Thank you for purchasing the FSXC CUTTER from Malco. The FSXC CUTTER

may be used by professionals to cut the ver cal leg of mechanically seamed

panels in the event the roof needs to be removed or repaired. Keep reading

to learn more about how to setup and use the FSXC CUTTER.

Video instruction

sPECIFICATIONS

•

Malco Products warrants to the original customer/consumer that its

products will be free from manufacturing defects in materials or work-

manship when subject to normal and proper use.

DEVICE WEIGHT

MAX. CUTTING DIMENSIONS

DESCRIPTION

MAX. SPEED

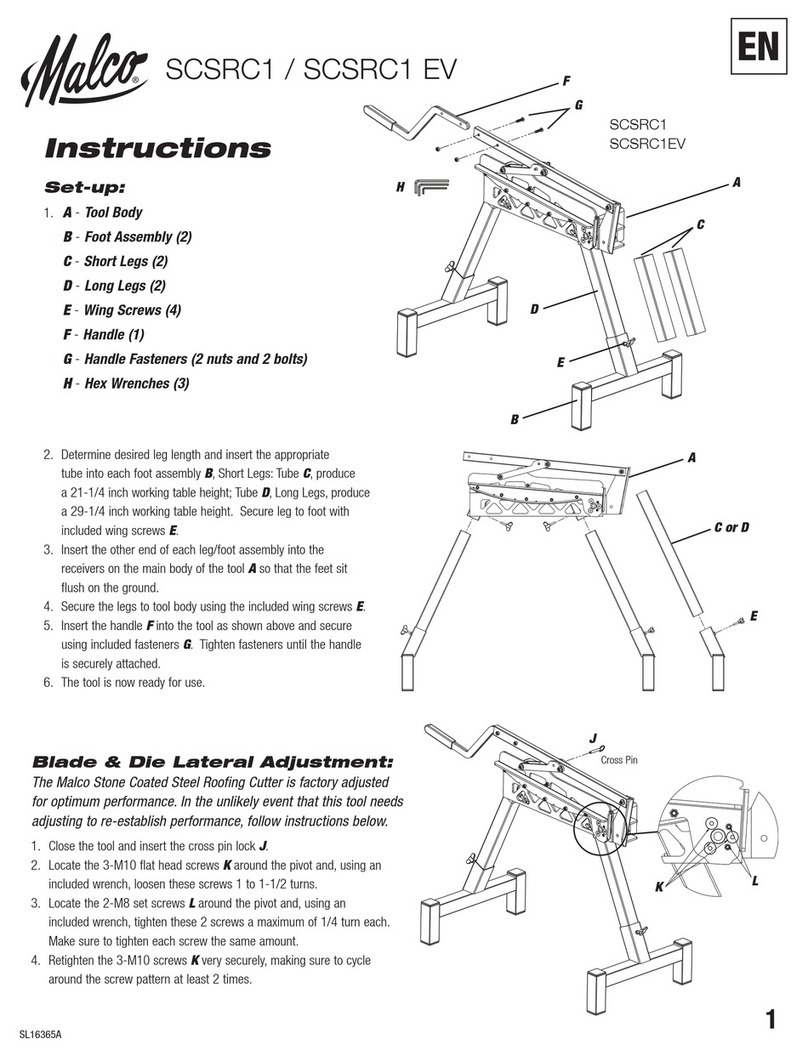

SET UP OPERATION

Always remove drills power source when se ng up the

FSXC CUTTER for your own safety!

1. Install drive sha into drill chuck. Tighten the chuck. If using a keyless

chuck we recommend ghtening fully by hand then rota ng the chuck

back to lock the chuck if equipped.

2. Adjust and ghten support bar.

3. Stretch the bunjee cord around the drills/drivers’ ba ery accordingly.

4. Set drill to drill mode, set drill speed to 1 (lowest RPM), then verify the

drill is spinning clock wise, this will ensure the cu er moves in a forward

direc on.

5. You are all set up and ready to go. Please move on to the opera on sec on.

The FSXC CUTTER is height adjustable for 1” and 1.5” profi les. The cu ng

discs must be posi oned under the seam, and all 4 wheels need to be set to

the same height for best results.

Height adjustment

All 4 wheels must be in the same height!

Check whether material thickness and roof profi le dimensions are

within allowable range specifi ed in this instruc on.

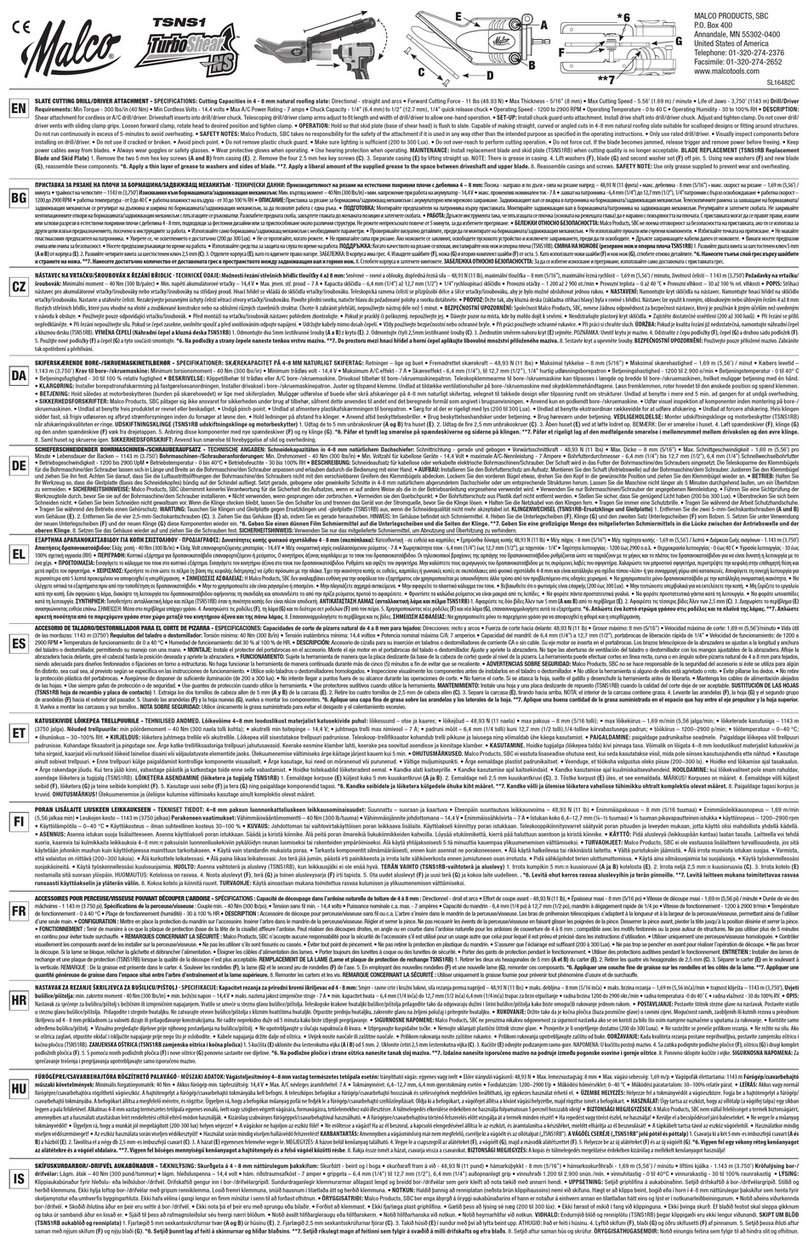

TO CUT FULL LENGTH PROFILE

TO CUT FROM THE MIDDLE OF THE PROFILE

Use correct cu ng posi on! Machine is not designed to cut the mid-

dle of the seam con nuously. It is only allowed for crossing the seam

– going in and out. Do not cut more than 4 layers of metal!

Warranty

• Should any such defect occur following original purchase, Malco Prod-

ucts will repair or replace, at its discre on, the defec ve product.

• See full terms and condi ons on our website.

• Malco Products shall not be liable or responsible for labor charges or

other expenses whatsoever in connec on with removal or installa on

of either the original or replacement product. In the event of repair

or replacement under the terms of this warranty, the original warranty

shall apply to the repaired or replacement product.

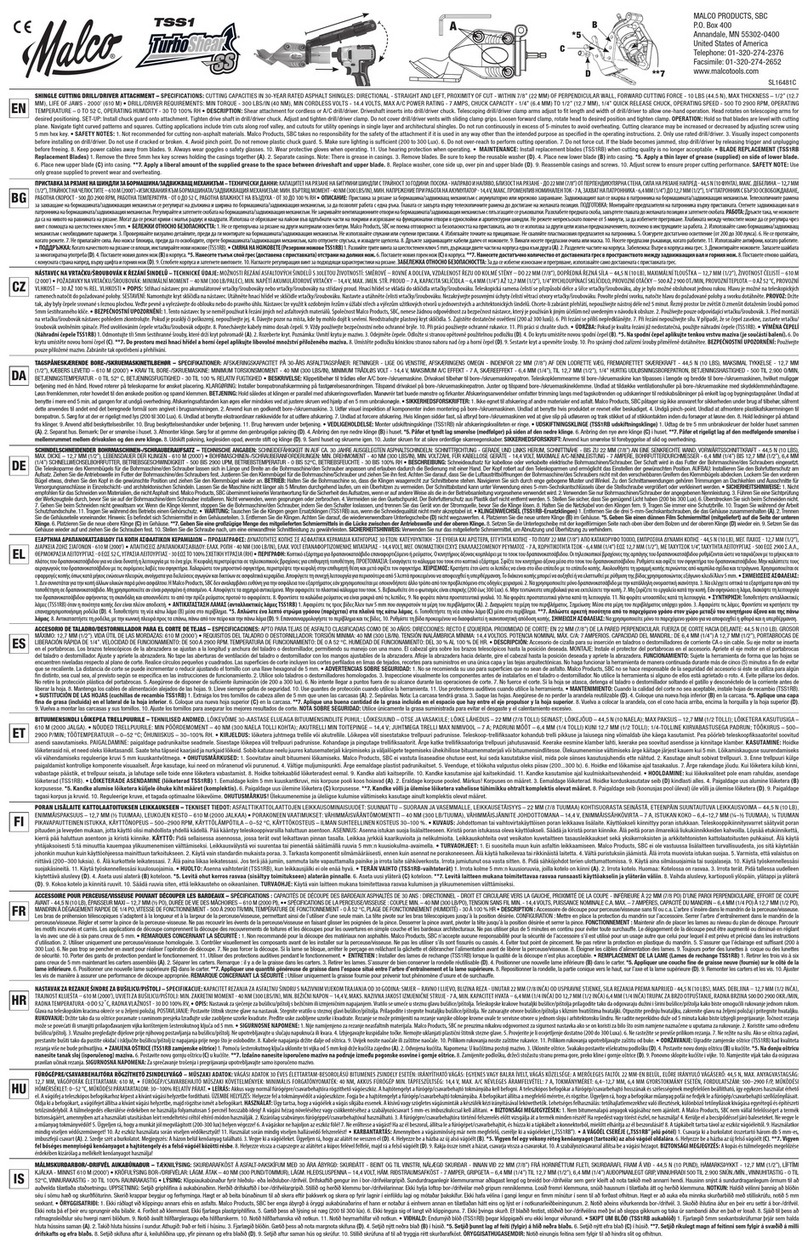

Cu ng wheels must ride under the seam.

Cu ng disc

Cu ng disc

Roof seam

Tilt the drill by 20 ° to 30 °

and start cu ng.

Wheels must touch the sheet while cu ng!

Do not use impact driver or hammer drill in hammer mode

while opera ng this tool.

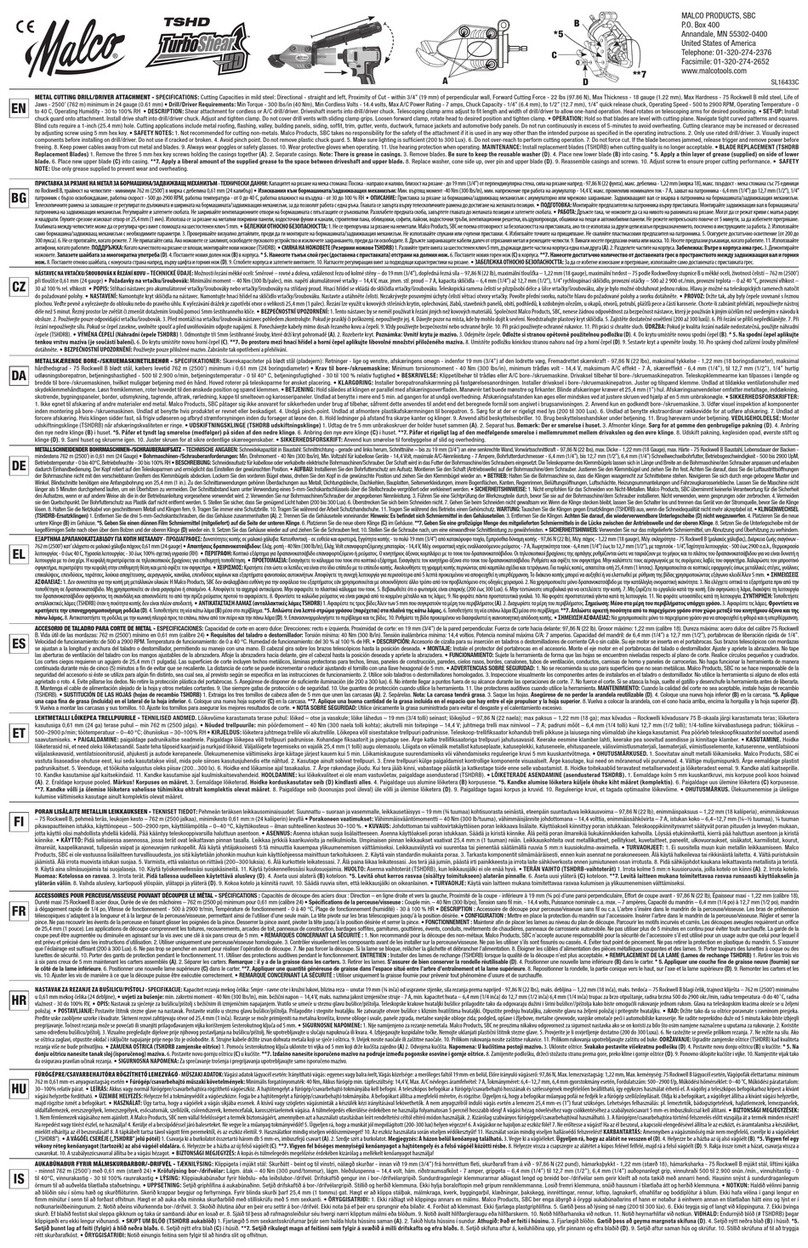

FIRST STage SECOND STage

Standard

Seaming Profiles

7/16” (11.5 mm)9/16” (15.5 mm)

1 1/2” (38mm)

11/16” (18.5 mm)

1

2

3

4

Special design

to adjust tension

MAX. THICKNESS

• Stainless steel: 26 ga. (0.5 mm)

• Aluminum, Copper, Zinc: 20 ga. (0.8 mm)

• Steel: 24 ga. (0.7 mm)

dRILL/DRIVER REQUIREMENTS

• 1325 in./lb.

MAX. TORQUE

• 975 in./lb.

RECOMMENDED TORQUE

• 535 in./lb. for so roof material

MIN. TORQUE

Before cu ng the ver cal leg, confi rm the cu er is able to ride under the

seamed profi le as shown in the image below.

1. Expose both ends of the seam to ensure the FSXC CUTTER may operate

over the full length of the seam.

2. Posi on the FSXC CUTTER at a seam end with the seam centered be-

tween the wheels.

3. With the drill set to speed 1, use the variable speed trigger to feed the

cu er on to the seam. Once the cu er is feeding material correctly, fully

depress the trigger and cut the seam off of the roofi ng material.

The FSXC CUTTER may be started or stopped mid seam if required.

1. Center the cu er over the seam and lt the cu ng wheels down (20-30

degrees towards the direc on you intend to cut.

2. Apply downward pressure towards the direc on of cut and use the vari-

able speed trigger to feed the material into the cu er. Once the seam

has been cut, fully depress the trigger and cut the ver cal leg as needed.

1. Remove the wheels using the provided 5mm wrench.

2. Refasten the wheels in correct posi on.

3.

Visually confi rm the height of the cu ng discs is correct for the seam

height and that all 4 wheels are contac ng the material.

4. Tighten the fasteners retaining the wheels.

5. You are all set up and ready to go. Please move on to the opera on sec on.

• 9 lbs. (4.0 kg)

• 56 ./min. (17 m / min)

1” (25 mm) profi le

1.5” (38 mm) profi le

1” (25 mm) profi le

1.5” (38 mm) profi le