Proaster THCR-12 User manual

Document number: THCR12-M02

Revised number: Rev. 02

Date : 2014. 04. 03

Manufacture / Sales :

Taehwan Automation Industry Co., Ltd

2

0

1. Product information

(1) About the coffee roaster

(2) Characteristics of the product

2. Safety regulations

(1) General safety

(2)-1 Safety mark

(2)-2 Safety device

3. Installation

(1) Carry

(2) Before you install

(3) Installation

4. Use of the product

(1) General

(2) Structure and manipulation (Components, structure)

(3) Roasting (Roasting level and handling)

5. Cleaning and maintenance

(1) How to clean – Procedure

(2) Maintenance – (Disassembly)

(3) After cleaning the product

(4) Inappropriate maintenance

(5) Solutions to common problems

6. Disposal information

(1) Disposal instructions

7. List of replacement parts

8. Product warranty and A/S

<Reference > Equipment maintenance

3

1

General

-Place your manual somewhere close to the machine for easy access

-Read the manual before you use the product

-Wear appropriate gloves while handling the machine to avoid burns

- Do not try to fix the machine yourself in the event that it fails

- Start and stop the machine only after giving it enough time to heat and cool down

- Do not touch the upper part of the machine due to burn risk.

(1) Coffee roaster

- This coffee roaster is manufactured as an industrial roaster for roasting coffee beans

- This roaster is manufactured for indoor use

(Using the machine outdoors might result in failure to roast due to moisture,

malfunctioning of the machine, and/or other accidents)

- Inappropriate use of the machine (cooking grains, foods, etc.) is prohibited and any

repairing of the machine must be done by the Taehwan headquarters or designated

service centers.

- Carefully review safety regulations before you use the coffee roaster and contact the

designated service center or store if you have any problem during use.

* Warning: Your warranty will not apply for any damage caused by the following:

- Inappropriate use of the product

- Random disassembly including part replacements

- Repairs done by unauthorized personnel

- Use of the wrong power/ gas (use of a different kind of gas from the original one)

(2) Characteristics of the product

-The product’s dual direct roast/hot air roasting method uses a combination of

radiation and hot air for superb results and even roasting.

-Designed to maximize heat efficiency for quick roasting up to 15 minutes faster,

preserving the unique flavor and aroma of the beans.

- By controlling the damper you can control the volume of the air exhaust and achieve

your specific roasting profile and aroma.

- Strong blower motor allows for fast cool down (as quick as 2~3 min)

- The safety system terminates the gas supply and shuts off the heater if the preset

MAX temperature is exceeded.

4

2

1) Burns and injury

-You may get burned if you touch the main surface, handle, or pipe

- Be cautious as you may suffer injury from the rapid rotation of the bearings and

motor.

2) Fire

- Do not put in any foreign object in the machine

- Do not place any unnecessary flammable material, cloth, paper, or other accessories

in the machine

- Do not open or disassemble the inspection door while machine is in use as this

creates a fire hazard.

3) Electricity and gas

- Avoid touching power with wet hands to prevent electric shock

Be careful to keep power cable and gas hose away from the hot surface

-After use, close the gas valve, switch off the power at the back, and unplug the

power cord.

- Inspect for any gas leakage from connecting parts with soapy water before and after

use

4) Cleaning and general care

-Avoid exposing machine to moisture. Always follow specified directions for cleaning

and care, paying attention to order of steps. Clean the machine regularly to ensure

smooth functioning. (See directions for cleaning and care)

5) Damages

- We will not be responsible for damage caused by the following:

- Inappropriate use

- Damage caused by self disassembly, repair, manipulation

- Use of the wrong voltage or gas pressure

- Breakdown from insufficient cleaning and general care

* We will not be responsible for damages caused as a result of users not complying

with safety regulations

(1) General safety

5

2

(2)-1 Safety mark

(2)-2 Safety device

1) Gear safety cover

2) A gear safety cover is attached for user safety against the rotation of pulley and

bearings between the drum and control box

-Make sure the gear cover is sealed before you use the product

-Fully cool the machine down before you open the cover to perform maintenance

1) Hazardous voltage

This label is to warn of hazardous voltage.

Turn off the power to avoid any electric

shock or burns before using

2) Moving parts

This label is to warn of its moving part. Use

the safety cover to avoid any injury. Always

turn off the power before doing any

Maintenance

3) Burns

This label is to warn of possible burns. Do

not touch its surface as it’s hot

4) Fire hazard

This label is to warn of Fire hazard.

Especially, watch out for short circuit or gas

leakage, and flammable objects near the

product

2

2) Emergency Stop Switch

-This button is used to prevent exposure to heat and electricity in case of

emergency

- Do not stop the drum or blower when the machine is overheated. Doing so may

cause a fire or breakdown

- The drum will keep working after emergency button is pressed

- Do not stop the drum or blower when they are overheated. The machine’s

special design makes fire or breakdown likely if the drum is completely stopped.

3) Overheating protection device

-Once roasting temperature on the product’s temperature display window reaches

the preset temperature, the heat supply is cut off to avoid overheating

-Do not reset the temperature above the originally pre-programmed temperature.

Otherwise, the machine will overheat.

4) Overflowing voltage protection system

- Power shuts off in the event of electrical malfunctions (short circuit, etc.)

5) Fire extinguishing safety device : Consumer safety device prevents overheating

and automatically shuts off gas when power is off

6) Short circuit protection device : Users should contact their own Gas maintenance

company

3

1) Package

- For export machines, first remove nails from the

wooden container and take out slats and

boards. Please recycle packaging materials in

accordance with your country’s regulations.

- Please confirm that the roaster unit, filter

cyclone 2, instruction manual, and tool kit have

been included.

2) How to carry

- Weight: about 500 kg

- Method: use a forklift to transport over level

ground. Be sure to keep a close, firm hold on

the bottom part of the machine.

(1) Carrying the product

1) Installation

-The machine is designed for indoor use. Malfunctions may occur if used

outdoors.

- Level plane

Must be operated at a level plane

-Exhaust: there must be a ventilator, door or window located within 1m radius of

the machine.

-Insufficient ventilation may affect quality and evenness of roasting, and is also a

safety hazard.

-Table: must be able to bear the listed weight. Portable tables should not be used.

Use a table with wheels for convenience when cleaning.

- Exhaust: exhaust impedance (length of vent pipe, environment, etc.) may affect

roasting results

7

3

1) Before you install

1)-1 Electricity code and power

This machine is designed to be connected to a standard wall socket

Install according to your country’s voltage system

1)-2 Gas pressure

The machine was manufactured for low voltage home use. Install according to the

requirements of your gas system. You may use a separate safety device for

preventing gas leaks.

1)-3 Exhaust pipe condition

Make sure the gas pipe does not become bent

If a ventilator is not used, make sure there is a hole in the wall for the gas pipe.

(2) Before you install the product

(3) Installation

8

4

(1) General

1) Those operating the machine should have received training in roasting at the

company headquarters or agency, or otherwise be experienced in roasting.

2) Before operating machine

Check to see that the plug is secure in the wall socket and that the power switch

is ON.

- Do not touch power cord or surface of the machine when it is hot.

- Do not tamper with control box buttons.

- Make sure there is adequate ventilation

- To ensure problem-free roasting, always make sure the waste (grounds)

drawer, ventilator, and cyclone are clean.

-avoid cramped spaces: space of over 1m is necessary for cooling and flame control,

-Misc.: for safety and optimal roasting, do not place the machine any closer than

20cm from a wall or window. Avoid contact with moisture (do not use near a sink,

espresso machine, etc.)

2) External power connection

-Power connection: plug power cord only into wall sockets with correct voltage

-Power requirements are listed on the machine’s label

2)-1 Supply condition

Electric-type model: AC 230V (1PH) 60Hz 10.6A 2.5kw

Gas pressure: low for home use. Follow proper specifications for gas supply.

Gas pressure varies with region/location. Please contact your local gas supply

company.

2)-2 How to connect

-manufactured for general wall sockets

-Gas connection: inquire about gas supply hook-up at your gas supply company.

Always follow proper procedures when connecting.

9

4

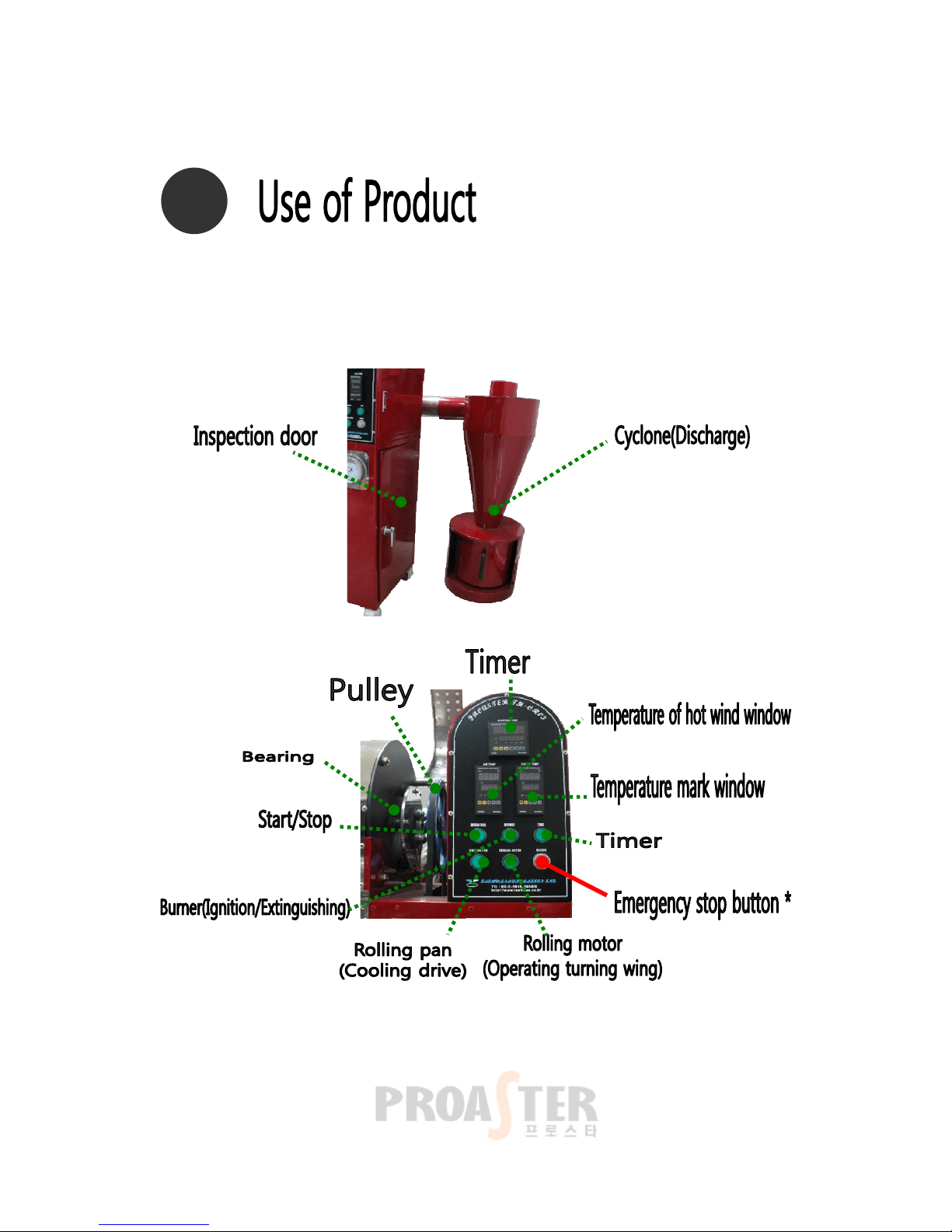

(2) Structure and manipulation – Components

Controls the amount and speed of hot air coming

into the drum

“0” with the least amount air to be come into and “10”

with he most

1) Control the amount of heat inside the drum

2) Discharge used coffee grounds and smoke during

roasting

3) Hold/ discharge aroma during roasting

Equipment to program pre-heat time or roasting

time

The upper number shows the current time and the

one below shows set time

How to set : Press ◀ to move the cursor and ▲ ▼

to increase / decrease numbers

Finalize your setting by pressing MD button

Damper

Timer

Knob

Equipment to control discharge

The rest numbers except the part forced to change

become vague when you press ENT

How to set : Press ◀ to move the cursor and ▲ ▼ to

increase / decrease numbers

Finalize your setting by pressing ENT button

0(Maximum discharge) < 60 (Minimum discharge)

Equipment to control heating power during roasting

Make the gas gage standard and control sensitively

(Gas gage should be the heating standard because the gas

pressures are different according to places and conditions)

Inverter

Ignition Reset

Button

Function of resetting automatic ignition equipment

Press the reset button when the red light is on m which means

that ignition fails because of the air inside of gas pipe.

※ Press reset and ignition button repeatedly until empty air

inside its gas pipe when ignition fails

10

4

(2) Structure and manipulation - Structure

11

4

(2) Structure and Manipulation– Product structure

*Note : Emergency stop button must be pulled

out to operate the machine

12

4

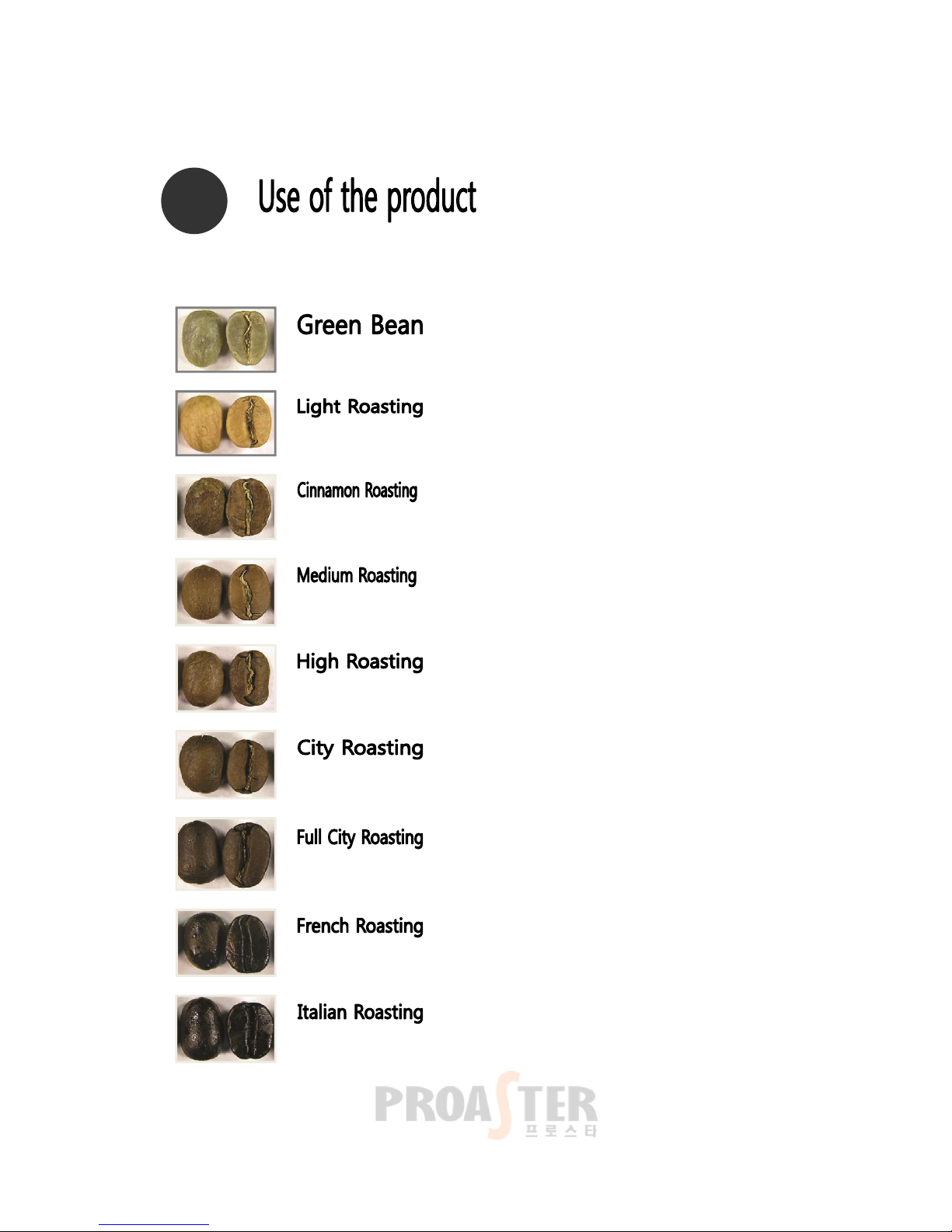

(3) Roasting – Roasting level

Has various colors depending on fresh beans’

condition and place of production

Sweet aroma yet doesn’t fully brew *(yellow

bean)

Sour taste. Easy to separate used coffee grounds.

Cinnamon color

Called American roast. Good for tasting fresh

sour taste. Initial extracting stage. Brown color

Sour taste, unique characteristic. Their body

becomes strengthened. Brown color

Sour, sweet, bitter tastes are all balanced .

Their body becomes bigger. Dark brown color

Shining surface. Bitter taste with smaller body .

Dark brown color

Surface of the beans are covered by oil . Tastes

like charcoal

Less sour taste and more sweet and bitter taste.

Bigger body . Very dark brown color with some

oils on surface . Espresso standard.

13

4

(3)-1 Roasting method - Important points before roasting

1) Fresh beans

- Educate yourself about moisture and quality of fresh beans

* Dryness in the beans may affect roasting results

2) Preheating

Excessive moisture inside or outside the machine may result in scale

accumulation or roasting failure. Begin roasting only after sufficient

preheating.

3) External environment

Weather: Condensation caused by cold or humid weather may influence

roasting results. Allow sufficient preheating time.

Ventilation: Roasting is a combustion process requiring adequate amounts

of oxygen. Please check ventilation conditions.

4) Exhaust

Cleaning: Failure to keep machine clean may result in poor cooling due to

vent pipe blockage and decreased air flow. Taste and aroma of the beans

may be adversely affected if waste (grounds) is not discharged properly.

Always inspect vent pipe and cooling unit before roasting.

5) Roasting level

-Set to appropriate roasting level (hand drip, espresso, etc.)

① Press the Reset switch. After approximately 15 minutes, visually

confirm that high voltage electric flow is being emitted from the

high pressure electrode.

② Confirm that the end of the igniter is making proper contact with the

fuel mouth (proximity of about 3~5mm)

③ Confirm that the heat sensor behind the igniter is making proper

contact with the fuel mouth (proximity of about 5~7mm)

◎ Attention

14

4

(3)-2 How to roast

1) Connect the power cable. Turn power ON

2) OPEN the gas valve

3) After opening the damper to 10, press operation button

4) BURNER button (for user safety, ignition occurs 15 minutes after gas flow has

stabilized.

•If ignition is unsuccessful, first confirm that the inside red ignition reset button is

on, then press the reset button and the burner button. After the air inside the

gas pipe is evacuated, ignition will occur.

Repeat if necessary

5) After reheating at Damper 10/low flame (about 30% of the gas gauge’s maximum

firing capacity)

6) After 110 degrees is exceeded, adjust to moderate flame (50% or more) and

close the damper to 3.

7) Put beans in the hopper before the temperature reaches the appropriate

temperature to put them

8) Press time button after putting in beans when the temperature becomes around

200 degree (Start timing)

Adjust the heating power to be at 70~80% once the temperature starts increasing

9) Stay flame in middle high stage(50~80%)

10) before1st crack (Yellow Bean)

Adjust damper to make pressure a little high and before 1st crack (yellow bean) and

supply the MAX heating power

11) 1st Crack Acting point

Open damper 2 to above 8 slowly and adjust heating power to middle-high

flame(50~80%).

12) A point right after 1st crack

Adjust the heat by 15%~30% and close the damper (3 ~ 6)

Preparation Preheat Roasting

Exhaust mode

13) just before emission (empty just a little before reaching the desired

temperature!!)

Damper 10 dischargelower damper at cooling mode (left) press the

BURNER button and close after confirming the timer, press the TIME

button and close

•Do not put your hand in before fully cooling down!

•After cooling is completed, check the cooling fan!!

14) Cooling machine (Idling)

Fully open the damper till the temperature decreases below 100 degree

(Damper10), Press stop button to turn off after idling with the vent closed, press

operation button to STOP and turn off the control box

15) After roasting!! Important!!.

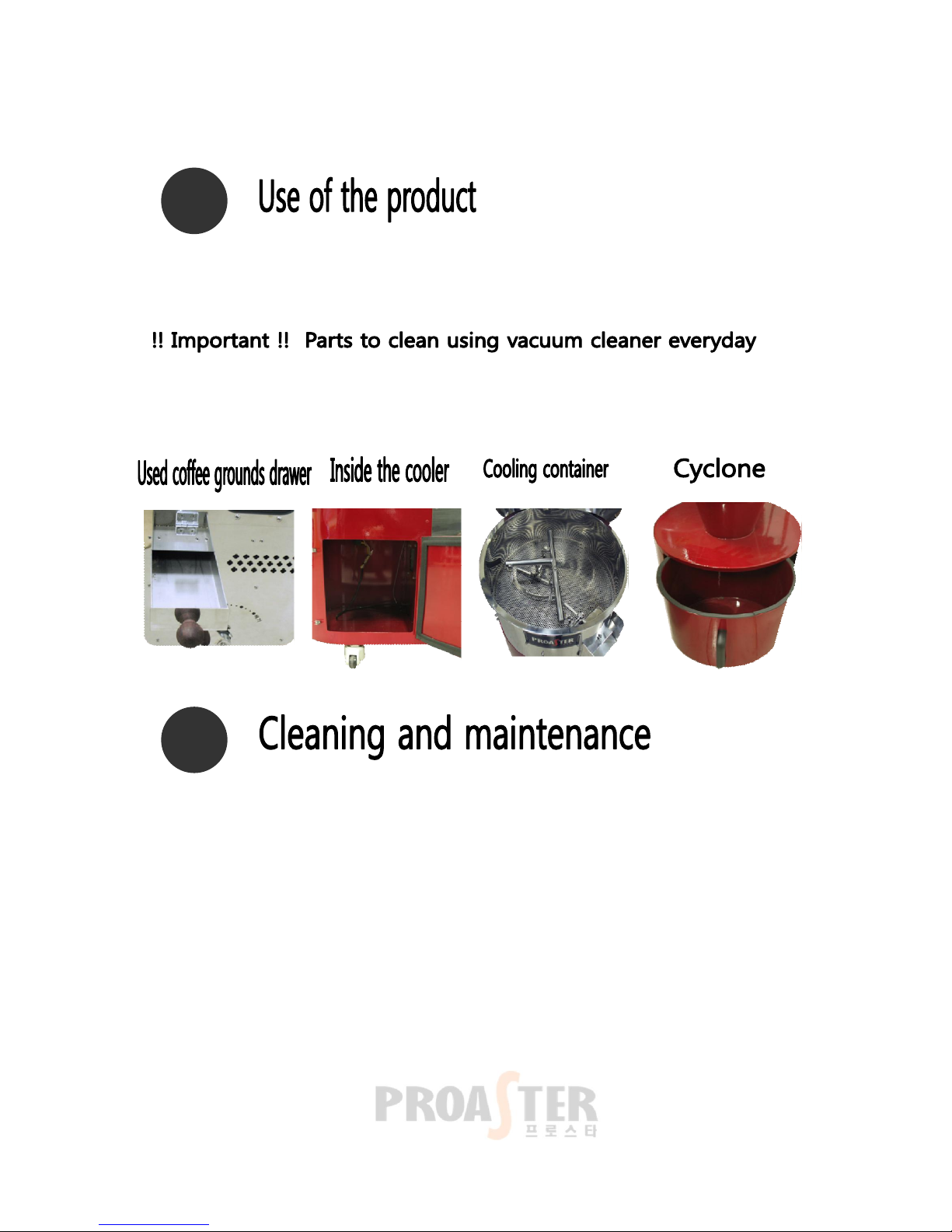

Use vacuum cleaner to clean the cyclone, inside the cooling unit, grounds (waste)

drawer, hopper, and confirmation door

(There is a charge incurred when service is requested due to neglect in cleaning

and maintenance

Discharge After use

Exhaust modeCooling mode

Inside of control box

15

4

(3)-3 How to roast – After roasting

Cleaning is the most important factor to uniformly ensure against

malfunctions and the quality taste and aroma of your coffee.

5

(1)Cleaning method –before you start

-Tool kit, mask, cotton gloves, vacuum cleaner, beans for cleaning (used

to remove dust after cleaning)

-Tool kit is for use when installing

-When cleaning machine, always wear mask and gloves to avoid

accidental injury

-Refer to manual when cleaning, and follow the directions carefully.

16

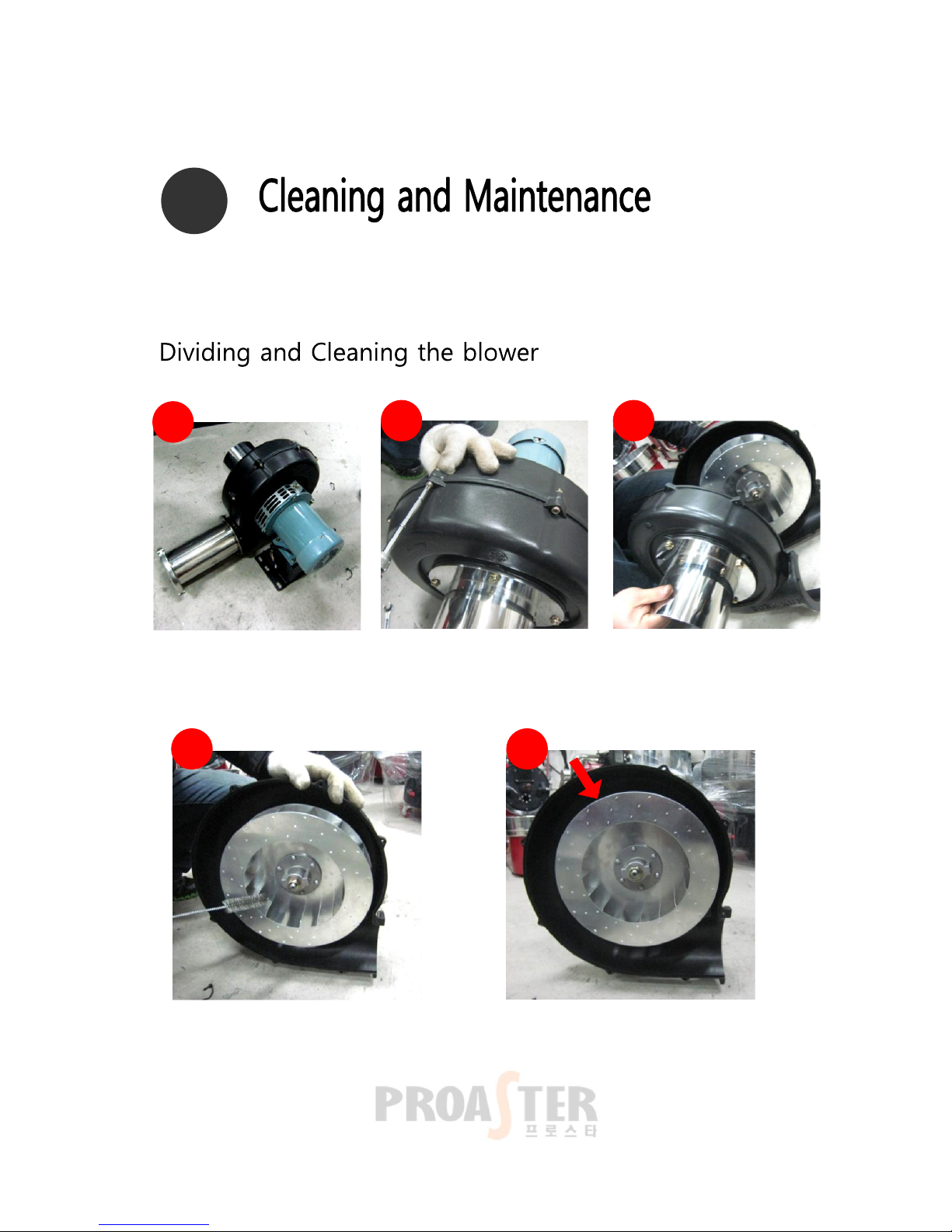

Unscrew 4 bolts below the blower.

* Be careful since it is heavy

* Be careful when handling rubber

* Do not screw too tight as it may

cause bending.

12

3 4

Caution!!

It is heavy so please be

careful and move to the floor.

Disconnect the clamp Separate the blower from wiring.

5

(2) Cleaning- Separating the parts before cleaning Removing the

piping connecting the cyclone

17

5

(2) Cleaning- Separating the parts before cleaning Removing the

piping connecting the cyclone

Using the brush, clean the wing as

shown. (Do not divide the wing, it is

hard to re-assemble.)

5

7 8

Caution

Clean the dust from wing and

body together without separating.

Place the blower on the floor.

6

Unscrew the bolts above.

7

You can see the blower

18

1

Caution !!

Do not divide the 3 bolts, it is hard

to re-assemble.)

* Simple clean

Turning around the temper

to clean by using the wood

stick and brush

2

When you clean the

deeper pipe inside then

divide the clamp.

3

Unscrew the 4 bolts.

caution

Caution !! Do not divide the bolt

as marked, it is hard to re-assemble.)

5

(2) Cleaning and maintenance

caution

(2) Cleaning Directions – Cleaning and disassembly

Unclamp the hand clamp Use the hex wrench (in toolbox) for bolts shown.

1

5. Cleaning & Maintenance

2

!! Do Not Remove

Any Other Bolts!!

19

3

(2) Cleaning Directions – Cleaning and disassembly

5. Cleaning & Maintenance

Please clean the air compressor in the following order.

Wing/ Left wing/ In front and behind the wing. If you

carefully clean then you will prevent scale buildup.

Chaff between drum

and front plate

Please clean as shown

important!

Clean the air compressor

blower as shown

Cleaning the Hopper

Use a brush to remove any

debris and vacuum.

Occasionally

Space below Cooling

Tray

Vacuum the area below the

tray occasionally.

important!

Important!

Pipe Cleaning

Bend the brush to reach deep

into the pipe to remove any

debris.

Infrequent cleaning of pipe

will lead to stubborn buildup

whereas frequent cleaning will

lead to easier removal of

debris.

20

You can loosen the bolt

shown above to clean

using a vacuum.

Important!

Important!

Table of contents

Other Proaster Kitchen Appliance manuals