5

6.1. Servicing the LW-351

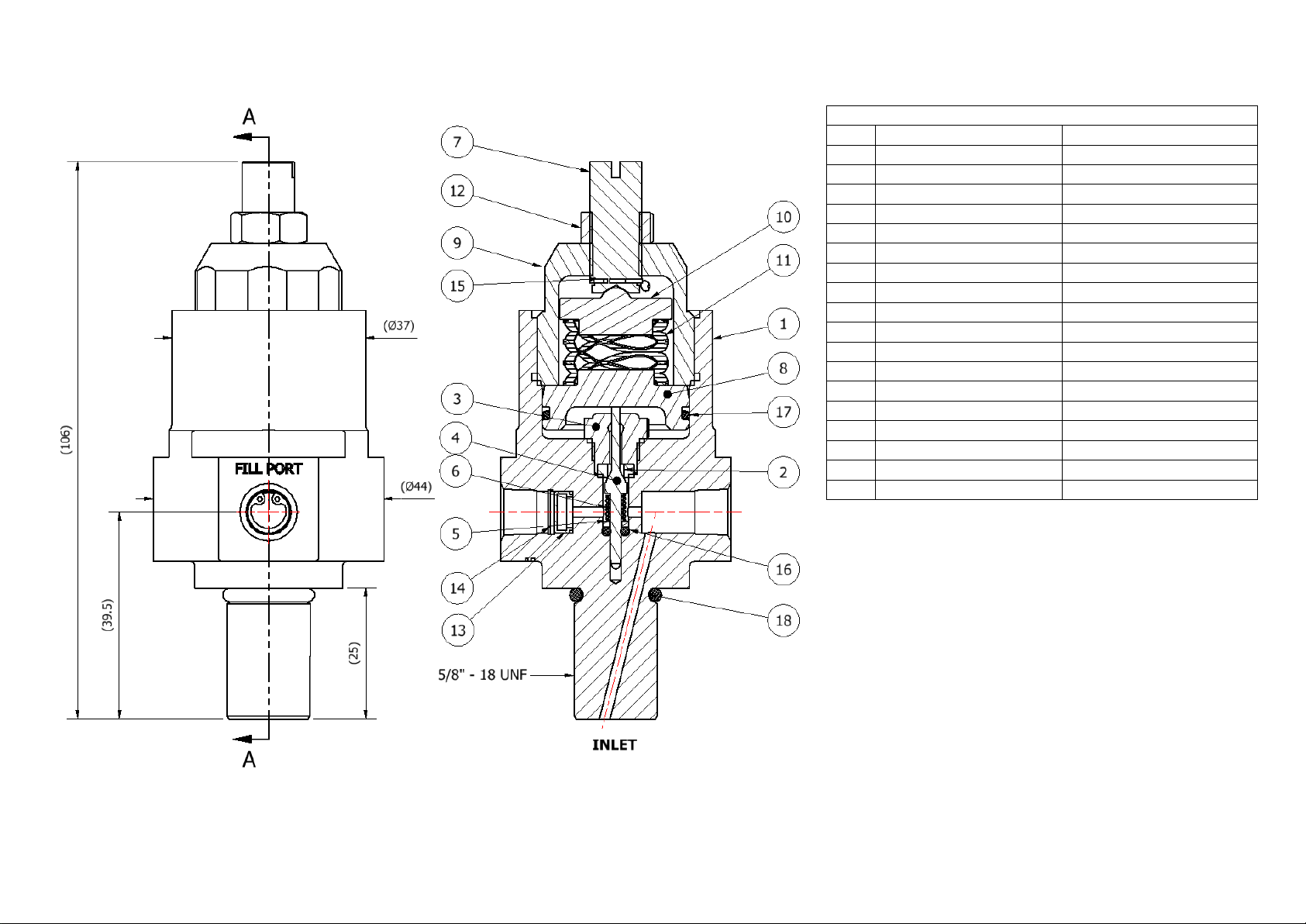

*Note: fig 1 should be used as a reference for the following set of instructions

6.1.1. Accessing the Main Valve Assembly

To access the Main Valve Assembly (MVA):

i. With the flats of the Regulator Body (1) secured in a vice, ensuring that the

Adjusting Screw (7) is fully wound anti-clockwise (*Ref. 6.1.2), loosen and

remove the Bonnet Assembly (7, 9, 12, 15) using a 27mm wrench

ii. Remove the Upper Spring Rest (10) and Load Spring (11)

iii. Using needle nosed pliers, remove the sensor assembly (8,17)

iv. The Solid Disk Seat (3) and Soft Seat (2) can then be removed using a 12mm

socket.

v. Visually inspect the Solid Disk Seat (3) and soft seat (2) for any potential damage

under a microscope

*Note: As the seat is a compression fit, it is likely that the soft seat will be secure

in the Solid Disk Seat. As such it is always recommended to replace both the

parts during service, where necessary.

vi. Remove the Main Valve (4) and Main Valve Spring (6) from the regulator body (1)

vii. Visually inspect the Main Valve (4) for any potential damage under a microscope

viii. Remove and replace the main valve O-Ring (16)

ix. Replace the Main Valve Spring (6) and Main Valve (4) and place into the

Regulator Body (1)

x. Guide the Solid Disk Seat (3) and Soft Seat (2), over the stem of the Main Valve

(4) taking care not to damage its sealing face against the tip of the valve.

xi. Screw the Solid Disk Seat (3) into the regulator body (1) and tighten to 4.5Nm,

using a 12mm socket

xii. Replace the O-ring (17) from around the sensor (8), then place the sensor

assembly (8,17), into the Regulator Body (1)

xiii. Position the Load Spring (11) around the top of sensor (8) and place the Upper

Spring Rest (10) on the to the assembly

xiv. Screw the Bonnet assembly (7, 9, 12, 15) into the Regulator Body (1) and using a

torque wrench with a 27mm open ended attachment, tighten to 15Nm

It is recommended that all parts in the repair kits are used. Any defect parts removed during

the service should be disposed of. Parts should be kept clean in line with media

requirements. Following re-assembly of the regulator, pressure tests should be made to

both the inlet and outlet side of the regulator, to ensure there is no internal or external

leakage across the regulator.

To ensure that the main valve assembly has been correctly and effectively installed it may

be required to perform the appropriate seat leak test as per ANSI/FCI 70-2.