Proactive NJ1 e-assistant User manual

Usage instructions Adapter & Adaptation

0

Usage instructions

Assembly instructions

Adapter and adaptation

for the WHEEL-E traction device, FREEWAY steering attachment,

NJ1 e-assistant, NJ1, SPIKE and HUSK-E adaptive bike

Usage instructions Adapter & Adaptation

1

Contents

1Preface ............................................................................................................................................... 3

2Legend................................................................................................................................................ 3

3General............................................................................................................................................... 3

4Central adapter for folding mechanism (TRAVELER adapter) .................................................. 4

4.1 Assembly work on the wheelchair .............................................................................................. 4

4.2 Assembly work on adapter ......................................................................................................... 4

4.3 Adaptation of the adapter on the wheelchair.............................................................................. 6

4.4 Setting options on steering head................................................................................................ 8

5Central adapter for fixed frame wheelchairs .............................................................................. 9

5.1 Assembly work on the wheelchair .............................................................................................. 9

5.2 Assembly work on adapter ....................................................................................................... 10

5.3 Adaptation of the adapter on the wheelchair............................................................................ 11

5.4 Setting options for the clamping bracket .................................................................................. 13

5.5 Setting options on steering head.............................................................................................. 14

6Front adapter............................................................................................................................ 15

6.1 Assembly work on adapter ....................................................................................................... 15

6.2 Assembly work on the wheelchair ............................................................................................ 16

6.3 Adaptation of the adapter on the wheelchair............................................................................ 17

6.4 Setting options on steering head.............................................................................................. 17

6.5 Changing the distance of the front adapter to the wheelchair.................................................. 18

7Adaptive bikes NJ1 e-assistant, NJ1, SPIKE & HUSK-E: Adaptation on the product and

detachment from product .................................................................................................................. 19

7.1 Terminology.............................................................................................................................. 19

7.2 Adaptation on the product......................................................................................................... 19

Additional information for the front adapter: ............................................................................. 21

7.3 Detaching the adapter from the product................................................................................... 22

Additional information for the front adapter: ............................................................................. 22

8FREEWAY: Adaptation on the product and detachment from product............................................ 23

8.1 Terminology.............................................................................................................................. 23

8.2 Adaptation on the product......................................................................................................... 23

8.3 Detaching the adapter from the product................................................................................... 25

9WHEEL-E: Adaptation on the product and detachment from product ............................................. 25

9.1 Terminology.............................................................................................................................. 25

9.2 Adaptation on the product......................................................................................................... 26

9.3 Detaching the adapter from the product................................................................................... 27

Usage instructions Adapter & Adaptation

2

10 Appendix: Front adapter settings ............................................................................................. 29

11 Appendix: Assembly of the coupling fittings for the front adapter............................................ 34

12 Appendix: Tightening torques and securing details ......................................................................... 37

The following instructions are intended for and may only be carried out by the rehabilita-

tion specialist dealer or PRO ACTIV.

This document is available in PDF format at

www.proactiv-gmbh.com for visually impaired people. Using the zoom function, the font

can be increased as desired.

Usage instructions Adapter & Adaptation

3

1 Preface

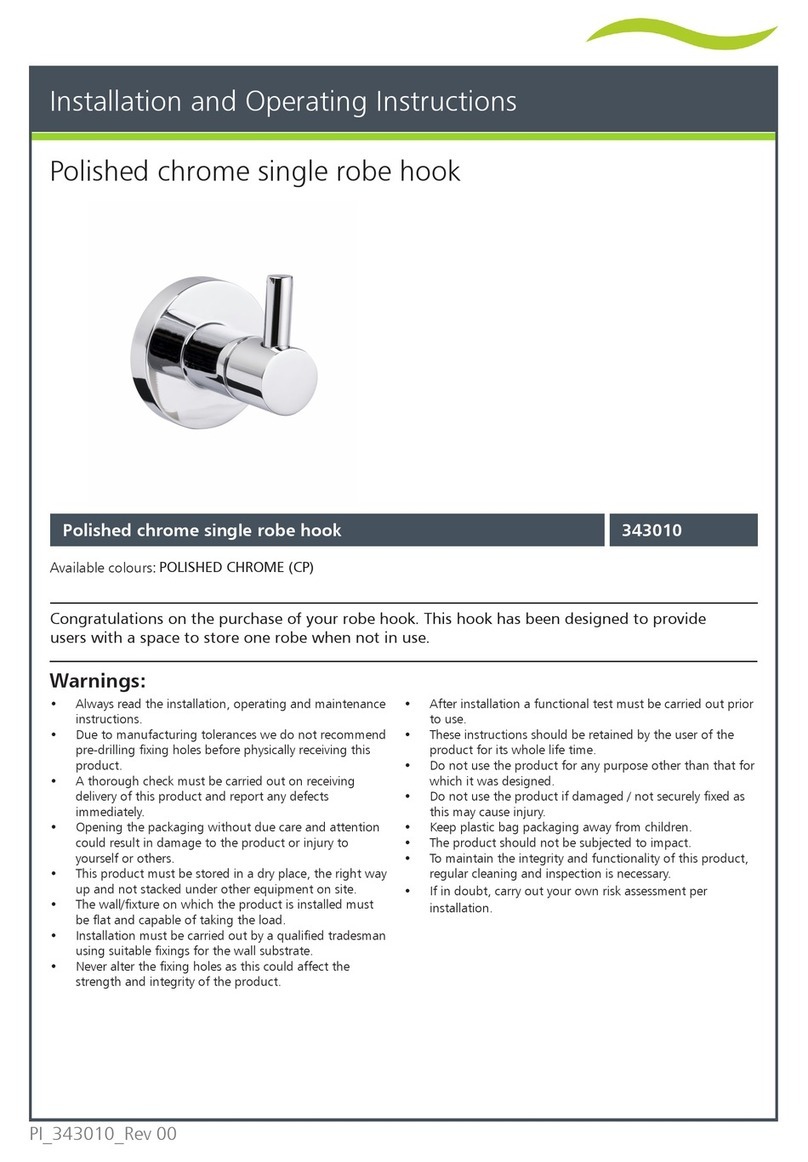

Dear Customer,

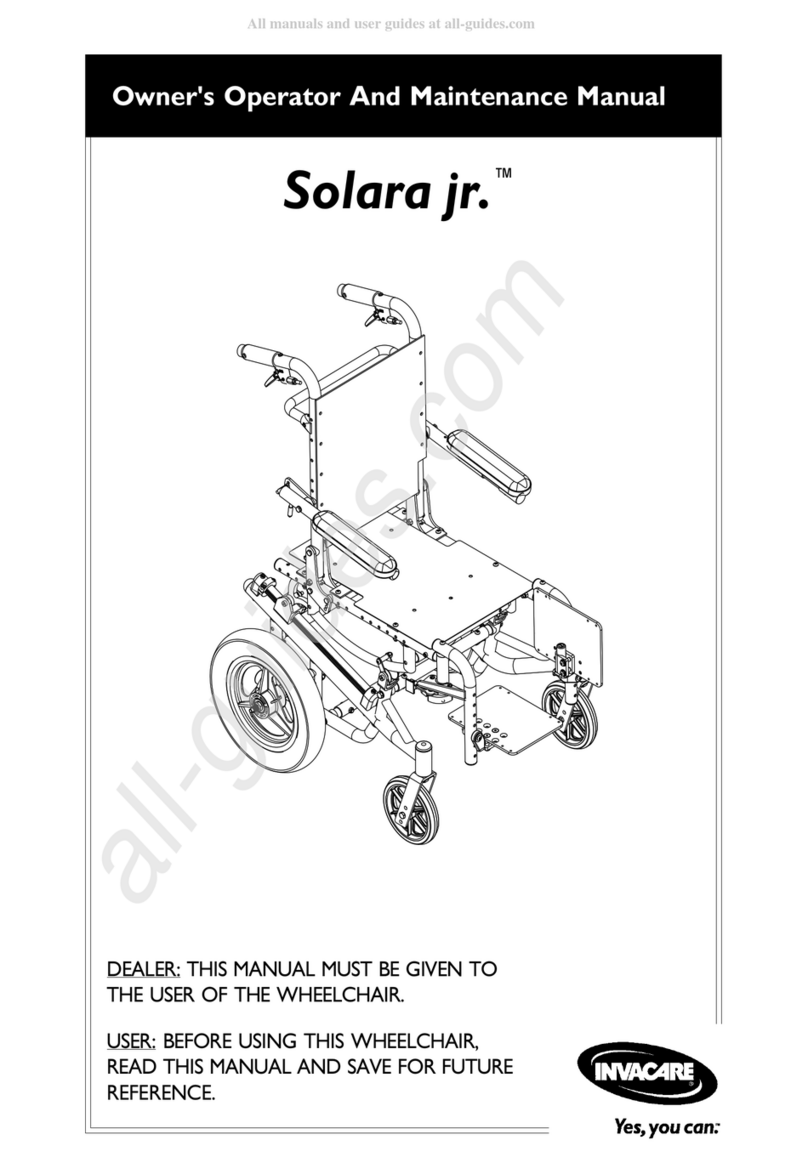

Congratulations on purchasing your new

PRO ACTIV product.

Please note that these usage instructions /

assembly instructions are simply an addition to

your usage instructions for the wheelchair and

adapted product (hereinafter referred to as the

product). Read the usage instructions for your

wheelchair and product – in particular all of the

safety advice – carefully before using the

wheelchair product traction system.

You will find below some information on the

correct and safe use of the adapter. Please

read these instructions before using the wheel-

chair product traction device. There is also

some assembly information in these instruc-

tions that is primarily aimed at rehabilitation

specialist dealers in order to ensure that they

assemble the products correctly.

If you have any further questions about this or

any of our other products, we would be glad to

be at your disposal.

Enjoy your trips and the best possible mobility.

Your PRO ACTIV team

2 Legend

The symbols used in these usage instructions

have the following meanings:

Manufacturer

Note

3 General

PRO ACTIV differentiates between the central

adapter and the front adapter. The central

adapter is mounted under the wheelchair seat

on the folding mechanism or on the cross

tubes. In contrast, the front adapter must be

mounted on the front frame tubes of the

wheelchair.

The adjustments on the adapter and product

must be made by rehabilitation specialist deal-

ers so that when the product is coupled, the

wheelchair steering wheels are raised 30 mm

to 50 mm above the ground.

For loading, transportation or in tight spaces,

the adapter can be removed from the wheel-

chair in a few moves without tools and can

then be stowed away.

As with all new devices, it takes time to get

used to adapting the product on the wheel-

chair. If necessary, a trained assistant should

observe the correct adaptation process initially

so that they are able to provide assistance if

required.

The product may only be adapted and

detached on dry, stable and flat surfaces.

For NJ1 e-assistant: The drive may only

be switched on after completing the adaptation

process. The product may only be adapted

when the drive signal transmitter is inactive in

order to avoid unintended drive signals.

Assembly work, for example centring

semi-shells and centring columns on the

wheelchair or necessary adjustment work on

the adapter and product, may only be con-

ducted by your rehabilitation specialist dealer

or PRO ACTIV.

Note: PRO ACTIV produces adapters, centring

semi-shells, and centring columns in various

designs, for example as a complete individual

part or made from separate parts. Illustrations

in these usage instructions may therefore vary

from the holders mounted on your wheelchair.

Usage instructions Adapter & Adaptation

4

4 Central adapter for folding

mechanism (TRAVELER

adapter)

The following instructions are intended

for and may only be carried out by a rehabilita-

tion specialist dealer or PRO ACTIV

The product is coupled using a central adapter

on the wheelchair's folding mechanism.

Figure 1: Central adapter on folding mechanism

4.1 Assembly work on the wheelchair

In the first step, fix the centring column to the

rear middle part of the folding mechanism. To

do so, remove the M8 lens head screw (Metric

size 5 mm) that connects the back central part

of the folding mechanism with the central tube.

Figure 2: M8 oval head screw that connects the

back central part of the folding mechanism with the

central tube (wheelchair from behind)

Place the adaptation plate with the centring

column from behind against the central part of

the folding mechanism and screw it to the cen-

tral piece and tube using the supplied cylinder

head screw M8x20 (Metric size 6 mm). Ensure

that the screw is tightened with a tightening

torque of 17 Nm and is secured using thread

locking fluid.

Figure 3: Folding mechanism with adaptation plate

and centring column (wheelchair from behind)

Figure 4: Folding mechanism with adaptation plate

and centring column (wheelchair from side)

4.2 Assembly work on adapter

The adapter has adaptation elements that are

pushed onto the fixing elements available or

assembled on the wheelchair and locked in the

adaptation position:

•At the end of the adapter is the centring

column mount; its position is infinitely ad-

justable.

•In the centre of the adapter is the locking

plate that can be positioned in a range of

105 mm in seven 15 mm steps and the

gap between it and the adapter tube can

be adjusted using spacers.

Adaptation plate with

centring column

Shock absorption O-ring

M8 cylinder head screw

Centring column

M8 oval head screw

Usage instructions Adapter & Adaptation

5

Figure 5: Adaptation elements on the adapter

The horizontal adjustment option of 105 mm in

seven 15 mm steps and the potential angle

adjustment of the locking plate as well as the

infinite horizontal adjustment of the centring

column mount enables the position of the

adapter to be modified on the wheelchair and

adjusts the adapter to the geometry of the

wheelchair. Adapt the adapter to the wheel-

chair as described in Chapter 4.3 and check

the necessary adjustment work.

To position the locking plate horizontally,

the M8 fixing screw (Metric size 6 mm) must be

released and tightened again in the right

thread hole in the fixing rail at 17 Nm and pro-

tected with locking fluid.

Figure 6: Positioning the locking plate in 15 mm

steps

Figure 7: M8 fixing screw to horizontally position the

locking plate

To adjust the angle of the locking plate, the

four M4 adjustment screws (Metric size 2 mm)

must first be released. The four M6 fixing

screws are then loosened (Metric size 5 mm

and 4 mm). The locking plate can now be

moved into the correct angle. When the angle

adjustment is completed, the four fixing screws

can then be tightened with 7 Nm and the four

adjustment screws with 2 Nm. Secure the ad-

justment screws with locking fluid.

Figure 8: M6 fixing screws and M4 adjustment

screws to adjust the angle of the locking plate

To position the centring column mount

horizontally, loosen the two M6 fixing screws

(Metric size 5 mm). You can now infinitely ad-

just the centring column mount along the

adapter tube. At the desired position, tighten

the fixing screws again with 7 Nm and secure

these with screw locking fluid.

Centring column mount

Locking plate

Fixing rail with thread

holes

M6 fixing screws

M4 adjustment screws

M8 fixing screw

Usage instructions Adapter & Adaptation

6

Figure 9: M6 positioning screws to horizontally posi-

tion the centring column mount

Ensure that the locking plate and centring

column mount align precisely.

The items delivered include spacers which

can be assembled as required between the

locking plate and fixing rail as well as in the

correct number between the central column

holder and terminal clamp. The distance that

the wheelchair steering wheels are lifted off the

floor on the adapted product can be modified

by the assembly / removal of several spacers.

When fitting spacers, it may be necessary to

use a longer M8 fixing screw (Metric size

6 mm). Make sure that the screw-in depth is at

least 12 mm and the fixing screw is not resting

on the adapter tube.

Before you now adapt the adapter to the

wheelchair, check (this is usually pre-installed

by the factory) whether the two centring pins

on the locking plate are mounted correctly for

the size of the central part of the folding

mechanism on the wheelchair (two sizes pos-

sible). To do so, compare the perforation dis-

tance on the folding mechanism with the dis-

tance of the centring pins. If the positioning is

incorrect, you can modify the centring pin posi-

tion by loosening the M5 fixing screws (Metric

size 3 mm). After repositioning the fixing

screws tighten with 4 Nm.

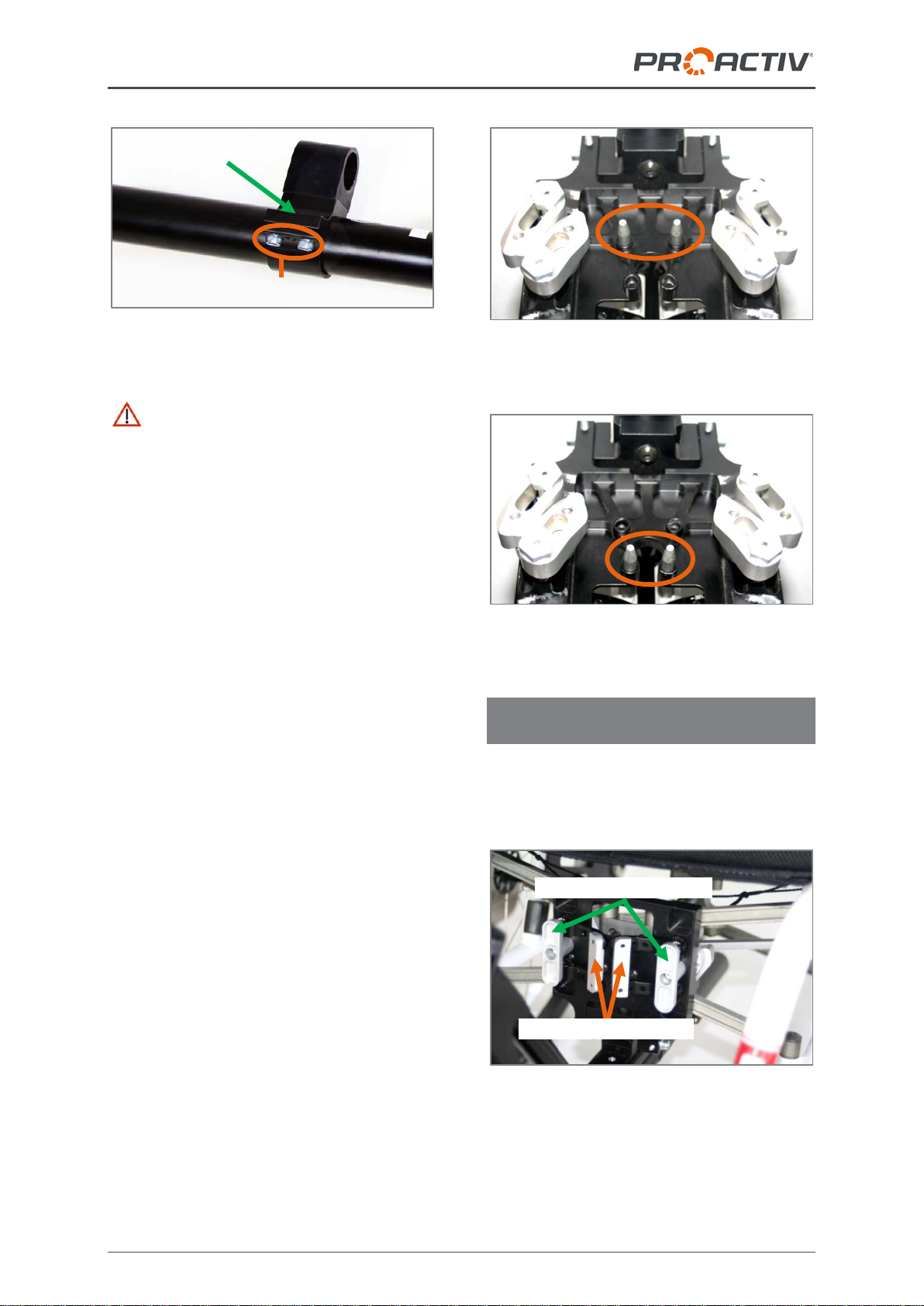

Figure 10: Centring pins assembled for wide centre

part

Figure 11: Centring pins assembled for narrow cen-

tre part

4.3 Adaptation of the adapter on the

wheelchair

Before adapting the wheelchair, the clamp

levers must be released inwards and the lock-

ing heads must be placed in the vertical posi-

tion.

Figure 12: Locking heads in open (vertical) position

and clamp levers released

Locking heads opened

M6 fixing screws

Clamp

Clamp levers released

Usage instructions Adapter & Adaptation

7

Figure 13: Back view of folding mechanism with

open locking sliders

Now the adapters can be attached to the

wheelchair. To do so, slide the adapter from

the front under the folding mechanism and

insert the centring column holder on the cen-

tring column.

Figure 14: Centring column with inserted holder

The centring pins on the locking plate must

reach the drill holes on the front centre piece of

the folding mechanism.

To fix the adapter, the two locking heads on

the locking plate must first be turned by 90° –

lever in horizontal position. Then the two clamp

levers must be firmly tightened externally so

that they generate the necessary force to firmly

adapt the adapter. Only in this position may the

adapter be operated with the adapted product.

Figure 15: Locking heads and clamp levers in

locked position, folding frame adapter assembled

and ready for operation

The tension of the clamp levers in the

new position must always be ensured, i.e.

when the clamp levers are tightened, there

must be no play between the locking sliders

and folding arms and there must always be a

noticeable resistance when tightening the

clamp levers. If necessary, the tension may be

adjusted via the nuts on the locking slider (Met-

ric size 17 mm), after loosening the M5

threaded pins (Metric size 2.5 mm), so that the

tension is the same as it was when new. Even

tension must be ensured on all 4 locking slid-

ers. Once the tension has been set, tighten the

nuts by hand at 20 Nm and the threaded pins

at 4 Nm and secure the threaded pins with

screw locking fluid.

Figure 16: Rear view of folding mechanism with

closed locking sliders, nuts to adjust the tension of

the clamp levers

Locking sliders

Nuts

Clamp levers

tightened

Locking

heads closed

Threaded pins

in the middle

of the nuts

Usage instructions Adapter & Adaptation

8

If the locking heads cannot be turned, this is

usually because the release cord of the folding

mechanism is incorrectly positioned (release

cord in front of the drill holes for the centring

pins) and therefore the locking plate cannot

rest completely on the folding mechanism.

Figure 17: Release cord positioned correctly, drill

holes for centring pins free

Figure 18: Release cord positioned incorrectly, drill

holes for centring pins hidden to the bottom left

If this is not the reason, then the distance of

the locking sliders must be adjusted. To

achieve this the distance measurement via the

nuts on the locking sliders (Metric size 17 mm)

after loosening the M5 threaded pins (Metric

size 2.5 mm) must be adjusted (Fig. 16) so that

the locking heads can be turned and the ten-

sion on the clamp levers is ideal (i.e. when the

clamp levers are tight there can be no play

between the locking sliders and folding arms

and there must always be a noticeable resis-

tance when tightening the clamp levers). Even

tension must be ensured on all 4 locking slid-

ers. Once the distance measurement and ten-

sion has been set, tighten the nuts by hand at

20 Nm and the threaded pins at 4 Nm and

secure the threaded pins with screw locking

fluid.

Note: You can watch a video on attaching the

adapter to the wheelchair on YouTube:

http://www.youtube.com/watch?v=EqY

hslW7HBQ

4.4 Setting options on steering head

The angle-adjustable steering head can influ-

ence various parameters, such as the lifting

distance of the wheelchair steering wheels on

the adapted product, the distance between the

product wheel and wheelchair foot bed, or the

distance of the product's operating elements to

the user's body.

To adjust the angle of the steering head, the

four M6 adjustment screws (Metric size 3 mm)

must first be released on the top and bottom

on the steering head.

Figure 19: M6 adjustment screws at the top of the

steering head connection

After finally loosening the two M6 clamp

screws (Metric size 5 mm), the steering head

can be tilted by 25°. When the right position

has been found, the two clamp screws must be

tightened up again with tightening torque of

7 Nm and secured with screw locking fluid. The

associated nuts (Metric size 17 mm) must be

tightened for this.

M6 adjustment

screws

Steering

head con-

nection

Usage instructions Adapter & Adaptation

9

Figure 20: M6 clamp screws on steering head

Note for NJ1 e-assistant, NJ1 adaptive

bike, SPIKE adaptive bike and Freeway:

When adjusting the angle of the steering head,

you must ensure that the wheel can run freely

(horizontal dimension between the extended

steering axis) between 60 mm and 120 mm.

Figure 21: Free run depending on the angle adjust-

ment of the steering head

When the angle adjustment of the steering

head is completed, the M6 setting screws

(Metric size 3 mm) must be turned again to-

wards the steering head connection so that

they rest on the steering head connection. The

setting screws are used so that the steering

head can no longer turn after the setting has

been made.

Figure 22: M6 setting screws resting on the steering

head connection

5 Central adapter for fixed frame

wheelchairs

The following instructions are intended

for and may only be carried out by a rehabilita-

tion specialist dealer or PRO ACTIV.

The product is coupled using a central adapter

on the wheelchair frame's cross pipes.

Figure 23: Central adapter on the frame cross pipes

5.1 Assembly work on the wheelchair

In the first step, assemble the two supplied

centring semi-shells (Fig. 24) at a distance of

87 mm (dimension between the two large di-

ameters of the centring semi-shells) at the

centre of the front frame cross tube. This en-

sures the central adaptation of the adapter on

the wheelchair and prevents sideways shifting

during use. The M5 fixing screws (Metric size

4 mm) of the centring semi-shells must be

tightened with a tightening torque of 4 Nm; if

the tightening torque is higher, there is a risk

that the centring semi-shells could break.

M6 clamp screws

60-120 mm

Extended

steering

axis

Wheel con-

tact point

M6 adjustment screws

Usage instructions Adapter & Adaptation

10

Then insert the enclosed cable ties into the

internal grooves on the centring semi-shells

designed for this purpose. When tightening the

cable ties, ensure that their closures are at the

back so that they do not affect the adapter

when it is being adapted. The cable ties ensure

the proper position of the clamping bracket

fixing hooks and thus prevent flapping.

Figure 24: Fully assembled centring semi-shells

Now assemble the centring column with the

terminal clamp on the back frame cross tube.

Before you tighten the M6 fixing screws (Metric

size 5 mm), you must adapt the adapter as

described in Chapter 5.3 and turn the centring

column by twisting the terminal clamp on the

back frame cross tube to the correct angle.

With the adapted adapter, you must then

tighten the fixing screws with a tightening

torque of 7 Nm. Ensure that the centring col-

umn remains located at the centre of the back

frame cross tube.

Figure 25: Centring column with terminal clamp

5.2 Assembly work on adapter

The adapter has adaptation elements that are

pushed onto the fixing elements available or

assembled on the wheelchair and locked in the

adaptation position:

•At the end of the adapter is the centring

column mount; its position is infinitely ad-

justable.

•In the centre of the adapter is the clamping

bracket that can be positioned in a range

of 105 mm in seven 15 mm steps and the

gap between it and the adapter tube can

be adjusted using spacers.

Figure 26: Adaptation elements on the adapter

The adjustment option on the clamping bracket

of 105 mm in seven 15 mm steps as well as

the infinite horizontal adjustment of the cen-

tring column mount enables the horizontal

position of the adapter to be set on the wheel-

chair and adjusts the adapter to the geometry

of the wheelchair. Adapt the adapter to the

wheelchair as described in Chapter 5.3 and

check the necessary adjustment work.

To position the clamping bracket horizon-

tally, the M8 fixing screw (Metric size 5 mm)

must be released and tightened again in the

right thread hole in the fixing rail at 17 Nm and

protected with locking fluid.

Figure 27: M8 fixing screw to horizontally position

the clamping bracket

87 mm

Cable ties on centring

semi-shells

Clamp

Centring column

M8 fixing screw

Fixing hooks

Centring column

mount

Clamping bracket with clamp

levers and fixing hooks

Pull loop on

clamp levers

Spacers

Usage instructions Adapter & Adaptation

11

Figure 28: Positioning the clamping bracket in 15

mm steps

To position the centring column mount

horizontally, loosen the two M6 fixing screws

(Metric size 5 mm). You can now infinitely ad-

just the centring column mount along the

adapter tube. At the desired position, tighten

the fixing screws again with 7 Nm and secure

these with screw locking fluid.

Figure 29: M6 fixing screws to horizontally position

the centring column mount along the adapter tube

When adjusting settings, make sure that the

clamping bracket and centring column mount

are exactly aligned.

When the adapter is attached to the wheel-

chair, the centring column mount should have

around 1 mm play to the terminal clamp on the

centring column (Fig. 30).

Figure 30: Centring column mount on the centring

column

The items delivered include spacers which

can be assembled as required between the

clamping bracket and fixing rail as well as be-

tween the centring column mount and terminal

clamp (fig. 26). The distance that the wheel-

chair steering wheels are lifted off the floor on

the adapted product can be modified by the

assembly / removal of several spacers. When

fitting spacers, it may be necessary to use a

longer M8 fixing screw (Metric size 5 mm).

Make sure that the screw-in depth is at least

12 mm and the fixing screw is not resting on

the adapter tube.

5.3 Adaptation of the adapter on the

wheelchair

Figure 31: Adaptation elements on the adapter and

pull loop on the clamping bracket

First open the adapter's clamp lever by pulling

the pool loops forward in the direction of the

adapter's steering head. Then guide the cen-

tring column mount onto the centring column

on the back cross tube, and then past the fix-

ing hook of the clamping bracket after pushing

Fixing rail with

thread holes

0.5-1 mm play

Centring column terminal clamp

Centring

column

mount

M6 fixing screws

Clamp

Centring column

mount

Clamping bracket with clamp

levers and fixing hooks

Pull loop on

clamp levers

Usage instructions Adapter & Adaptation

12

back the adapter tube (Fig. 27) over the two

centring semi-shells. The fixing hook must sit

with no play on the centring semi-shells (Fig.

32) and may only move sideways by a mini-

mum amount (< 0.5 mm).

Figure 32: Clamp lever with pull loop in the open

position and fixing hook must sit with no play on the

centring semi-shells; for fixed positioning of the

adapter on the wheelchair, the clamp lever must be

pressed until the lock audibly clicks into place

If the distance between the clamping bracket

and centring column mount is set correctly, the

clamping bracket will rest gently on the front

frame cross tube by itself. If this is not the

case, the position must be modified accord-

ingly by sliding the centring column mount

(refer to Chapter 5.2).

Only by pressing the clamping bracket first

from above and then the clamping lever from

the front (Fig. 32) does the knee lever override

and the lock firmly closes on the clamping

bracket. The overriding of the knee lever and

engagement of the lock must be clearly notice-

able and audible. In addition, check the lock to

see if the clamping lever can be opened (do

not pull via the pull loop – this would release

the lock again). If it can't be opened, then at-

tach the pull loop to the front part of the

adapter using a Velcro strap to secure it. This

ensures that the adapter is securely locked

onto the wheelchair and it can be used as in-

tended.

Figure 33: Clamp lever with pull loop in the closed

position, fixed frame adapter mounted and ready for

operation

Figure 34: Centring column mount on the centring

column, fixed frame adapter mounted and ready for

operation

"Lever extension of the quick release

clamp” option: With this option, you do not

have to press the clamp lever under the seat to

close the clamp lever, but you operate the

clamp lever by pressing the lever extension in

front of the wheelchair seat.

Figure 35: "Lever extension of the quick release

clamp” option

Clamp

lever with

pull loop

Closing:

1. Press on the clamping bracket from above

2. Press on the clamp lever from above

Clamp lever with pull loop

0.5-1 mm play

Centring column terminal clamp

Centring

column

mount

Lever extension of the

quick release clamp

The fixing hook

must sit

on the centring

semi-shells

with no play

1.

2.

Usage instructions Adapter & Adaptation

13

Note: You can watch a video on attaching the

adapter to the wheelchair on YouTube:

https://www.youtube.com/watch?v=Z4g

hHsAE4Ok

5.4 Setting options for the clamping

bracket

The closing width of the clamping bracket may

need adjusting later if e.g. the clamp lever

cannot be closed or the clamping bracket does

not surround the tube firmly. The width of the

clamping bracket can be adjusted for tube

thicknesses of 24-26 mm.

Figure 36: Clamping bracket closed

Figure 37: Clamping bracket opened

The M5 protection screw (Metric size 2.5 mm)

and the M4 clamp screw (Metric size 2 mm)

must be released for adjustment. This enables

the width of the clamping bracket to be ad-

justed (clockwise for a smaller diameter/anti-

clockwise for a larger diameter) by turning the

eccentric shaft.

Figure 38: M5 securing screw to fix the eccentric

shaft

Figure 39: M4 clamp screw to set the activation

force for opening and closing the clamping bracket

Attention must be paid here to ensure that the

slit on the back of the eccentric shaft points

precisely to one of the marking points attached

to the clamp by turning the eccentric shaft (Fig.

40). This ensures that the securing screw

points precisely to one of the areas attached to

the eccentric shaft for this purpose during

tightening. Only then is independent turning of

the eccentric shaft excluded.

Figure 40: Turning the eccentric shaft along the

marking points (clockwise for smaller Ø, anti-

clockwise for larger Ø)

smaller Ø

M5 securing

screw

M4 clamp

screw

Usage instructions Adapter & Adaptation

14

Figure 41: Eccentric shaft with areas for securing

screw

After completing the width adjustment, first fix

the eccentric shaft again using the M5 securing

screw to 4 Nm and protect with screw locking

fluid. Then adjust the activation force for open-

ing and closing the clamping bracket again

using the M4 clamping screw as per the cus-

tomer's requirements and protected with screw

locking fluid.

5.5 Setting options on steering head

The angle-adjustable steering head can influ-

ence various parameters, such as the lifting

distance of the wheelchair steering wheels on

the adapted product, the distance between the

product wheel and wheelchair foot bed, or the

distance of the product's operating elements to

the user's body.

To adjust the angle of the steering head, the

four M6 adjustment screws (Metric size 3 mm)

must first be released on the top and bottom

on the steering head.

Figure 42: M6 adjustment screws at the top of the

steering head connection

After then loosening the two M6 clamp screws

(Metric size 5 mm) the steering head can be

tilted by 25° on the side of the steering head

connection. When adjusting the angle of the

steering head, you must ensure that the wheel

can run freely (horizontal dimension between

the extended steering axis) between 60 mm

and 120 mm.

Figure 43: Free run depending on the angle adjust-

ment of the steering head

When the right position has been found, the

two clamp screws must be tightened up again

with a tightening torque of 7 Nm and secured

with screw locking fluid. The associated nuts

(Metric size 17 mm) must be tightened for this.

Figure 44: M6 clamp screws on steering head

Then, the M6 setting screws (Metric size

3 mm) must be turned again towards the steer-

ing head connection so that they rest on the

steering head connection. The M6 setting

screws are used so that the steering head can

no longer turn after the setting has been made.

M6 adjustment

screws

Steering

head

connection

M6 clamp

screws

60-120 mm

Extended

steering axis

Wheel

contact point

Usage instructions Adapter & Adaptation

15

Figure 45: M6 setting screws resting on the steering

head connection

6 Front adapter

The following instructions are intended

for and may only be carried out by a rehabilita-

tion specialist dealer or PRO ACTIV.

The product is attached via one of the adapters

adapted on the wheelchair's front frame tubes.

Figure 46: Front adapter on the front frame tubes

6.1 Assembly work on adapter

The adapter is supplied with standard settings

from the factory depending on the product's

wheel size. The default settings can be viewed

in the table in Chapter 10. If the product is to

be adapted to a third party product or a PRO

ACTIV wheelchair with special dimensions,

changes may still need to be made to the set-

tings. Potential changes stating the dimensions

can also be taken from the table in Chapter 10.

The width of the front adapter must then be

modified to the width of the wheelchair. To

achieve this four M6 tensioning screws on

each side (Metric size 5 mm) must be loos-

ened. By then screwing in all four M4 threaded

screws (Metric size 2 mm), the clamp is

opened and the clamps on the steering head

connection can be moved to the side.

Figure 47: Clamp steering head connection and M6

tensioning screws

Figure 48: M4 threaded pins to open the clamp to

move the clamp steering head connection to the

side

The distance of the two frame clamps must

now be adapted to the distance of the frame

tubes on the wheelchair. The distance of the

frame clamps must be centred so that the

steering head is positioned in the middle.

Clamp steering

head connection

M6 tensioning screws

M4 threaded pins between

the tensioning screws

M6 adjustment screws

Usage instructions Adapter & Adaptation

16

Figure 49: Adaptation elements on the adapter

The M4 threaded pins must then be loosened

again by several turns and the M6 tensioning

screws tightened again with a tightening torque

of 7 Nm and secured with screw locking fluid.

The threaded pins are then screwed in again

gently, making contact with the clamp. The

protruding pieces of tube can be shortened

using a metal saw and the tubes blocked with

the stoppers provided.

Figure 50: Fully assembled adapter with modified

tube lengths and tube end stoppers

6.2 Assembly work on the wheelchair

For adapting to the wheelchair, one of the two

clamp cover stoppers (Fig. 53) supplied must

be mounted on the left as well as the right

frame tube.

In the first step, clamp the front adapter tempo-

rarily on the two frame tubes of the wheelchair.

To achieve this, the frame clamps are first

opened fully (turn clamp lever anti-clockwise).

Then the frame clamps must be attached to

the frame tube. By turning the clamp levers

clockwise, the frame clamps are then fixed

gently to the frame tube.

Now the correct fixing height must be achieved

by moving the adapter on the frame tubes. The

fixing height of the adapter on the wheelchair's

frame tubes is determined by the measure-

ments from the floor to the hook on the inser-

tion shaft on the steering head. This dimension

depends on the wheel size of the product to be

adapted. The guide values are shown below:

20" wheel 490 mm

24" wheel 540 mm

26" wheel 570 mm

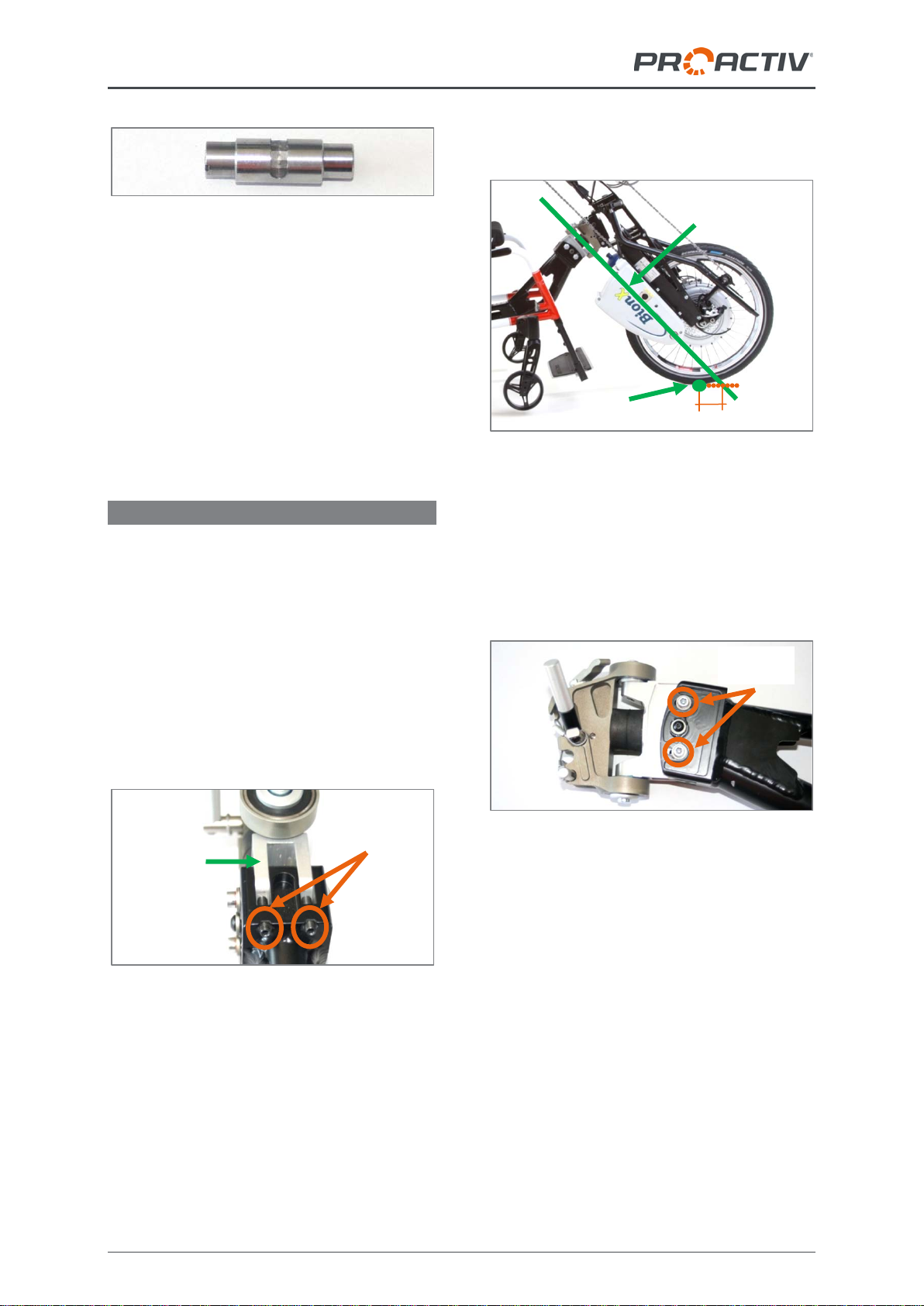

Figure 51: Measurement from floor to front of the

insertion shaft

When the adapter sits temporarily in the rele-

vant position on the wheelchair's frame tubes,

the positions of the clamp cover stoppers can

be marked on the back of the wheelchair's

frame tube.

Figure 52: Drawing the position of the clamp frame

stopper on the back of the wheelchair's frame tube

Frame clamps

Steering

head

Clamp lever

Front of

the inser-

tion shaft

Measure-

ment from

floor to

front

Rear wheel-

chair frame

tube

Tube end

stoppers

Usage instructions Adapter & Adaptation

17

The adapter is then removed, the clamp cover

stoppers are inserted on the markings, and the

associated M5 fixing screws (Metric size

4 mm) are tightened with a tightening torque of

4 Nm.

Figure 53: Fully assembled clamp cover stopper

(wheelchair from the side)

6.3 Adaptation of the adapter on the

wheelchair

You now only have to open the frame clamps

fully to adapt the adapter on the wheelchair. To

do so, turn the clamp levers fully anti-

clockwise. Then the frame clamps must be

attached to the frame tube. The height is

shown by the already attached clam cover

stoppers. The frame clamps are then turned by

hand clockwise using the clamp lever.

Figure 54: Fully assembled front adapter

Note on attaching third party products:

PRO ACTIV supports third party attachments

in terms of geometric and functional queries,

but cannot indemnify the person creating the

product/wheelchair combination from the appli-

cable regulations relating to the compulsory

test regulations that always apply to those

creating such aid combinations. PRO ACTIV

does not undertake a compatibility check. All

product tests on the combination must be un-

dertaken by the rehabilitation specialist dealer.

PRO ACTIV is to be indemnified for all defects

or damage on the wheelchair in such a combi-

nation with regard to liability for product defects

or accepting a warranty by the rehabilitation

specialist dealer; this is to be requested from

the relevant wheelchair manufacturer.

6.4 Setting options on steering head

The angle-adjustable steering head can influ-

ence various parameters, such as the lifting

distance of the wheelchair steering wheels on

the adapted product, the distance between the

product wheel and wheelchair foot bed, or the

distance of the product's operating elements to

the user's body.

To adjust the angle of the steering head, the

four M6 adjustment screws (Metric size 3 mm)

must first be released on the top and bottom

on the steering head connection.

Figure 55: M6 adjustment screws at the top of the

steering head connection

After then loosening the two M6 clamp screws

(Metric size 5 mm) the steering head can be

tilted by 25° on the side of the steering head

connection (Fig. 44). When adjusting the angle

of the steering head, you must ensure that the

wheel can run freely (horizontal dimension

between the extended steering axis) between

60 mm and 120 mm.

M6 ad-

justment

screws

Steering

head

connection

M5 fixing screw

Usage instructions Adapter & Adaptation

18

Figure 56: Free run depending on the angle adjust-

ment of the steering head

When the right position has been found, the

two clamp screws must be tightened up again

with a tightening torque of 7 Nm and secured

with screw locking fluid. The associated nuts

(Metric size 17 mm) must be tightened for this.

Figure 57: Nuts for the M6 clamp screws on the

steering head

Then, the M6 setting screws (Metric size

3 mm) must be turned again towards the steer-

ing head connection so that they rest on the

steering head connection. The M6 setting

screws are used so that the steering head can

no longer turn after the setting has been made.

Figure 58: M6 setting screws resting on the steering

head connection

6.5 Changing the distance of the front

adapter to the wheelchair

In order to change the distance of the front

adapter to the wheelchair, the M6 fixing screws

(Metric size 5 mm) that are used to clamp the

clamp covers are loosened and the clamp

covers are pulled out towards the wheelchair

(maximum until the cover is flush with the edge

of the clamp for the steering head connection

on the product side; refer to following image).

The fixing screws are then tightened again at

7 Nm.

Figure 59: Clamp cover fully extended (if possible,

with screw heads also visible)

The clamp covers are also available in various

lengths if the setting range available is not

adequate. Other setting options can be taken

from the table in Chapter 10.

M6 adjust-

ment screws

M6 fixing

screws (back)

Nuts for the

M6 clamp

screws

Clamp cover

60-120 mm

Extended

steering axis

Wheel contact

point

Usage instructions Adapter & Adaptation

19

7 Adaptive bikes NJ1 e-assistant,

NJ1, SPIKE & HUSK-E: Adapta-

tion on the product and detach-

ment from product

The adaptation of the adapter on the product is

shown below using the central adapter and the

NJ1 e-assistant. The approach is also applica-

ble to the front adapter and the NJ1 adaptive

bike, the SPIKE adaptive bike and the HUSK-

E.

With the Adaptive Bike HUSK-E, ensure that

the eccentric clamp lever and the safety bolts

are on the right side. Not on the left side, as is

the case with the other adaptive bikes.

7.1 Terminology

Here you will find an illustration of the terms

used in the following to make it easier for you

understand:

Figure 60: Steering head terms

Figure 61: Docking plate terms

7.2 Adaptation on the product

For the NJ1 e-assistant & HUSK-E:

Please ensure that the drive system is

switched off.

For adaptation, the securing pin on the docking

plate must be pulled out to the outer stop (Fig.

61). On the steering head, the pre-selection

lever lock mechanism must be set to "lock"

(lying flat) and the eccentric clamping lever to

"loose" (Fig. 62).

Figure 62: Adapter settings at the start of adaptation

The product must be fixed with the handbrake

and – if possible – also parked against a wall

(refer to the "Parking brake" chapter in the

product usage instructions). Now move your

wheelchair with the adapted adapter towards

the product until the contact areas on the

adapter and docking plate touch each other.

Figure 63: Moving forward to the product

For adaptation, the insertion bolt of the docking

plate must be inserted into the insertion shaft

on the steering head.

Pre-selection lever

grid mechanism

Eccentric clamp

lever

Mount for

safety bolts

Insertion shaft

Eccentric clamp lever to "loose"

Pre-selection grid mechanism to "lock"

Direction

of travel

Insertion bolt

Securing bolt

Other manuals for NJ1 e-assistant

1

This manual suits for next models

2

Table of contents

Other Proactive Wheelchair manuals