PrismCut P28 User manual

PrismCut

Cutter/Plotter with WiFi

Quick Start Guide

POWER SWITCH

CONTROL PANEL

touch screen

CARRIAGE HEAD (white)

moves the blade across cutting area

PINCH ROLLERS (black)

position pinch rollers under arrows

KEY STEPS FOR GETTING OPTIMAL RESULTS

• Use a short blade depth. In most cases, the blade does not need to be extended more than 1/2 the thickness of a credit card. New

users tend to expose too much blade. The idea is to cut through just the top layer of the vinyl and to leave the backing layer with only

minimal scratches. This allows you to weed the top layer o the backing easily. If corners or small detail do not cut all the way through,

consider increasing the force before extending the blade depth. You only need to extend the blade depth or use the 60 degree (blue tip)

blade for thicker materials.

• Set a safe and reliable speed. A good starting value for speed is 400. When you have accumulated experience with the material you

are cutting and production time becomes a factor, you can look to increase the speed. Also, intricate jobs typically require lower speeds.

• Set the correct force. A good starting value for force is 70, then adjust force up or down depending on how thick/dense the material

is to be cut. With cutting mat and test material in place, use the the Test Cut icon on the cutter’s main screen to cut a small square in

your test material to see that it cuts all the way through and can be weeded easily.

• Align the pinch rollers so that they are under the guide arrows. The pinch rollers must align with the gritted sections on the bottom

roller. Note that the small levers on top of each pinch roller should be set to the down position unless extra strong pressure is needed.

• The cutting mat is used when cutting materials that do not have their own backing. Place your material on the cutting mat so that

the pinch rollers roll on the mat, not the material. Move unused pinch rollers out of the way so they don’t touch the parts of the material

being cut. Use a brayer roller to flatten your material on the sticky part of the cutting mat or tape the edges of thicker materials to the

cutting mat. For wider jobs it sometimes cannot be avoided and the pinch rollers will need to roll over areas of the material being cut,

however typically this is not a problem.

• When cutting long pieces of material it is important to carefully position the material so that it is completely straight and doesn’t drift

to one side when cutting. CONSULT THE USER MANUAL OR WATCH VIDEOS FOR ADDITIONAL TIPS

POWER PLUG

USB CABLE PORT

connect to computer

only if not using WiFi

U-DISK SLOT

cut files without computer

PINCH ROLLER LEVER

Up/Down pinch rollers

ver 1.7 - Oct 3, 2019

Use 45 degree blade for

most common uses

Use 60 degree blade for

thicker materials

Set blade depth to cut only

the material not the backer

BLADE SETUP

Quickstart Video: www.prismcut.com/videos

BLADE HOLDER (silver)

(caution: blade inside!)

Turn on Cutter for WiFi SETUP (follow prompts on cutter main display)

Connect to your home

WiFi using the same

WiFi password you

use for your tablet or

other home devices

START HERE

NOTE: You do NOT need the USB cable if using WiFi. WiFi is recommended

YOU CAN ALSO ACCESS THE WiFi MENU BY PRESSING THE SETTINGS ICON

For Windows PC download VinylMaster at: https://fcws1.com/info/vmlinks.php

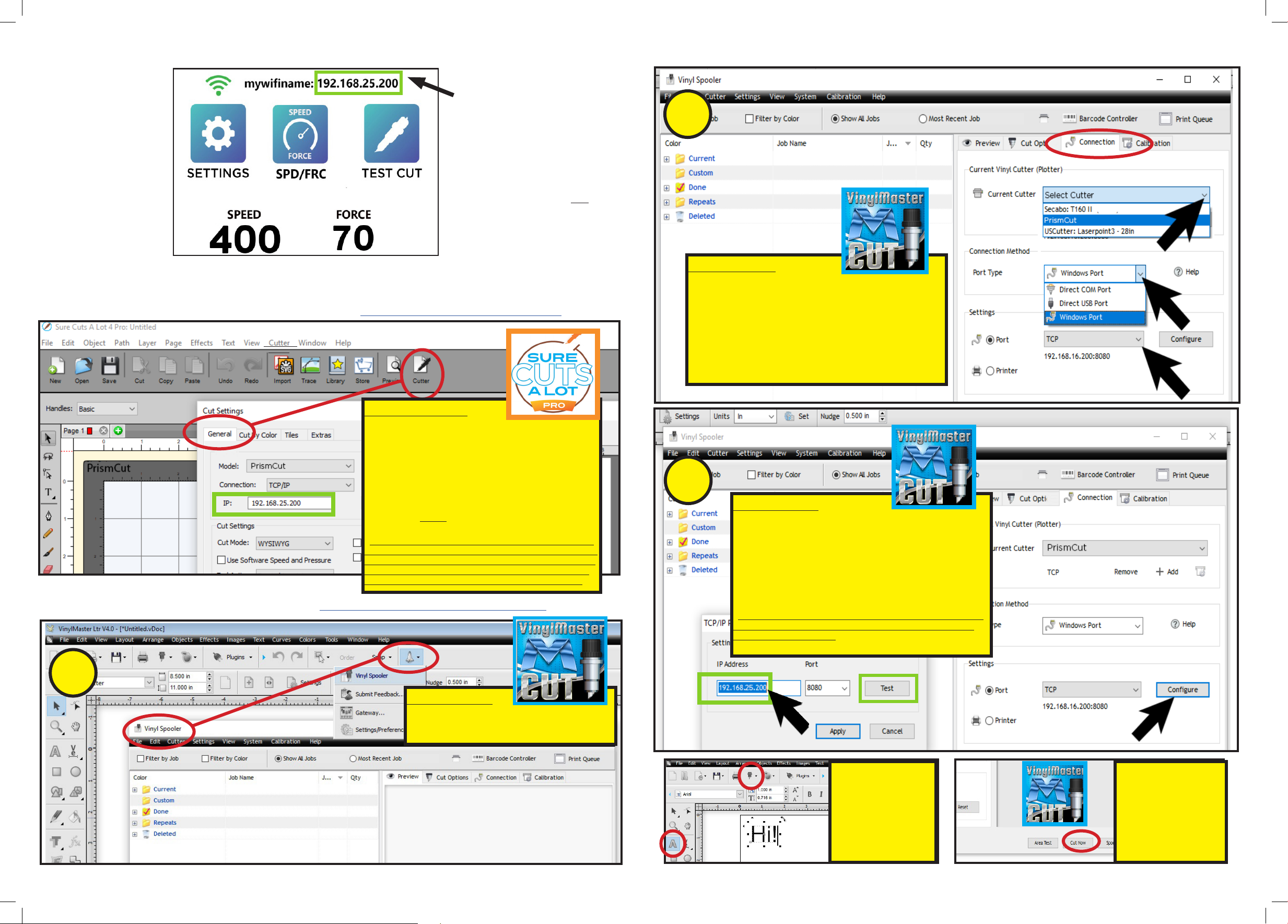

SURE CUTS A LOT (MAC screen)

For MAC computers download Sure Cuts A Lot software at: www.craftedge.com/register/scal4pro

Sure Cuts A Lot - Step 1

To configure WiFi if your software is Sure Cuts a Lot,

click on Cutter icon to open Cut Settings menu.

Select Model = PrismCut, Connection = TCP/IP and

enter the IP address displayed on the cutter’s home

screen.

The IP address on both the cutter and the computer

must match in order for WiFi communications to work.

If you do not see PrismCut as a model selection, on

the very top line where you see File, Edit, Object, Path

etc. click on Cutter->My Cutter->Manage Cutters and

add PrismCut

Your cutter and computer should now be connected.

In the Sure Cuts A Lot program, try dragging the heart

shape from the library onto the design mat and send it

to the cutter (click the cutter icon to send to cutter).

With no blade yet, you will not damage your cutter.

VinylMaster - Step 1

To configure WiFi if your software is VinylMaster,

first click on Shuttle icon to open the

Vinyl Spooler menu.

VinylMaster - Step 2

* Click on the Connection Tab within the Vinyl Spooler menu

to display cutter Connection Settings (red oval, top right)

* In Current Vinyl Cutter section click on the pull down menu

for Current Cutter and select PrismCut (see black arrows)

* If you need to add a new cutter click the +ADD button

under Current Cutter

* In Connection Method section click on the pull down menu

for Port Type and select Windows Port

* In Settings section click on the pull down menu for Port

and select TCP

VinylMaster - Step 3

* Within the same Connection Tab, click on the Configure

button in the Settings section to open a window to

configure the TCP/IP port values.

* Connect cutter to WiFi IP before adding IP in VinylMaster

* Enter the IP address that is displayed at the top of the

PrismCut cutter’s home screen.

* The IP address MUST be the same for both cutter and PC

* Ignore port number (leave it at 8080)

* Press the Test button to verify that communications work

Your cutter and PC should now be connected. You can try

creating a simple design in VinylMaster and send to your

cutter as outlined below

AFTER SETTING UP WiFi ON THE CUTTER, DOWNLOAD AND INSTALL EITHER SURE CUTS A LOT

OR VINYLMASTER SOFTWARE AND CONFIGURE YOUR SOFTWARE WiFi TO MATCH CUTTER WiFi

THIS IS THE IP ADDRESS.

IT MUST MATCH ON BOTH THE

CUTTER AND COMPUTER.

IP STARTS WITH 192.168.... (or

sometimes IP starts with 172....

or 10.....) BUT YOUR NUMBERS

WILL BE DIFFERENT.

Note: if the top line starts with

HI-LINK_xxxx you are not yet

connected to your home router.

Go to WIFI in SETTINGS to set up

WiFi connection.

1

2

3

Click on the A icon

on the left side of the

screen and then click

inside the design area.

Type Hi! and then click

on the cutter icon on

the top line to send

the job to the cutter

Click on “Cut Now” to

confirm your choice.

Since the blade is not

yet inserted you will not

damage your material

but you should see the

control head move,

confirming you have

communications

You will need the software serial number you received with your purchase to download software

This manual suits for next models

1