PRODUCT

P 1/ 11

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Note: The standard equipment for the tool shown above may vary by country.

GA4034, GA4534, GA5034

Angle Grinders 100mm (4"), 115mm (4-1/2"), 125mm (5")

Models GA4034, GA4534 and GA5034 are paddle switch version

of GA4030 series models which feature easy-to-grip slim housing.

Features more compact and lightweight design compared with

the predecessor models of 9556PB series.

Lock nut wrench 20 ...................... 1 (for GA4034)

Lock nut wrench 28 .......................1 (for GA4534/ GA5034; USA, Canada, Mexico, Panama)

Lock nut wrench 35 ...................... 1 (for GA4534/ GA5034; all countries except USA, Canada, Mexico, Panama)

Depressed center wheel ................ 1 (100-36 for GA4034, 115-36 for GA4534, 125-36 for GA5034)

Side grip ........................................ 1

Model No.

No load speed: min.-1 = rpm

Diameter

Hole diameter

Wheel size: mm (")

Protection against electric shock

Power supply cord: m (ft)

Net weight*: kg (lbs)

GA4034

100 (4)

Brazil, Australia: 2.0 (6.6), Other countries: 2.5 (8.2)

1.8 (4.0) 1.9 (4.2)

11,000

Double insulation

16 (5/8)

GA4534

115 (4-1/2)

22.23 (7/8)

GA5034

125 (5)

Optional accessories

Wheel guards for Cut-off wheel, Cut-off wheels, Abrasive discs, Rubber pad (for abrasive disc), Sanding lock nuts,

Wire cup brushes, Wire bevel brush (for GA4034 only), Wheel brush (for GA5034 only), Anti-vibration grip

L

H

W

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output

440

Max. Output (W)

110

120

220

230

240

6.9

6.0

3.4

3.3

3.2

50/60

50/60

50/60

50/60

50/60

720

---

720

720

720

960

960

960

960

960

Current (A)

440

440

440

440

*Weight according to EPTA-Procedure 01/2003, with Side grip, Wheel cover, Inner flange, Lock nut

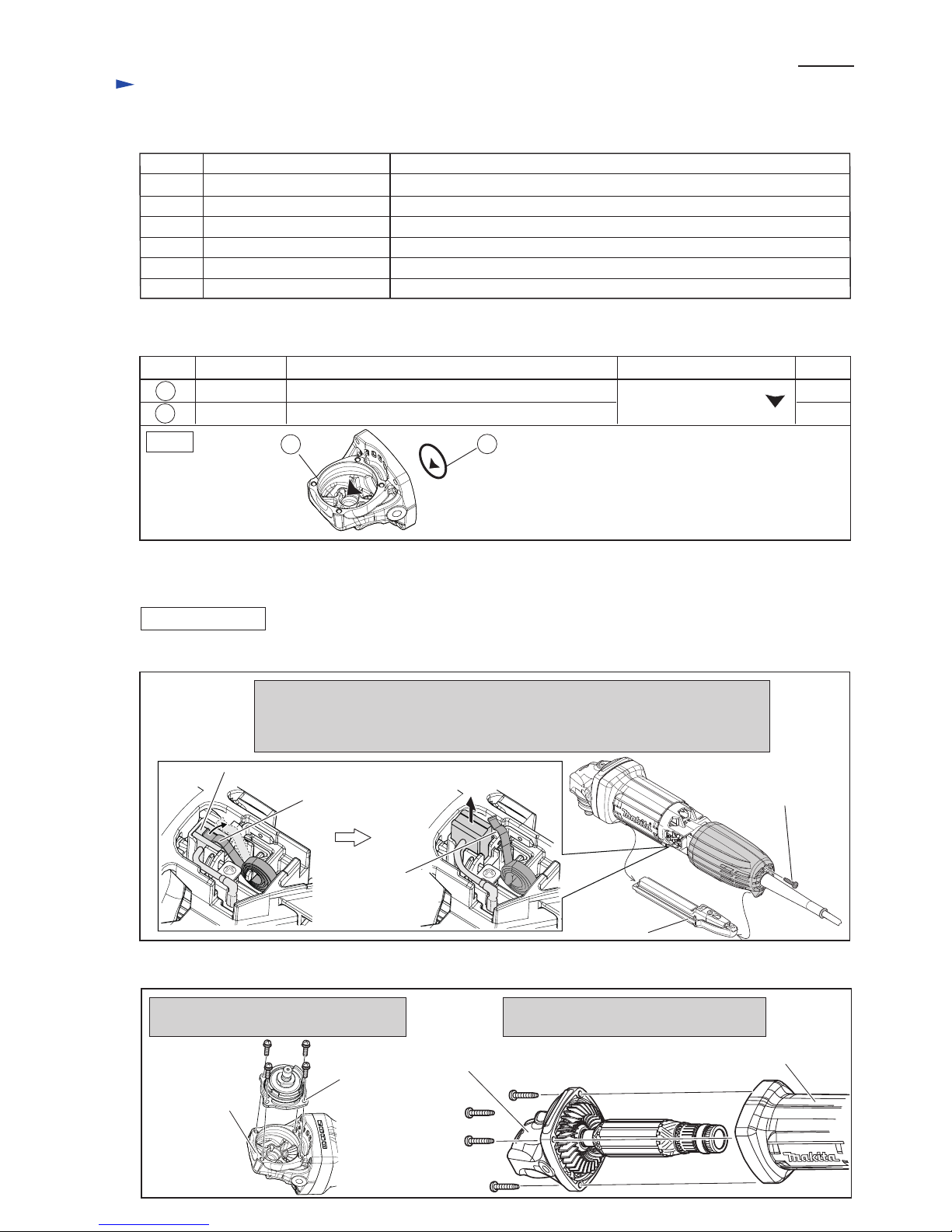

Specification

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

Model No. GA4034

265 (10-3/8)

118 (4-5/8)

GA4534 GA5034

128 (5)

95 (3-3/4)

139 (5-1/2)

103 (4-1/16)

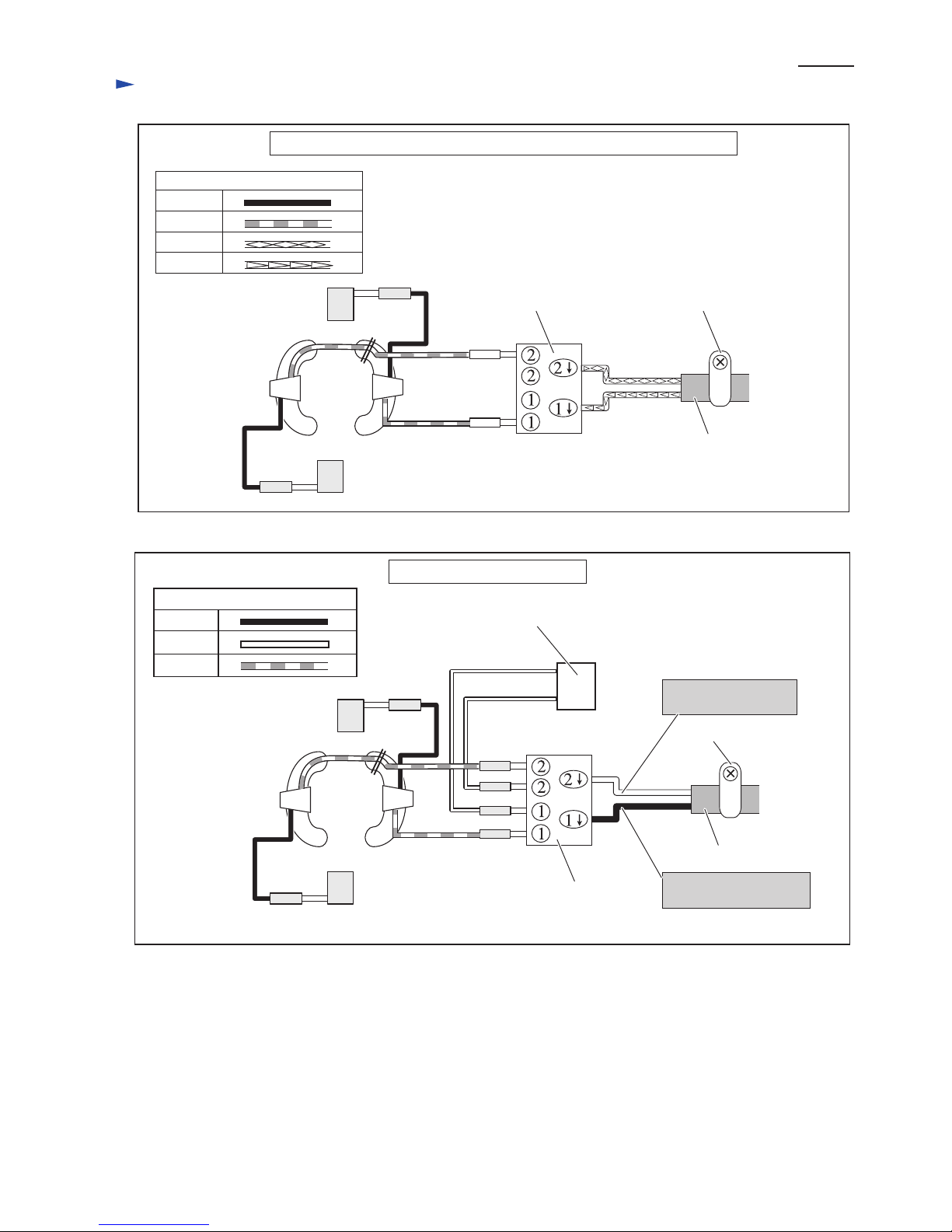

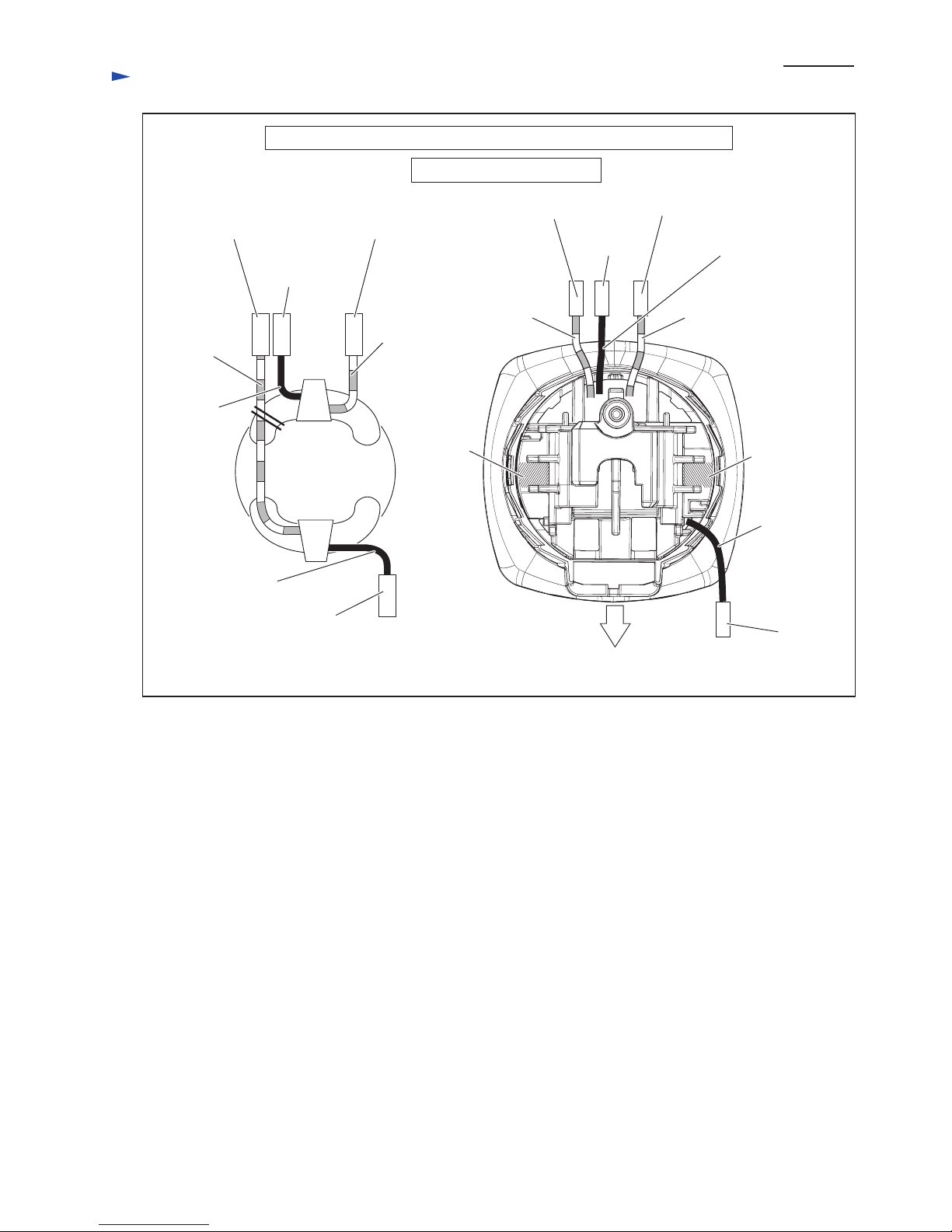

TECHNICAL INFORMATION