PROBOIL PROTHIA PT1130 User manual

PROTHIA

Installation Guide

www.proboil.co.uk

See top of boiler for contact details

Please read these instructions carefully before

installation or use and retain for future reference.

You must install the tap and filter before the boiler.

We have a policy of continued product and quality development and improvement. Accordingly we reserve

the right to amend the specification at any time. All errors and omissions excepted.

An information point or tip for

installation or usage.

A service, maintenance

or care consideration.

⚠

A technical or safety

consideration or warning of

hazardous situation with regard to

life and property.

Using the product

Thank you for choosing this product. Reading this guide will ensure that the product is used safely and will

give its best performance.

⚠WARNING: THIS APPLIANCE CAN BE USED BY CHILDREN AGED FROM 8 YEARS AND ABOVE AND

PERSONS WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPABILITIES OR LACK OF EXPERIENCE AND

KNOWLEDGE ONLY IF THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTION CONCERNING USE OF THE

APPLIANCE IN A SAFE WAY AND HAVE UNDERSTOOD THE HAZARDS INVOLVED. CHILDREN SHALL NOT PLAY

WITH THE APPLIANCE. CLEANING AND USER MAINTENANCE SHALL NOT BE MADE BY CHILDREN. ALL

WIRING AND INSTALLATION MUST BE SUPERVISED BY A SUITABLY QUALIFIED PERSON.

⚠Please also fully read and understand the boiler user instructions before use.

It is normal for the hot water to take a moment to both dispense upon each use and stop fully after

the handle is closed as water remains within the product.

⚠Do not add to, exchange or modify any component of the boiler or mixer tap, only genuine parts must

be used. The spout exit or any part of the system must not include any additional third-party adaptors,

components or connections that will add resistance or modify the system.

The installation should be periodically checked for damage, if the property is left unattended for a

prolonged period we recommend isolating water supplies and switching off the boiler at the mains socket.

On reconnection flush thoroughly.

Clean the tap with a damp soft cloth and a mild dish soap to remove any grease marks created during

installation as per the care instructions.

Each time the product is used you should flush a small amount of boiled water through before use,

typically this can be used to preheat your cup, if unused for extended periods then flush the product a

longer time.

This tap has been designed to have a spout rotation range of 180°.

Your tap can dispense 3 types of water:

•Hot (boiled) filtered water Slide the hot (boiling) button across horizontally (Fig. 2)and then

simultaneously turn the handle backwards (Fig. 3), the further backwards the handle is turned the greater

the flow. It is normal for the hot water to take a moment to start and stop dispensing as the water empties

from the product after use.

•Hot & Cold (domestic) water - This is delivered when the right-side handle is tilted right (Fig. 4) to increase

flow. Cold water is 45° backwards position becoming warmer as the handle is rotated forwards (Fig. 4).

Fig 1. Off position

Fig 2. Slide horizontally

Fig 3. Twist anti-clockwise

Fig 4.Single lever operation

Care instructions for your kitchen tap mixer

To maintain the appearance of this tap, ensure that it is regularly cleaned only using a clean, soft damp cloth. A

solution of warm water and a mild liquid detergent may be used where necessary, and then the fitting rinsed

thoroughly and wiped dry. Any other cleaning action will invalidate your warranty.

Abrasive cleaners, scouring cleaners and acidic cleaners must not be used under any circumstances. Avoid

contact with all solvents (including chlorinated solvents, ketones or acetones as these may result in surface

deterioration or etching). Also avoid contact with any harsh household chemicals such as oven cleaners, drain

cleaners, rust removers, paint strippers and toilet bowl cleaners, bar keepers friend or Brasso.

Where the tap has a removable aerator on the spout exit it can be removed and cleaned periodically to

maintain optimum flow performance and remove any limescale, when reattaching please ensure to reconnect

the center stem of the aerator to the center spout flexible tube fully.

Tap Warranty Terms and Conditions

In the unlikely event that you should experience any defect in the materials or workmanship of your new

Abode mixer within 5 years of purchase, the purchaser’s sole remedy shall be the replacement (at the

manufacturer’s discretion) of all or any part of the product that is defective. All working parts and valves are

guaranteed for a period of 5 years from purchase. Decorative surface finishes and O-rings are guaranteed for 1

year from the date of purchase provided that our advice concerning care has been observed and no scouring

agents have been used. This is provided that the mixer or tap has been used for normal domestic purposes and

that the care, installation and maintenance instructions have been observed. The warranty extends to the

original purchaser only.

Marks, scuffs and scratches caused by improper installation or accidental damage are not covered by this

guarantee. Neither are shade variations or any damage or defect caused by incorrect installation or abuse of

the fitting.

As we are continuously improving and developing our range of products, finishes & colours, in the event of a

valid claim, we may not be able to provide an identical replacement for the defective product throughout the

guarantee period. Where an identical product is no longer available, we will supply the nearest equivalent from

our then current product range. In assessing your claim, we must be given the opportunity to inspect the

product as installed prior to removal. Any product returns must be packaged as received and complete.

No other warranties, express or implied, are made, including merchantability or fitness for a particular purpose.

Under no circumstances shall the manufacturer be liable for any loss or damage arising from the purchase, use

or inability to use this product, or for any special, indirect, incidental or consequential damages. No liability is

accepted for consequential damage to other household fixtures, fittings or furnishings arising from this claim,

even if attached to the product. No installer, dealer, agent or employee of Norcros Group (Holdings) Ltd. has

the authority to modify the obligations or limitations of this warranty.

Tap installation

Important Technical Data

Minimum operating pressure (hot): 0.75 bar

Minimum operating pressure (cold): 1.5 bar

Maximum operating pressure: 5.5 bar*

Maximum domestic hot water temperature: 60°C*

Flow characteristics: Domestic Hot & Cold share

outer single flow spout.

Boiled filtered water: Through centre spout channel.

Recommended domestic hot water Temperature: 46°C

⚠*If these temperatures or pressures are exceeded, even for short periods, damage can result. In these

instances, a thermostatic mixing or pressure reducing valve should be installed.

⚠This product is manufactured in accordance with recognised European standards. Please ensure that

your kitchen mixer is fitted in accordance with Local Water Byelaws. Where hot and cold water mix within

the tap, then suitable non return (check) valves should be installed to both the hot and cold supplies to

prevent backflow, a preinstalled non return valve on the cold supply flexi hose (B6) is already supplied (see

instructions key).

Hot and cold supply pressures should be as closely balanced as possible for best results. Supply pipes

should maintain the maximum diameter until immediately before the fitting. The differential between the hot

and cold water supply temperatures should be sufficient to allow correct mixing function.

⚠These installation guidelines have been prepared for your direction and you must exercise due care at all

times. We do not accept responsibility for problems that may occur through improper installation. Whilst

assembling the tap take care not to accidentally loosen any factory fixed assemblies.

This tap has been 100% assembly tested; therefore you may expect a small residual amount of water to

remain in the tap when delivered. Any water marks can be removed using the care advice.

Installation Preparation

⚠You must install the mixertap and filter before the boiler.

⚠Before installing the new mixer it is essential that you thoroughly flush through the supply pipes in order

to remove any remaining solder, swarf or impurities from your system. Failure to carry out this simple

procedure could cause problems or damage to the workings of the mixertap or boiler.

We recommend installing particle filters (not shown) and isolation valves (B6) to both the hot and cold

feed pipes in an accessible position. This will help to prevent premature failure of the valves and ease any

future maintenance.

⚠Ensure you have suitable domestic hot and cold water pressure before installing this product (see

technical data).

All parts should be removed from their packaging and inspected for any transport damage and

completeness prior to installation.

Loosely position the tap, pipes and other principal supply components to check if any alterations to the

existing supply pipework is required, if this is the case do this now.

⚠Shut off your water heating system and ensure that your mains stopcock is closed. Open the lowest hot

and cold taps in the house and allow the water to run until fully stopped.

If replacing an existing tap, remove the tap & clean the end of the feed pipes using wire wool, the tap hole area

should be free from dirt and sealant.

This mixertap requires a Ø35mm tap hole.

This tap is designed to be installed in a worktop

with a maximum thickness of 50mm.

Parts and Contents

Key

Description

Qty

A1

Mixer tap

1

A2

Base plinth

1

A3

Base plinth seal

1

A4

Sink or worktop (max. 50mm)

0

A5

White triangular plate (for use

with steel sinks only)

1

A6

Lower gasket

1

A7

Metal horseshoe (M9)

1

A8

Fixing stud (M8 x 120mm)

1

A9

Fixing nut (M9)

1

B1

Domestic hot in (from mains

feed) red banded flexible hose

M8 x ½”BSPF

1

B2

Domestic cold in (from mains

feed) blue banded flexible hose

M8 x ½” BSPM

1

B3

15mm Olive

0

B4

15mm nut

0

B5

15mm pipe

0

B6

15mm isolation valve

0

B7

Non return valve (factory fitted

into flexible hose B2)

1

C1

Cold out (from tap to filter)

flexible hose (M8 x 3/8”F)

1

C2

14mm Ø fibre washer

1

C3

3/8” M x ¼”F brass adaptor

1

C4

¼” NPT M x ¼” pushfit

1

C5

¼” outside diameter plastic pipe

1**

C6

Filter bracket screw

1

C7

Filter bracket

1

C8

Filter cartridge

1

C9

¼” outside diameter plastic pipe

(cut from C4)

1**

D1

Steaming hot water (from boiler

to tap) silicone tube

1

D2

7mm spring steel clip

1

D3

3/8"F(BSP) x 6mm barbed stem

brass adaptor

1

D4

14mm Ø fibre washer

1

**Part supplied with boiler pack, cut to form

required lengths to and from filter and boiler,

for the boiler parts list and connections please

refer to the instructions supplied with the

boiler for more detail.

Install the tap:

This diagram shows the view of the

base of the tap (A1) with the 98°C

water handle to the left of the body.

⚠YOU MUST

CAREFULLY RESPECT

THE INLETS AND

OUTLETS AS SHOWN

1. Screw the fixing stud (A8) into base of tap (A1) as shown on the diagram.

2. Place the base plinth (A2) and base plinth seal (A3) onto the base of the tap (A1).

3. Hand tighten the domestic hot in flexible hose (B1) as shown in the diagram.

4. Hand tighten the domestic cold in flexible hose (B2) as shown in the diagram.

5. Hand tighten the cold out flexible hose (C1) as shown in the diagram.

6. Place the tap (A1-A3) centrally and straight to the tap hole, passing the fixing stud (A8), flexi hoses (B1, B6, C1) and

silicone tube (D1) through the tap hole.

7. Pass the lower gasket (A6) then the metal horseshoe (A7) over the fixing stud (A8). Note: only if the tap is to be

fitted to a stainless steel sink then the white triangular plate (A5) can be fitted where shown to improve the stability

of the tap.

8. Using a 13mm box spanner or small adjustable spanner tighten fixing nut (A9) onto the fixing stud (A8).

9. Screw pushfit (C4) into brass adaptor (C3).

⚠We recommend using PTFE tape (do not use sealing compound) on the thread of the pushfit fittings to make a

good seal without applying excessive force (which may damage the plastic pushfit if overtightened).

10. Screw pushfit (C4) and adaptor (C3) into the cold out flexible hose (C1) ensuring fibre washer (C2) is in place.

11. Connect the domestic hot water flexible hose (B1) to the hot water isolation valve (B6).

12. Connect the domestic cold water flexible hose (B2) to the cold water isolation valve (B6) using a section of 15mm

pipe (B5) and compression nut (B4) and olive (B3). Note: Parts (B3, B4, B5 & B6) are not supplied.

⚠If your customer has a water softener installed you must attach cold water flexible hose (B2) to an unsoftened

cold water source.

13. Compress (using pliers or similar) and pass spring clip (D2) over silicone tube (D1) then push barbed stem adaptor

(D3) fully into silicone tube (D1), then compress and position the spring clip (D2) over both the middle of the barbed

section of adaptor (D3) and silicone tube (D1).

Silicone hose (D1) can be cut to length if it is longer than required, we suggest this is only adjusted if needed

after the installation of the boiler (after the boiler’s output silicone tube has been cut to length).

14. Fibre washer (D4) will need to be inserted inside the threaded end of adaptor (D3) when connecting the tap to the

boiler later in the installation, we suggest taping washer (D4) to adaptor (D3) until this time so it is not misplaced.

Install the Filter:

1. Find a suitable place to mount the filter cartridge (C8) under the sink, it must be mounted vertically, easily

accessible (to be changed periodically), away from any heat source or electrical connections and close

enough not to exceed the available length of the ¼” plastic pipe (C5, C9) supplied to reach between the tap,

filter and boiler (place the boiler temporarily to help judge the required lengths of ¼” plastic pipe).

2. Using the self-tapping screw (C6) securely fix the filter bracket (C7) to the cabinet wall.

3. Write the installation date onto the filter label in permanent pen.

4. Clip the filter cartridge (C8) into the bracket (C7) as shown.

You must respect the direction of flow as indicated on the filter cartridge (C8).

5. Measure and then cut required length of ¼” pipe (C5) to connect pushfit (C4) to the filter cartridge (C8) inlet,

allow a small amount of extra length to make it easier to change the filter.

6. Firmly push connect the ¼” pipe (C5) between pushfit (C4) and filter cartridge inlet (C8).

7. Firmly push connect the remaining ¼” pipe (C9) into the filter cartridge outlet (C8).

After Installation:

1. Reconnect the domestic hot and cold water supplies and open hot and cold isolation valves (B6). As the

system starts to refill, check carefully all new water connections for leaks. After the product installation is

complete we recommend you recheck for any slower leaks.

2. ⚠It is normal for new filter cartridges to lose a small amount of loose carbon when first used and will

dissipate with flushing, whilst harmless to consume if the carbon particles are not flushed prior to connection

to the boiler they may partly block the boiler and reduce the flow rate. You must flush the filter for at least 2

litres with cold water or until the water become clear (without black carbon particles).

3. Place the ¼” pipe (C9) from the filter cartridge (C8) outlet into a bowl or bucket.

4. Turn on the 98°C backwards handle fully, keep the lever open until all air is expelled and cold (filtered) water

exits the ¼” pipe (C8) into the bowl, flush a minimum of a further 2 litres of cold (filtered) water through the

¼” pipe (C8). You may notice a discolouration to the water at first, this is loose carbon particles from the

filter it is normal, harmless and will pass with flushing. Continue to flush the filter until the water runs clear.

Once complete turn off the 98°C handle.

5. Please refer to ‘PROBOIL.2X User & Installation Guide’ for the next steps on how to install the boiler and

connect the tap and filter.

Please leave these instructions for your customer

01/2020

This manual suits for next models

4

Table of contents

Popular Plumbing Product manuals by other brands

Remer

Remer SE18 installation instructions

Luxart

Luxart Poydras PO341 installation manual

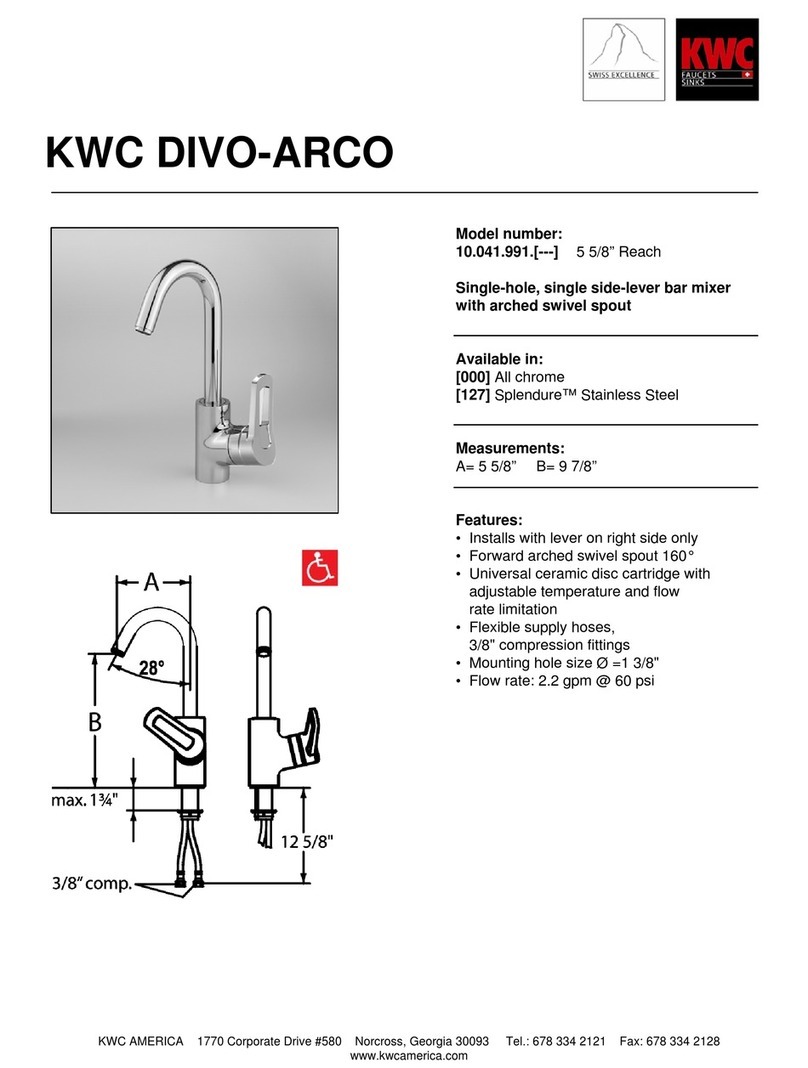

KWC

KWC DIVO-ARCO 10.041.991 Specifications

Clou

Clou wash me CL/02.01032 installation instructions

American Standard

American Standard Dazzle 6028.801 installation instructions

Moen

Moen CA84004 Series quick start guide