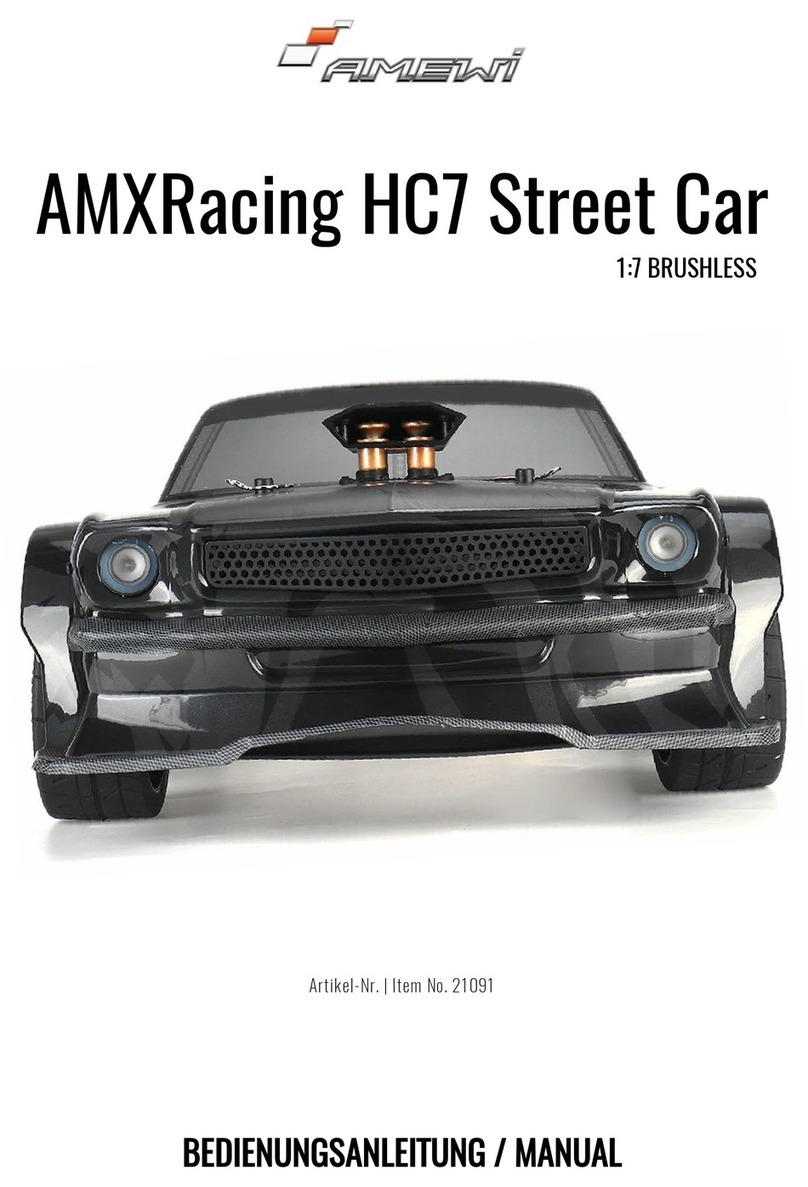

PRO1 Racing PRO1 2004 User manual

PRO1 2004

THE ULTIMATE RACING MACHINE

Dear Customer

Enclosed you will find several data sheets and illustrations for the 2004PRO1

race car. All this data is based on what our factory engineers and drivers

have developed In design, testing and actual racing conditions.

The PRO1 ¼scale race car is a precision built machine. For it to operate

properly the following must be adhered to:

- Keep the car clean

- Rebuild shocks every 3 to 4 races

-Always check the suspension for free movement, replace damaged

components.

-Make sure servos and servo savers are functioning properly. Never bottom

out servos at end points.

-Tire maintenance is very important, all ways check for proper wear and loose

Bands.

-Use a quality fuel such as VP16 and keep the air filter clean.

-Do not over tighten the drive belt, make sure it has about ¼” deflection at

the center of the belt.

-Have a check list that you can go by every time you put your PRO1 on the track

Sincerely

PRO1 Racing

118 E Swan Ave

Konawa, OK 74849

580-320-7761

www.pro1z.com

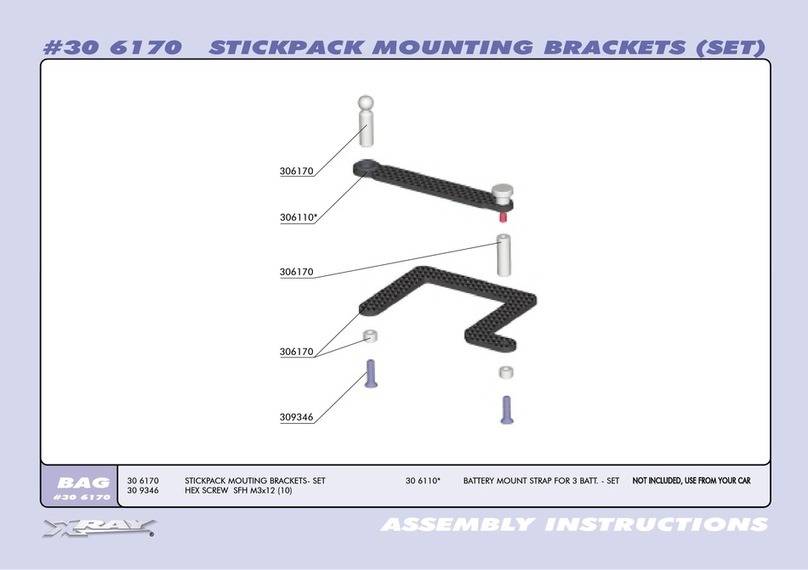

RECOMMENEDED RECEIVER BOX AND BATTERY

MOUNTING

SHOCK ASSEMBLY DIAGRAM

SPRING COLOR CODE

AND RATES

COLOR RATE (in /lb)

ORANGE 8

YELLOW 10

WHITE 14

SILVER 18

GREEN 20

BLUE 22

RED 31

BLACK 38

BASIC SETUP

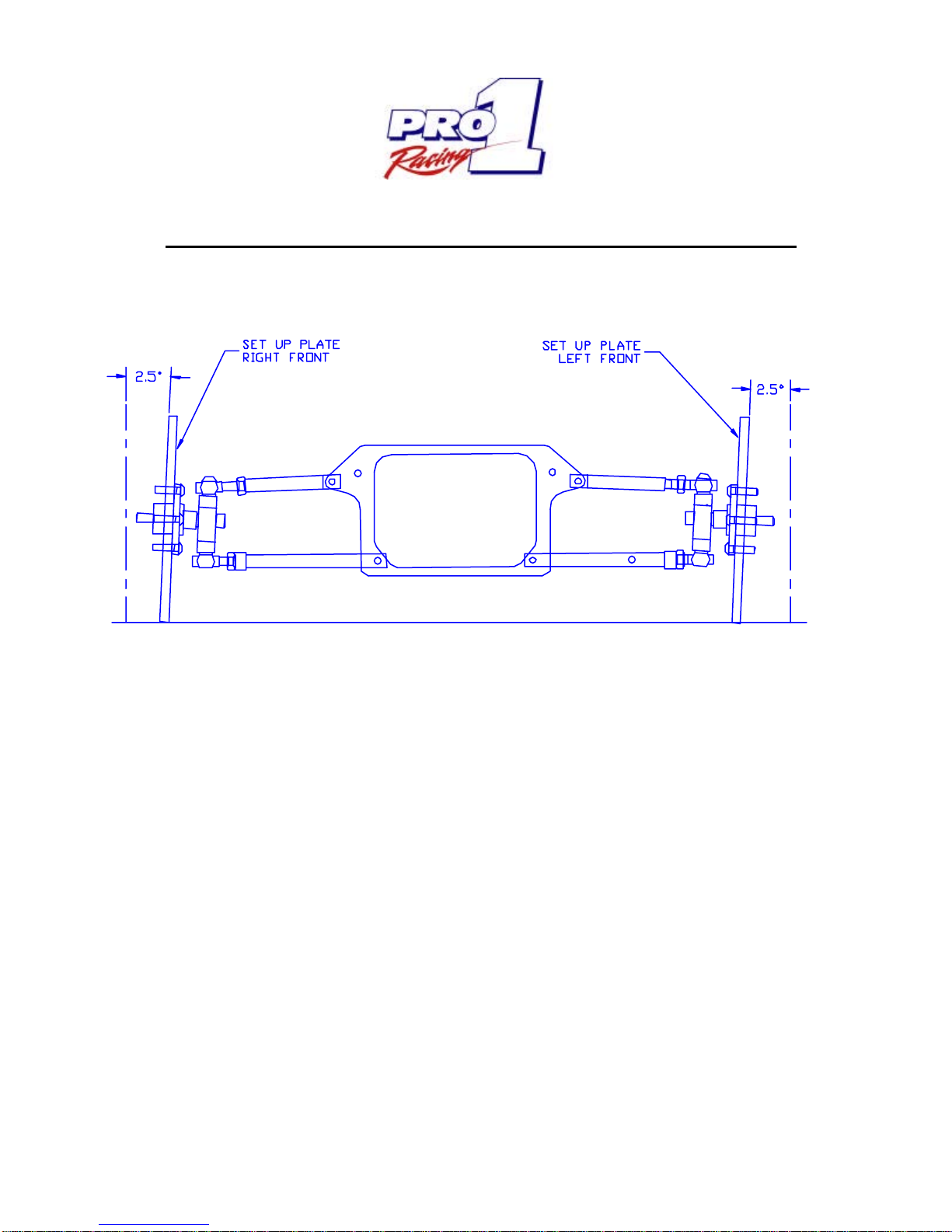

Front Tow: 1/8" tow out

Front Caster, left: 2 to 3 degrees positive (shim adjustable)

Front Caster, right: 4 to 6 degrees positive (shim adjustable)

Rear tow, left: 0"

Rear tow, right: 1/8" tow in

Front Camber, left: positive 2 ½ degrees

Front Camber, right: negative 2 ½ degrees

Rear Camber, left: positive 3 ½ degrees

Rear Camber, right: negative 4 ½ degrees

Shocks

Front left – red spring, 20w silicone shock oil

Front right – blue spring, 20w silicone shock oil

Rear left – white spring, 10w silicone shock oil

Rear right – red spring, 20w silicone shock oil

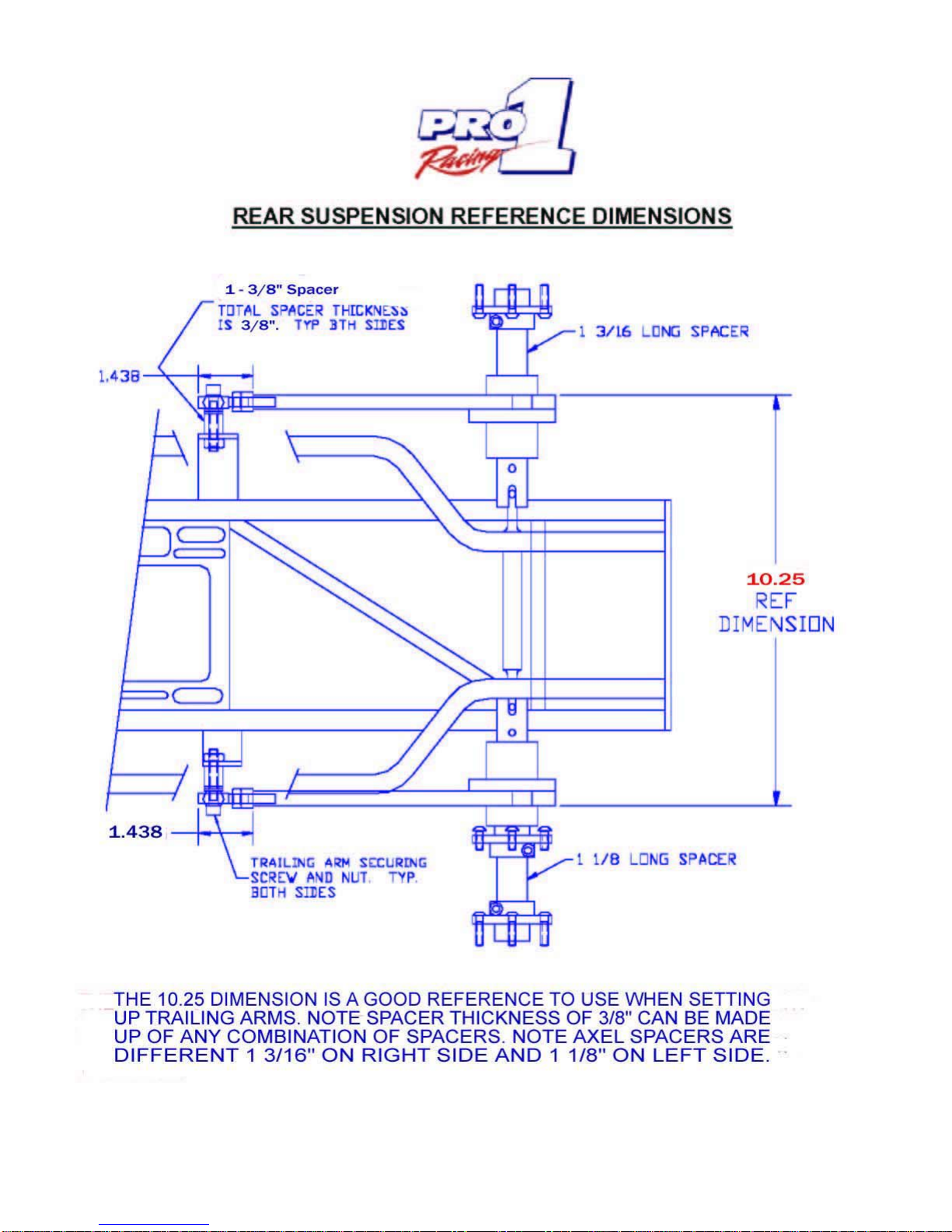

Rear Toe Measurement

Mount 6" aluminum disks on the rear hubs. Clamp a straight edge on disk as

shown. Using a 12" rule measure at points "A" and shimming trailing arm pivot

point until "A" points are1/8" towed in. Use trailing arm pivot points for gross

adjustments and rear links for fine adjustments. When adjusting rear links turn

them in or out equally. See “notes” page on how to fabricate your own straight

edge and alignment disks.

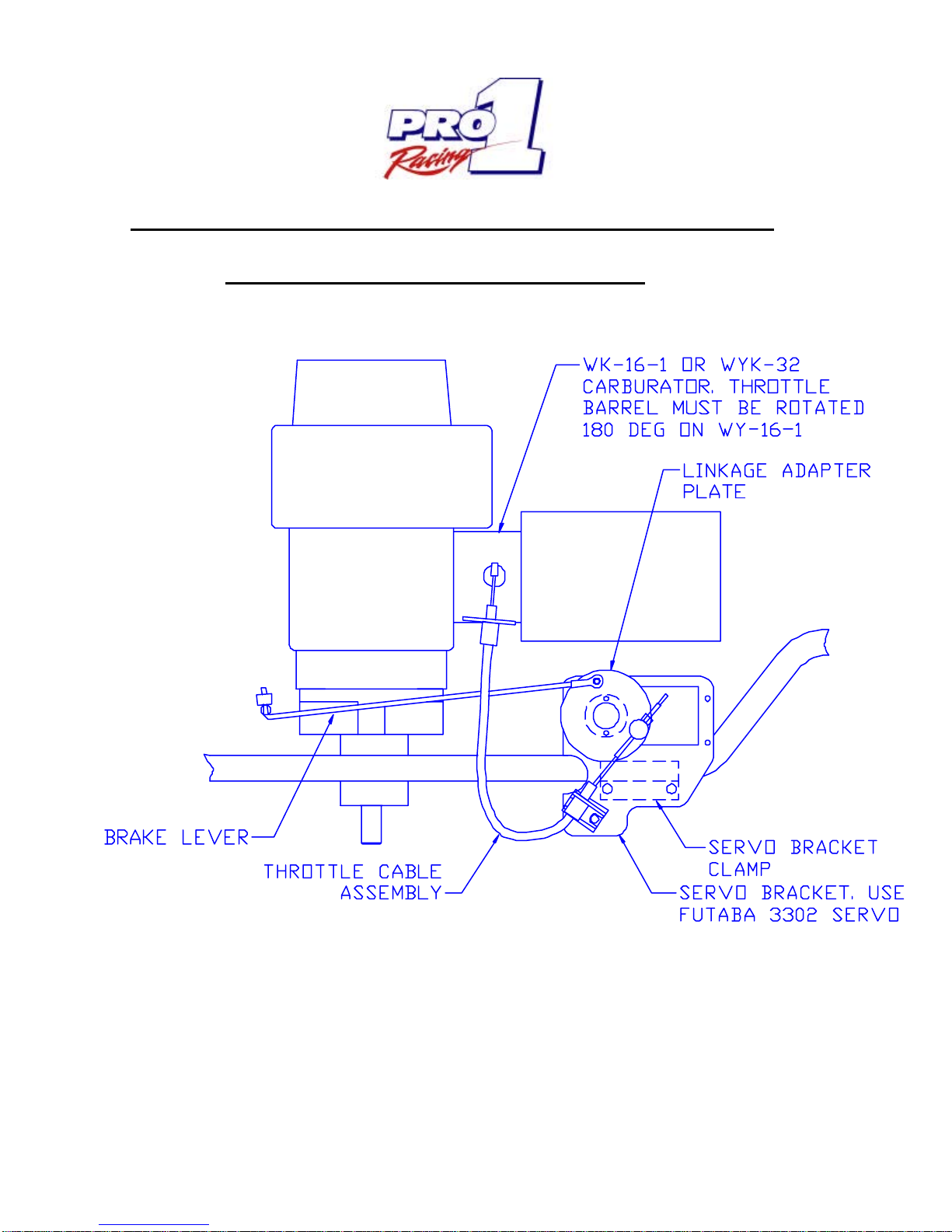

THROTTLE LINKAGE AND CLUTCH HOUSING DIAGRAM

FOR CARS BUILT AFTER TO 5-1-01

THE WY-16-1 ORWYK-32 CAN BE USED WITH THIS DESIGN. WHEN USING THE

WY-16-1 THE THROTTLE BARREL MUST BE ROTATED 180 DEG. USE A FUTABA

3302 SERVO.

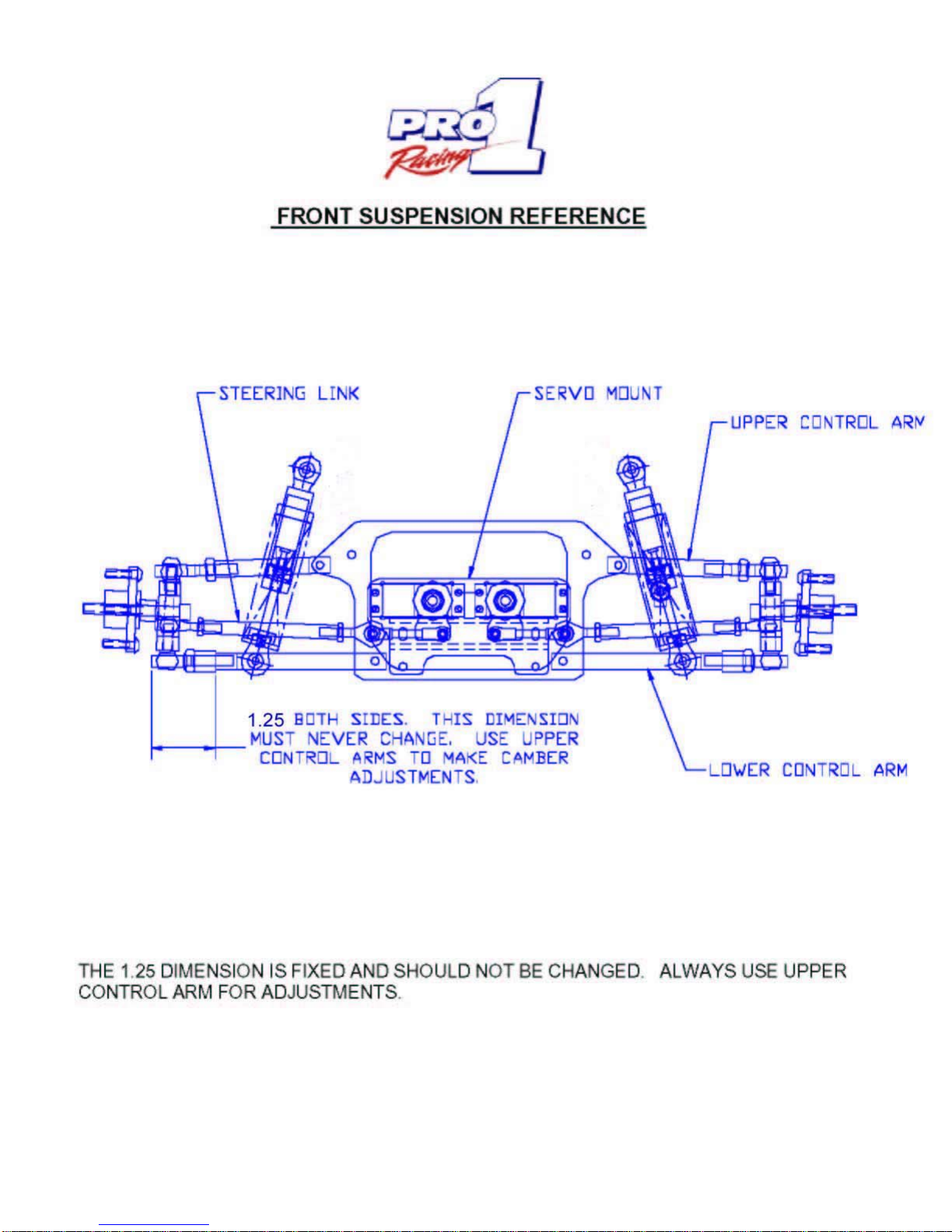

UPPER CONTROL ARM SETTINGS

THE POSITIONING OF THE CONTROL ARMS ARE FACTORY SETTINGS AND ARE

FOR YOUR REFERENCE. RIGHT CASTER ANGLE IS 4.25 DEG., LEFT CASTER ANGLE

IS 3.50 DEG. BOTH BEING POSITIVE. A 1/32 INCH SPACER CHANGE WILL CHANGE

THE CASTER ANGLE BY .75 DEG. WHEN MAKING CAMBER ADJUSTMENTS NEVER

OVER TIGHTEN THE JAM NUTS.

REAR CAMBER SETUP (LOOKING FROM REAR OF CAR)

Left Rear:Left Rear: 3.5 deg. is the factory setting. Increasing the

angle will tighten the car up and decreasing the angle will

loosen up the car.

Right Rear:Right Rear: 4.5 deg is the factory setting. Increasing the

Angle will tighten the car up and decreasing the angle will

Loosen up the car.

FRONT CAMBER SETUP (LOOKING FROM FRONT OF CAR)

Right Front:Right Front: 2.5 deg. is the factory setting. Increasing

The angle will cause the car to turn into the corner.

Decreasing the angle will cause the car to push.

Left Front:Left Front: 2.5 deg. is the factory setting. Adjust angle

As required to obtain even tire wear.

The Pro1 ¼ scale race car is a precision crafted machine. The frame is

constructed of 4130 Chrome moly tubing which is CNC formed and fixture

welded. The space frame impact resistant bumper design has a solid track

record for protection of all critical components. Precision components are CNC

machined for accuracy, interchangeability and structural integrity. Over 3500

hours of engineering, research and development have been performed on this

car to assure you the customer that you have the ULTIMATE RACING

MACHINE.

PRO 1PRO 1 ¼Scale Racing Machine

FEATURES

-- 5 Years engineering, research and development

-- Precision Racing ChassisPrecision Racing Chassis

1. Frame structure: 4130 chrome moly steel tubing.

2. Rigid design: Computer analysis's of chassis.

3. Maximum protection: Impact resistance space frame

design.

4. Finish: Powder coat finish

-- Front SuspensionFront Suspension

1. CNC machined upper and lower control arms with

bushings at the pivot points.

2. Custom shock absorbers with a variety of machined

pistons, o-ring sealing and heavy duty rod end

connections.

3. Adjustable ride height with double shear connection

at both ends of the shock absorbers.

4. New steering rack design.

5. Heavy duty spindles, axles and precision ball bearings.

6. Sway bar.

7. BRP tires

-- Rear SuspensionRear Suspension

1. CNC machined trailing arms.

3. Custom shock absorbers with a variety of machined

pistons, o-ring sealing and heavy duty rod end

connections.

4. Adjustable ride height.

5. Ridged pivot point connection for trailing arm

assembly

6. Heavy duty rear hubs and axles with precision ball

bearings.

7. Precision dog bone design, CNC machined.

8. BRP tires

-Drive SystemDrive System

1. RC230 Zenoah engine

2. Dual bearing clutch assembly with precision ball

bearings.

3. Low rotating mass clutch spindle.

4. 8 oz fuel tank.

5. Aluminum drive gear and nylon driven gear

A large range of gears are available.

-- Adjustable FeaturesAdjustable Features

- Camber

- Caster

- Toe, front and rear

- Ride height

- Sway Bar

- Shock spring rate and oil viscosity

This racing machine has a solid design foundation, is

fully adjustable and fun to race.

The PRO 1PRO 1 is available fully assembled and ready to

race. A full line of spare parts are also available.

Price: $1,595.00 fully assembled, less electronics and body

TermsTerms: 50% with order, 50% at delivery, sales tax and: 50% with order, 50% at delivery, sales tax and

shipping are extra.shipping are extra.

NOTES

Straight edge and alignment disk drawings

NOTES

NOTES

Table of contents

Popular Motorized Toy Car manuals by other brands

ZEROTRIBE

ZEROTRIBE T4 FWD ConversationKit manual

Jamara

Jamara BMW i8 instructions

HPI Racing

HPI Racing jumpshot SC instruction manual

REVELL

REVELL '06 Shelby GT-H Assembly instructions

Kyosho

Kyosho Mini-Z Racer MR-015 RML Type instruction sheet

Carrera RC

Carrera RC 370160139 Assembly and operating instructions