Pressure Tech Turret Series User manual

PressureTech Turret Series

High Pressure Coolant Pumps

Models: EU-1000, EU-1000-2

PressureTech

Perfection Under Pressure

New England Tool Corp.

161 Sanrico Drive

Manchester, CT 06042

MAINTENANCE MANUAL

EU-1000-2

EU-1000

Table of Contents

Safety Instructions ................................................................................................. pg. 3

Operation ................................................................................................. pg. 4

Maintenance Schedule ................................................................................................. pg. 6

Electrical Diagram ................................................................................................. pg. 7

Sheet Metal Assembly ................................................................................................. pg. 8

Motor Assembly ................................................................................................. pg. 10

Valve Assembly ................................................................................................. pg. 11

Left Filter Assembly ................................................................................................. pg. 12

Right Filter Assembly ................................................................................................. pg. 13

Maintenance Manual for EU-1000 & EU-1000-2

• Make sure electrical power is disconnected before servicing pressure pump or electrical

cabinet.

• Do not move high pressure pump while it is powered on.

• For maintenance purposes, only use parts provided or recommended by PressureTech and

New England Tool Corporation.

• In case of emergency press the E-STOP (Emergency Stop) button on the CNC machine and

disconnect power by shutting OFF the main circuit breaker (CBI) on the high pressure pump.

• Allow only qualified personnel to handle and service your high pressure pump system.

• Make sure high pressure pump is not making any erratic (unusual) noise during operation, and

inspect for any signs of leakage around pump area.

• lnspect hydraulic hoses for tightness and leaks. Make sure that the filter vessel cover is latched

and secure.

• Take extra precaution if you run high pressure pump and machine unatended. Fire hazard may

exist during operation of the machine and pump. This is especially true if you are in the process

of machining materials such as Magnesium, Titanium, etc.

• We recommend installing a fire suppression system inside the machine, especially if the

machine is running unattended.

• Your high pressure pump system is not provided with a coolant flow switch. The system relies

on the machines coolant level alarm to ensure pump is not running dry without coolant oil or

fluid.

• Always ensure that there is enough oil in the machine, oil reservoir and high pressure pump

filter vessel. Refill the oil tank as necessary.

• Prevent oil or water from coming into contact with electrical equipment.

• Under no circumstances should you ever come into contact with high pressure coolant streams.

• Never install shut-off valves between the pump and discharge pressure regulator, or in the

regulator bypass line.

SAFETY INSTRUCTIONS

Page 3Maintenance Manual for EU-1000 & EU-1000-2

FILTER SYSTEM START-UP PROCEDURE

Prior to turning on the flow to the inlet service, please make the following checks:

1. Check inside filter unit to be sure basket and filter bag (if applicable) are in housing and do not require

cleaning or replacement. If necessary install a clean filter basket and bag (if applicable).

2. Check that filter unit cover is securely fastened to housing. You are now ready to open the flow to the inlet

service line. Slowly open the inlet service line approximately 25% of normal operational flow (open slowly

so as not to displace filter bag inside the housing). After filter unit is pressurized and vented, slowly open

outlet service line unit valve until completely open. Complete opening of inlet service line until desired flow

rate is reached.

Once the desired service flow has been established, the filter will operate efficiently until dirty. However,

under no circumstances should more than 5 PSI differential pressure through the filter be obtained.

Operating the filter unit with a high differential may cause filter bags to rupture and/or cause damage to filter

system and downstream equipment.

To prevent excessive drop through the filter unit, regular inspection of the filter media is required. Monitoring

of differential pressure through the housing can be utilized as a means of determining whether or not the

filter media needs cleaning or replacement.

MAINTENANCE

When it becomes necessary to clean or replace filter media, follow the procedure outlined below:

1. First close the flow from the inlet service line.

2. Close the flow to the outlet service line. (In some applications closing flow to outlet is not required.)

3. Relieve the pressure from the filter unit.

OPERATION

WARNING

CONTENTS UNDER PRESSURE

Relieve Pressure in accordance

with Manufacturer’s instructions

before opening the Filter Vessel.

FAILURE TO DO SO MAY RESULT

IN SERIOUS BODILY INJURY.

Page 4Maintenance Manual for EU-1000 & EU-1000-2

4. Drain housing sufficiently to access filter basket.

5. Remove cover by loosening the T-bolt clamp sufficiently to allow removal of the clamp assembly.

6. Remove filter basket and clean thoroughly, remove the filter bag (if applicable) and throw away. (Cleaning

and reusing the filter bag is not recommended.)

7. Remove debris and sludge from inside the inlet portion of housing to avoid interference with flow of fluid

being filtered.

8. Install clean filter basket and filter bag (if applicable). Place the basket into the filter housing,

make sure the basket flange is firmly seated onto the step on the inside of the housing. Insert

bag into the bag basket making sure filter bag ring is firmly seated against the top of the basket

flange. For best results, be sure filter bag is installed fully extended to the bottom of the basket.

9. Inspect cover gasket for cuts or other signs of failure and make sure it is properly seated. Your

PressureTech Turret Series unit is now ready for operation. Refer to filter system

start-up procedure.

SPARE PARTS (FOR MAINTENANCE)

Your PressureTech Turret Series unit will give you many years of reliable service provided periodic

inspections are made of various components and replacement of worn parts are made promptly.

The following is meant to be a recommended spare parts list, these parts are illustrated on the

following page.

KE5K12S

KE15K12S

B-6493

8LCOCG

5 MICRON BAG (TALL)

15 MICRON BAG (TALL)

FILTER VESSEL BASKET

GASKET FOR FILTER VESSEL

PART # DESCRIPTION

Page 5

Maintenance Manual for EU-1000 & EU-1000-2

DAILY

Check the pressure difference between input and output gauges on the filter body (part # 610027).

Pressure difference should not be greater than 5 PSI while the unit is in operation, anything over

this indicates the bag may need to be replaced. UNDER NO CIRCUMSTANCES should the output

gauge should read negative pressure (vacuum) as that condition might cause pump to fail. A

pressure difference or negative pressure is a sign that the filter bag needs to be changed. Always

use 5 micron bag filter, a less fine filter will let unwanted particles pass through and possibly

damage the pump. Make sure to clean the filter vessel completely before installing a new filter

bag. When putting the new filter bag in, make sure that it is seated all the way down and that the

filter ring makes tight contact with the vessel gasket. Make sure that the vessel lid is latched

properly. Open the bleed valve on the top of the filter vessel (part # 610016). Do not start the

pump unless the filter vessel is full of oil and there is a solid stream of coolant coming out of the

bleeder line through the provided 1/4’’ clear hose (this line returns to the machines oil tank). This

will purge air pockets in the hydraulic system.

WEEKLY

Clean the machines main coolant tank by removing all chips and debris. A dirty holding tank will

cause the filter to clog prematurely. The weekly maintenance schedule is a recommendation and

may vary from application to application. When cutting aluminum you may find that the filter bag

clogs faster than when cutting stainless steel. Also, three shifts of operation a day vs one, may

require additional attention and frequency of maintenance.

SPECIAL NOTES

• During pump operation, make sure that oil based coolant does not create a lot of foam.

Contact your coolant supply company to get an additive that prevents foaming. Check and fill

the machine reservoir as needed.

• When turning the unit on frequently in your program (more than 3 times per minute)

change your program so that you alternate the line being used with an interval of at least 2

seconds between. This will keep the pump running constantly. Frequent starting and stopping

puts unnecessary load on the unit.

• Pay extra attention to the level of oil in the pump head. Running the pump unit with no hydraulic

oil will cause the pump to fail.

MAINTENANCE SCHEDULE

Page 6

Maintenance Manual for EU-1000 & EU-1000-2

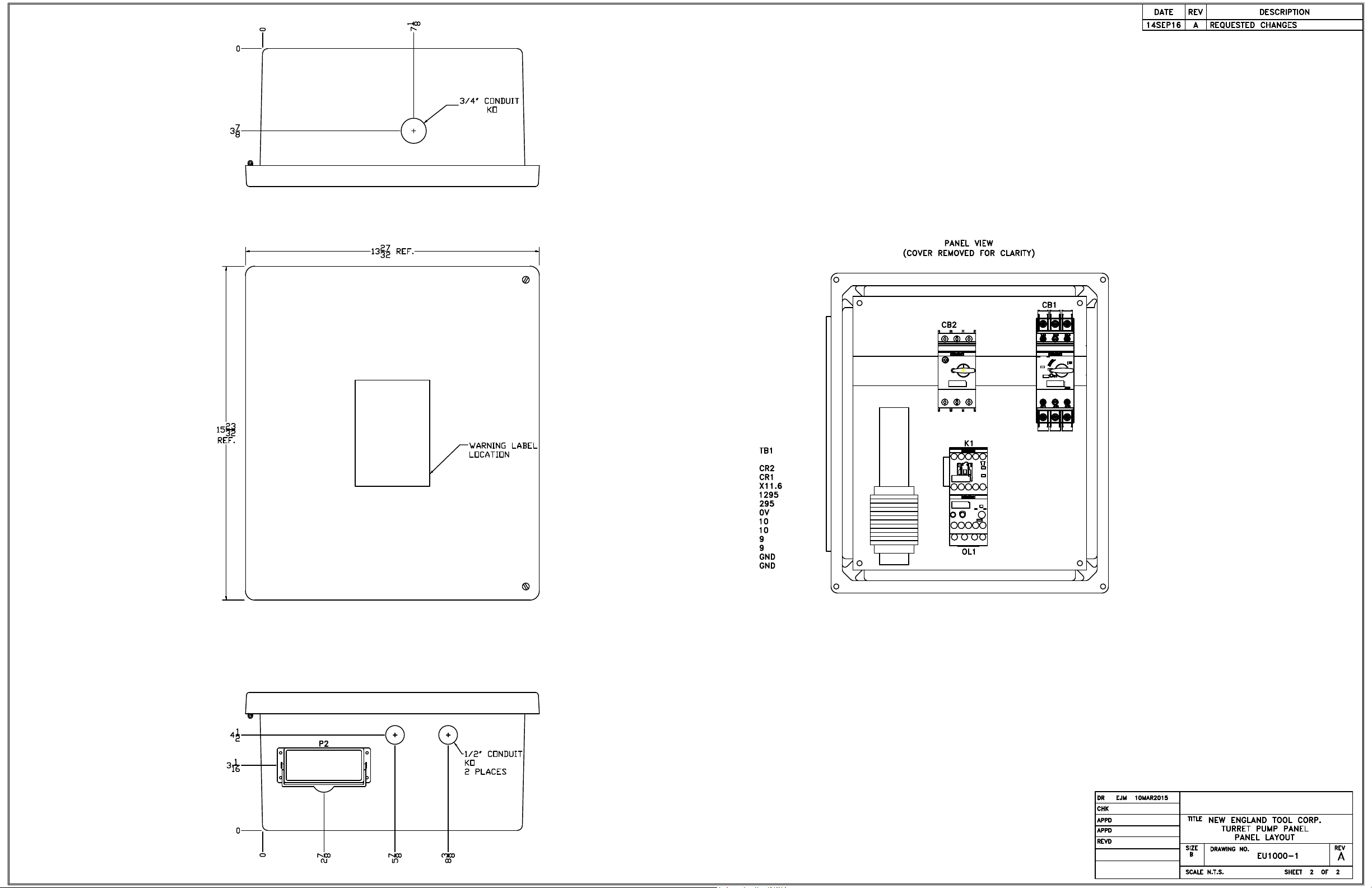

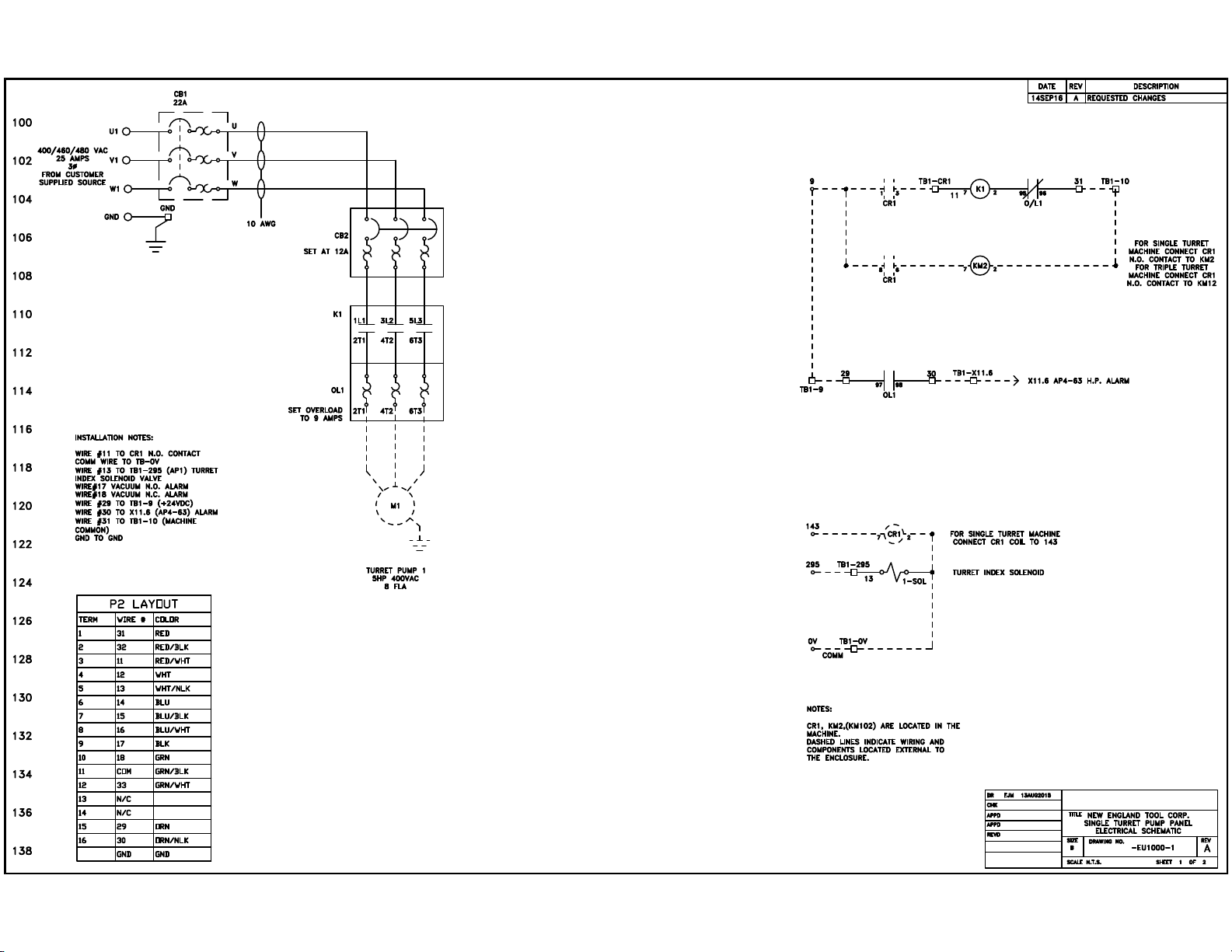

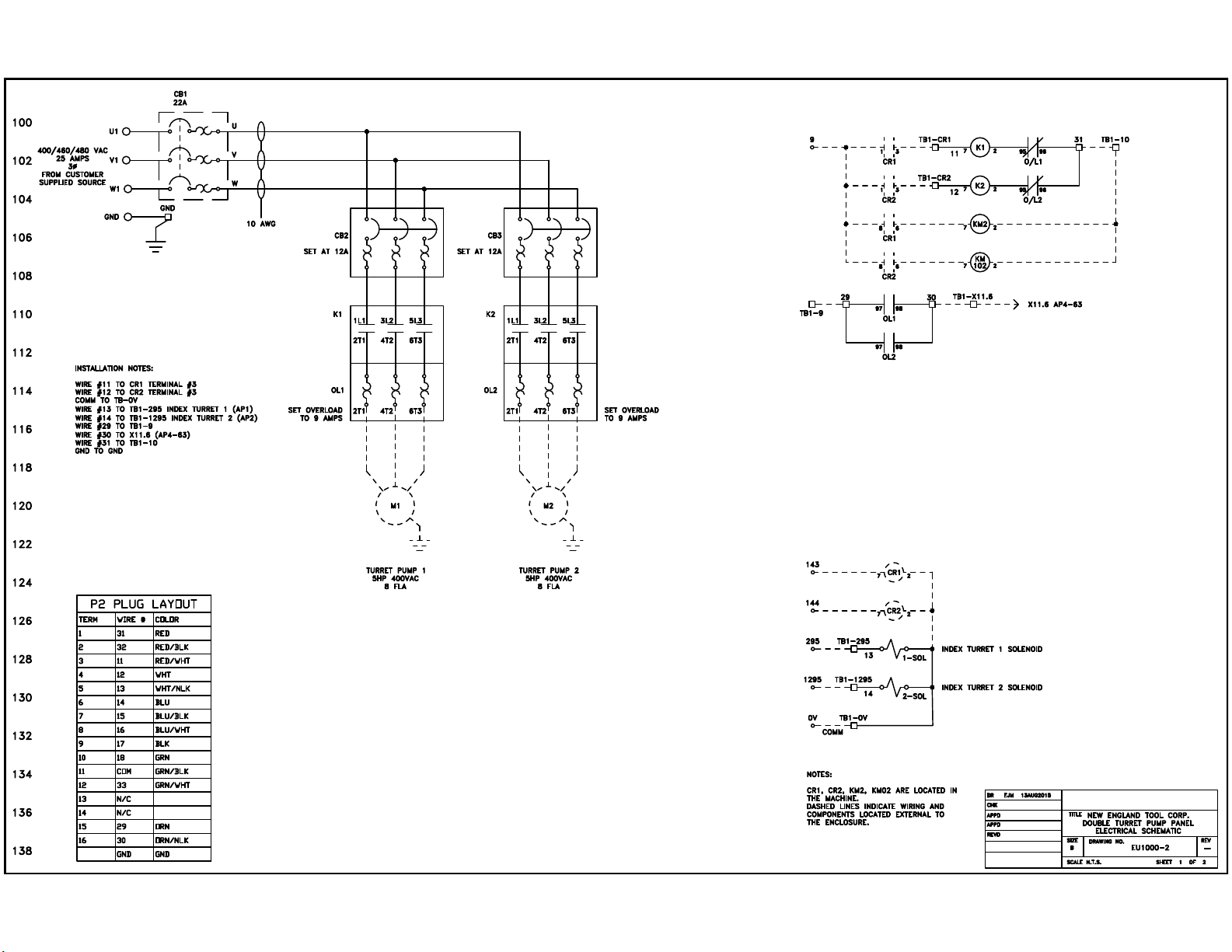

ELECTRICAL DIAGRAM

PART NUMBER

300007

300113

300063

300015

PT-CABLE-16-V1

990012

DESCRIPTION

MAIN DISCONNECT SWITCH

CONTACTOR AC-3 16 A, 7.5 kW / 400V 1 NO, 24V DC

O.L. RELAY

MTR PROT. CB COMBINATION

20' LONG SIGNAL CABLE

ELECTRICAL BOX

Page 7

Maintenance Manual for EU-1000 & EU-1000-2

***Please See Appendix***

QUANTITY

1

1

1

1

1

1

QUANTITY

1

1

1

1

1

ITEM #

1

2

3

4

5

PART #

EU-1000_920001-1

EU-1000_920001-2

EU-1000-920001-3

EU-1000-940004

EU-1000-920001-5

DESCRIPTION

BASE PLATE

TOP BASE PLATE

BLANK SIDE COVER

FRONT COVER

PUMP FILL COVER

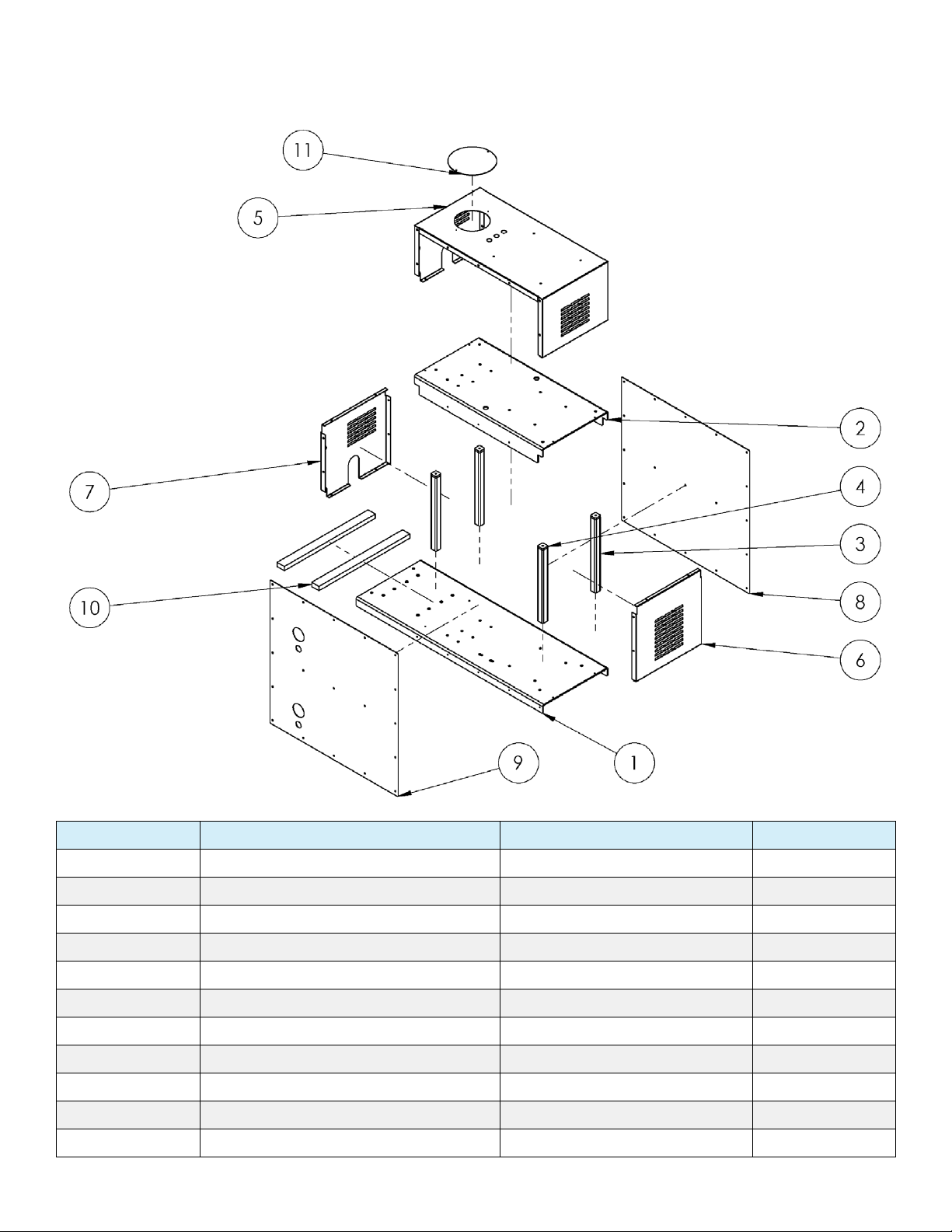

SHEET METAL ASSEMBLY

Page 8

Maintenance Manual for EU-1000 & EU-1000-2

QUANTITY

1

1

4

4

1

1

1

1

1

2

1

ITEM #

1

2

3

4

5

6

7

8

9

10

11

PART #

EU-1000-2_501_BASE

EU-1000-2_501B_TOP_BASE

EU-1000-2_507_UPRIGHT

EU-1000-2_508_UPRIGHT-END5

EU-1000-2_503_BODY

EU-1000-2_510-BOTTOM-RIGHT-PANEL

EU-1000-2_511-BOTTOM-LEFT-PANEL

EU-1000-2_516_REAR_PANEL

EU-1000-2_515_FRONT_PANEL

FILTER SUPPORT

EU-1000-2_517_FILLCOVER

DESCRIPTION

BASE PLATE

TOP BASE PLATE

VERTICAL SUPPORT

VERTICAL SUPPORT CAP

TOP WRAP AROUND COVER

FRONT COVER

REAR COVER

BLANK SIDE COVER

HYDRAULIC SIDE COVER

FILTER SUPPORT BRACKET

PUMP FILL COVER

SHEET METAL ASSEMBLY

Page 9

Maintenance Manual for EU-1000 & EU-1000-2

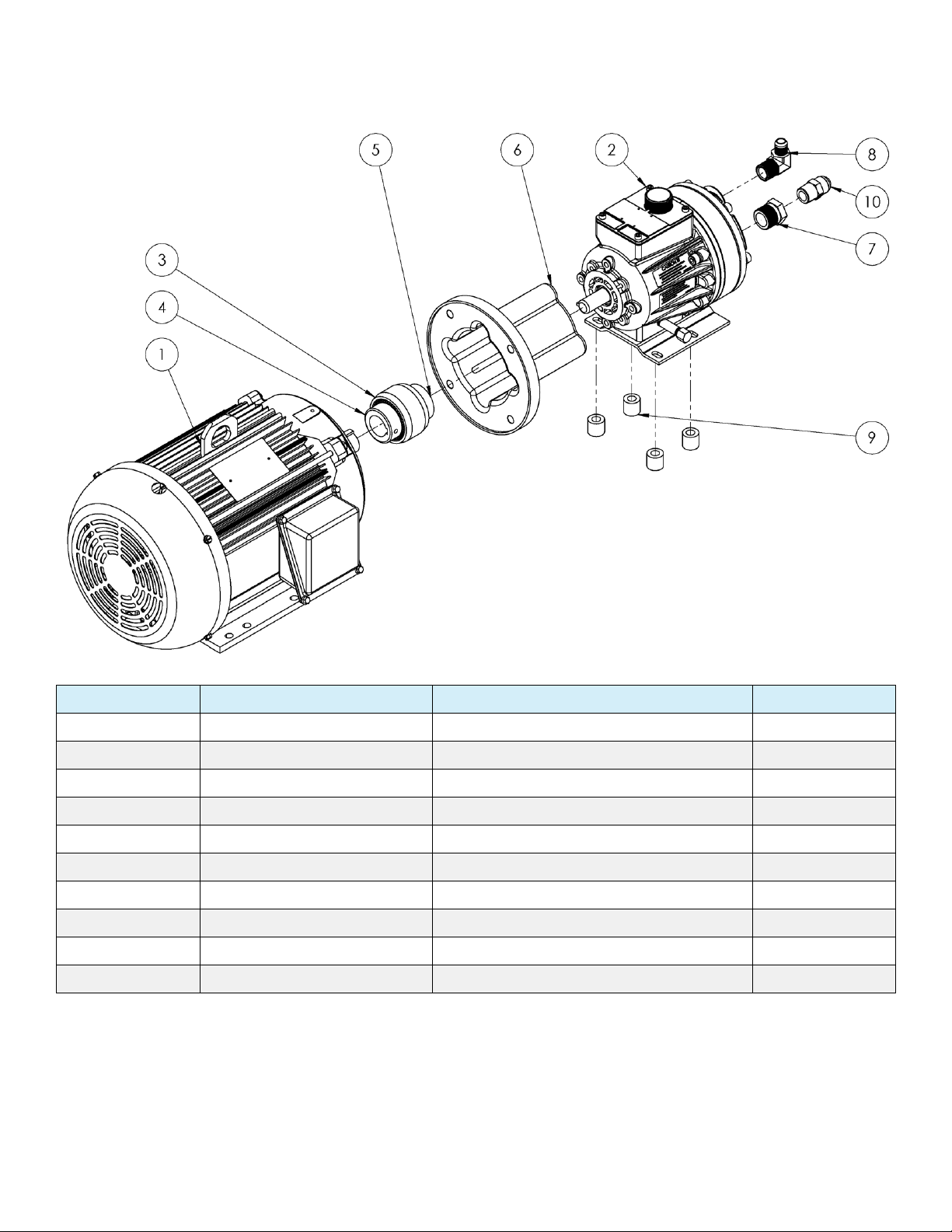

QUANTITY

1

1

1

1

1

1

1

1

4

1

ITEM #

1

2

3

4

5

6

7

8

9

10

PART #

520002

530002

520003-1

520003-2

520003-3

530001

610026

620006

NJ FILTER SPACER

620072

DESCRIPTION

5 HP MOTOR, 1150 RPM, 6 POLE

8.8 GPM DIAPHRAM PUMP

BOWEX M-38 COUPLING

BOWEX MOTOR GEAR

BOWEX PUMP GEAR

MOTOR PUMP ADAPTER

1" MALE X .75" FEMALE BRASS BUSHING

3/4" MPT X 1/2" MJIC BRASS ELBOW

SPACER FOR MOTOR

3/4" MPT X 3/4" MJIC STRAIGHT

MOTOR ASSEMBLY

Page 10

Maintenance Manual for EU-1000 & EU-1000-2

QUANTITY

1

1

1

1

1

1

1

2

2

1

1

ITEM #

1

2

3

4

5

6

7

8

9

10

11

PART #

610020

510007

710001

630070

880001

880002

1X1080002

610008

610007

630067

610011

DESCRIPTION

PRESSURE GAUGE

MANIFOLD BLOCK

PRESSURE RELIEF VALVE

1/2 NPT X 6" PIPE NIPPLE

SOLENOID VALVE

24VDC SOLENOID VALVE COIL

24VDC SOLENOID ELECTRICAL CABLE

1/2" O'RING MALE X 1/2" JIC MALE ELBOW

3/8" MNPT PLUG

1/2" FNPT ELBOW

1/2" NPT MALE X 3/4 BRASS BARB

VALVE MANIFOLD ASSEMBLY

Page 11

Maintenance Manual for EU-1000 & EU-1000-2

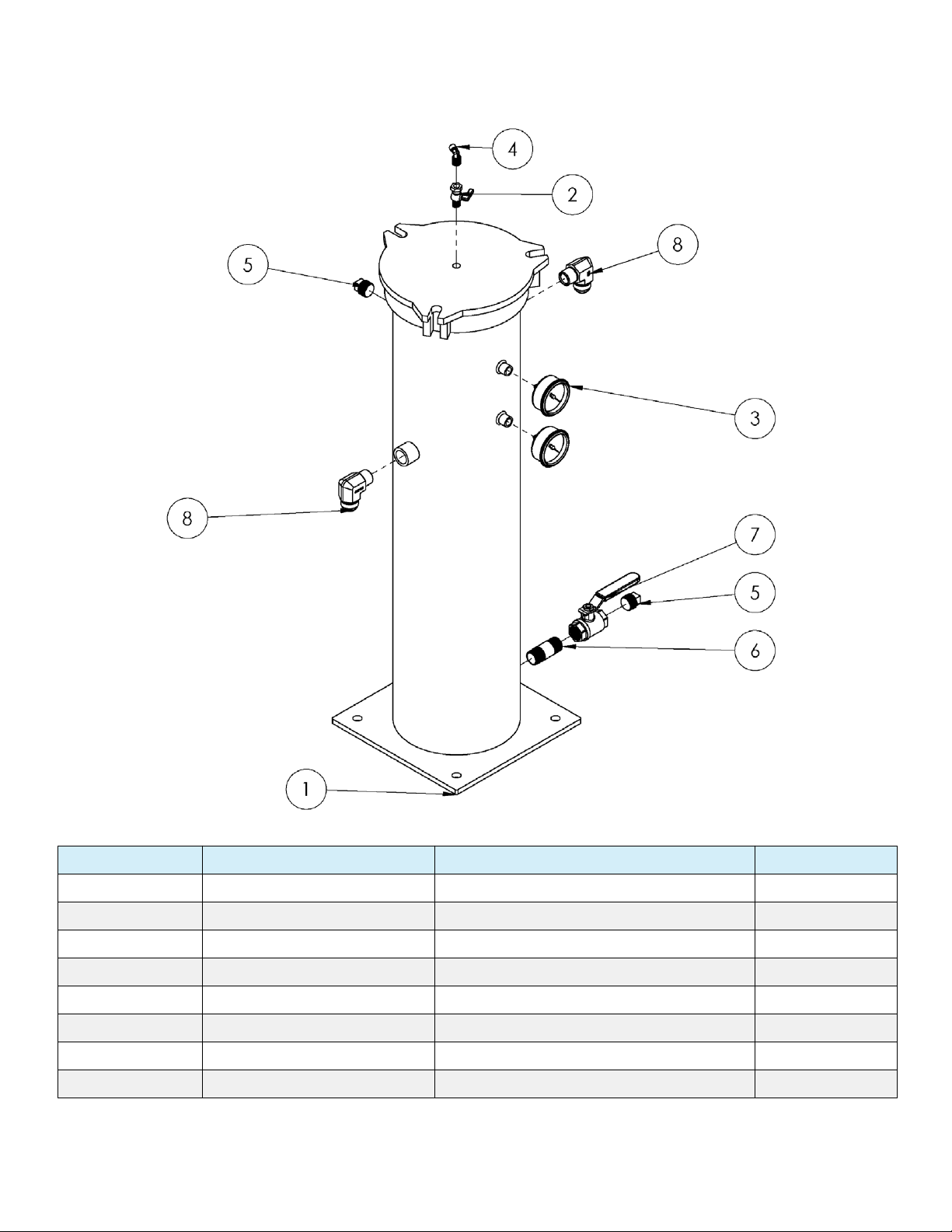

QUANTITY

1

1

2

1

2

1

2

1

1

ITEM #

1

2

3

4

5

6

7

8

9

PART #

510005

610016

610027

610015

610034

610018

620066

610003

620004

DESCRIPTION

FILTER VESSEL

SHUTOFF VALVE

PRESSURE GAUGE

1/4" HOSE COMPRESSION ELBOW

3/4" MNPT PLUG

BRASS BALL VALVE, 3/4" FNPT

3/4" MNPT X 3/4" MJIC ELBOW

3/4" NPT STREET ELBOW

3/4" X 5" PIPE NIPPLE

LEFT FILTER ASSEMBLY

Page 12Maintenance Manual for EU-1000 & EU-1000-2

QUANTITY

1

1

2

1

2

1

1

2

ITEM #

1

2

3

4

5

6

7

8

PART #

510005

610016

610027

610015

610034

610004

610018

620066

DESCRIPTION

FILTER VESSEL

SHUTOFF VALVE

PRESSURE GAUGE

1/4" HOSE COMPRESSION ELBOW

3/4" MNPT PLUG

BLACK STEEL PIPE NIPPLE, 3/4" X 2-1/2"

BRASS BALL VALVE, 3/4" FNPT

3/4" MNPT X 3/4" MJIC ELBOW

RIGHT FILTER ASSEMBLY

Page 13

Maintenance Manual for EU-1000 & EU-1000-2

New England Tool Corp.

161 Sanrico Drive

Manchester, CT 06042

tel.: 860-783-5555

fax: 860-783-5552

www.PressureTechSystems.com

This manual suits for next models

2

Table of contents

Other Pressure Tech Water Pump manuals