PrimeWeld CUT50DP User manual

MODEL: CUT50DP

Please Call

856-537-4368

www.primeweld.com

Need Help

OWNER`S

MANUAL

PLASMA CUTTER OPERATION MANUAL

CONTENTS

Dear Valued Customer. Thank you for purchasing our Plasma

Cutter Read this manual thoroughly. Incorrectly installed or

improperly grounded equipment is a hazard. And can cause

serious damage. Properly install and ground this equipment

according to this manual and national. State. And local codes.

Safety...................................................................................02

Main Parameter.................................................................07

Layout..................................................................................09

Operation............................................................................12

Trouble Shootting..............................................................17

Accessories ........................................................................20

EC DECLARATION OF CONFORMITY

We hereby declare that our machines for industrial and

professional use as stated below.

Model: IGBT plasma cutting machine Cut50dp, CUT5OPi,

CUT50D,CUT5ODP. Conforms with EMC Directives:

73/23/EEC and 89/336/EEC European Standard:

EN/IEC60974

Please read and understand this instruction manual

carefully before the installation and operation of this

equipment.

The contents of this manual may be revised without prior

notice and without obligation.

This instruction manual is issued on 05st May 2019.

01

PLASMA CUTTER OPERATION MANUAL

SAFETY

Welding and cutting is dangerous to the operator،people in or near the working

and surrounding areas, if the equipment is not operated correctly. Therefore the

performance of welding/cutting must only be under the strict and

comprehensive observance of all relevant safety regulations.

WARNING

Electric Shock: Maybe fetal

• Avoid all contact with live components of the welding circuit,

Electrodes and Wires with bare bands. Wear dry gloves before

start welding task.

• Wires with bare bands Keep operator insurance from welding

metal and welding pieces.

Smoke and gas generated while welding or cutting Harmful to

health of people

• keep head distance away from gas.

• Avoid breathing the smoke and gas of welding or cutting.

• keep the working area in good ventilation.

Fire Hazard

work place.

ready to use it.

ARC light-emission: Harmful to the eyes & skin of people

• Wear a welding helmet, Anti-radiation glass and work clothes

while the welding Operation is performed.

• Keep working area in ventilation.

CYLINDER may explode if damaged.

• Always keep cylinders in an upright position securely chained to

• Never allow the electrode, electrode holder or any other

electrically `hot" parts to touch a cylinder

• Keep your face and head away from the cylinder valve outlet

when it to be opening.

Engine fan can hurt the hands

• Do not put your hands near the engine fan.

• Do not attempt to override the governor or idler by pushing on

the throttle Control rods while the engine is running.

ELECTRIC SHOCK can kill.

• Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical.

• Ground the work or metal to be welded to a good electrical

ground.

• Never dip the electrode in water for cooling.

before working on the equipment.

• Install equipment in accordance with electric standard code.

Symbol Descripiton

02

SAFETY

CAUTION

1. Working Environment

1.1 The environment in which this welding equipment is installed

humidity.

1.2 When using the machine outdoors protect the machine from

direct sun light. rain water and snow etc:the temperature of

working environment should be maintained within -14'F to +

104°F.

1.3 Keep this equipment distant from the wall.

1.4 Ensure the working environment is well ventilated.

2.Safety Tips.

2.1 Ventilation

This equipment is small-sized, compact in structure, and of

The fan is used to dissipate heat generated by this equipment

during the welding operation.

Important: Maintain good ventilation of the louvers of this

equipment.

The minimum distance between this equipment and any other

objects in or near the working area should be 1ft. Good

ventilation is of critical importance for the normal performance

and service life of this equipment.

2.2 Thermal Overload protection.

temperature environment, poorly ventilated area or if the fan

malfunctions the Thermal Overload Switch will be activated and the machine

will cease to operate. Under this circumstance, leave the machine switched on

to keep the built-in fan working to bring down the temperature inside the

equipment. The machine will be ready for use again when the internal

temperature reaches safe level.

2.3 Over-Voltage Supply

Regarding the power supply voltage range of the machine, please refer to '

Main parameter table.

This equipment is of automatic voltage compensation, which enables the

maintaining of the voltage range within the given range. In case that the

possible to cause damage to the components of this equipment. Please ensure

your primary power supply is correct.

03

Fire Hazard

work place.

ready to use it.

PLASMA CUTTER OPERATION MANUAL

2.4 Do not come into contact with the output terminals while the machine is in

operation. An electric shock may possibly occur.

machine. In order to prevent any possible failure or fault of this welding

equipment, clean the dust at regular intervals with clean and dry compressed air

of required pressure.

Please note that: lack of maintenance can result in the cancellation of the

guarantee: the guarantee of this welding equipment will be void if the machine

sealing of the machine without the consent of an authorized representative of

the manufacturer.

Note:

• Our equipment as described in this manual conforms to all applicable rules

and regulations of the 'Low Voltage Directive' (European Council Directive

73/23/EEC) as set out and amended by Council Directive 93/68/EEC) and to the

National legislation for the enforcement of this Directive.

• Our equipment as described in this manual conforms to all applicable rules

and regulations of the European Council Directive 89/336/EEC. (EMC Directive)

and to the National legislation for he enforcement of this Directive.

Plasma cutters work by passing an electric arc through a air/gas that is passing

The electric arc elevates the temperature of the gas to the point that it enters a

gas. Scientists call this additional state plasma. As the metal being cut is part of

the cireuit, the electrical conductivity of the plasma causes the arc to transfer to

the work. The restricted opening (nozzle) the gas passes through causes it to

squeeze by at a high speed, like air passing through a venturi in a carburettor.

This high speed gas cuts through the molten metal.

Plasma cutting was invented as the result of trying to develop a better welding

process. Many improvements then led to making this technology what it is today.

Plasma cutter equipment. For your safety and to avoid Electrical Shock. please

observe all safety notes and precautions detailed in this manual.

SAFETY

Maintenance

Air plasma cutting technology

Trouble shooting

04 PLASMA CUTTER OPERATION MANUAL

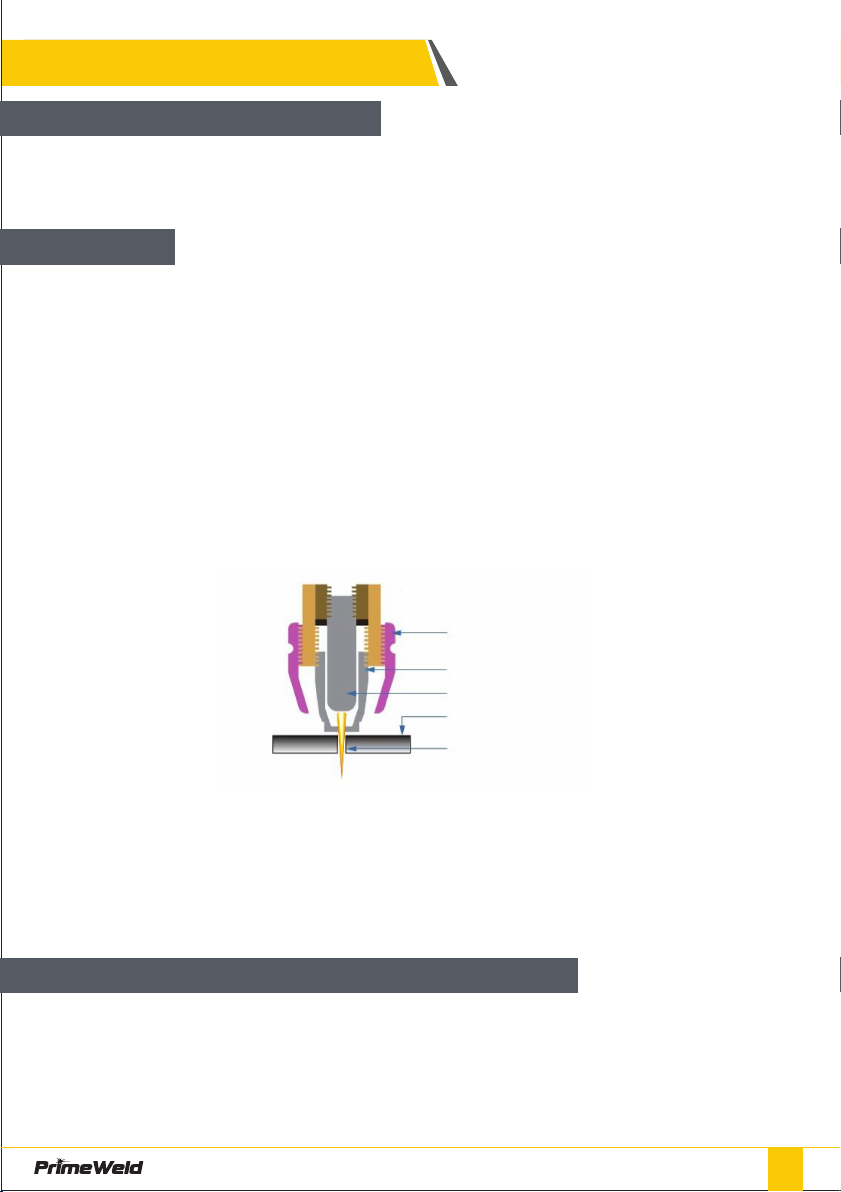

AG-60 / AG60P

Shield Cup

Nozzle

Electrode

Steel

Plasma Stream

Basic plasma cutters use electricity to superheat air into plasma (the 4th state of

matter), which is then blown through the metal to be cut. Plasma cutters require

a compressed air supply and AC power to operate.

SAFETY

How a plasma Cutter works

nozzle.

cutting nozzle.

supply increases voltage in order to maintain a constant current through the

joint.) Electrons arc across the gap. ionizing and super heating the air creating

a plasma stream.

Notes:

The nozzle and electrode require periodic replacement. The electrode has an

insert of tough high conductive material such as hafnium and cerium. This insert

Quality of the air used is paramount to longer life of electrodes and nozzles, in

short clean dry air gives longer parts life, the cleaner and dryer the better. We

recommend use of a Plasma Air Filter.

Operation

Virtually any metal can be plasma cut including steel, stainless steel, aluminium,

brass, copper, etc. Any thickness from 30 gauge through 13116" can be cut,

depending on the power of the plasma cutter used.

What kinds of materials can the plasma cut?

05

PLASMA CUTTER OPERATION MANUAL

SAFETY

Plasma cutting can be performed on any type of conductive metal - mild steel,

and thus it can cut aluminium, stainless and any other conductive material. While

compressed air for the plasma gas. In most shops, compressed air is readily

operation. Plasma cutting is typically easier for the novice to master, and on

plasma machines are required for plasma cutting applications.

How Does Plasma Cutting Compare to Oxy-fuel (gas) cutting?

The plasma Cutting process involves creating and electrical channel of

super¬heated. electrically ionized gas i.e. plasma from the plasma cutter itself,

through the work piece to be cut, thus forming a completed electric circuit back

to the plasma cutter via a grounding clamp. This is accomplished by a

which is blown through a focused nozzle at high speed toward the work piece. An

electrical arc is the formed within the gas. between an electrode near or

integrated into the gas nozzle and the work piece itself. The electrical arc ionizes

some of gas. thereby creating and electrically conductive channel of plasma. As

heat to melt through the work piece. At the same time, much of the high velocity

plasma and compressed gas blow the hot molten metal away. thereby separating

i.e. cutting through the work piece.

NOTE: This machine is designed to use only compressed air as gas.

Plasma Introduction

generally cut thicker sections (>63164 inch) of steel more quickly than plasma.

What are the limitations to Plasma Cutting?

Where is Oxyfuel preferred?

06 PLASMA CUTTER OPERATION MANUAL

07

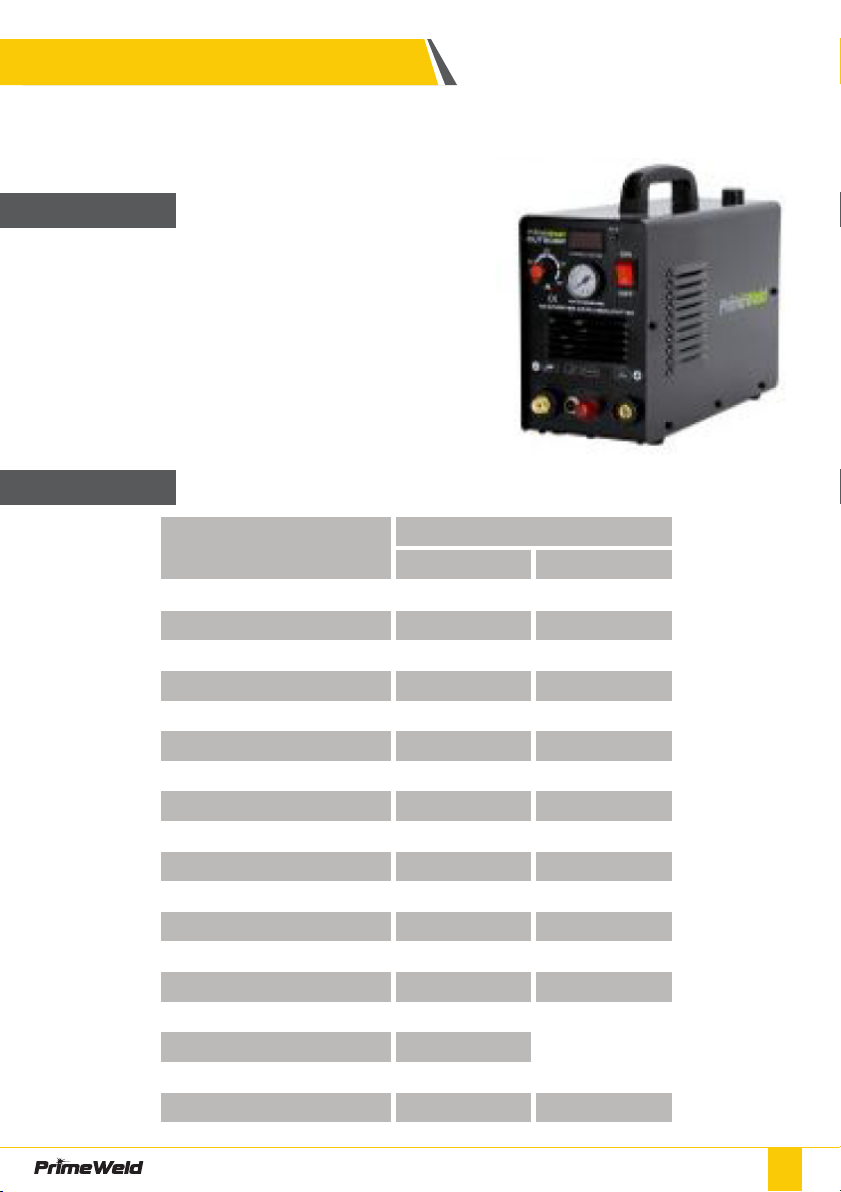

Cut50dp with 50 Amps cutting current.

Inverter with Industrial Rated, Lightweight and Portable.

PARAMETER

• Latest IGBT Inverter Technology

• Safe torch connection

• Industrial application

• Tolerant to variable power supply

• Quality Air regulator with preset air pressure

• Suitable to cut all electrically conductive materials

• Light weight and compact

• Strong metal housing

Amperage

Amperage

Model

Power Supply / Phases (V-Ph)

Duty Cycle @ 78°F ( 25 C)

Input Current Range (A)

35-40 40-45

Rated Power (KVA) 5.90 4.40

Output Current Range (A) 20-50 Amps 20-40 Amps

Rated Output Voltage (V) 100 96

No-Load Voltage (Open CricuC(V)

260 260

60 60

Insulation Class F F

Protection Class IP21S IP21S

Plasma Arc Starting

Air Flow Pressure Range (PSI) 40 - 65 psi 40 - 65 psi

Air Flow Rate (CFM) 5 L/min 5 L/min

Clean Cutting Thickness (mm) 12mm 12mm

Cutting Thickness Severance (mm)

16mm065psi 12mm065psi

Shipping Weight (kgs)

8.9kgs 8.9kgs

Cutting speed 10mm

200mm/min(065 psi 150mm/minG65 psi

Machine Dimenswns (inch)

Cut5ODP (110/220V)

220V 110V

PLASMA CUTTER OPERATION MANUAL

PARAMETER

Need to adjust the current and air pressure properly under metal thickness to

get best cutting surface

GENERAL DESCRIPTION

This unit is designed for light cutting project and weights only 11 kgs include

accessories. This powerful unit is good enough to cut 12mm ( 75PSI air pressure )

to 16mm severance thickness, making it an good idea for cost conscious DIY

hobbyists.

1. 50Amps inverter plasma cutter

3. suitable for stainless steel. Alloy steel, Mild steel. Copper and Aluminum, etc.

Cutting Thickness chart

SPECIFICATIONS

Cut50dp -220V 50Amps

12mm

20Amps 30Amps 40Amps

5mm 6mm 10mm

40-50psi 40-50psi 50-60psi 60-70psi

Thickness (mm)

Air Pressure (psi)

1

Cut50dp -110V

Thickness (mm)

Air Pressure (psi)

2

20Amps 30Amps 40Amps

5mm 6mm 10mm

40-50psi 40-50psi 50-60psi

Power source

Consumables AG60 Cutting Torch

Earth Clamp & Cable Air hose

08 PLASMA CUTTER OPERATION MANUAL

09

LAYOUT

How to install machine

Power Switch

Current Display

Current knob

Connecting torch to machine

Torch switch

For Pilot arc

Earth Clamp

Air Pressure Display

G1/4 Screw Air Connector

Fan

Input power cable

Air hose

Air regulator

PLASMA CUTTER OPERATION MANUAL

LAYOUT

Connection

Air Pressure

Current Knob

Torch connector Torch switch Earth Clamp

For Pilot arc

Power Switch

Display

Air Compressor

Air regulator

Input power

Earth clamp

Metal Piece

Torch

10 PLASMA CUTTER OPERATION MANUAL

11

LAYOUT

Back Connection

Explosive View of Machine

Air Compressor

Air regulator Input power

Regulator

Air Plug

Fan

Top PCB Air Meter

Case

Knob

Earth Socket

Torch Switch

Torch plug

Front Piece

Foot

Bottom case

Electric Valve

Cable Clamp

Power Switch

Center

PCB

Digital

PCB

Front Sticker

PLASMA CUTTER OPERATION MANUAL

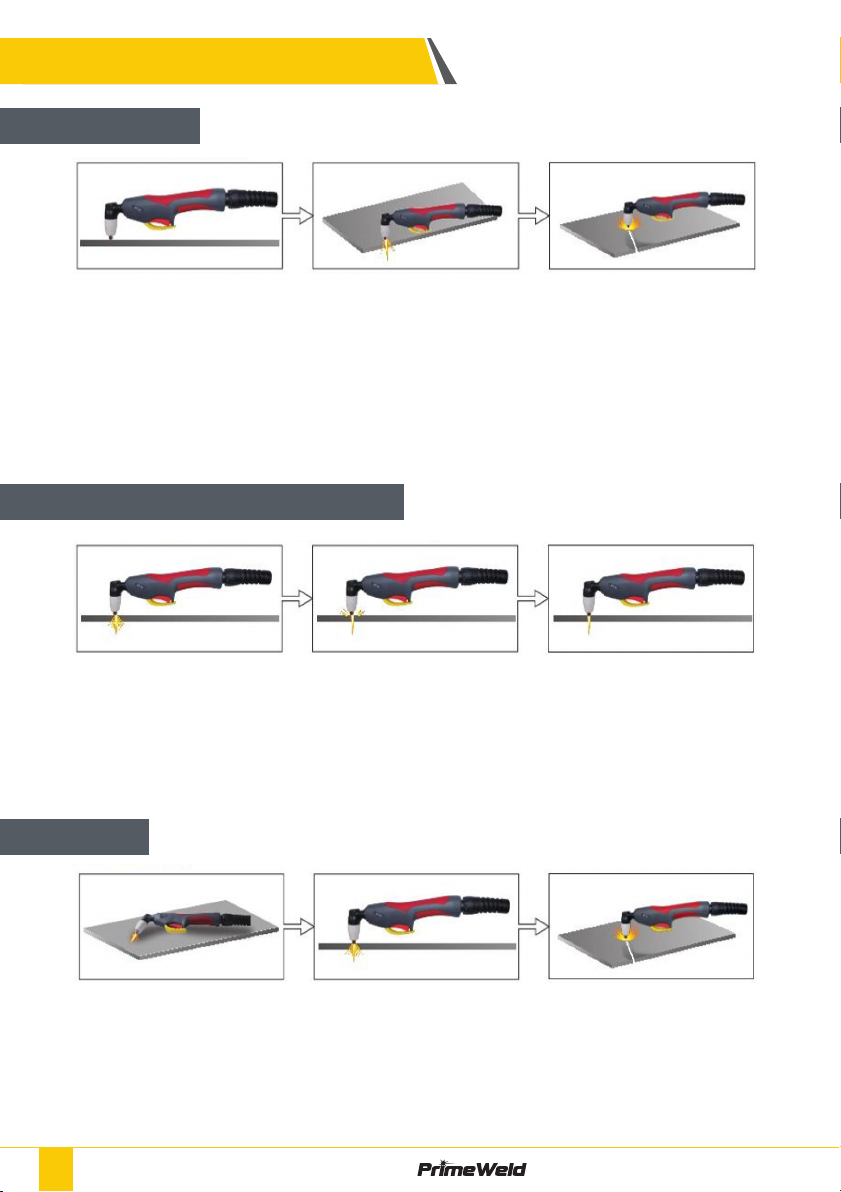

OPERATION

Start Cutting

Hand Torch cutting technique

Piercing

at the odge Of he work

piece

Then. Proceed with

the cut.

Pull the Trigger to start

the arc , the cutting arc

will initial when the

Torch tip is close

enough to the work

Piece. Start Cutting on

the edge until the Arc

has cut completely

through.

When cutting make

sure that sparks are

bottom of the work

piece.

vertical and watch

thearc as it cuts

along the line.

If sparks are spraying

up from the work

Piece, you are

moving the torch too

fast, or you don't

have enough amps

sel.

angle to the work

piece, pull the trigger

to start the arc and

slowly rotate it to an

upright position.

When the pierce is

complete, proceed

with cutting

When sparks are

bottom of the work

piece, the arc has

pierced through the

material

12 PLASMA CUTTER OPERATION MANUAL

13

OPERATION

How to use air regulator

Machine Dimensions

Clockwise increase air pressure

Pull up Pull down

Air regulator

Water release

Anti-Clockwise Reduce air pressure

143mm 348mm

234mm

PLASMA CUTTER OPERATION MANUAL

OPERATION

Standard rule of thumb is the thicker the material the more amperage required.

On thick material, set the machine to full output and vary your travel speed.

On thinner material, you need to turn down the amperage and change to a

lower-amperage tip to maintain a narrow kerf. The kerf is the width of the cut

material that is removed during cutting.

Amperage

Amperage and speed are critical to producing a good quality cut. The faster you

move (especially on aluminium), the cleaner your cut will be. To determine if

you're going too fast or too slow, visually follow the arc that is coming from the

the direction of travel. If it's going straight down. that means you're going too

slow. and you'll have an unnecessary buildup of dross or slag. If you go too fast, it

will start spraying back onto the surface of the material without cutting all the

way through. Because the arc trails at an angle, at the end of a cut, slow your

cutting speed and angle the torch in to cut through the last bit of metal.

Speed

It is easier to pull the torch towards you than push it. The plasma stream swirls

material and needs to taken into consideration before starting your cut as you

Direction

Torch tip height & position

bevel is by cutting at the proper speed and height for the material and amperage

that is being cut.

Correct torch height and

Square to the material

Minimum bevel & equal

bevel Longest

consumable life

Torch Angled to the

material unequal bevel,

one side may be

14 PLASMA CUTTER OPERATION MANUAL

15

OPERATION

at lower settings for use on thin-gauge material. Using a 25 amp tip at an 60 amp

Conversely. using an 80-amp tip on the lower settings will not allow you to focus

produce a distorted plasma stream resulting in a poor cut quality.

Tip size and condition

Electrons arc across the gap, ionizing and super heating the air creating the

plasma stream. The electrode contains an insert in the end made of a highly

conductive material called hafnium. This insert erodes with use and develops a

pit in the end of the electrode, when the pit becomes too much poor quality cuts

will result and necessitate replacement of the electrode.

Electrode condition

consumable life span.The required air pressure and volume can vary from model

to model and the manufacturer will provide the specs.The primeweld cut50 air

capacity of your compressor is important. if you have a small compressor with

continuously when you are plasma cutting. a compressor with a l/min rating

slightly higher than the plasma would be more adequate. If you are doing a lot of

cutting, cutting thick plate (same air consumption but slower cut speeds = longer

cut time) then choose a compressor at 1.5 to 2 times the plasma system

requirement.

Air pressure and volume

Torch height too high

Stream may not cut all the

way through the material

Torch height too low Reverse

bevel. Tip may contact the work

piece and short out or damage

the tip.

PLASMA CUTTER OPERATION MANUAL

Good air quality is essential to quality plasma cutting and consumable life span.

Compressors take in air at atmospheric pressure and increase the pressure and

producing water, more so in humid environments. Moisture that forms in air

lines has a tendency to condense into larger drops when the air pressure

decreases as it is entering the plasma torch. When these droplets enter into the

high temperatures (as much as 19832°f) in the plenum of the torch, they immedi-

content of air in the torch. These elements will then dramatically change the

plasma arc which causes the torch consumable parts to wear very quickly, alters

squareness, dross formation, and edge smoothness. Minimising the moisture in

the air supply is absolutely critical to quality plasma cuts and longevity of

consumable parts. As a minimum be sure to drain the receiver (tank) on the air

compressor at least daily. Most air plasma systems from reputable manufactur-

drain that will remove some moisture from the air supply. For home workshop

quality of the plasma cutter and in most cases it is recommended to install a sub

changed after it is near saturation, it should be installed close as possible to the

air intake of the plasma cutter.

•It is easier to pull the torch through the cut than to push it.

•To cut thin material reduce the amperage until you get the best quality cut.

•For Straight cuts use a straight edge or cutting buggy as a guide. For circles, use

a template or circle cutting attachment.

•Check that the front end consumable parts of the plasma cutting torch are in

good condition.

OPERATION

Air Quality

Technique Tips

Torch Connector cover

16 PLASMA CUTTER OPERATION MANUAL

17

1. Power indicate not

lighting when power up

, the fan not working ,

torch also not working

while press torch trigger

No power go into

machine through power

cable(AC220 orAC110)

no input

2.Power cable, switch or

other wire loosen

3.Power cable inside of

machine connect not

well

4.Power board problem

2.Check the power

cable: power switch,

power plug and all wires

inside of machine if any

loosen, check if any

wires loosen from

power switch to main

board.

3 Change the board

2. power indicator not

lighting up after switch

on , fan stop working

only works some

seconds, machine stop

working once the torch

touch the metal get arc

starting.

1.The starting circuit

problem, or relay

problem.

2.Too many times

machine over heat can

not get working

1 Check the power

components or change

the main board,.

2.Let the machine rest

some time restart it

again.

3. power indicator

lighting after switch on

machine, fan works, but

machine not working

while press torch trigger

1.Check the torch switch

or if any torch wires

loosen from torch

2.The torch switch

loosen or any wires

loosen

3. The switch wires

loosen inside of

machine for the torch

1 Check if any torch

2.Check if any wires

loosen on torch

3.Check if any wires

loosen inside of

machine

4. the power indicator

lighting, the fan works,

torch trigger but no air

blow out of torch head

or the air keep blowing

out ) The electric valve

not working

1.The electric valve

problem it is DC24V)

2.Maybe the air hose

stuck

3.The circuit for air valve

control problem

3.Check it:

4.Change the board,

Problems Analysis Solution

TROUBLE SHOOTTING

PLASMA CUTTER OPERATION MANUAL

TROUBLE SHOOTTING

5. Power indicator

lighting up, 0.0

indica¬tor not lighting,

Fan works, The gas blow

out of torch after

pressure torch trigger

( gas valve works )No

metal and electrode

broken

1.Check if any wires

loosen

capacitor.

6. Power indicator

lighting up, Fan works,

Gas blow out of torch

while pressing trigger,

0.0 lighting while

pressing torch trigger

1.Diode problem :

a1.Check every diode,

replace it if any

damaged 2.Check every

IGBT to see If any one

damaged

, Regisistor. Diode,

Replace it if any one

damaged

7. Power indicator

lighting , Fan works, Air

can blow out of torch

head after press torch

trigger, 0.0 indicator not

lighting, But it is lighting

up while cutting.

Check IC3140 and other

compoents

if any wires loosen.

2.Does the feedback

wire loosen or broken ,

Check and replace.

3.Replace the board.

8. The cutting current

can not be adjust

1.The wires loosen or

potentiometer

damaged

2.The setting circuit

problem.

1. Check the

potentiome¬ter if

middle pin to earth get

0-5V voltage. Replace it

if any damaged

2. Check if any wires

loosen from front board

to main board

3. Boards problem0

Problems Analysis Solution

18 PLASMA CUTTER OPERATION MANUAL

TROUBLE SHOOTTING

9. Machine auto shut

down after switch it on.

1.Maybe Power cable or

circuit board short

circuit

2.Silicon bridge probـ

lem

2.Check and replace it

3.Replace silicon bridge

10. After pressure torch

sound and spark, but

can not get arc start

starting not good

enough

0

after press torch switch

1.Welding torch broken

or loosen or Earth

clamp and cable

connecting not good

enough to the earth and

2.The connector for

positive or negative

loosen

1.The Gap for tip to the

metal not in good range,

The tip and electrode

3.GAS/AIR connector

damaged, power

leakage between

connector and front

panel

torch switch board and

disturb it.

1.Adjust the tip to metal

1.Check the GAS/AIR

torch connector, earth

female socket and torch

switch connector, if

between them to front

metal

Problems Analysis Solution

19

PLASMA CUTTER OPERATION MANUAL

Table of contents

Other PrimeWeld Welding System manuals

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual