3130075 BBB3130075 5/16" Bolt 3/4"

27 90034 50384 3/16" x 130' Cable 1-50384

28 90012 48517 Cable Drum Shim 2-48517

29 90007 10049 Spring Extension 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

30 90007 13211 Eye Bolt 5/16” x 3” 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

31 90007 48510 Brake Linkage 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

32 90007 10603 Cotter Pin 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

33 90008 10604 Large Cotter Pin 2-10604

35 90007 10033 Strap Brake 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

36 10047 10047 Belt B 51in. (5L510) formerly #10034 50"

37 48506A 48506A Brake Handle with Rubber Grip

62002 62002 COMPLETE Base Section

48491A 48491A Complete Cable Drum

Rev. 3-21-111

Rev. 3-21-11

1

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

9

LH-4000 4 ft. Base Section

LH-4000 4 ft.

Base Section

Parts List

1

2

11

19

19

4

15

15

15

17

17

30

28

17

15

15

13

29

29

31

37

30

33

12

16

16

33

33

17

5

8

9

7

6

14

14

14

10

10 18

18

3

21

20

22

23

23

35

36

35

26

24

26

24

24

24

25

25

32

32

25

31

Complete Drum

Assembly

#48491A

Number Kit Part # TDE Part # Description Kit Contains (Quanity-Part #)

1 10089 10089 4' Alum Platform with Safety Shoes

2 90033 48487 Right Carriage Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

3 90033 48488 Left Carriage Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

4 90032 48503-7R Right Carriage Lock Down 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

5 90032 48503-7L Right Carriage Lock Down 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

6 90002 48489R Drive support plate Right 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

7 90002 48489L Drive support plate Left 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

8 48525 48525 Cable Drum Shaft

9 90001 10057 Screw Collars 2-10057

10 90033 46434 Bumper Stop 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

11 48524 48524 Brake Control weldment

12 90006 48564 Brake Control spacer 2-48564

13 48525 48525 Brake control shaft

14 90032 see also 90033 10916 Carriage Bolt 3/8-16 x 1.5" 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

15 90032 see also 90033 10627 3/8-16 Nyloc Nut 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

16 90002 10804 Carriage Bolt 3/8-16 x 1" 10-10627, 4-10804, 6-10916, 10-48519, 1-48503-7R, 1-48561, 1-48562, 1-48489L, 1-48489R

17 90032 see also 90033 48519 Guide Shim 1-48503-7R,1-48503-7L, 4-10916, 4-10627, 4-48519

18 90033 10806 1/2-13 x 1.5" Bolt 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

19 90033 10645 Nyloc Nut 1/2-13 1-48487, 1-48488, 4-10916, 8-48519, 2-46434, 2-10806, 2-10645

20 90003 10946 1/4-20 Bolt 1-10946, 1-10027

21 90003 10027 1/4" nut 1-10946, 1-10027

22 See 48491A 48491 Cable Drum-400lb quick change

23 90009 11080 Bearing 2-10080

24 90007 10650 Nyloc Nut 5/16-18 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

25 13000 13000 Drum Brake

26 BBB3130075 BBB3130075 5/16" Bolt 3/4"

27 90034 50384 3/16" x 130' Cable 1-50384

28 90012 48517 Cable Drum Shim 2-48517

29 90007 10049 Spring Extension 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

30 90007 13211 Eye Bolt 5/16” x 3” 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

31 90007 48510 Brake Linkage 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

32 90007 10603 Cotter Pin 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

33 90008 10604 Large Cotter Pin 2-10604

35 90007 10033 Strap Brake 1-10033, 1-10049, 2-10603, 1-48510, 1-13211, 1-10650

36 10047 10047 Belt B 51in. (5L510) formerly #10034 50"

37 48506A 48506A Brake Handle with Rubber Grip

62002 62002 COMPLETE Base Section

48491A 48491A Complete Cable Drum

Rev. 3-21-111 Rev. 3-21-11

1

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

2

32

5

1

6

4

3

92

82

03

13

16

15

14 15

19

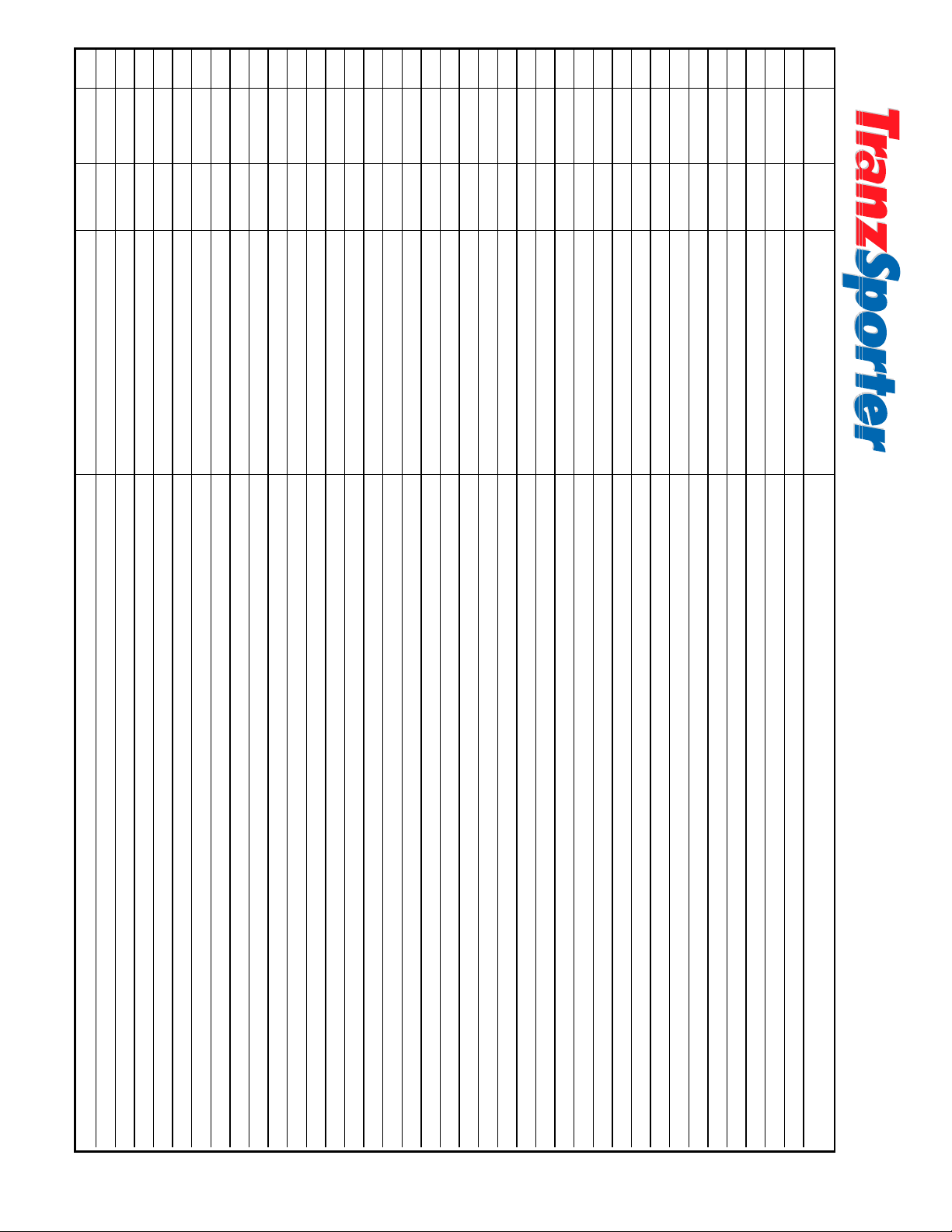

LH4000 Carriage Parts Detail

LH4000 Carriage

Parts Detail

Carriage Flap

16

16

16

9

15

34

18

18

33

Rev. 3/21/2011

22

62

72

1

32

52

42 52

02

7

61

12

01 51

11

91

21

31

9

71

81

81

61

Carriage

Dual Guide Wheel Assembly

(2 per side)

17

15

16

9

9

13

15

Rev. 3/21/2011

# Kit # TDE # Description Kit Contains (Quanity-Part #)

1 48481 48481 Carriage Weldment

2 48482 48482 Top Carriage Support Bar

3 48483 48483 Carriage Cross Support

4 48484 48484 Support Tube

5 90030 48485L Roll/Plywood Holder, Left 1-48485L, 1-48485R, 4-10801, 4-10646,

6 90030 48485R Roll/Plywood Holder, Right 1-48485L, 1-48485R, 4-10801, 4-10646,

7 48486 48486 Tube Cap

8 48492 48492 COMPLETE Carriage

9 90031 48536 Guide Wheel 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

10 90031 48556 Flanged Wheel 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

11 90031 11083 Bearing Flanged (Inside Guide Bearing) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

12 90031 11081 Bearing Flanged (Outside) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

13 90031 48519 Spacer 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

14 90031 13132 PulleyAssembly 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

15 90031 10517 Washer 1/2" x 3/4" 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

16 90031 10645 1/2” Nyloc Nut (Used On All 1/2” Bolts) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

17 90031 10864 1/2” x 2-1/4” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

18 90031 10806 1/2” x 1-1/2” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

19 90031 10931 1/2” x 2” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

20 90031 10027 1/4” Nyloc Nut 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

21 90031 10866 1/4” x 3-1/4” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

22 90028 17020-1 Latch Handle 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

23 90028 48481-11 Plunger Safety Latch 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

24 90028 10054 Compression Spring 2 Inch 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

25 90028 17020-5 Latch Wear Plate 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

26 90028 10650 5/16" Nyloc Nut 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

27 90028 10952 5/16" x 1 Bolt, Grade 5 Zinc 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

28 90030 10646 1/2” Nut 1-48485L, 1-48485R, 4-10801, 4-10646,

29 90030 10801 1/2” x 2-1/2” Carriage Bolt, Zinc 1-48485L, 1-48485R, 4-10801, 4-10646,

30 10690 10690 1/8” X 1-1/4” Cotter Pin, Zinc

31 10693 10693 1/2” Quick Release Pull Pin

32 48527 48527 Carriage Flap

33 10016 10016 1/2” x 1” Bolt, Grade 5 Zinc

34 10573 10573 Washer 1/2" x 3/4"

(404) 344-0000 • Fax (404) 349-0401 • www.tranzsporter.com 12

2

32

5

1

6

4

3

92

82

03

13

16

15

14 15

19

LH4000 Carriage Parts Detail

LH4000 Carriage

Parts Detail

Carriage Flap

16

16

16

9

15

34

18

18

33

Rev. 3/21/2011

22

62

72

1

32

52

42 52

02

7

61

12

01 51

11

91

21

31

9

71

81

81

61

Carriage

Dual Guide Wheel Assembly

(2 per side)

17

15

16

9

9

13

15

Rev. 3/21/2011

# Kit # TDE # Description Kit Contains (Quanity-Part #)

1 48481 48481 Carriage Weldment

2 48482 48482 Top Carriage Support Bar

3 48483 48483 Carriage Cross Support

4 48484 48484 Support Tube

5 90030 48485L Roll/Plywood Holder, Left 1-48485L, 1-48485R, 4-10801, 4-10646,

6 90030 48485R Roll/Plywood Holder, Right 1-48485L, 1-48485R, 4-10801, 4-10646,

7 48486 48486 Tube Cap

8 48492 48492 COMPLETE Carriage

9 90031 48536 Guide Wheel 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

10 90031 48556 Flanged Wheel 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

11 90031 11083 Bearing Flanged (Inside Guide Bearing) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

12 90031 11081 Bearing Flanged (Outside) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

13 90031 48519 Spacer 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

14 90031 13132 PulleyAssembly 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

15 90031 10517 Washer 1/2" x 3/4" 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

16 90031 10645 1/2” Nyloc Nut (Used On All 1/2” Bolts) 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

17 90031 10864 1/2” x 2-1/4” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

18 90031 10806 1/2” x 1-1/2” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

19 90031 10931 1/2” x 2” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

20 90031 10027 1/4” Nyloc Nut 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

21 90031 10866 1/4” x 3-1/4” Bolt, Grade 5 Zinc 10-48519, 10-48536, 4-11081, 4-11083, 4-48556,1-13132,22-10517, 23-10645, 8-10806, 2-10027, 2-10866, 8-10864, 6-10931

22 90028 17020-1 Latch Handle 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

23 90028 48481-11 Plunger Safety Latch 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

24 90028 10054 Compression Spring 2 Inch 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

25 90028 17020-5 Latch Wear Plate 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

26 90028 10650 5/16" Nyloc Nut 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

27 90028 10952 5/16" x 1 Bolt, Grade 5 Zinc 1-10952, 1-10650, 2-17020-5, 1-10054, 1-48535, 1-17020-1, 1-48481-11

28 90030 10646 1/2” Nut 1-48485L, 1-48485R, 4-10801, 4-10646,

29 90030 10801 1/2” x 2-1/2” Carriage Bolt, Zinc 1-48485L, 1-48485R, 4-10801, 4-10646,

30 10690 10690 1/8” X 1-1/4” Cotter Pin, Zinc

31 10693 10693 1/2” Quick Release Pull Pin

32 48527 48527 Carriage Flap

33 10016 10016 1/2” x 1” Bolt, Grade 5 Zinc

34 10573 10573 Washer 1/2" x 3/4"

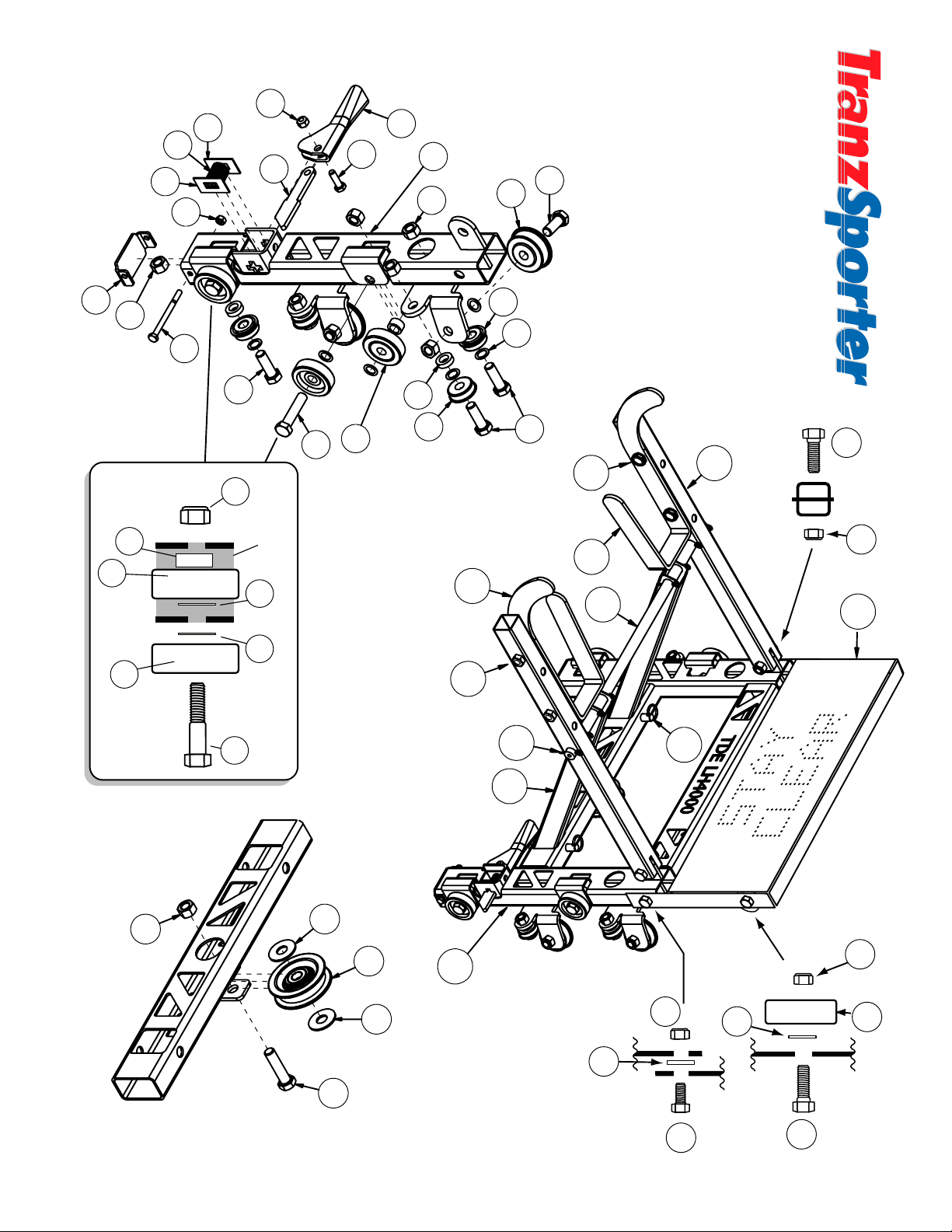

031711,E1080

2

1

3

6

8

9

11

3

10

10

11

11

11

10

1 90021 10954 Bolt 5/16"x1-1/2" Zinc 4-10954, 4-10650

2 90021 10650 Nyloc Hex Nut 5/16"-18 4-10954, 4-10650

3 90019, see also 90020 10026 Bolt 1/4"-20 x 3" 3-10518,7-10507, 7-10027, 1-48514,3-10026

4 90022 10037 Sheave for drive motor 1-10037, 1-48502

5 12570A 12570A Lifan Gas Engine with Low Oil Sensor

6 90020 45005 Block Pivot Saddle 1-45005, 2-10026, 2-10027, 2-10507

7 48500 48500 Motor Mount Weldment

8 90019 48514 Belt Guard 3-10518,7-10507, 7-10027, 1-48514,3-10026

9 90019 10518 Bolt 1/4" x 3/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026

10 90019, see also 90020 10027 Nut 1/4"-20 Zinc 3-10518,7-10507, 7-10027, 1-48514,3-10026

11 90019, see also 90020 10507 Flat Washer 1/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026

12 90022 48502 Key 3/16"x3/4 1-10037, 1-48502

48471 48471 Complete Kit: Lifan Engine and weldment

48500AA 48500AA Complete Base Kit without motor

# Kit Part # TDE Part # Description Kit Contents

7

Lifan Engine (5)

Lifan Motor

Mount Assembly Detail

4

12

Engine block

mounting bolts

#5

Engine Assembly

Includes 10037 & 48502

NEW!

Comes with low oil

shut off feature

Note

NOTE: Use front hole set for LIfan engine mount

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

13

031711,E1080

032111,E1080

031711,E1080

2

1

3

6

8

9

11

3

10

10

11

11

11

10

1 90021 10954 Bolt 5/16"x1-1/2" Zinc 4-10954, 4-10650

2 90021 10650 Nyloc Hex Nut 5/16"-18 4-10954, 4-10650

3 90019, see also 90020 10026 Bolt 1/4"-20 x 3" 3-10518,7-10507, 7-10027, 1-48514,3-10026

4 90022 10037 Sheave for drive motor 1-10037, 1-48502

5 12570A 12570A Lifan Gas Engine with Low Oil Sensor

6 90020 45005 Block Pivot Saddle 1-45005, 2-10026, 2-10027, 2-10507

7 48500 48500 Motor Mount Weldment

8 90019 48514 Belt Guard 3-10518,7-10507, 7-10027, 1-48514,3-10026

9 90019 10518 Bolt 1/4" x 3/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026

10 90019, see also 90020 10027 Nut 1/4"-20 Zinc 3-10518,7-10507, 7-10027, 1-48514,3-10026

11 90019, see also 90020 10507 Flat Washer 1/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026

12 90022 48502 Key 3/16"x3/4 1-10037, 1-48502

48471 48471 Complete Kit: Lifan Engine and weldment

48500AA 48500AA Complete Base Kit without motor

# Kit Part # TDE Part # Description Kit Contents

7

Lifan Engine (5)

Lifan Motor

Mount Assembly Detail

Honda Motor

Mount Assembly Detail

4

12

Engine block

mounting bolts

#5

Engine Assembly

Includes 10037 & 48502

NEW!

Comes with low oil

shut off feature

Note

NOTE: Use front hole set for LIfan engine mount

1 90023 10955 Bolt 5/16"x1-3/4" Zinc 4-10955, 4-10509, 1-48518, 4-10650

2 90023 10650 Nyloc Hex Nut 5/16"-18 4-10955, 4-10509, 1-48518, 4-10650

3 90019, see also 90020 10026 Bolt 1/4"-20 x 3" Grade 2 3-10518,7-10507, 7-10027, 1-48514,3-10026,

4 90022 10037 Sheave for Honda drive motor 1-10037, 1-48502

5 10039A 10039A Honda Motor Assembly 4.0 HP

6 90020 45005 Block Pivot Saddle 1-45005, 2-10026, 2-10027, 2-10507

7 90023 10509 Flat Washer 4-10955, 4-10509, 1-48518, 4-10650

8 48500 48500 Motor Mount Weldment

9 90022 48502 Key 3/16"x3/4 1-10037, 1-48502

10 90019 48514 Belt Guard 3-10518,7-10507, 7-10027, 1-48514,3-10026,

11 90023 48518 Honda Mounting Shim 4-10955, 4-10509, 1-48518, 4-10650

12 90019 10518 Bolt 1/4" x 3/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026,

13 90019, see also 90020 10027 Nut 1/4"-20 Zinc 3-10518,7-10507, 7-10027, 1-48514,3-10026,

14 90019, see also 90020 10507 Flat Washer 1/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026,

# Kit Part # TDE Part # Description Kit Contents

1 10804 10804 Bolt 3/8"x1" Zinc

2 10627 10627 Nyloc Hex Nut 3/8"

3 90020 10026 Bolt 1/4"-20 x 3" 1-45005, 2-10026, 2-10027, 2-10507

4 90022 10037 Sheave for Honda drive motor 1-10037, 1-48502

5 12561 Leeson 1 hp Electric Motor

6 90020 45005 Block Pivot Saddle 1-45005, 2-10026, 2-10027, 2-10507

7 47500 47500 Motor Mount Weldment

8 90019 48514 Belt Guard 3-10518,7-10507, 7-10027, 1-48514,3-10026,

9 90019 10518 Bolt 1/4" x 3/4" 3-10518,7-10507, 7-10027, 1-48514,3-10026,

10 90020 10027 Nut 1/4"-20 Zinc 1-45005, 2-10026, 2-10027, 2-10507

11 90020 10507 Flat Washer 1/4" 1-45005, 2-10026, 2-10027, 2-10507

12 90022 10037 Sheave for Honda drive motor 1-10037, 1-48502

60034 60034 Complete Kit includes Electric Motor and weldment

# Kit Part # TDE Part # Description Kit Contents

#5

Engine Assembly

Includes 10052 & 48502

7

1

3

6

10

12

14

13

14

14

14

13

3

11

8

Honda Engine (5) 2

4

9

Engine block

mounting bolts

13

2

1

3

6

8

9

11

3

10

10

11

11

11

10

7

Electric Motor

#5

1 HP Electric Motor

Mount Assembly Detail

(for use on all platform hoist) 4

12

Engine block

mounting bolts

#5

Engine Assembly

Includes 10037 & 4850

2

(404) 344-0000 • Fax (404) 349-0401 • www.tiedown.com 14

031711,e640

LH400 &

LH4000

Track Section

Parts Detail

Top Cap Assembly

(Placed on the inside)

Splice Plate Assembly

(Placed on the inside)

3

4

8

2

1

3

3

5

4

4

65

9

10

2

7

9

1 See 48526A 48526 Top Track Cap

2 10081 10081 Platform Hoist Track 8' for LH400/LH4000 with pair of splice plates

3 90024 see also 90025 10622 Nuts Krebs 3/8" 16-10622, 16 10914

4 90024 see also 90025 10914 Bolt Carriage 3/8" x 3/4" 16-10622, 16 10914

5 90014 10645 Nut Nyloc Hex 1/2" 2-13132, 4-10573, 2-10517, 2-10931, 2-10645

6 90014 10931 Bolt HHCS 1/2" x 2" 2-13132, 4-10573, 2-10517, 2-10931, 2-10645

7 90014 13132 Sheave Idler 2-13132, 4-10573, 2-10517, 2-10931, 2-10645

8 90025 10093 Splice Plate w/Hardware (Sold In Pairs) 2-10093, 8-10622, 8-10914

9 12107 12107 Washer Flat 1/2"

10 10806 10806 Bolt 1/2" x 1-1/2"

48526A 48526A Top Track Cap Complete with Sheave

10080 10080 Platform Hoist Track 4' for LH400/LH4000 with pair of splice plates

# Kit Part # TDE Part # Description Kit Contents

Tie Down Engineering • 5901 Wheaton Drive • Altanta, Georgia 30336

15

Table of contents

Other TRANZSPORTER Lifting System manuals

Popular Lifting System manuals by other brands

Challenger Lifts

Challenger Lifts 4018XFX Installation, operation & maintenance manual

twin busch

twin busch TW M-04 Installation, operation and maintenance manual

Sabaj

Sabaj WP-560 Assembly and operating manual

Case

Case SR130 Service manual

BVA Hydraulics

BVA Hydraulics H0500 instruction manual

pela tools

pela tools 513949 manual