PrimeWeld CT520D User manual

MODEL:CT520D

IGBT INVERTER PLASMA CUTTER

OWNER`S

MANUAL

Need Help

Please Call

856-537-4368

www.primeweld.com

1

CONTENTS

EC DECLARATION OF CONFORMITY

We hereby declare that our machines for industrial and

professional use as stated below.

Model: CT520D.

Conforms with EMC Directives:

73/23/EEC and 89/336/EEC

European Standard: EN/IEC60974

Please read and understand this instruction manual carefully

before the installation and operation of this equipment.

The contents of this manual may be revised without prior notice

and without obligation.

This instruction manual is issued on 20 July 2020.

SAFETY ......................................................................................... 2

PARAMETER ................................................................................. 7

LAYOUT ......................................................................................... 8

OPERATION .................................................................................. 16

ACCESSORIES ............................................................................. 30

TROUBLE SHOOTTING............................................................... 32

2

SAFETY

WARNING

Welding and cutting is dangerous to the operator, people in or near the working

and surrounding areas, if the equipment is not operated correctly. Therefore the

performance of welding/cutting must only be under the strict and comprehensive

observance of all relevant safety regulations.

Symbol Description

Electric Shock: Maybe fetal

Avoid all contact with live components of the welding circuit, Electrodes and Wires

with bare bands. Wear dry gloves before start welding task.

Wires with bare bands Keep operator insurance from welding metal and welding pieces.

Smoke and gas generated while welding or cutting

Harmful to health of people

Keep head distance away from gas.

Avoid breathing the smoke and gas of welding or cutting.

Keep the working area in good ventilation.

Fire Hazard

Welding sparks, Power cable leakage both can cause the re.

Please do not welding in inammable, it’s can cause explode.

Sparks may cause re, Remove ammable material from the work place.

Keep re extinguisher nearby and have a trained re person ready to use it.

ARC light-emission: Harmful to the eyes & skin of people

Wear a welding helmet, Anti-radiation glass and work clothes while the

welding Operation is performed.

Keep working area in ventilation.

CYLINDER may explode if damaged.

Always keep cylinders in an upright position securely chained to an

Undercarriage or xed support.

Never allow the electrode, electrode holder or any other electrically “hot”

parts to touch a cylinder.

Keep your face and head away from the cylinder valve outlet when it to

be opening.

Engine fan can hurt the hands

Do not put your hands near the engine fan.

Do not attempt to override the governor or idler by pushing on the throttle

Control rods while the engine is running.

ELECTRIC SHOCK can kill.

Insulate yourself from work and ground using dry insulation. Make certain

the insulation is large enough to cover your full area of physical.

Ground the work or metal to be welded to a good electrical ground.

Never dip the electrode in water for cooling.

Turn o input power using the disconnect switch at the fuse box before

working on the equipment.

Install equipment in accordance with electric standard code.

3

SAFETY

CAUTION

1.Working Environment.

1.1 The environment in which this welding equipment is installed must be free of

grinding dust, corrosive chemicals, ammable gas or materials etc, and at no

more than maximum of 80% humidity.

1.2 When using the machine outdoors protect the machine from direct sun light,

rain water and snow etc;the temperature of working environment should be

maintained within -14°F to +104°F.

1.3 Keep this equipment distant from the wall.

1.4 Ensure the working environment is well ventilated.

2.Safety Tips.

2.1 Ventilation

This equipment is small-sized, compact in structure, and of excellent

performance in amperage output.The fan is used to dissipate heat generated

by this equipment during the welding operation. Important: Maintain good

ventilation of the louvers of this equipment. The minimum distance betweenthis

equipment and any other objects in or near the working area should be 1ft.

Good ventilation is of critical importance for the normal performance and

service life of this equipment.

2.2 Thermal Overload protection.

Should the machine be used to an excessive level, or in high temperature

environment, poorly ventilated area or if the fan malfunctions the Thermal

Overload Switch will be activated and the machine will cease to operate. Under

this circumstance, leave the machine switched on to keep the built-in fan

working to bring down the temperature inside the equipment. The machine will

be ready for use again when the internal temperature reaches safe level.

2.3 Over-Voltage Supply

Regarding the power supply voltage range of the machine, please refer to“Main

parameter”table. This equipment is of automatic voltage compensation, which

enables the maintaining of the voltage range within the given range. In case

that the voltage of input power supply amperage exceeds the stipulated value,

it is possible to cause damage to the components of this equipment. Please

ensure your primary power supply is correct.

2.4 Do not come into contact with the output terminals while the machine is in

operation. An electric shock may possibly occur.

4

SAFETY

Maintenance

Exposure to extremely dusty, damp, or corrosive air is damaging to the welding

machine. In order to prevent any possible failure or fault of this welding

equipment, clean the dust at regular intervals with clean and dry compressed air

of required pressure.

Please note that: lack of maintenance can result in the cancellation of the

guarantee; the guarantee of this welding equipment will be void if the machine

has been modied, attempt to take apart the machine or open the factory-made

sealing of the machine without the consent of an authorized representative of the

manufacturer.

Trouble shooting

Caution: Only qualied technicians are authorized to undertake the repair of this

Plasma cutter equipment. For your safety and to avoid Electrical Shock, please

observe all safety notes and precautions detailed in this manual.

Note:

• Our equipment as described in this manual conforms to all applicable rules and

regulations of the ‘Low Voltage Directive’ (European Council Directive 73/23/EEC)

as set out and amended by Council Directive 93/68/EEC) and to the National

legislation for the enforcement of this Directive.

• Our equipment as described in this manual conforms to all applicable rules and

regulations of the European Council Directive 89/336/EEC, (EMC Directive)

and to the National legislation for he enforcement of this Directive.

Aip plasma cutting technology

Plasma cutters work by passing an electric arc through a gas that is passing

through a constricted opening. The gas can be air, nitrogen, argon, oxygen. etc.

The electric arc elevates the temperature of the gas to the point that it enters a

4th state of matter. We all are familiar with the rst three: i.e.,Solid, liquid, and gas.

Scientists call this additional state plasma. As the metal being cut is part of the

circuit, the electrical conductivity of the plasma causes the arc to transfer to the

work. The restricted opening (nozzle) the gas passes through causes it to

squeeze by at a high speed, like air passing through a venturi in a carburettor.

This high speed gas cuts through the molten metal.

Plasma cutting was invented as the result of trying to develop a better welding

process. Many improvements then led to making this technology what it is today.

Plasma cutters provide the best combination of accuracy, speed, and aord ability

for producing a variety of at metal shapes. They can cut much ner, and faster

than oxy-acetylene torches.

5

SAFETY

How a plasma cutter works

Basic plasma cutters use electricity to superheat air into plasma (the 4th state of

matter), which is then blown through the metal to be cut. Plasma cutters require

a compressed air supply and AC power to operate.

Operation

1. When the trigger is squeezed, DC current ows through the torch lead into the

nozzle.

2. Next, compressed air ows through the torch head, through the air diuser that

spirals the air ow around the electrode and through the hole of the cutting

nozzle.

3. A xed gap is established between the electrode and the nozzle. (The power

supply increases voltage in order to maintain a constant current through the

joint.) Electrons arc across the gap, ionizing and super heating the air creating a

plasma stream.

4. Finally, the regulated DC current is switched so that it no longer ows to the

nozzle but instead ows from the electrode to the work piece. Current and airow

continue until cutting is stopped.

Shield Cup

Nozzle

Electrode

Plasma Stream

Steel

Notes:

The nozzle and electrode require periodic replacement. The electrode has an insert

of tough high conductive material such as hafnium and cerium. This insert erodes

with use, also the nozzle orice will erode with use.

Quality of the air used is paramount to longer life of electrodes and nozzles, in

short clean dry air gives longer parts life, the cleaner and dryer the better. We

recommend use of a Plasma Air Filter.

6

SAFETY

What kinds of materials can the plasma cut?

Virtually any metal can be plasma cut including steel, stainless steel, aluminium,

brass, copper, etc. Any thickness from 30 gauge through 13/16" can be cut,

depending on the power of the plasma cutter used.

How Does Plasma Cutting Compare to Oxy-fuel (gas) cutting?

Plasma cutting can be performed on any type of conductive metal - mild steel,

aluminium and stainless are some examples. With mild steel, operators will

experience faster, thicker cuts than with alloys. Oxy-fuel cuts by burning, or

oxidizing the metal it is severing. It is therefore limited to steel and other ferrous

metals which support the oxidizing process. Metals like aluminium and stainless

steel form an oxide that inhibits further oxidization, making conventional oxy-fuel

cutting impossible. Plasma cutting however does not rely on oxidation to work

and thus it can cut aluminium, stainless and any other conductive material. While

dierent gasses can be used for plasma cutting, most people today use

compressed air for the plasma gas. In most shops, compressed air is readily

available, and thus plasma does not require fuel gas and compressed oxygen for

operation. Plasma cutting is typically easier for the novice to master, and on

thinner materials, plasma cutting is much faster than oxy-fuel cutting. However,

for heavy sections of steel (1" and greater), oxy-fuel is still preferred since

oxy-fuel is typically faster and, for heavier plate applications high powered

plasma machines are required for plasma cutting applications

What are the limitations to Plasma Cutting?

Where is Oxyfuel preferred?

The plasma cutting machines are typically more expensive than oxy/acetylene.

Also, oxy/acetylene does not require access to electrical power or compressed

air which may make it a more convenient method for some users. Oxyfuel can

generally cut thicker sections (>63/64 inch) of steel more quickly than plasma.

7

PARAMETER

INPUT/OUTPUT SPECIFICATIONS

IGBT Inverter Type: IGBT

Voltage/phase: Dual Voltage 120/240 1 Phase

TIG output type: DC only

TIG Start Type: High Frequency Only

Pulse: No

Plasma Cutter Arc Start Type: High Frequency

PilotArc: No

OK-to-Cut Indicator/Low Air pressure safety: No

OCV:

▪TIG: 70 V

▪Stick: 70 V

▪Plasma: 220V

Max Inrush ( I1MAX ) Amps: ▪@ 110V: 31A

▪@ 220V: 27A

Maximum Rated (I1EFF ) Input Amps: ▪@110V: 19A

▪@220V: 17A

TIG Output Amps/Volts @ Rated Duty Cycle:

120V:

▪ 120A/14.8V @ 35% Duty Cycle

▪ 93A/13.7V @ 60% Duty Cycle

▪ 72A/12/9V @ 100% Duty Cycle

240V:

▪ 200A/18V @ 35% Duty Cycle

▪ 160A/16.4V @ 60% Duty Cycle

▪ 130A/15.2V @ 100% Duty Cycle

Stick Output Amps/Volts @ Rated Duty Cycle:

F120V:

▪ 120A/24.8V @ 35% Duty Cycle

▪ 93A/23.7V @ 60% Duty Cycle

▪ 72A/22.9V @ 100% Duty Cycle

240V:

▪ 160A/26.4V @ 35% Duty Cycle

▪ 130A/25.2V @ 60% Duty Cycle

▪ 100A/24V @ 100% Duty Cycle

Plasma Output Amps/Volts @ Rated Duty Cycle:

120V:

▪ 27A/90.8V @ 60% Duty Cycle

▪ 21A/88.4V @ 100% Duty Cycle

240V:

▪ 50A/100V @ 35% Duty Cycle

▪ 40A/96V @ 60% Duty Cycle

▪ 30A/92V @ 100% Duty Cycle

TIG DC Amp/Volt Range: ▪120V: 10A-120A, 10.4V-14.8V

▪240V: 10A-200A, 10.4V-18V

Stick Amp/Volt Range: ▪120V: 10A-120A, 20.4V-24.8V

▪240V: 10A-160A, 20.4V-26.4V

Plasma Amp/Volt Range: ▪120V: 10A-27A, 84V-94V

▪240V: 10A-50A, 84V-100V

Preow time: Fixed

Post Flow Time: Fixed

OverCurrent Protection: Yes

8

LAYOUT

Duty Cycle Protection: Yes

Air Pressure OK Safety Indicator: No

Stick Arc Force Control: Auto-Adaptive

Torch Type: t AG-60 High Frequency

Recommended Cutting Air Pressure: 55-60 psi

Front & rear panel layout

Front Panel Rear Panel

91

2

3

4

5

10

11

13

12

6

7

8

14

16

17

18

20

19

15

9

LAYOUT

1Overheating indicator, It illuminates when the working temperature of the IGBT is

overly high. Meanwhile,The machine stop working.

2It is current indicator, Lighting when machine power on

3 LED Current Display.

4 Amperage Control Knob.

5 Time adjument for post air

6Air Pressure Gauge.Suggest Air Range: 45-70PSI

7

Machine indicator, Current knob can use in this selection, can not use pedal.

Pedal: current knob on machine can not be used in this selection, Can use the

pedal adjust the current

8

4T is selected press and release trigger Arc starts, press and release trigger Arc

stops.

2T is selected press trigger Arc starts, release trigger Arc stops.

9

TIG function please select it before using machine

Cutting function please select it before using machine

Stick function please select it before using machine

10 Stick connector

11 TIG and Cutting torch connector

12 Switch connector for TIG and Cutting torch

13 Earth clamp connector

14 Air regulator

15 Power switch

16 Quick air connector

17 Power cable Input Voltage 110/220v, Voltage Automatic Identication, no need hand switch

18 Argon Gas in

19 Air in

20 To Air Meter

10

LAYOUT

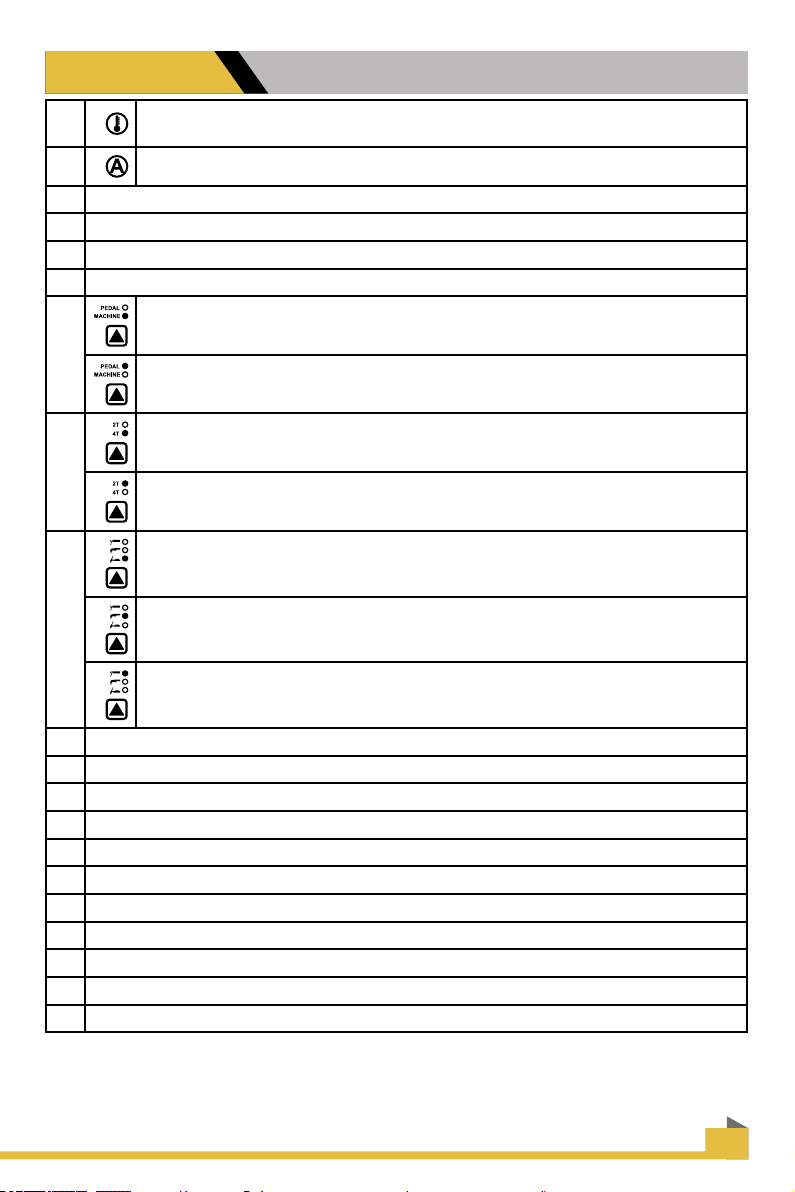

Set up procedure for plasma cutting machine

1. Connect the AG60/AG60P Plasma Torch to the machine. Insert the torch connection into the

torch.Connection receptacle at the front of the machine and screw up hand tight. Caution: Be

careful not to bend the pins located inside the torch connector.

2. Connect the earth lead to the output terminal of the machine and tighten.

3. Connect the air supply to the air connection located at the rear of the machine. Turn on the air

supply.

4. Connect the machine to the correct power supply and switch on the machine using the on/o

switch located at the rear of the machine.

5. Select 2T / 4T operation

Operating procedure using the 2T / 4T Function with AG60/AG60P torch. Set torch operation

2T / 4T.

• When 2T operation is selected press trigger Arc starts, release trigger Arc stops.

• When 4T operation is selected press and release trigger Arc starts, press and release trigger

Arc stops.

6. Set amperage dial.

How to begin use this machine

Before use this machine, you need to read the blow information carefully, Put the

accessories ready before operate this unit.

Connect the earth

lead to the output

terminal Of the

machine and tight

Connect the Plasma cutting torch to the

machine set the torch connection into

the torch connection

Receptacle at the front of the machine

and Screw up hand tight.

11

LAYOUT

CONNECTION

Switch

connector for TIG

and Cutting torch

Stick

connector

TIG and Cutting

torch connector Earth clamp

connector

Before use pedal, please switch function "Machine"to "Pedal " please connect torch and

ground clamp well, leave torch switch free(do not plug it to TIG torch switch port), Connect

foot pedal to panel of machine.

5 PIN CONNECTOR FOR FOOT PEDAL

1

2

5

3

4

Ground

Torch Switch

Torch Switch

Power

Setting

Amps

VR in the foot pedal

FOOT PEDAL

12

LAYOUT

Connection

Air Compressor

AU UK EURO

USA 110V USA 220V

Air

regulator

Air input

Power cable

Air hose

to air

meter

Air hose to

torch

How to use air regulator

Anti-Clockwise

Reduce air pressure

+

Pull up Pull down

Clockwise increase

air pressure

Air Pressure range: 40-70 PSI

13

LAYOUT

Function & Install instruction

HOW TO USE MMA(Stick)

Select MMA mode, Stick holder connect to

left socket, same time connect earth clamp

to the right socket.

HOW TO USE CUT

Before start use cutting function, need to

select cut mode, then connect torch and

switch and pilot arc wire also earth clamp

to panel of machine. start cutting after all

connectting.

HOW TO USE TIG

Select TIG mode, connect torch, switch and

earth clamp to panel of machine. start TIG

welding after nish all connectting.

1. For connect stick holder

2. GAS/AIR OUTLET

3. PEAL/ Torch switch

4. For connect earth clamp

12 3 4

14

LAYOUT

How to connect wire for TIG

welding.

1. Connect the TIG torch & switch to

panel of machine

2. connect the plug of earth clamp to

the machine socket.

How to connect wire for

cutting function

1. connect the plasma torch & switch

to socket of panel, ( also need to

connect the pilot arc wire if machine

with pilot arc function )

2. connect the earth clamp to socket

on panel of machine

How to connect wire for

stick welding

1. connect the plug on wire of stick

holder to panel of machine ( there is

symbol mark on machine )

2. connect the plug on wire of earth

clamp to panel of machine.

15

LAYOUT

Cutting Thickness Chart

Need to adjust the current and air pressure properly under metal thickness to get best cutting

surface

1

CT520 (220V) 20Amps 30Amps 40Amps 50Amps

Thickness (mm) 4mm 6mm 10mm 14mm

Air Pressure (psi) 40psi 50psi 60psi 70psi

Tip size φ0.8-φ0.9 φ0.8-φ0.9 φ0.9-φ1.0 φ0.9-φ1.0

2

CT520 (110V) 25Amps 35Amps

Thickness (mm) 4mm 6mm

Air Pressure (psi) 40psi 50psi

Tip size φ0.8-φ0.9 φ0.8-φ0.9

Accessories

Following accessories come with machine

1. machine x 1

2. plasma cutting torch x 1

3. earth clamp with cable x 1

4. air hose x 1

5. cutting torch tip x 2

6. cutting torch electrode x 2

7. Air regulator x 1

8. Power plug wire adaptor x 1

9. TIG torch * 1

10. Arc holder with cable *1

16

LAYOUTOPERATION

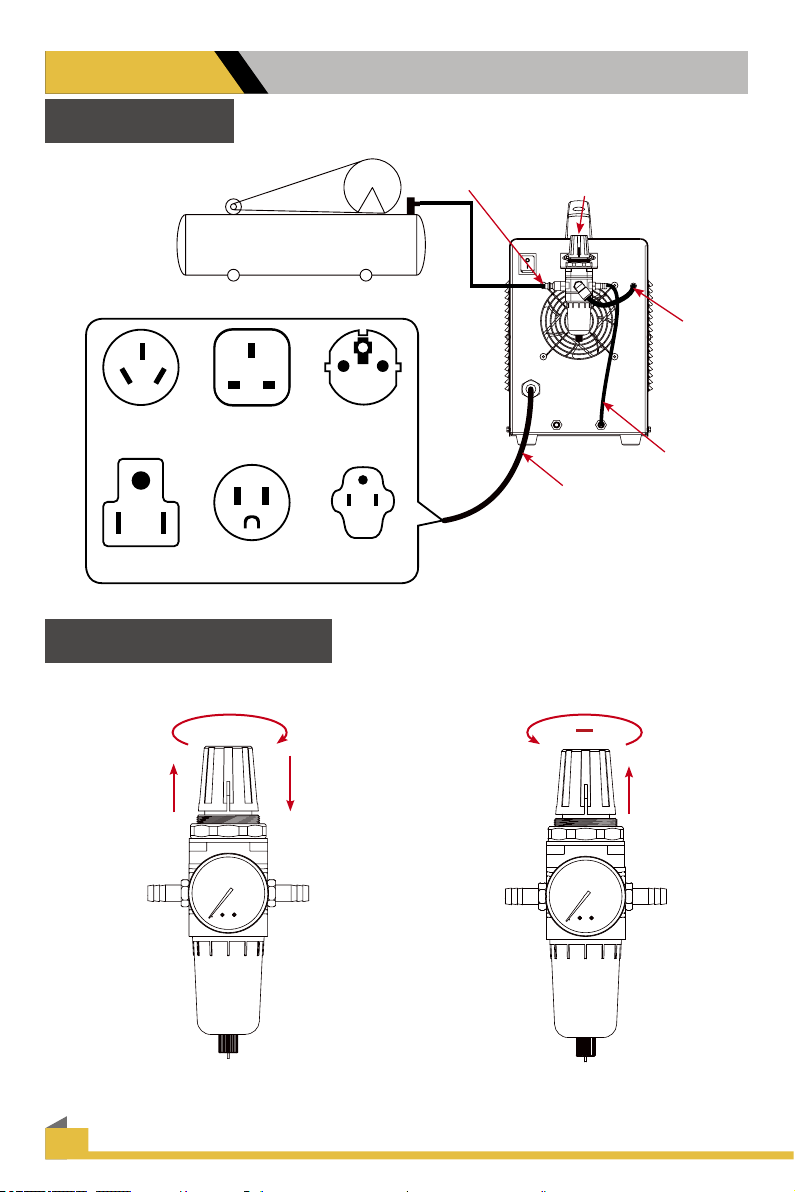

1.place and hold the torch vertical At the

edge of the plate.

2. Pull the trigger to energise the pilot arc.

The cutting arc will start when the nozzle

is moved closer to the edge of the work

piece. When the cutting arc has cut

through the edge of the plate start moving

evenly in the direction you wish to cut.

3. Correct amperage and travel speed arc

importand and relevant to material

thickness and are correct when sparks

are exiting from the work piece. if sparks

are spraying up from the work piece there

is insucient amps selected or the travel

speed is too fast.

4. To nish the cutting release the torch

switch. The air ow will continue for 20

seconds to cool the torch head.

Cut Quality

A clean cut depend on several factors: Poor quality cut

● amperage

● travel speed

● tip height & position

● tip and electrode quality Good quality cut

● air pressure and quality

● technique

The best quality cut will be produced when all these variables are set correctly

for the material thickness and type of material being cut.

17

LAYOUTOPERATION

Amperage

Standard rule of thumb is the thicker the material the more amperage required.On thick material,

set the machine to full output and vary your travel speed.On thinner material, you need to turn

down the amperage and change to a lower-amperage tip to maintain a narrow kerf. The kerf is the

width of the cut material that is removed during cutting.

Speed

Amperage and speed are critical to producing a good quality cut. The faster you move (especially

on aluminium), the cleaner your cut will be. To determine if you're going too fast or too slow, visually

follow the arc that is coming from the bottom of the cut. The arc should exit the material at a slight

angle away from the direction of travel. If it's going straight down, that means you're going too slow,

and you'll have an unnecessary buildup of dross or slag. If you go too fast, it will start spraying back

onto the surface of the material without cutting all the way through. Because the arc trails at an

angle, at the end of a cut, slow your cutting speed and angle the torch in to cut through the last bit

of metal.

Direction

It is easier to pull the torch towards you than push it. The plasma stream swirls as it exits the tip,

biting one side and nishing o on the other leaving a bevelled edge and a straight edge. The

bevel cut eect is more noticeable on thicker material and needs to taken into consideration before

starting your cut as you want the straight side of the cut to be on the nished piece you keep.

Torch tip height & position

The distance and postion of the plasma torch cutting tip has an aect on the quality of the cut and

the extent of the bevel of the cut. The easiest way to reduce bevel is by cutting at the proper speed

and height for the material and amperage that is being cut.

Correct torch height and

Square to the material

Minimum bevel & equal bevel

Longest consumable life

Torch angled to the material

unequal bevel, one side may

be excessively beveled.

18

LAYOUTOPERATION

Torch height too high

excessive bevel, plasma

Stream may not cut all the

way through the material

Torch height too low

Reverse bevel. Tip may

contact the work piece and

short out or damage the tip.

Tip size and condition

The tip orices focus the plasma stream to the work piece. It is important to use the correct size tip

for the amperage being used,for example a tip with a 3/64" orice is good for 0-40 amps whereas a

1/16" orice is better for 40-80 amps.

The low-amp tip has a smaller orice which maintains a narrow plasma stream at lower settings for

use on thin-gauge material. Using a 25 amp tip at an 60 amp setting will blow out and distort the tip

orice and require replacement. Conversely, using an 80-amp tip on the lower settings will not allow

you to focus the plasma stream as well and creates a wide kerf.The condi tion of the tip orice is

critical to the quality of the cut result, a worn or damaged tip orice will produce a distorted plasma

stream resulting in a poor cut quality.

Electrode condition

A xed gap is established between the electrode and the inside of the cutting tip.

Electrons arc across the gap, ionizing and super heating the air creating the plasma stream. The

electrode contains an insert in the end made of a highly conductive material called hafnium. This

insert erodes with use and develops a pit in the end of the electrode, when the pit becomes too

much poor quality cuts will result and necessitate replacement of the electrode.

Air pressure and volume

Air pressure, ow rate and air quality are critical to quality plasma cutting and consumable life span.

The required air pressure and volume can vary from model to model and the manufacturer will

provide the specs.The air pressure is pre-set at 4.5 psi and requires a ow rate of 6.0 CF/M. The

volume capacity of your compressor is important, if you have a small compressor with exactly the

same l/min rating as the plasma, then the compressor will run continuously when you are plasma

cutting, a compressor with a l/min rating slightly higher than the plasma would be more adequate.

If you are doing a lot of cutting, cutting thick plate (same air consumption but slower cut speeds =

longer cut time) then choose a compressor at 1.5 to 2 times the plasma system requirement.

19

LAYOUTOPERATION

TIP: For longer consumable life do not use the pilot arc unnecessarily. Rapid wear will occur

if the pilot arc stays engaged more than 3 seconds at a time.

TRAVEL

FLAME AT NORMAL TRAVEL SPEED

TRAVEL

FLAME AT FAST TRAVEL SPEED

TRAVEL

FLAME AT SLOW TRAVEL SPEED

NOTE: When stepping down amps to cut thinner material, or using on 120V, you must

change to smaller orice nozzle for the best cutting results. Too large of an orice diameter

will result in arc instability and a rough cut. Lowering the air pressure below 50 psi to try to

get the torch to cut will only result in a lazy, wandering arc or an arc that sputters on and o

continuously.

TIP

IMPORTANT: Check consumables regularly for wear and change them out before they

are completely worn. Allowing the consumables to wear until they quit working may damage

related torch components, creating a more costly repair.

Table of contents

Other PrimeWeld Welding System manuals