Primal RC Raminator User manual

1/5 SCALE RAMINATOR MONSTER TRUCK

INSTRUCTION MANUAL

WWW.PRIMALRC.COM

Table of Contents

01

01

11-12

Assembly

13

14-18

19-21

21-25

25-27

28-32

33

34-36

36

37

38

02

02

39-41

41-43

43-44

44-49

Differential

Front Axle

Rear Axle

Transmission

Engine

Chassis

Fuel Tank

Receiver Box

Main Sway Bar

Linkage

Axle

Shock

Sway Bar Link

Tire

Roll Cage

Body

1/5th RAMINATOR MONSTER TRUCK

50-51

Parts List

03

04

04

05

06

07

Safety Guidelines

Terms of Use

Safety is Your Responsibility

Gas Engine Use Warning

Assembly Instructions

Wiring Diagram

Remote Engine Killswitch & Fail-Safe

Radio Details

Before You Drive

Running Your Truck

After you Drive

Choke Removal Instructions

07

08

Steering Servo Saver Adjustments 08

Troubleshooting Guide

09

Transmission Gears Adjustment 10

Brake Adjustments

Pg.

This product is sold by Primal RC with the understanding that the buyer accepts full responsibility for all actions associated with its use. Serious injury,

property damage, or death can result from driving the monster truck or using any of the included accessories in an unsafe or irresponsible way. The

buyer assumes all liability with this product including any actions that occur due to a failure to follow its safety and operating instructions resulting in

unsafe or improper use or any action that violates the pertinent laws and regulations. Primal RC, and all the Primal RC dealers, will not be held

accountable under any circumstances with the use of this product resulting in property damage, personal injury, or death. This includes any willful or

unintentional damages that may arise out of the assembly or use of the product or its accessories. The user accepts all liability by the act of using and

operating the truck and releases Primal RC, and all Primal RC dealers of any and all liability associated with its use. Primal RC requests that you do not

use this product if you as a user do not accept liability of ownership. If you don’t accept liability, please do not open any of the enclosed accessories, do

not attempt to start it, and contact us to make arrangements to return the product. Used vehicles cannot be accepted for returns or exchanges under

any circumstances. The material included in this manual can be changed without notice. Primal RC reserves the right to make improvements to the

products with no commitment to integrate those improvements into products sold previously. The manual is subject to change at the discretion of Primal

RC. For the latest version of the manual please visit www.PrimalRC.com.

If you have any questions regarding this Terms of Use, stop and do not go any further. Do not run your vehicle and contact Primal RC at

Terms of Use

Thank you for purchasing the Primal RC 1/5 Scale Monster Truck.

This manual contains the instructions you need to operate and

maintain your truck. It is very important that you take the time to read

and understand the instructions and radio manual. Make sure you read

and follow the precautions and warnings in the Safety Guidelines

section. These guidelines will educate you on how to run your truck

safely and maximize its longevity and performance.

This truck requires advanced R/C user experience and expertise. You

must be 18 years of age or older to operate this vehicle. Even if you

are an experienced R/C driver, it is important to read and follow the

safety guidelines in this manual.

If you have any questions regarding this vehicle or this manual: Stop.

Do not use this vehicle and contact us at [email protected].

Thank you again for your purchase and we look forward to exceeding

your expectations.

Safety Guidelines

WARNING – RISK OF FIRE, INJURY OR DEATH

The truck is not a toy. The truck requires an advanced set of skills and is not

intended for use by children or minors under the age of 18. The truck is

intended to be purchased and operated by competent, adult R/C users

possessing qualified skills and experienced driving ability. The user of this

vehicle should be practical, mature, intelligent and display good common

sense.

Caution must be taken to ensure the safety of yourself and others around you.

This truck is very large and is capable of high speed and quick acceleration.

Collisions of a critical nature (injury, death, severe property damage) can

result if the truck is operated in a careless or unsafe manner. Always take

great care to make sure all systems are working properly before operating.

The user must be aware of their limits and abilities. Make certain to have

adequate space where the truck can be run safely.

The truck requires the use of 2-stroke gasoline for its engine. Gas engines

and 2-stroke gasoline have a very high risk of fire and injury if they are

handled improperly. The truck comes equipped with a NI-MH receiver battery.

Please read and understand the proper procedures for charging the battery.

The user must read and understand all the included instructions regarding the

proper operation, maintenance and safety precautions in using a 2-cycle gas

engine and charging batteries.

Instruction Videos Available at

PrimalRC.com/Video/TruckInstructions

1

52

1/5th RAMINATOR MONSTER TRUCK

Safety is Your Responsibility

•Your radio system may be subject to radio interference from many sources that are out of your control. Please be aware that

radio interference may cause a temporary loss of control. Allow adequate space in all directions when running your truck to

prevent collisions if radio interference should occur.

Test the range of your transmitter in the area you are driving. Make sure not to drive too far and go out of range.

After testing the range, start by driving slowly in the area to make sure there is no interference that can cause temporary losses

of control.

Always test the failsafe system every time before use to ensure it’s working properly (instructions are in the radio manual).

Use new or freshly charged batteries in order to boost signal output power and range.

The motor and exhaust become hot during use. Be careful not to touch them while hot to avoid getting burned.

Drive in the proper area. This product is not designed to be used in heavy traffic areas where its operation would cause

pedestrian and vehicle interruptions. This is recommended to prevent collisions causing property damage, injury, or death.

Try to always bring a friend while driving. Another set of eyes is helpful to identify potential hazards such as an animal or person

crossing in the driving path.

Always have a clear view of the model when driving. Do not drive at night or when your vision may be blocked in any way.

Don’t drive the model too close to you, other persons, or property where collisions may occur. Allow a comfortable amount of

space to maneuver the truck.

Be sure to check over the truck after each driving session. Check for damage or any loose parts and correct any issues right

away before using again. Make sure to check and tighten the wheel nuts before each session.

Do not pick up the truck by its wheels or tires. Keep your hands free and clear of any moving parts when the electronics are

turned on. Gravel, dirt, sticks, and other debris can be kicked up from the rear wheels during aggressive starts. Avoid standing

directly behind the truck and make sure other watchers are at a safe distance to avoid being hit. Eye protection is always

recommended.

Avoid making changes not shown or suggested in the instruction manual. You can cause damage to the model and injury to

yourself or others if the product is altered in a way not intended.

Remember: SAFETY FIRST. Create a safe environment to run the truck and use good common sense. This will ensure

maximal enjoyment while using the truck.

Gas Engine Use Warning

•A mixture of gasoline and 2-stroke oil is used for fuel. Please use caution when handling fuel.

Keep fuel away from open flames, heating sources, direct sunlight, smoke, batteries or any ignition source. Store fuel in a well-ventilated area.

Store fuel and truck in a location children can’t access.

Keep fuel and truck away from children.

Gasoline is flammable, toxic, and can produce noxious vapors. The exhaust emitted from the truck can also produce noxious vapors. These

vapors can irritate eyes, respiration, and be dangerous to your health. Always operate the truck in a well-ventilated area.

The 2-cycle engine that comes on this truck only uses a mix of gasoline and 2-stroke oil. The oil/gas mix is how the engine is lubricated. Never

run straight gas through the engine as catastrophic damage may result. Never use glow fuels intended for R/C car use.

•

•

•

•

•

WARNING – FIRE RISK: EMPTY THE FUEL TANK BEFORE STORING THE TRUCK.

•

•

•

•

•

•

•

•

•

•

•

•

•

2

1/5th RAMINATOR MONSTER TRUCK

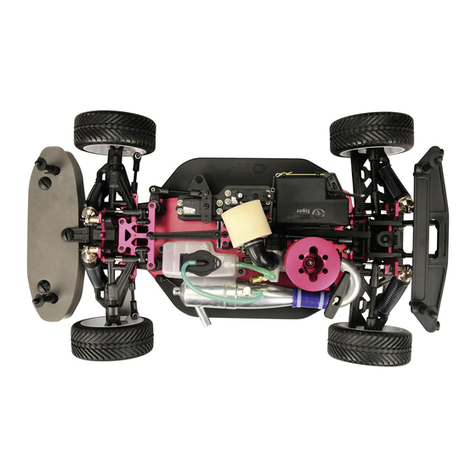

Assembly Instructions

This truck is shipped in two boxes. One box contains the main chassis with body installed, 3 sticker sheets, two wheels,

transmitter, battery, charger and accessories. The second box contains front and rear axle, brake system, two wheels and four

shocks.

Before assembling and starting your truck, read and understand all manuals and familiarize yourself with the truck completely.

If you decide this truck is not the right choice for your or you do not want to assume responsibility for your safety, then do not

attempt to assemble or start it. Do not run the vehicle at all and please contact us to make arrangements to return the vehicle.

If your vehicle arrives with damage from transit please do not run the vehicle, and contract us instead. Used vehicles cannot be

accepted for returns or exchanges under any circumstances. If you have any questions about your truck, please email us at

[email protected]. Maintenance and replacement parts may be purchased directly from www.PrimalRC.com.

If you are prepared to assemble the truck, visit our website and view the installation videos.

See instruction video on www.PrimalRC.com/Video/TruckInstructions

Then follow along the instructions provided below. If you do not feel comfortable completing the assembly below. STOP. Do not

use the truck. Contact us and we can discuss the concerns with you on the phone or by email.

This truck is intended for users that have extensive experience with gas R/C vehicles and 2-Stroke engines.

1. Position main frame and axles on a surface with enough clearance for assembly.

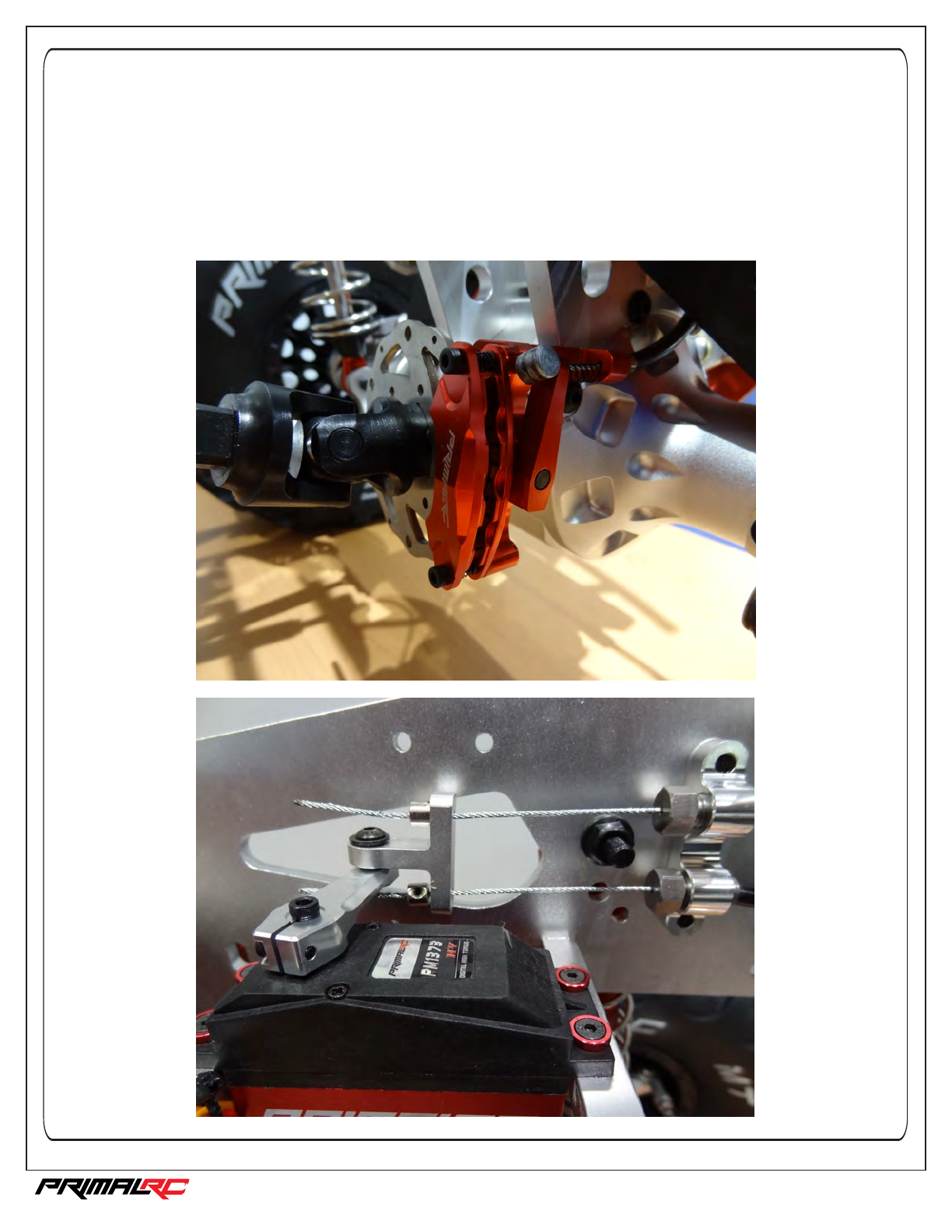

2. Install the brake rotor on the driveshaft and install the drive shaft pin through the drive shaft and pinion gear shaft.

3. Slide the drive shaft from the axle into the drive shaft coming out of the transmission. Make sure the brake rotor is installed on

the axle.

4. Attach the axle to the four links already assembled on the main chassis.

5. Install shocks on the main chassis and axles. Note: hardware is already installed on axles and chassis.

6. Connect the two servo wires to the wires coming out of the receiver box. There is no preference for left or right servos –either

servo can go into either plug.

7. Attach top sway bar links to already installed sway bar on the chassis. Then attach lower sway bar links to the axle.

8. Install the brake calipers with one pad on each side of rotor (see diagram assembly instructions #66).

Note: The two bolts that hold the brake pads to the caliper should be installed using RED lock tight at the right position.

Without lock tight, these screws will come undone very easily.

10. Install the brake cables (see diagram assembly instructions #66). Make sure to route cables as smoothly as possible for

ease of operation. Cables should not be bent sharply. Zip-tie cable in strategic location to avoid snagging during operation.

Ensure suspension can travel smoothly without pulling on brake cable. See instruction video on www.primalrc.com/video/

TruckInstructions.

11. Initial brake cable adjustment: First, ensure your throttle servo is working properly and giving full throttle to carburetor. Then

in neutral (i.e. your throttle is not being applied) slide the brake cables into the brake servo cable splitter. Adjust the stop collars

so that the breaks are about to apply as soon as you trigger the transmitter to brake position. This adjustment is something that

you will fine tune to your needs. Front and rear bias can also be adjusted at the same time.

See instruction video on www.PrimalRC.com/Video/TruckInstructions.

12. Install wheels using supplied lug wrench. The hex nuts have a serrated side, ensure it is facing the rim.

13. Remove protective body film, then install stickers on the body.

See instruction video on www.PrimalRC.com/Video/TruckInstructions.

14. Charge the battery with included charger.

15. Install batteries into transmitter.

16. Follow the instructions in the “Before You Drive”, “Running Your Truck” and “After You Drive” sections of this manual.

Note: Looking at the pictures of the truck on our website can guide you to ensure that you are assembling the truck correctly. Also

viewing the instruction videos will give you tips on how to install everything correctly and easily.

3

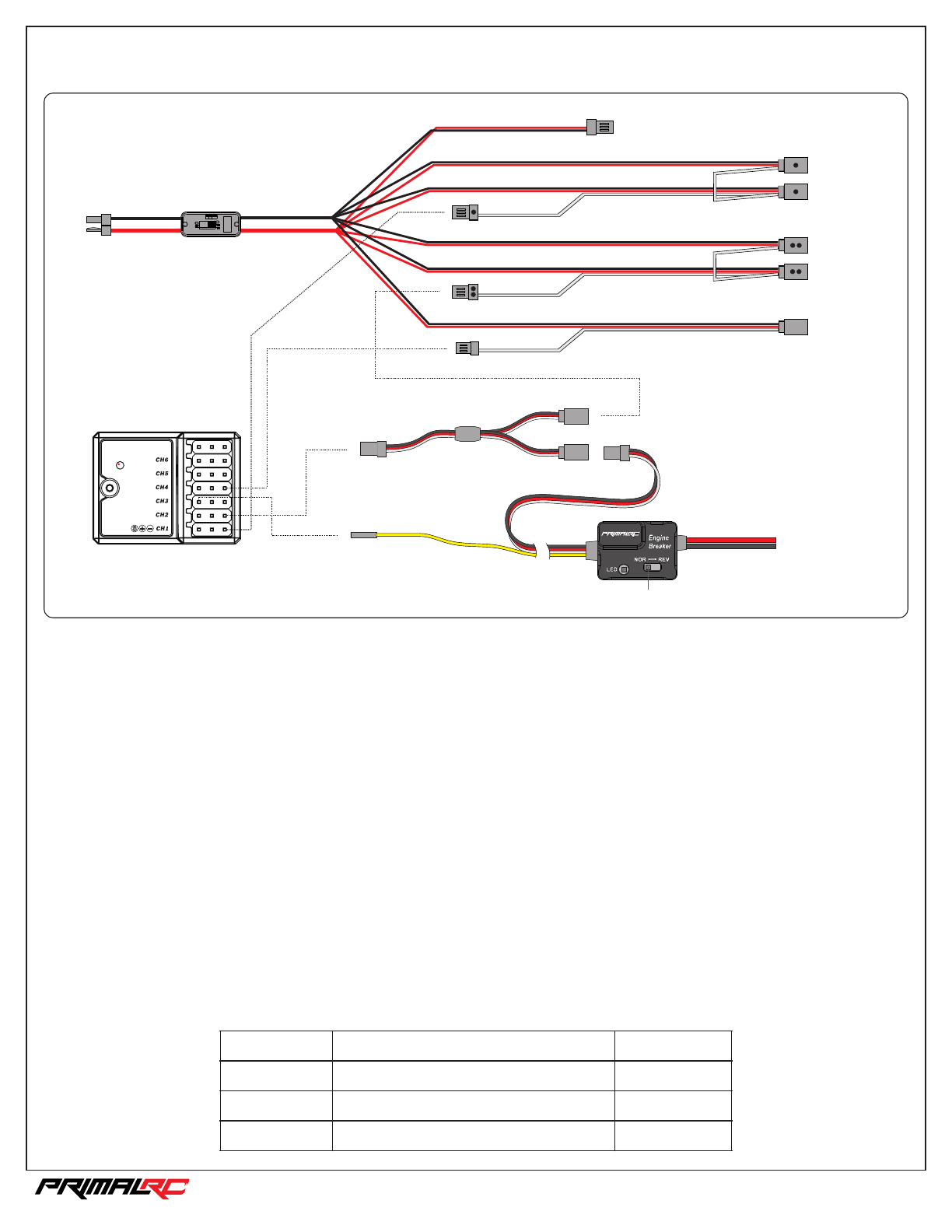

Wiring Diagram

_

+

S

_

+

S

_

+

S

_

+

S

_

+

S

_

+

S

_

+

S

_

+

S

S

+

-

CH1

CH1

CH2

CH4

CH4

Switch

T plug

To battery To receiver CH1

To Y-link

To receiver CH4

To receiver BATT.

When using extra battery for the receiver,

pull out the positive pin (Red).

VCC

Steering servo 1

Steering servo 2

Throttle servo

Brake servo

Reverse servo

Receiver

_

+

S

_

+

S

_

+

S

CH2 Y-link

To Engine Switch

CH3 S

Reverse switch

Bind/VCC

REMOTE ENGINE KILL-SWITCH & FAIL SAFE

Features

Setup

1. If receiver loses signal, the RED LED will light and engine will cut off. The fail safe will also engage the brakes to stop the vehicle.

2. The engine can manually be cut off by CH3(AUX) from the transmitter. The RED LED will flash.

3. If low battery voltage is detected the RED LED will light and engine will cut off.

LED DESCRIPTION Engine status

System Ready Can start

Cut-off

Cut-off

Low Battery Voltage or no signal

CH3(AUX) is on

DON'T start the engine yet!

Hold the throttle trigger fully to the brake position and set the brake end point adjustment (EPA) to 100%. The RED LED should light signaling

an engine cut-off. If the LED doesn't light, toggle the REVERSE SWITCH and try again. As you setup the receiver's Fail-Saf function, push the

throttle trigger to full brake. Once the Fail-Safe function is setup, return the EPA to its original setting. To verify the Fail-Safe function has been

correctly set, turn off the transmitter. The RED LED should turn on.

If everything is setup and connected correctly the GREEN LED will light up and you're ready start the engine.

The engine can be manually cut-off at any time by pressing the CH3(AUX) button. The RED LED will blink red when successful.

LED Status Display

Green

Red

Red Blinking

1/5th RAMINATOR MONSTER TRUCK

4

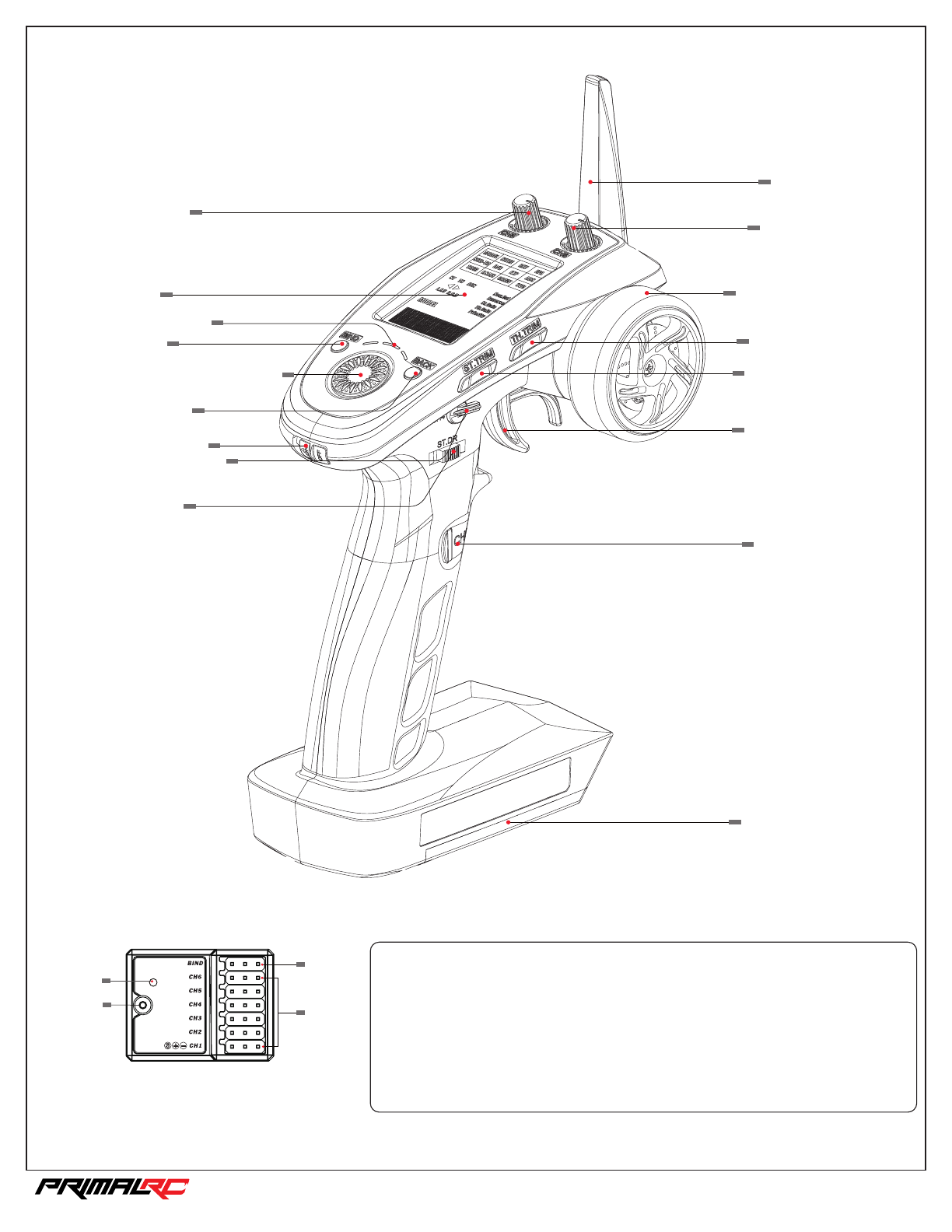

Radio Details

Bind/VCC

LED

Antenna CH 1-6

Receiver

Battery

Compartment

Engine Kill Switch

(Channel 3)

Throttle/Brake

(Channel 2)

LCD

Channel 5

LED Indicator

BIND

NaviKey

(Rotate to “Select”, press to

“Confirm”)

BACK/Exit

Power Switch

Reverse Activation

(Channel 4)

Steering

D/R

Steering Trim

(Channel 1)

Throttle Trim

(Channel 2)

Steering Wheel

(Channel 1)

Channel 6

Antenna

Transmitter

5. Check to make sure everything functions as expected. If not repeat the steps above.

4. Once binding is complete the transmitter will exit bind mode. Remove the power and

bind cable from the receiver then apply power to the B/VCC port.

3. Press and hold the transmitter’s bind key and turn on the transmitter at the same time.

2. Connect power to any other port.

1. Connect the bind cable to the receiver’s B/VCC port.

The transmitter and receiver have been pre-bound.

If you are using another transmitter or receiver, follow the steps below to bind the

transmitter and receiver:

Binding setup

1/5th RAMINATOR MONSTER TRUCK

5

1/5th RAMINATOR MONSTER TRUCK

Before You Drive

It is extremely important that you read, understand, and follow all instructions in the manuals included with this truck

in order to prevent serious damage to your truck, yourself, and your property. If the user fails to follow these

instructions, it will be considered negligence.

Before assembling and starting your truck, read and understand all manuals and familiarize yourself with the truck

completely. If you decide this truck is not the right choice for your or you do not want to assume responsibility for

your safety, then do not attempt to start it. Do not run the vehicle at all and please contact us to make arrangements

to return your vehicle.

Used vehicles cannot be accepted for returns or exchanges under any circumstances. If you have any questions

about your truck, please email us at [email protected]. Maintenance and replacement parts may be purchased

directly from www.PrimalRC.com.

Follow these steps before each drive session:

1. Mix Gas and 2-Stroke Oil

•Pump gasoline – 87 octane or higher – ethanol-free gas is highly recommended

•2-stroke oil. Amsoil Saber (recommended): Mix 25:1 ratio (gas/oil)

2. Check to make sure you have a fully charged receiver/servo battery in truck.

3. Check to make sure your transmitter batteries are good.

4. Check all servos (Steering, Throttle, Brake, Reverse).

• DON’T start your vehicle’s engine yet!

•Turn your transmitter on.

•Turn the truck’s battery switch on (located in the back of roll cage).

•Hold the trigger on the transmitter into full brake position. Confirm that the brakes prevent the truck from moving

when you try to push it. If it rolls easily adjust brakes as described in the Assembly Instructions section above.

•Test left and right steering servos by lifting the front of the truck and moving the servos via the transmitter.

Ensure the servos are moving smoothly and there is no excessive play or binding. Adjust as necessary.

•Test throttle servo by giving full throttle and ensure carburetor is moving to full throttle position.

5. Check Remote Engine Kill Switch:

• DON’T start your vehicle’s engine yet!

•Make sure the Manual Engine switch is ON (located on frame under front right wheel well).

•The Remote Engine Kill switch system is located on the truck near your receiver box and has an LED light. The

light is GREEN when it is ready to start and run. If the light is RED this means the Remote Kill switch is on and

your engine will not start. Your transmitter’s third channel button operates the Remote Kill switch.

•To test the Remote Kill switch, press the third channel button on the transmitter. The light should turn RED.

Press it again to change it back to GREEN before you run the truck.

6. Check the Radio Fail Safe: The radio system that comes with the truck has a fail safe automatically installed

ensuring that if your transmitter’s signal is not reaching your truck’s receiver the brakes will be applied

automatically. To test:

• DON’T start your vehicle’s engine yet!

•Turn your transmitter on.

•Turn the truck’s battery switch on (located in the back of roll cage).

•Turn your transmitter off.

•Your brake servo should now apply the brake on its own.

•You have now confirmed that the failsafe is working. Should the receiver lose signal from the transmitter, the

brake will automatically be applied.

•Turn your transmitter back on for normal use.

7. Go over truck to make sure there are no loose screws.

8. Check lug nuts by tightening with provided wrench. Ensure the serrated side of hex nut is facing the rim.

6

1/5th RAMINATOR MONSTER TRUCK

Running Your Truck

1. Add 2-Stroke gas and oil mix to gas tank.

2. Turn your transmitter on.

3. Turn the truck’s battery switch on (located in the back of roll cage).

4. Make sure your Manual Engine switch is set to the ON position (located on frame under front right wheel well).

5. Move choke lever to full choke position.

6. Push primer bulb several times, until you see gas going through carburetor and back into gas tank lines.

7. Pull start the engine with a steady, smooth, quick pull until you hear the first pop of the engine trying to start. This is an easy

pull start system. There is no need for aggressive, quick pulls. Do not over-extend the pull-start or your pull starter may

become damaged.

8. Flip the choke lever to off position (down). Make sure it stays in position.

9. Pull start the engine again with short, quick pulls until your engine starts.

Sometimes a little throttle input from the transmitter may be necessary to start the engine.

Be careful to not give too much gas – it may result in the engine flooding.

10. If you are running the truck for the first time, engine break-in is recommended.

The engine break-in process alternates heating and cooling the engine to allow all parts of engine to properly seat

themselves. It also allows 2-stroke oil from the incoming fuel to coat the interior parts of the engine.

Run the engine at varying speeds for periods of 3 to 10 minutes at a time. During this break-in process, never go full

throttle.

Try to stay below half throttle. Always let the engine idle for 30 seconds before turning it off. Allow the engine to cool off for

10 minutes before starting it again. Repeat this process 3 or 4 times (3 or 4 full heat cycles).

11. Reverse Driving Instructions

To drive the truck in reverse, ensure that the truck has come to a complete stop, then switch channel 4 from the

transmitter. Switch to the opposite position – it's a 3-position switch, so be sure to toggle between the furthest positions.

This will cause the servo to active the reverse function in the transmission. Test this by giving it a little gas to confirm that

reverse is engaged. You may need to toggle the switch ON and OFF again to engage if reverse is not working.

To go back to forward driving repeat the process of bringing the truck to a stop and then switching channel 4 to the

opposite position.

Note: Because of the size and weight of the truck, try to avoid steering the truck while it is not moving. This will extend the life

of your steering servos.

Note: This truck is not waterproof. Do not submerge this truck in deep water. Small puddles or shallow water should not be a

problem.

Note: If you are planning on driving this truck in excessive dirt, we recommend that you remove the installed choke.

Follow the Choke Removal Instructions in this manual. It might be more difficult to start the truck without the choke,

however, your engine will last longer because this choke system can let dirt into your engine.

Note: Using a 2S LiPo battery is possible and will provide better steering power, however, the large current will shorten the life

span of the smaller throttle and reverse servos. If you use a LiPo battery, we recommend that you upgrade the throttle and

reverse servos to high-voltage servos.

After You Drive

•Be sure to let the engine idle for 30 seconds to cool before stopping the engine.

•Press the Kill Switch button (channel 3) on your transmitter to shut the engine off.

•Turn battery switch OFF (located in the back of roll cage).

•Turn your transmitter OFF.

VERY IMPORTANT: ALWAYS turn off the truck first, then the receiver, then the transmitter in that order. If your receiver or battery switch is left

ON and your transmitter is OFF the failsafe will cause the servos to overheat and eventually burn out.

•If your truck is wet or dirty, we recommend rinsing the dirt off with a gentle stream of water and then using compressed air to

dry it off.

• Important! Lubricate joint areas and moving parts with WD40 to prevent rust and keep truck working properly for many years

to come.

(example: wheel bearings, suspension links, drive shafts, servo cables)

•Inspect the truck for loose screws, broken and missing parts. We recommend blue lock-tight for screws that are threaded into

aluminum parts that do not have nylon lock nuts.

•If you are storing your truck your truck for a month or more, we recommend draining the gas out of the tank and carburetor.

Love your truck by taking good care of it and it will love you back.

7

1/5th RAMINATOR MONSTER TRUCK

Choke Removal Instructions

•Watch the instruction video at www.PrimalRC.com/Video/TruckInstructions.

•Loosen air filter clamp and slide air filter off.

•Remove the two screws that are holding the choke system onto the carburetor. To prevent the carburetor from

falling off while you remove the screws, hold the carburetor in place.

•Remove the choke plate and lever system and reinstall the velocity stack directly onto the carburetor using the

same two screws that you removed earlier, but install 2 additional lock washers on each bolt to act as spacers

and allow for proper tightening.

•Reinstall the air filter and tighten the clamp.

Steering Servo Saver Adjustments

The steering system has both servos linked to an adjustable centralized servo saver system. This system helps

keep the servos from being damaged when force is put on the front wheels. You can adjust the sensitivity of the

system by loosening or tightening the large hex nut on the servo saver spring. Tightening the spring will allow

more control of the steering, however the servos will be more vulnerable to damage upon impact. Loosening the

spring will reduce steering control, but offer more protection for the servos. Finding the optimal ratio is a matter of

personal preference, so test different settings to find one that you prefer.

8

1/5th RAMINATOR MONSTER TRUCK

Brake Adjustments

Watch the instruction video at www.PrimalRC.com/Video/TruckInstructions.

Because the brake system is on the drive shafts, this truck can stop very quickly. If your truck is not stopping

quickly brake adjustment is necessary.

This may include changing brake pads and/or rotors, adjusting brake cable tension, and adjusting servo end

points. We recommend that you watch our detailed videos online to learn how to adjust your brakes.

9

1/5th RAMINATOR MONSTER TRUCK

Transmission Gears Adjustment

The truck uses a single-speed transmission that has five different gear ratios to choose from. The mid-range

gear set is installed in the truck out-of-the-box (spur/pinion ratio 25:25). Other gear sets that are included with

your truck change the driving and power experience. For crawling, we recommend switching to 20:30 or 23:27

ratio. We recommend 27:23 and 30:20 for optional high-performance engines with greater speeds.

The installed ratio is (25:25) is a good overall gear set that we recommend for common use.

To change the gearing in the transmission: (See diagrams #24 and #25 in this instruction manual)

•Remove the rear drive shaft from the rear output shaft of the transmission (a 4mm hex pin holds it in place).

•Remove the six screws (4mm hex) from the transmission case.

•Remove transmission cover and the two ball bearings that hold the gears on.

•Slide off the two gears and install the gear set with your preferred ratio (pinion gear on the left, spur gear on

the right which is also transmission output shaft)

Note: Ensure that the gears are greased. You can use the grease that is already in the transmission.

Note: The smaller the pinion gear, the slower the truck will drive, but the more low-speed power it will have.

•Reinstall the two bearings, the cover and the rear drive shaft to their original positions.

10

1/5th RAMINATOR MONSTER TRUCK

Troubleshooting Guide

The engine doesn’t start or is not running well

oMake sure your gas and oil are mixed properly.

Mix Gas and 2-Stroke Oil

•Pump gasoline – 87 octane or higher – ethanol-free gas is highly recommended

•2-stroke oil. Amsoil Saber (recommended)

•Mixed 25:1 ratio (gas/oil)

oFollow the instructions in this manual for “Running Your Truck”. If your truck still does not

start, try the following:

•Check to make sure your spark plug is clean and working. Remove the plug from the engine

and inspect the tip. If it is clogged, it will need to be cleaned or replaced. After the plug is

removed, check if the plug is working by:

oAttaching the wire to the top of the plug

oPlacing the tip of the plug very close to the metal of the cylinder.

oPull the pull start a few times. A spark should jump from the plug to the cylinder. If no

spark or a weak spark is observed, replace the plug, ensure the ignition coil and

flywheel are properly gapped, then check again.

oIf still no spark - you likely have a problem with the ignition coil and will need to replace

it.

•The Remote Kill Switch may not be working properly and will need to be tested.

•Check to make sure your carburetor is properly tuned. You may need to adjust the screw

slightly in either direction to find correct tuning for your carb.

•Your engine may be flooded. This can happen if you have pushed the primer bulb many

times, or pulled the pull start a lot of times.

oRemove the spark plug and allow all the fuel in the cylinder to evaporate.

•Your compression may be bad. If you have an older engine, the piston rings may need

replacement.

•Check your carb gasket, intake gasket, cylinder gasket, and crankcase gasket. Can you

hear air whooshing out of the cylinder gasket or crankcase gasket when you pull the

starter? Is air leaking in the manifold gasket behind the carb?

oA gasket leak results in a loss of compression and/or improperly mixed fuel and air. An

easy way to check for intake leaks is to spray the intake manifold and area surrounding

it with WD-40. If the idle changes after you spray the WD-40, there is an intake air leak.

oCommon areas for leaks are between the manifold and the cylinder, and between the

carb and the intake manifold. Inspect the manifold, carb gasket, and intake gasket for

cracks or other signs of damage, replace if necessary.

•Make sure your gas cap is venting properly. There should be a small hole in the plastic cap

and bladder. If it becomes blocked or clogged it can cause issues. Also check to make sure

fuel lines are connected correctly, the fuel lines aren't cut, and the fuel filter is attached.

•Make sure there is no debris (grass/dirt/etc.) clogging the pull start, air filter or engine. This

can result in the engine running too hot and becoming overheated.

11

1/5th RAMINATOR MONSTER TRUCK

Troubleshooting Guide (continued)

The servos aren’t moving in correct direction

oCheck servo reverse functions on the transmitter.

The brakes are not working, but the brake servos are moving

oAdjust cable wire to ensure that the brake is pulling properly on the calipers.

oCheck to make sure brake pads are not worn out.

oCheck that drive line axle pins and driveshaft pins are not broken.

Reverse is not working

oMake sure you stop the truck from rolling before switching to reverse.

oCheck that your idle is low. If idle is too high, The clutch may start to engage, preventing the reverse

function from working properly.

oAdjust the reverse servo cable to ensure that it is pulling enough to engage reverse properly.

oCheck that transmitter switch is on

oCheck that truck’s battery switch is on

oCheck the wire connections. Make sure they're intact and connected properly.

oCheck that your batteries are charged

oCheck to make sure your transmitter and receiver are bound.

The servos aren’t responding, or the transmitter is not connecting

oIf the idle is too low, turn the carburetor idle screw clockwise to raise idle. If the idle is too high turn it

counterclockwise until the desired idle is reached. Idling as low as possible is recommended without the

engine stalling. The clutch may start to engage, preventing the reverse function from working properly.

The engine doesn’t idle well

12

1/5th RAMINATOR MONSTER TRUCK

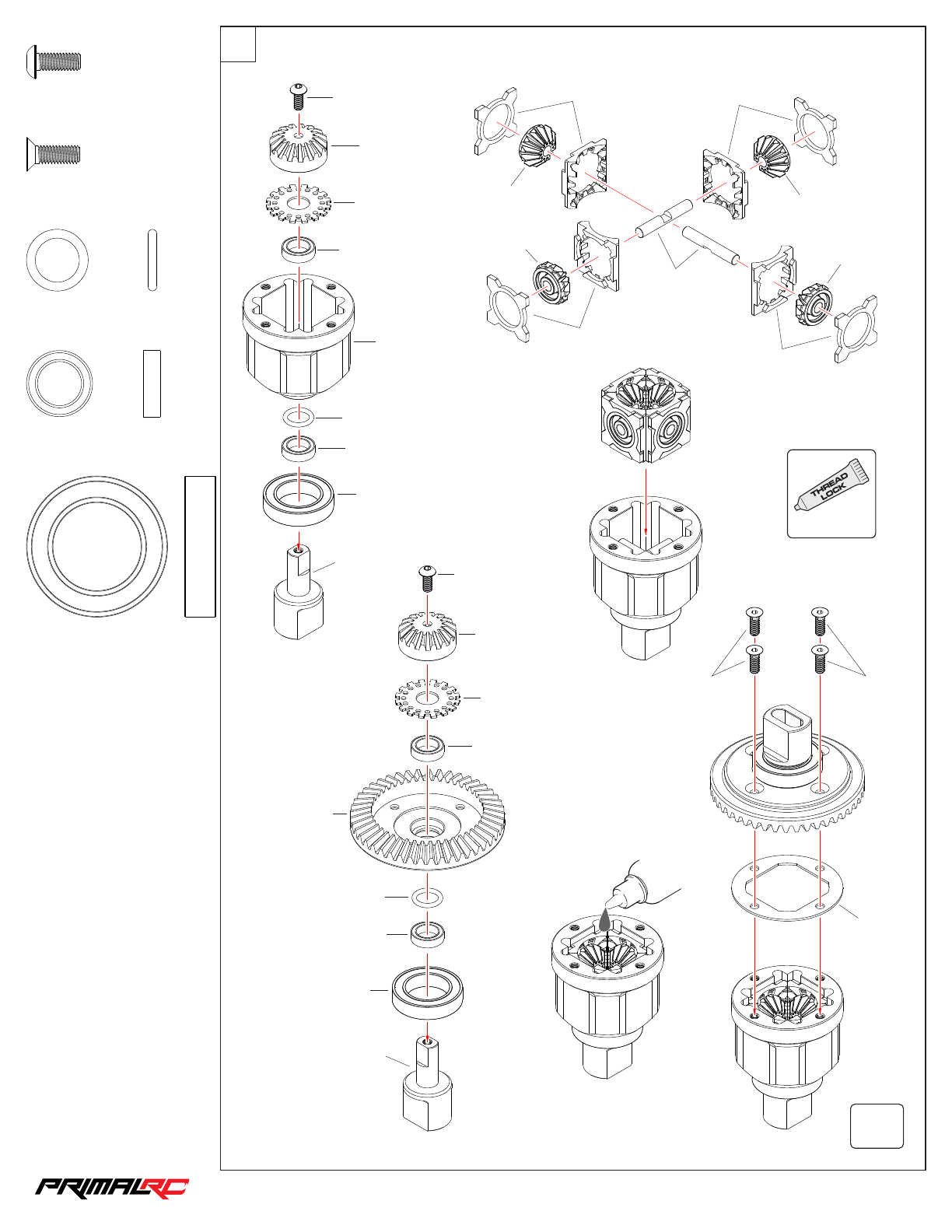

1

Diff Oil

#20000cst

×2

Differential Assembly

MBS4010 MBS4010

MBS4010

×4

M4×10mm

MFS4012

RMT108

RMT145

RMT108

RMT035

RMT051

RMT051

RMT086

RMT108

RMT108 RMT108

RMT108

RMT106

RMT107

RMT107

RMT107 RMT107

RMT107

RMT107

MFS4012

MFS4012

×8

M4×12mm

BBS101504

BBS101504

BBS101504

BBS101504

BBS101504

Bearing 10×15×4mm ×8

BBS203207

BBS203207

BBS203207

Bearing 20×32×7mm ×4

ORS14020

ORS14020

ORS14020

O-Ring D14×2mm ×4

ALWAYS

USE

13

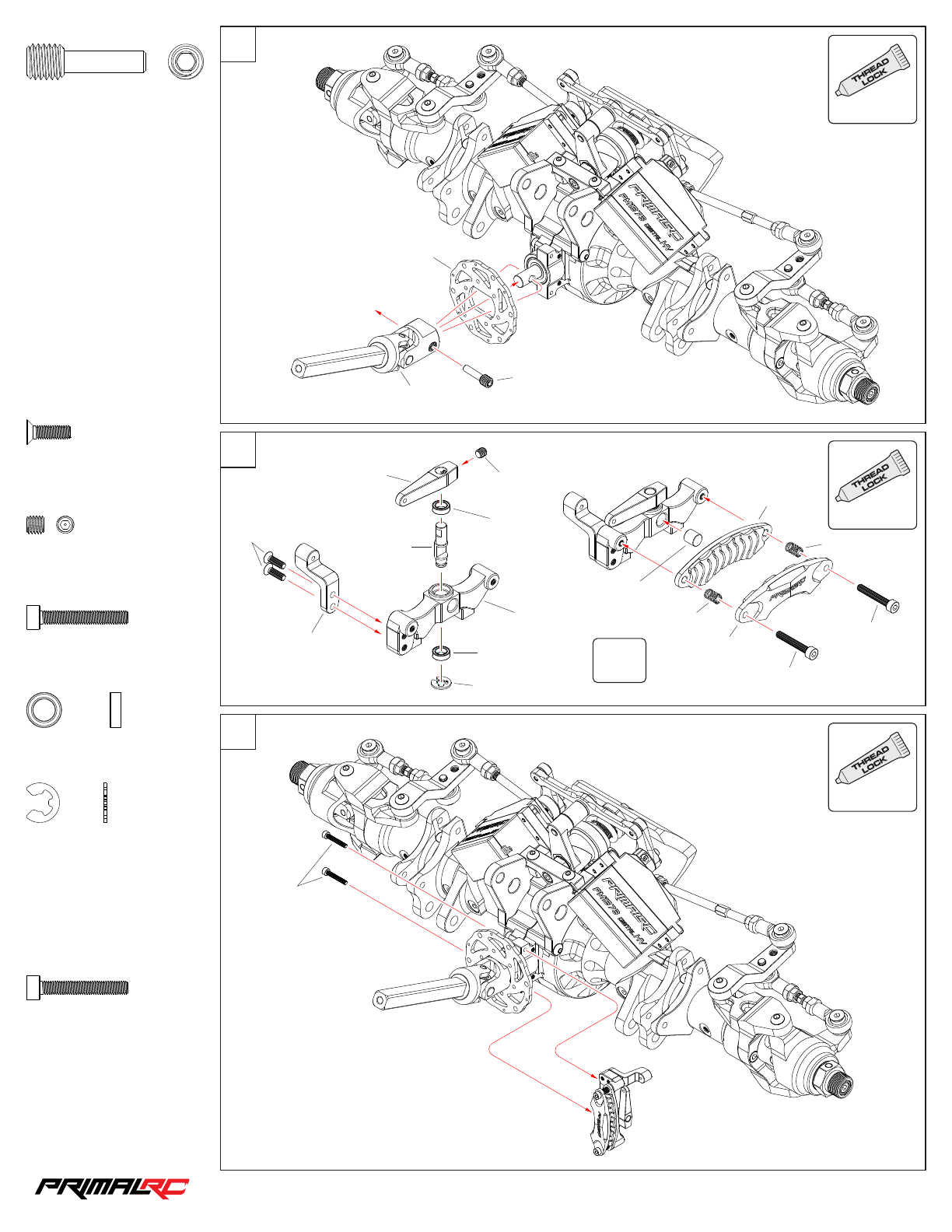

1/5th RAMINATOR MONSTER TRUCK

2

3

4

Front Axle Assembly

MCS4020 ×2

M4×20mm

MCS5040

M5×40mm ×7

MBS5020 ×6

M5×20mm

MCS5014 ×6

M5×14mm

MCS5016

MCS5016

MCS5016

MCS5020

MCS5020

×8

×4

M5×16mm

M5×20mm

MFS6016

MFS6016

MFS6016

×8

M6×16mm

L/R

BBS102206

BBS102206

Bearing 10×22×6mm ×2

BBS122406

BBS122406

BBS122406

BBS122406

Bearing 12×24×6mm ×4

ALWAYS

USE

ALWAYS

USE

ALWAYS

USE

Notice the direction

of the differential

×2

RMT085

RMT001

RMT001

RMT002

RMT006

RMT003

RMT003

RMT007

RMT007

RMT002

MCS5040

MCS4020

MCS5014

MCS5014

MCS5014

MBS5020

MBS5020

14

1/5th RAMINATOR MONSTER TRUCK

5

6

L/R

×2

MBS6020

MBS6020

MBS6020

MBS6020

×6

M6×20mm

MCS5010

MCS5010

×2

M5×10mm

PINS5024

PINS5024

×2

M5×24mm

MCS5016

MCS5016

×1

M5×16mm

MBS5016

MBS5016

M5×16mm ×2

BBS101504

BBS101504

BBS101504

Bearing 10×15×4mm ×2

ORS22025

ORS22025

O-Ring D22×2.5mm ×1

BBS122406

BBS122406

Bearing 12×24×6mm ×2

BBS203207

BBS203207

Bearing 20×32×7mm ×2

ALWAYS

USE

ALWAYS

USE

RMT019

RMT004

RMT052

RMT044

RMT044

RMT044

RMT041

RMT039

RMT009

RMT138

RMT009

RMT039

RMT016

RMT046

MWS202810

1 mm

15

1/5th RAMINATOR MONSTER TRUCK

7

8

9

MFS3014

MFS3014

MFS3014

PRE005

PRE005

MFS3014

MFS3014

×8

M3×14mm

MBS4012

MBS4012

RMT015 RMT015

RMT044

RMT103

RMT103

RMT042

RMT017

RMT018

RMT018

RMT015

RMT015

MBS4012

×4

M4×12mm

MBS6016

MBS6016

MBS6016

×2

M6×16mm

MFS5016

MFS5016

MFS5016

×4

M5×16mm

MBS4012

MBS4012

MBS4012

×2

M4×12mm

MBS6040

MBS6040

×1

M6×40mm

MCS3008

MCS3008

MCS3008

MCS3012

MCS3012

MCS3012

×2

×2

M3×8mm

M3×12mm

MCS2508

MCS2508

MCS2508

M2.5×8mm ×2

ALWAYS

USE

ALWAYS

USE

ALWAYS

USE

16

1/5th RAMINATOR MONSTER TRUCK

10

11

12

159 mm

99 mm

80 mm

20 mm

L/R

MNNS60

MNNS60 MNNS60

MNRS60

MNRS60

MNRS60

M6 Nut

M6 Reverse Nut

×4

×4

MFS6020

MFS6020

MFS6025

MFS6025

MFS6025

MFS6025

×2

×6

M6×20mm

M6×25mm

MCS5012

MCS5012

MCS5016

MCS5016

MCS5016

×1

×4

M5×12mm

M5×16mm

ALWAYS

USE

ALWAYS

USE

ALWAYS

USE

×2 ×2

RMT110

RMT080

RMT038

RMT080

RMT080

RMT050

RMT049

RMT110

RMT111

RMT111

17

1/5th RAMINATOR MONSTER TRUCK

13

14

15

RMT055 ×1

M8×27mm

MFS3010

MFS3010

×4

M3×10mm

MSS4004

MSS4004

×2

M4×4mm

BBS050825

BBS050825

BBS050825

Bearing 5×8×2.5mm ×4

MES40

MES40

E-clip 4mm ×2

MCS3020

MCS3020

MCS3020

×4

M3×20mm

MCS3020

MCS3020

×2

M3×20mm

×2

ALWAYS

USE

ALWAYS

USE

ALWAYS

USE

RMT036

RMT055

RMT095

RMT099

RMT099

RMT095

RMT096

RMT096

RMT097

RMT034

RMT097

RMT054

18

1/5th RAMINATOR MONSTER TRUCK

16

17

18

Rear Axle Assembly

MCS4020 ×2

M4×20mm

MCS5040

M5×40mm ×7

MBS5020 ×6

M5×20mm

MCS5014 ×6

M5×14mm

MFS6016

MFS6016

MFS6016

MFS6016

MFS6016

×8

M6×16mm

BBS102206

Bearing 10×22×6mm ×2

BBS122406

Bearing 12×24×6mm ×2

ALWAYS

USE

ALWAYS

USE

ALWAYS

USE

MBS6010

MBS6010

MBS6010

×2

M6×10mm

Notice the direction

of the differential

BBS102206

RMT085

RMT001

RMT001

MCS5040

MCS4020

BBS122406

BBS122406

RMT002

RMT008

RMT008

RMT002

MCS5014

MCS5014

MCS5014

MBS5020

MBS5020

RMT006

RMT006

19

Table of contents

Other Primal RC Motorized Toy Car manuals