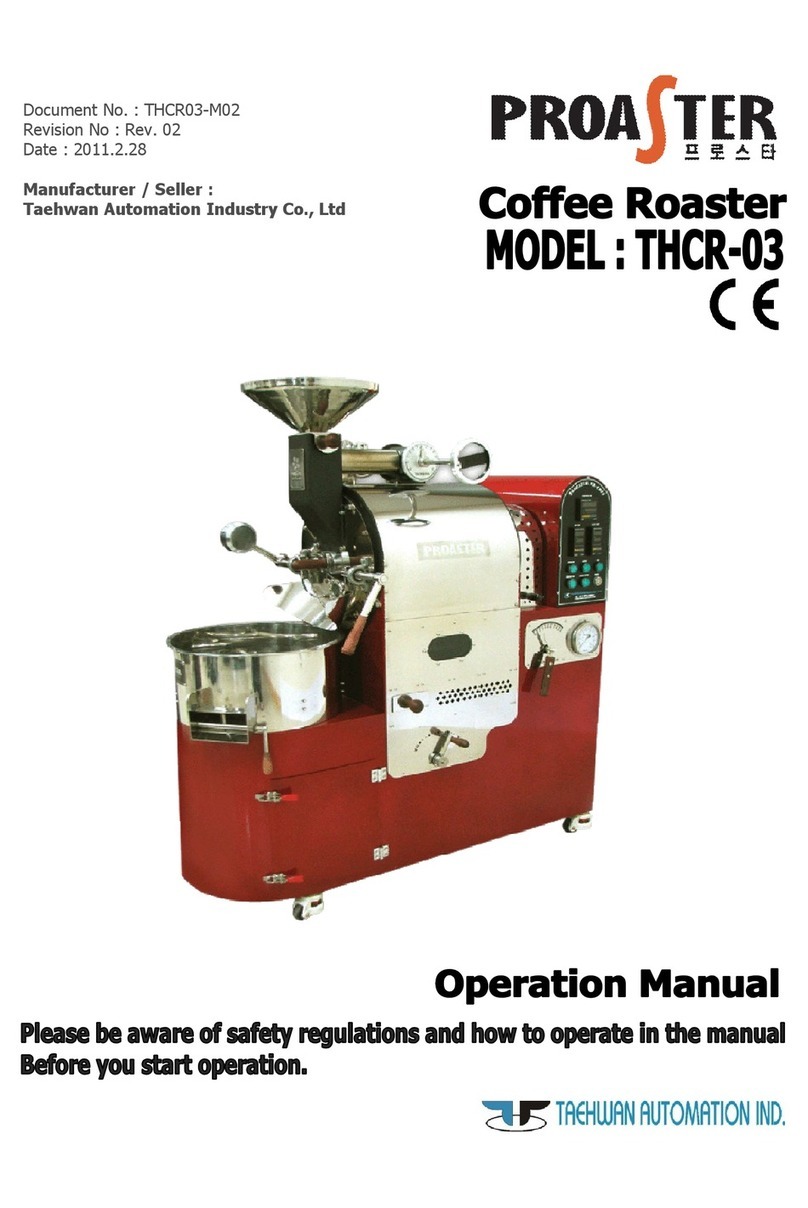

Proaster THCR-06 User manual

Coffee Roaster

THCR-06 (10KG)

Document number : THCR06-M04

Revised number : Rev. 04

Date : 2015. 07. 17

Manufactured by TaeHwan Automation Ind.

TEL: 82-32-624-3410~3 Fax: 82-32-624-3414

Operation Manual

Please carefully review the user before you use the machine.

You should fully understand the manual to use the machine property.

Ⅰ. General Information

1. Specifications

2. Purpose

3. Features

Ⅱ. Safety Regulations

1. General Safety Regulations

2-1. Safety Label

2-2. Safety Device

Ⅲ. Installation

1. Carriage

2. Preparation for installment

3. Installation

4. Disposal Instructions

Ⅳ. Operation

1. General Information

2. Components

3. Operation (How to Roast)

Ⅴ. Cleaning and Maintenance

1. How to Clean - Procedure

2. Maintenance - Disassembly

3. Post Cleaning

4. Trouble-Shooting

Ⅵ. Replacement Parts List

Ⅶ. Electrical diagram

Ⅷ. Warranty

Outline

P 4

P 4

P 5

P 5

P 6

P 6

P 7

P 8

P 9

P 14

P 23

P 23

P 31

P 37

P 41

P 45

P 4

P 48

P 8

P 3

2

Specification

HSK-NO MODEL Description Unit Q'ty

THCR-06 Coffee Roaster Set 1

Ⅰ. General Information

-Place this manual near the machine for easy access and read the manual completely

before operation.

-Please read and understand these instructions prior to operating this unit.

-Gloves are recommended to prevent injury.

-Start and stop the machine only after giving it enough time to heat and cool down.

3

Capacity 2~10kg/batch (MAX 10kg Green beans)

Operating time About 10~15min/Batch (depending on profiles)

Roaster Dimension 1,670(w)×700(L)×1,350(H)(mm) (Coffee Roaster)

Power 1Phase V220~240 (60Hz)

Power consumption: 2.0kw/hr, 9.1A

Heat Source GAS Pipe burner (18,000Kcal/hr Natural gas)

(1.5kg/hr LPG)

Gas Pressure Natural gas Above 2kpa / LPG: 2.8kpa Above

Parts Specification

Motor : AC / 220V / 1/2hp 1/30 / 60HZ

Blower : Cooling - AC 700w 60HZ

Exhaust – AC 340w 60HZ

1. Purpose

- This coffee roaster is manufactured as a commercial roaster for coffee beans

- Inappropriate use of the machine (grains, foods, etc.) is prohibited. Repair of the machine must be

done by a designated service center.

- Carefully review safety regulations before first use and please contact the designated service center

or store if you have any questions/problems.

2. Features

- The product uses two heating methods, radiation and hot-air convection, to bring out optimal roasting

control and uniformity of results.

- The design maximizes heat efficiency to extract the ideal aroma and taste of the beans.

- By adjusting the damper control, you can increase/decrease the volume of exhaust and hot air

flowing through the roaster to customize the roasting and flavor profile.

- The powerful blower cools the roasted beans in as little as 3~4 minutes.

- The safety system terminates the gas supply/shuts off the heater if the preset MAX

temperature is exceeded.

Ⅱ. Safety Regulations

1. General Safety Regulations

1) Injury Risk

You may risk injury if you touch the main surface, handle, or pipe while the machine is hot.

Be cautious of the rapid rotation of moving parts such as bearings, belts, and motors.

Stop the Cooling Motor prior to checking the bean temperature while cooling as the cooling tray stir arm

may cause injury.

2) Fire Risk

- Do not put in any foreign objects in the machine

- Do not place any flammable material, such as cloth or paper, in or near the machine

- Do not open or disassemble the machine while the machine is running

3) Electricity and Gas

- Avoid handling the machine with wet hands

- Keep power cables and gas hoses away from all heated parts and surfaces

- After use, close the gas valve, turn off the power (switch located on the back of machine), and unplug

the power cord.

- Inspect any gas leakage of connecting parts with soapy water before and after use

4) Cleaning and general care

1) Avoid exposing machine to moisture. Always follow the specified directions for cleaning and care,

paying attention to the order of the steps. Clean the machine regularly to ensure smooth functioning.

(See directions for cleaning and care)

4

5. Damages

Taehwan Automation is not responsible for any damage or injury caused by:

- Inappropriate use (different materials, incorrect operation)

- Damages caused by self disassembly / repair

- Use of the wrong voltage or gas pressure

- Breakdown from improper maintenance (cleaning and general care)

* We cannot guarantee coverage for damages caused by poor operation or unauthorized repair

2. Safety Label

1) Electric Shock Hazard

Warning of electric shock. Always turn off the power before

doing any maintenance.

2) Moving parts Hazard

Warning of moving parts. Use the safety cover to avoid

injury. Always turn off the power before maintenance.

3) Burn Hazard

Warning of possible burns by touching hot surfaces.

4) Fire Hazard

Warning of fire hazard. Be cautious of short circuits, gas

leaks, and flammable objects.

3. Safety Device

1) Safety Gear Cover

The safety gear cover is to protect the operator from moving parts such as the pulley and

bearings between the drum and the control box.

- Check that the gear cover is closed before operation.

- Wait until the machine is completely cooled down before turning off to avoid damage to the machine

due to rapid temperature changes.

2) Emergency Switch

This button is to be used in the case of emergency from heat exposure, fire, and

other situations. By activating the emergency switch all parts of the machine, with the exception of the

digital display, are shut down.

- To activate the emergency switch, pull out the button turn right slightly.

- The drum rotation, power, and gas supply are immediately stopped if activated. 5

Table of contents

Other Proaster Kitchen Appliance manuals