540876_A_PUB_DATE_1_FEB_2012.DOC PROGRAMOVACÍ MANUÁL 3

INTRODUCTION

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS..................................................................................................3

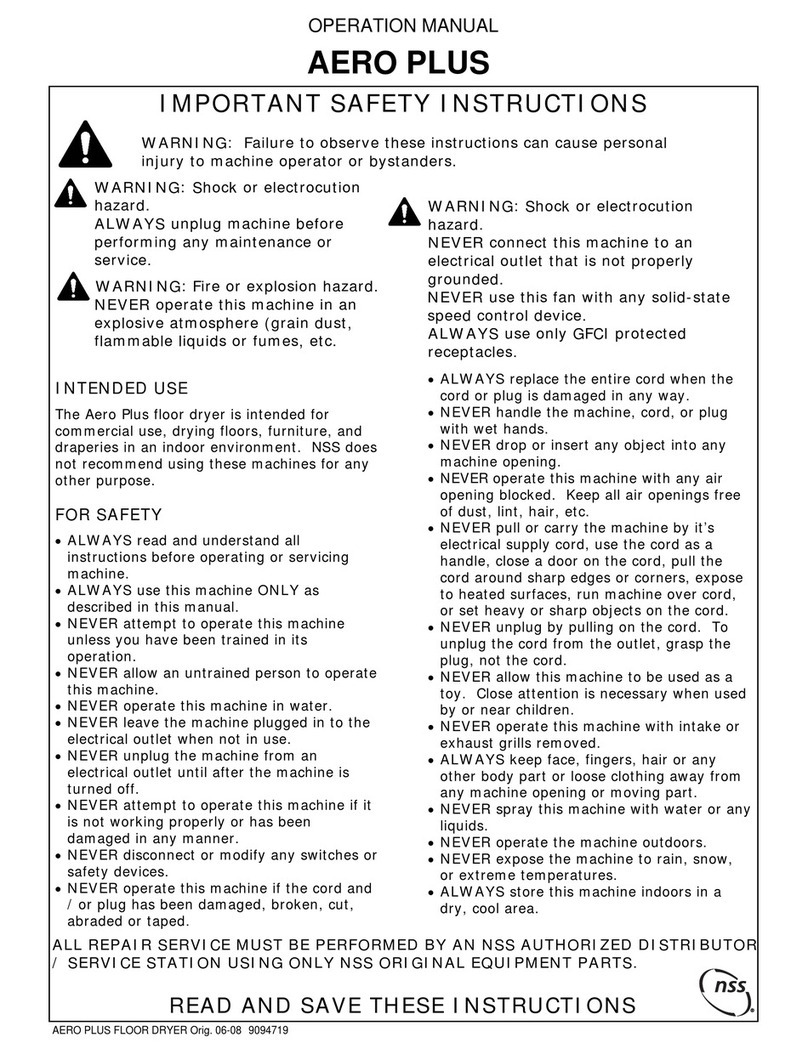

2.1. WARNINGS.................................................................................................................................................5

2.2. SYMBOLS USED........................................................................................................................................6

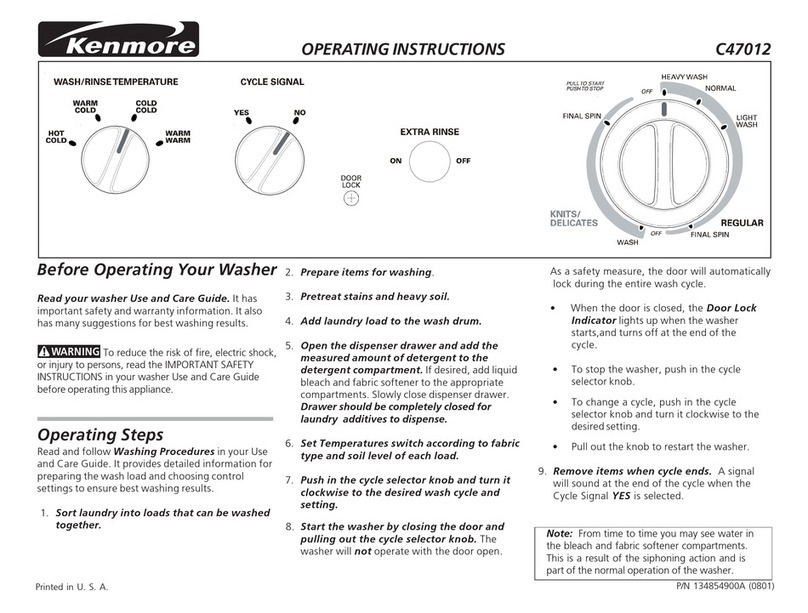

3. BASIC DESCRIPTION OF CONTROLS.........................................................................8

3.1. GENERAL ...................................................................................................................................................8

3.2. SPECIFIC....................................................................................................................................................9

3.3. HOW TO GET INTO THE SETUP MODE.................................................................................................10

3.4. THE CREATION OF A WASH PROGRAM...............................................................................................12

3.5. PROGRAMMING THE FUNCTIONS........................................................................................................14

4. INITIALIZING THE MACHINE.......................................................................................19

4.1 INITIALIZATION MENU..............................................................................................................................19

4.2 CONFIGURATION MENU..........................................................................................................................24

4.3 ADVANCED MENU....................................................................................................................................29

5. PROGRAMMING ..........................................................................................................34

5.1 GENERAL ..................................................................................................................................................34

5.2. STEP : PROGRAM MENU...................................................................................................................34

5.3. STEP : PROGRAM FUNCTIONS.........................................................................................................35

5.4. STEP : PROGRAM STEP FUNCTION ................................................................................................37

5.5. STEP : PROGRAMMING THE WASH PART ......................................................................................38

5.6. STEP : PROGRAMMING THE DRAIN STEP......................................................................................47

6. OPERATION MENU......................................................................................................50

6.1. STARTING UP ..........................................................................................................................................50

6.2. SWITCHING ON THE POWER.................................................................................................................50

6.3. LOAD THE WASHING MACHINE.............................................................................................................50

6.4. PUT SOAP INTO THE SOAP DISPENSER..............................................................................................50

6.5. STARTING A WASH PROGRAM .............................................................................................................50

6.6. PROGRAMMING A DELAY TIME............................................................................................................51

6.7. THE ACTIVE PROGRAM..........................................................................................................................51

6.8. ADVANCING A WASH PROGRAM..........................................................................................................52

6.9. WASH TIME..............................................................................................................................................52

6.10. PROGRAM END .....................................................................................................................................53

6.11. WATER FILL PROCESS.........................................................................................................................53

6.12. HEATING PROCESS..............................................................................................................................53

6.13. COOLDOWN FUNCTION .......................................................................................................................54

6.14. SPRAY FUNCTION.................................................................................................................................54

6.15. UNBALANCE...........................................................................................................................................54

6.16. PAUSE ....................................................................................................................................................54

6.17. STOP.......................................................................................................................................................54

6.18. WAIT STATE...........................................................................................................................................54

6.19. HOW TO HANDLE FAILURE MESSAGES.............................................................................................55

6.20. HOW TO HANDLE POWER INTERRUPTIONS.....................................................................................56

6.21. SPECIAL FUNCTION BUTTONS ...........................................................................................................56

6.22. EXTERNAL LIQUID SOAP BOXES........................................................................................................57

6.23. SYSTEM WITH MANUAL ENTERING OF THE LINEN WEIGHT (SMART LOAD) ...............................57

7. PRE-PROGRAMMED PROGRAMS .............................................................................58

7.1. LEGEND....................................................................................................................................................58