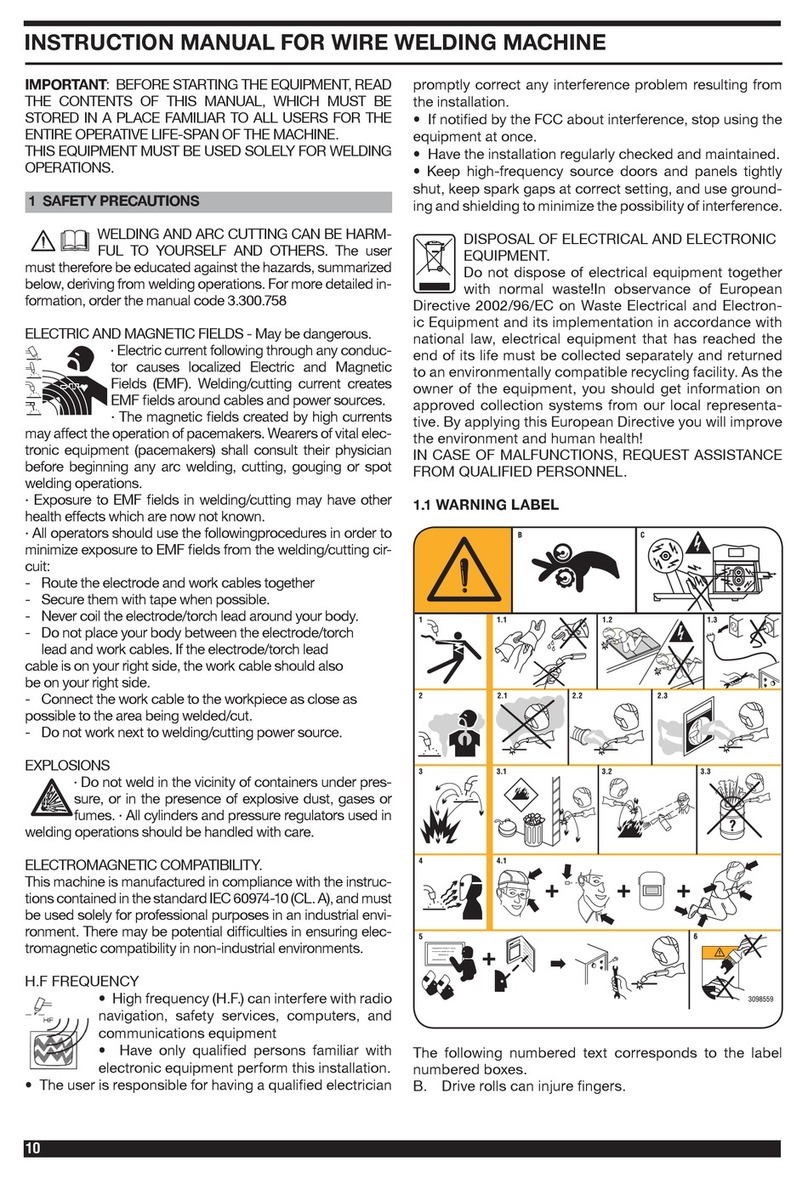

SAFETY

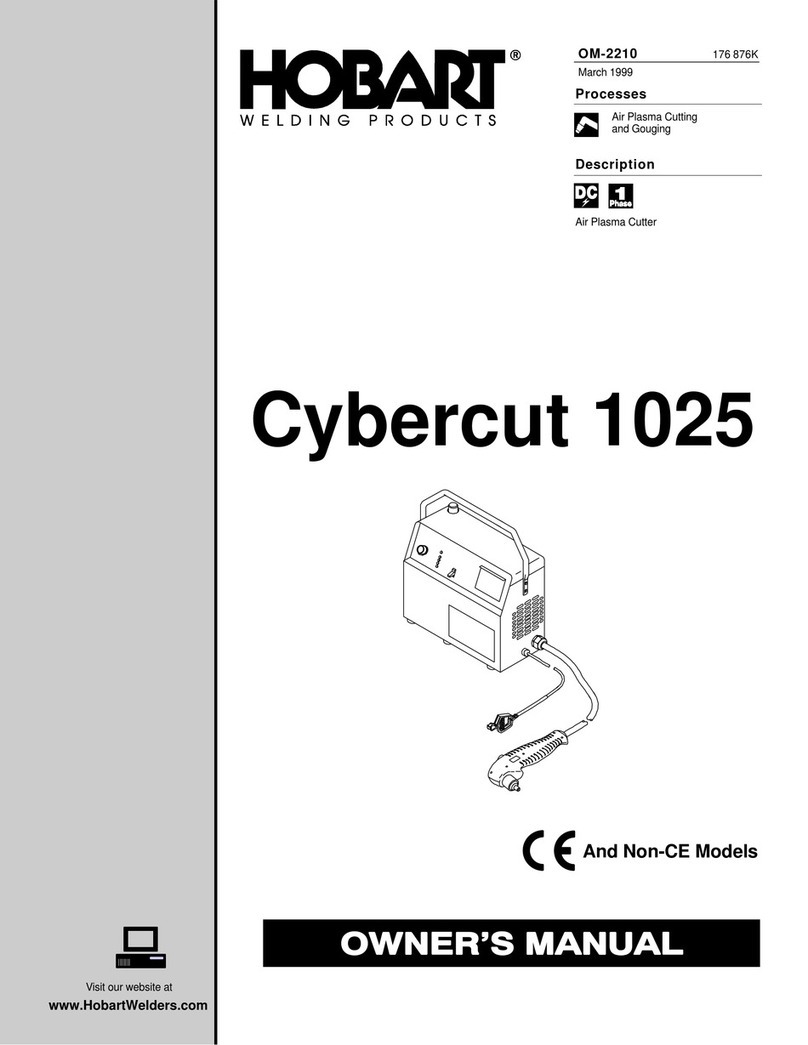

Plasma cutting can be performed on any type of conductive metal - mild steel,

and thus it can cut aluminium, stainless and any other conductive material. While

compressed air for the plasma gas. In most shops, compressed air is readily

operation. Plasma cutting is typically easier for the novice to master, and on

plasma machines are required for plasma cutting applications.

How Does Plasma Cutting Compare to Oxy-fuel (gas) cutting?

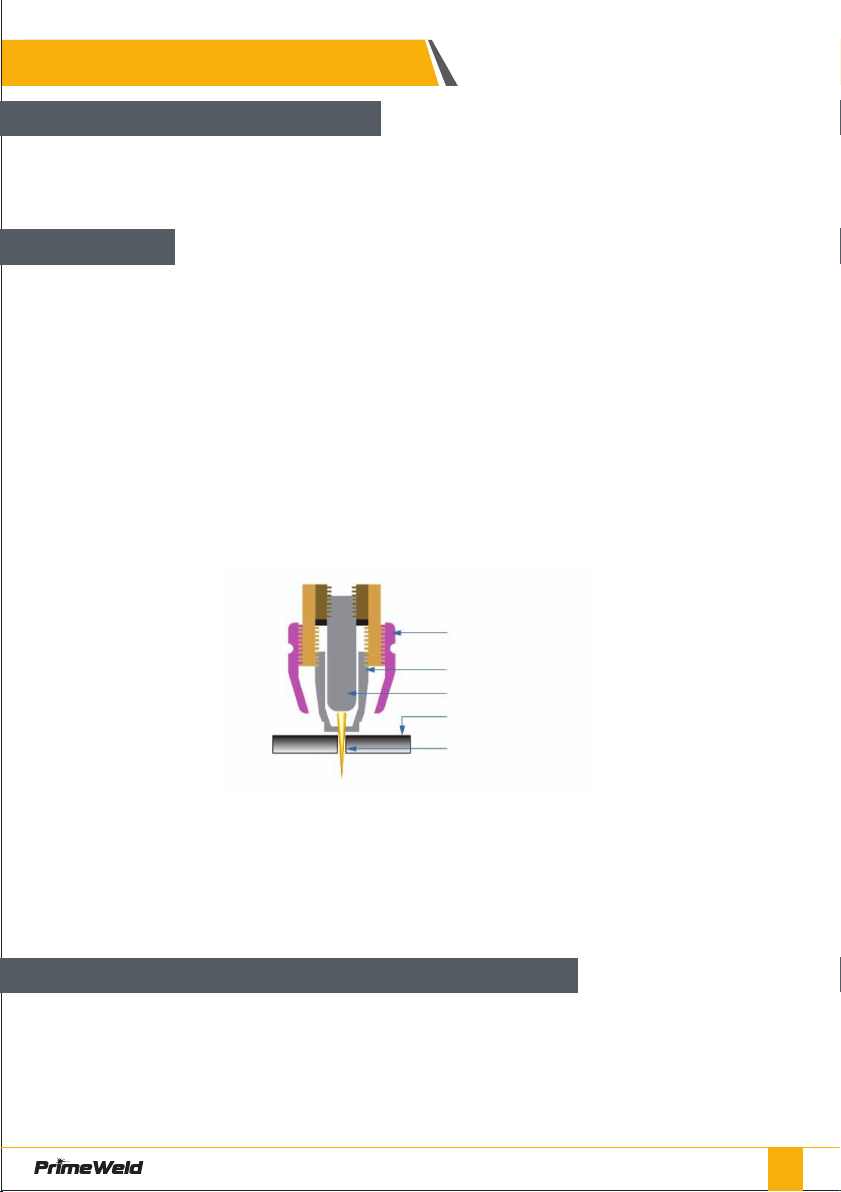

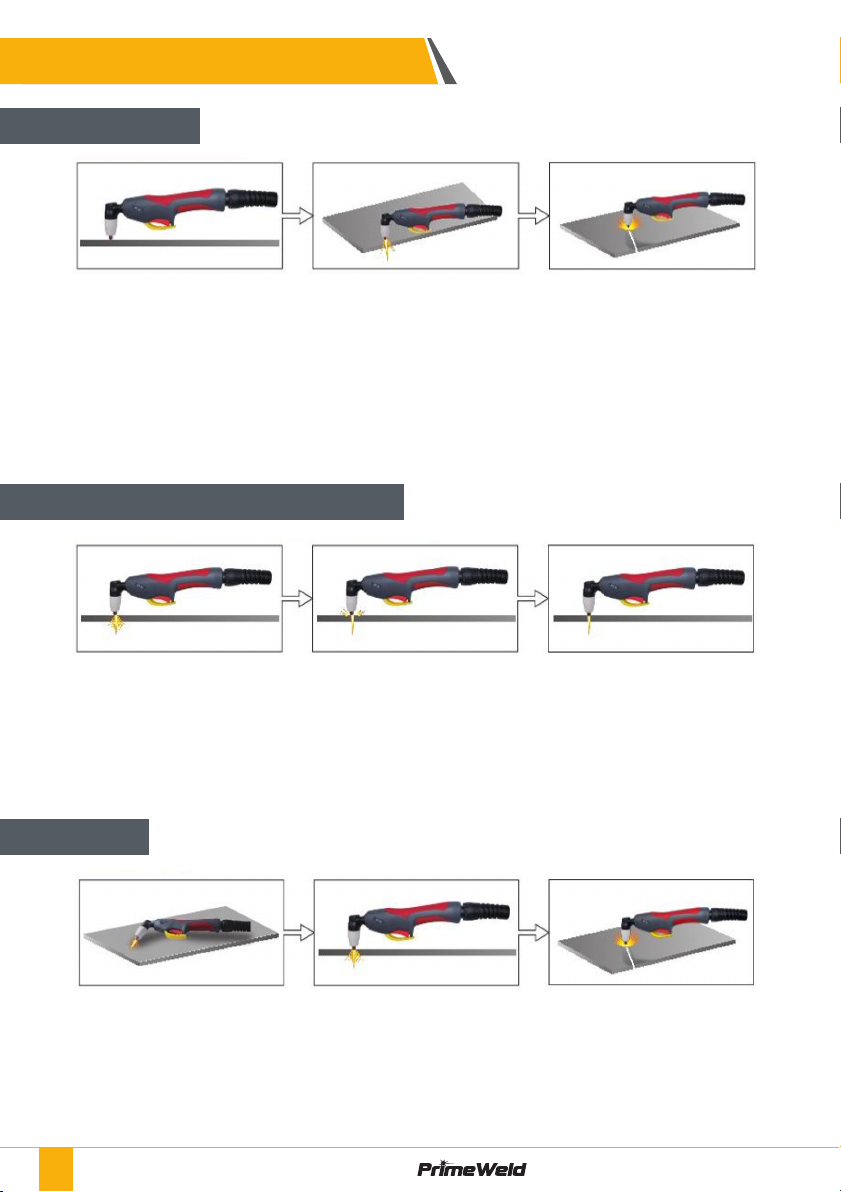

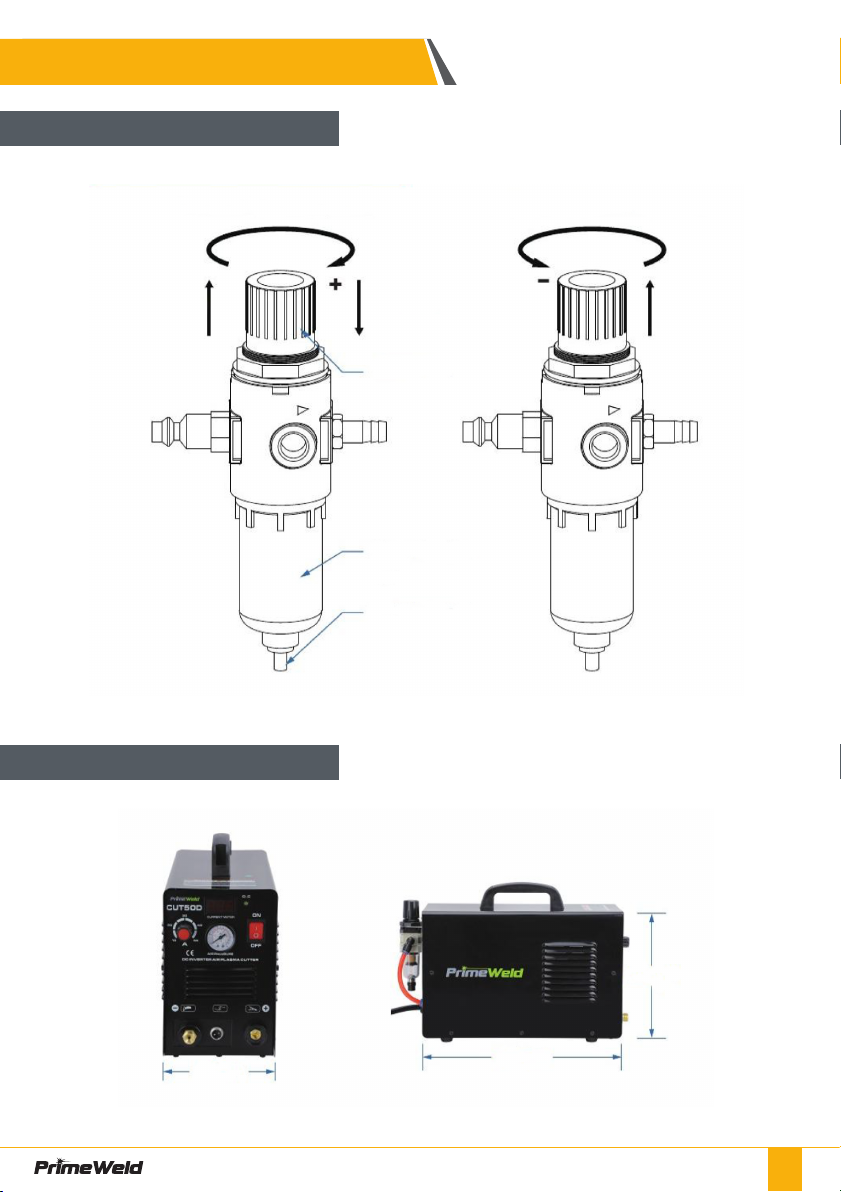

The plasma Cutting process involves creating and electrical channel of

super¬heated. electrically ionized gas i.e. plasma from the plasma cutter itself,

through the work piece to be cut, thus forming a completed electric circuit back

to the plasma cutter via a grounding clamp. This is accomplished by a

which is blown through a focused nozzle at high speed toward the work piece. An

electrical arc is the formed within the gas. between an electrode near or

integrated into the gas nozzle and the work piece itself. The electrical arc ionizes

some of gas. thereby creating and electrically conductive channel of plasma. As

heat to melt through the work piece. At the same time, much of the high velocity

plasma and compressed gas blow the hot molten metal away. thereby separating

i.e. cutting through the work piece.

NOTE: This machine is designed to use only compressed air as gas.

Plasma Introduction

generally cut thicker sections (>63164 inch) of steel more quickly than plasma.

What are the limitations to Plasma Cutting?

Where is Oxyfuel preferred?

06 PLASMA CUTTER OPERATION MANUAL