Premium Tool P1038 User manual

IMPORTANT SAFETY INFORMATION

Please read, understand and follow all safety information contained in these instructions prior to

the use of this tool. Retain these instructions for further use. These instructions are applicable for

CHINOOKTM Model Impact Wrenches offered by Premium Tool & Abrasives..

INTENDED USE

This product is designed for installing and removing threaded fasteners in wood, metal and plastic.

No other use is permitted. For professional use only.

WARNING

Always disconnect this tool from the air supply

before installing, adjusting or removing any

accessory for this tool, or before performing

maintenance. Failure to do so could result in

injury.

WARRANTY

Premium Tool & Abrasives warrants its Impact Wrenches for a period of 1 year from the purchase

date against manufacturing defects and will repair or replace (at its option) without charge any items

returned. Repairs or replacements are warranted as described for the remainder of the original

warranty period. Providing proof of purchase is strictly the responsibility of the customer. This

warranty is void if the item has been damaged by accident or unreasonable use, neglect, improper

service, or other causes not arising out of defects in material or workmanship. No other expressed

warranty is given or authorized. Premium Tool & Abrasives disclaims any implied warranty of

MERCHANTABILITY or FITNESS for any period beyond the expressed warranty and shall not be

liable for incidental or consequential damages.

To obtain warranty service, return the item(s) prepaid to your nearest Authorized Warranty Repair

Center or to Premium Tool & Abrasives at 10761 - 181 ST, NW. Edmonton, AB, Canada, T5S 1N3.

www.premiumtool.com

PTA Canada 10761 - 181 ST NW Edmonton, AB, Canada T5S 1N3

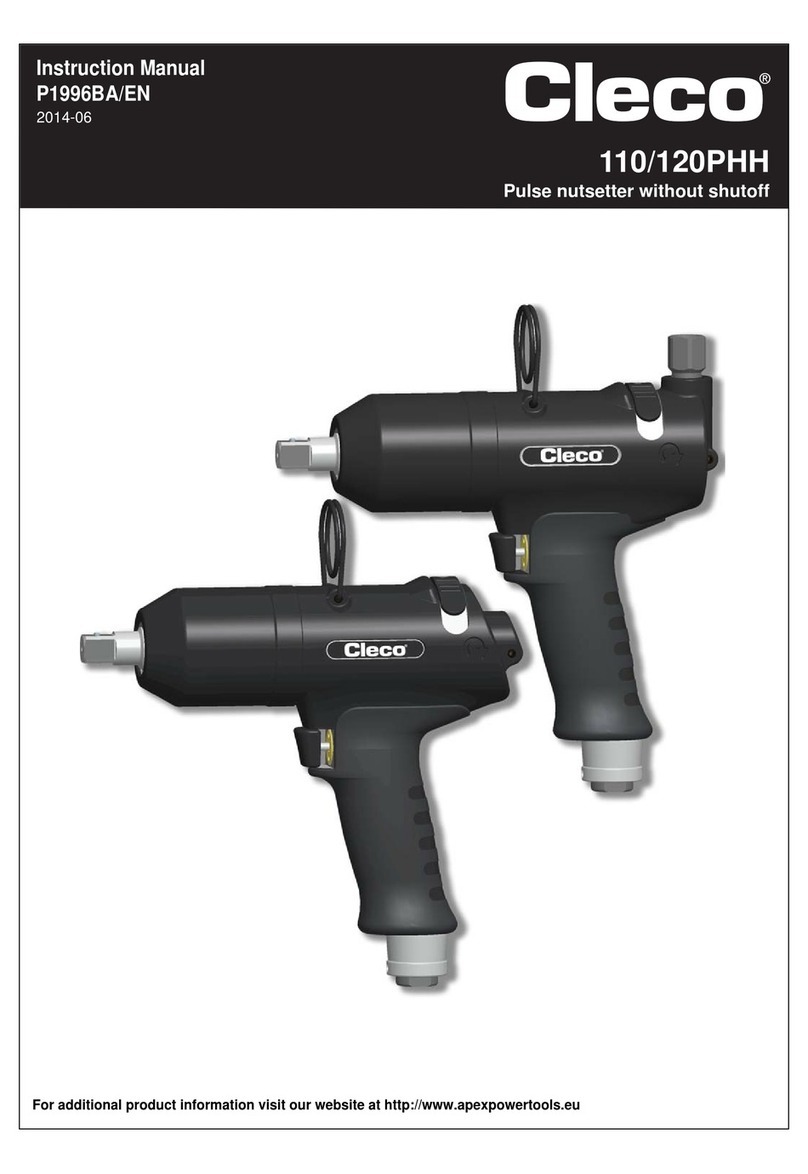

OPERATIONS MANUAL

IMPACT WRENCH

1/2” DRIVE MINI IMPACT WRENCH

P1038

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risks associated with the use of impact wrenches:

•Read, understand and follow the safety information contained in these instructions prior to using

this tool. Keep these instructions for further reference.

•Only properly trained personnel should service this tool. Any other service will void warranty.

• Practice safety requirements - work alert and do not operate tools under the influence of alcohol or

drugs.

• Operators and nearby personnel must always wear protection for eyes and ears when in the work

area or while operating this product. Follow your employer’s safety policy for PPE’s and/or ANSI

Z87.1 or local/national standards for eyewear and other personal protective equipment require-

ments.

• Never exceed marked maximum input pressure (90psi / .62Mpa / 6.2Bars).

• Proper eye protection must be worn at all times.

• Tool shall not be operated in the presence of bystanders.

• If you notice any abnormal noise or vibration when operating the product, immediately discontinue

its use and inspect for worn or damaged components. Correct or replace the problem component. If

the problem persists, return the tool to PTA Canada for repair or replacement. Please refer to war-

ranty instructions

• Make sure the tool is disconnected from its air source before servicing, inspecting, maintaining,

cleaning, and before changing impact product.

WARNING

www.premiumtool.com

PTA Canada 10761 - 181 ST NW Edmonton, AB, Canada T5S 1N3

RISKS PREVENTION

Vibration • If any physical discomfort is experienced, work should be stopped

promptly to seek medical attention. Injury may result from repetitive work,

motion and exposure to excessive vibration.

Loud Noise • Always wear protection for eyes and ears while operating this product.

Follow your employer’s safety policy for PPE’s and/or ANSI Z87.1 or local/

national standards for eyewear and other personal protective equipment

requirements..

Fire or Explosion • Do not operate the tool in explosive atmospheres, such as in the

presence of ammable liquids, gases, or dust.

Hazardous Voltage • Do not allow this tool to come into contact with electrical power sources

as the tool is not insulated against electrical shock.

Skin Abrasion/Burns/

Cuts/Entrapment

• Keep hands, hair, and clothing away from the rotating part of the tool.

• Wear suitable protective gloves while operating tool.

• Do not touch the rotating parts during operation for any reason.

• Do not force tool or use excessive force when using tool.

Hazardous Pressure

Rupture

• Be aware that incorrectly installed hoses and ttings might unexpectedly

come loose at any time and create a whipping/impact hazard.

PRODUCT CONFIGURATION / SPECIFICATIONS

PART

NO.

DRIVE

in.

STYLE TORQUE

ft-lbs

(N-M)

SPEED

rpm

PRODUCT

NET WT.

lb. (kg.)

BOLT

CAPACITY

in.

AIR

CONSUMPTION

cfm

INLET

in.

HOSE

SIZE

in.

(mm)

P1028 3/8 Aluminum

Mini 400 (540) 9,000 3.5 (1.6) 5/8 (16) 5.8 1/4 3/8 (10)

P1030 1/2 Composite 1,000 (1,357) 7,500 4.4 (2.0) 3/4 (19) 10.2 1/4 3/8 (10)

P1038 1/2 Aluminum

Mini 500 (680) 9,000 3.5 (1.6) 5/8 (16) 5.8 1/4 3/8 (10)

P1060 3/4 Composite 1,400 (1,900) 5,500 7.5 (3.4) 1-1/4 (32) 9.5 3/8 3/8 (10)

P1080 1 Composite 2,500 (3,390) 4,800 17.2 (7.8) 1-3/4 (44) 9.0 1/2 1/2 (13)

P1180 1 Composite 2,200 (2,980) 5,000 17.86 (8.1) 1-3/4 (44) 9.0 1/2 1/2 (13)

USE AND CARE

• Always operate, inspect and maintain tool in accordance with all regulations that may apply to

handheld, hand operated pneumatic tools

• Use a clean lubricated air supply that will give a measured air pressure at the tool of 6.2 bar (90

psig) when the tool is running with the lever fully depressed. Tool will operate at less than maximum

pressure - performance will be reduced.

Beginning of each use:

• Install desired impact wrench accessory

• Lubricate tool by putting 2 to 3 drops of suitable pneumatic motor lubricating oil into the hose end

(inlet) of the tool. Connect the tool to the air line and run slowly for a few seconds. Disconnect to

safely install desired impact accessory. If tool is used frequently, oil daily or when the tool begins to

slow or lose power.

• Adjust switch on the back of the tool to desired forward or reverse motion. If your tool has multiple

forward speeds, higher speed numbers represent higher tool power.

• Depress trigger to operate tool.

MAINTENANCE

LUBRICATION

Air tools require regular lubrication throughout the life of the tool. The air motor and bearing uses

compressed air to power the tool. Because the moisture in compressed air will rust the air motor,

you must lubricate the motor daily. An inline oiler is recommended.

To lubricate the air motor manually:

• Disconnect the tool from the air supply holding it so the air inlet faces up.

• Depress the trigger and place one or two drops of air tool oil in the air inlet.

• Connect the tool to the air source, cover the exhaust end of the tool with a tower and run for a few

seconds

• Do not lubricate tools with ammable or volatile liquids

www.premiumtool.com

PTA Canada 10761 - 181 ST NW Edmonton, AB, Canada T5S 1N3

AIR TOOLS AND PIPE FITTING SYSTEM

PART DESCRIPTION

1Air Tool

2 Air Hose (3/8”)

3 Oiler

4 Pressure Regulator

5B Filter

6 Shut Off Valve

7 Lead Hose

8 Coupler Body and Connector

9 Drain Daily

10 1/2” or Larger Pipe and Fitting

11 Air Dryer

12 1” or Larger Pipe and Fitting

13 Air Compressor

14 Auto Drain

15 Drain Daily

Premium Tool & Abrasives Co. Ltd.

10761 181 Street, NW

Edmonton, Alberta, Canada

T5S 1N3

Telephone: 780.438.6576

Facsimilie: 780.436.4103

e-mail: [email protected]

FOR OTHER PRODUCT CATALOGUES,

ASSISTANCE OR A DISTRIBUTOR IN YOUR AREA,

PLEASE CALL:

1 800 661 6576

Find us online at: www.premiumtool.com

Part Number:

Serial Number:

Date of Purchase:

P1038

PRODUCT INFORMATION

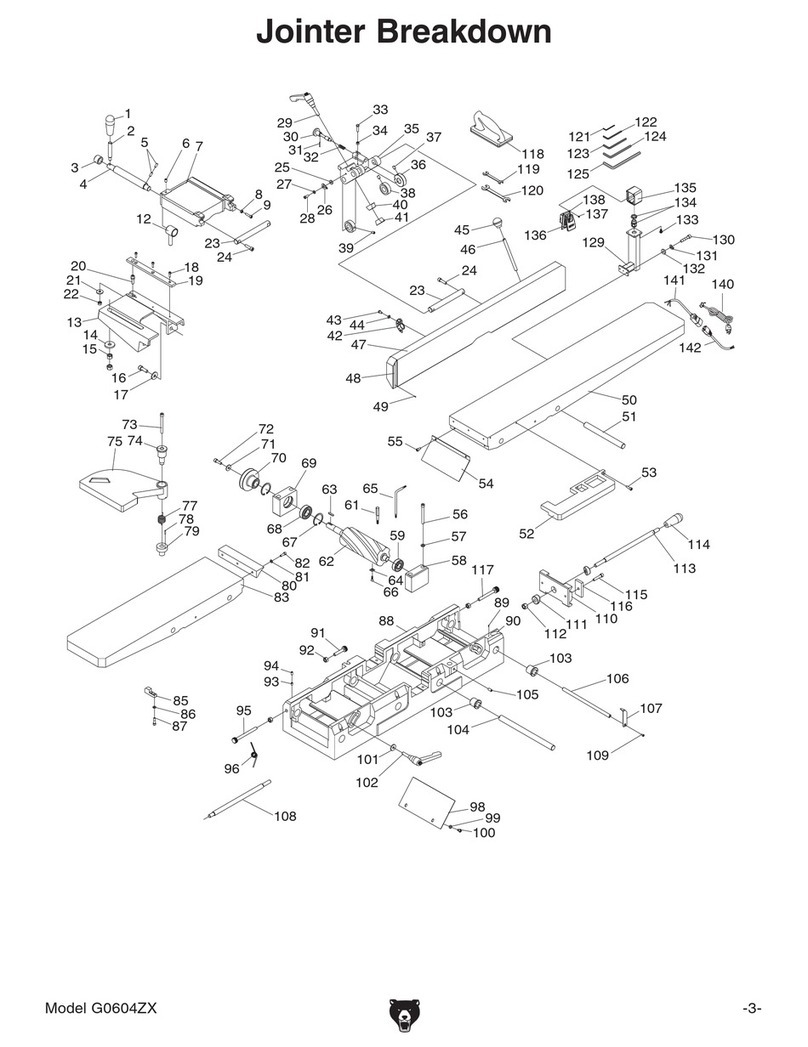

IMPACT WRENCH PARTS SCHEMATIC