Bradley S19-210FW User manual

Other Bradley Plumbing Product manuals

Bradley

Bradley Equa-Flo Pressure Balancing Valve Operation manual

Bradley

Bradley Terreon Quadra-Fount MF2949/IR User manual

Bradley

Bradley Verge LVLD Series User manual

Bradley

Bradley MG-2/BIR3 User manual

Bradley

Bradley COMBI5500 Manual

Bradley

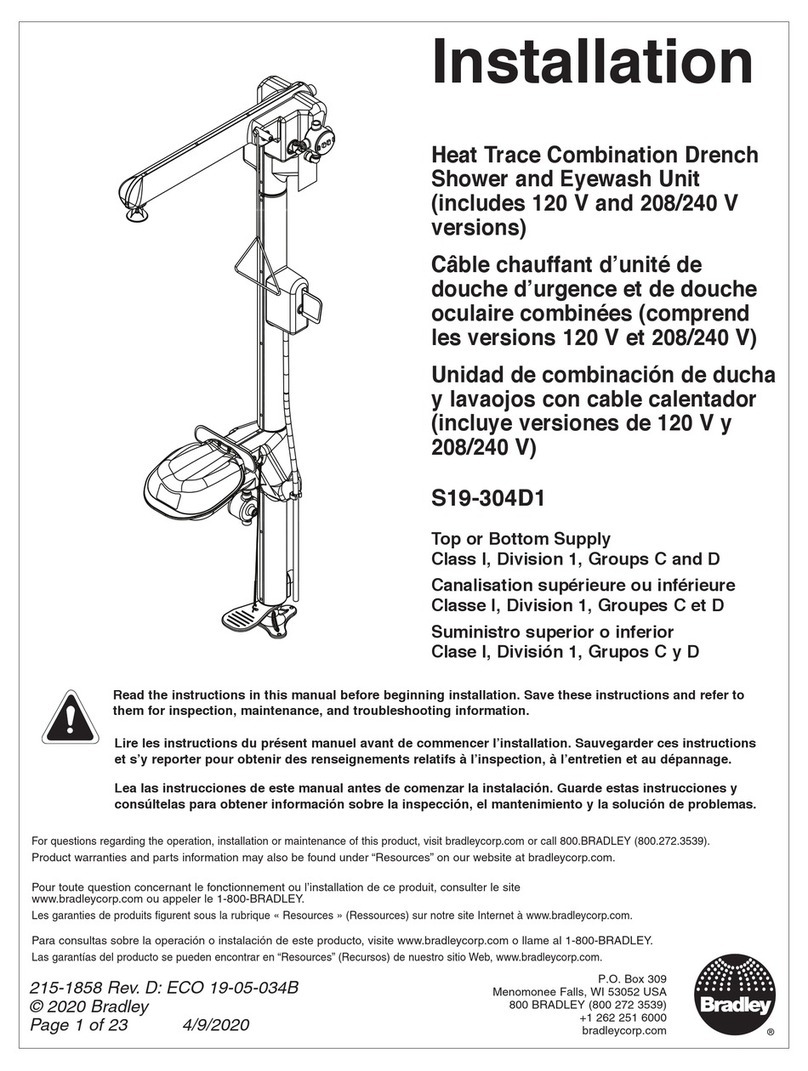

Bradley S19-304D1 User manual

Bradley

Bradley Verge LVGD1 User manual

Bradley

Bradley EXD-2N User manual

Bradley

Bradley 1WCA-BF User manual

Bradley

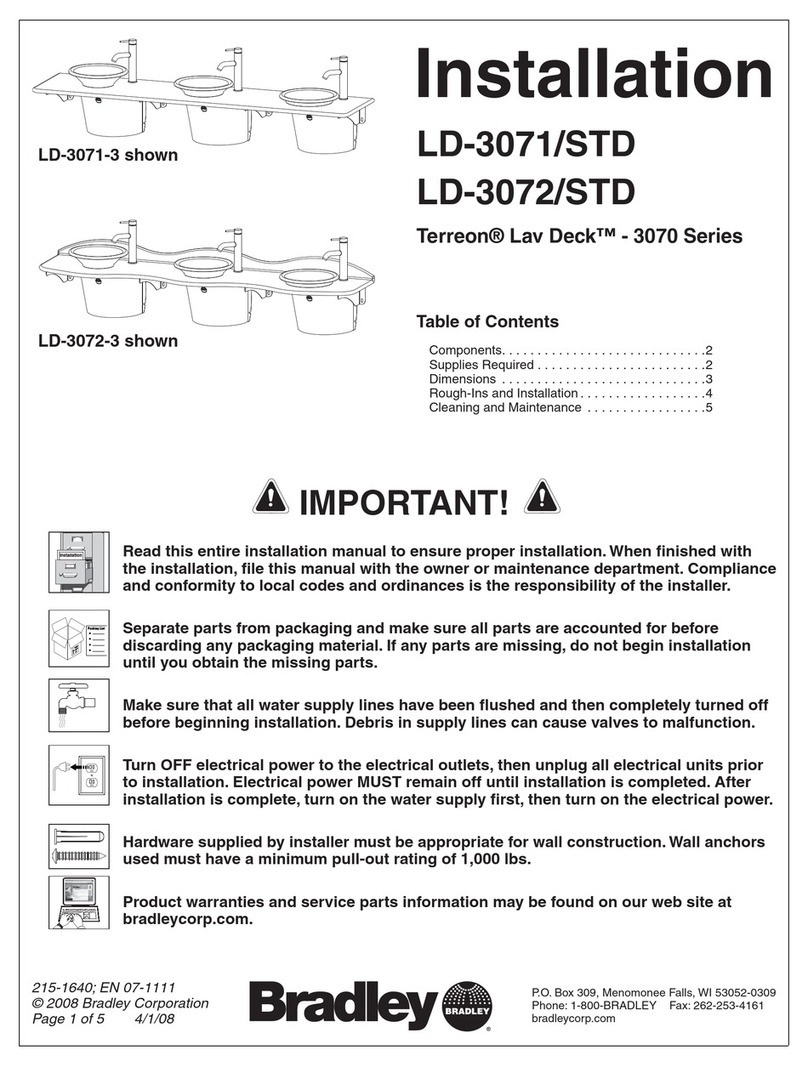

Bradley TERREON LD-3071/STD User manual

Bradley

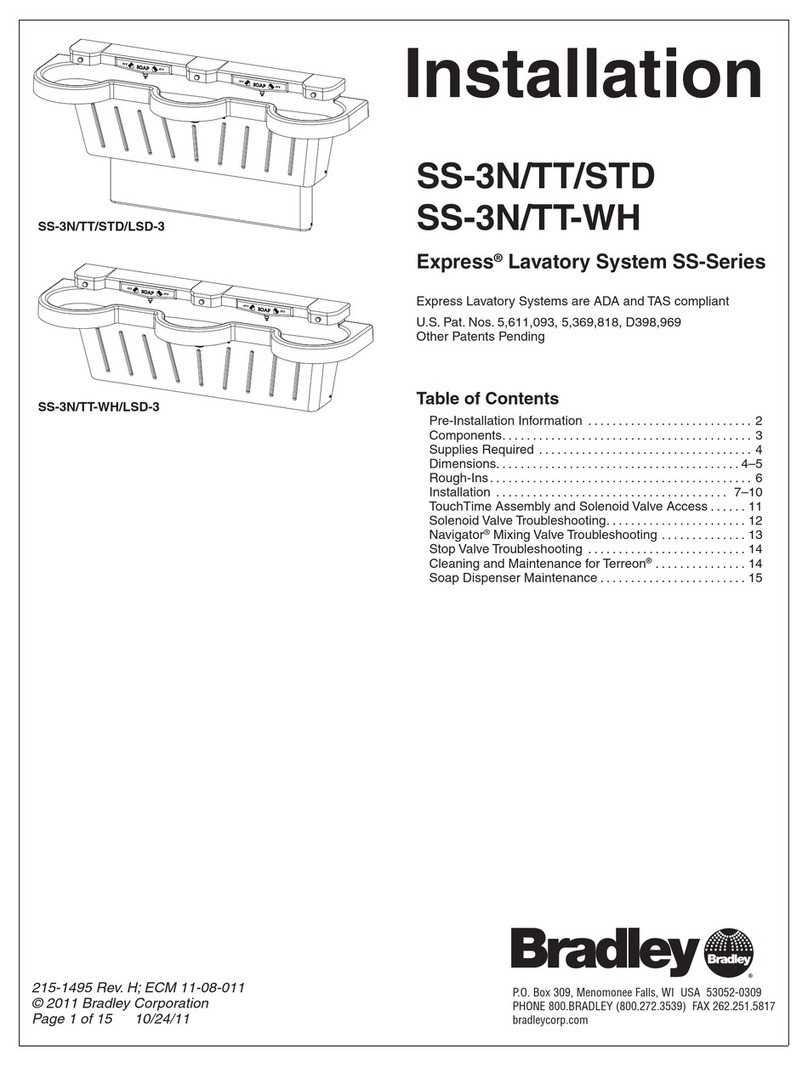

Bradley Express SS-3N/TT/STD User manual

Bradley

Bradley S19-430EH User manual

Bradley

Bradley Express ELX Series User manual

Bradley

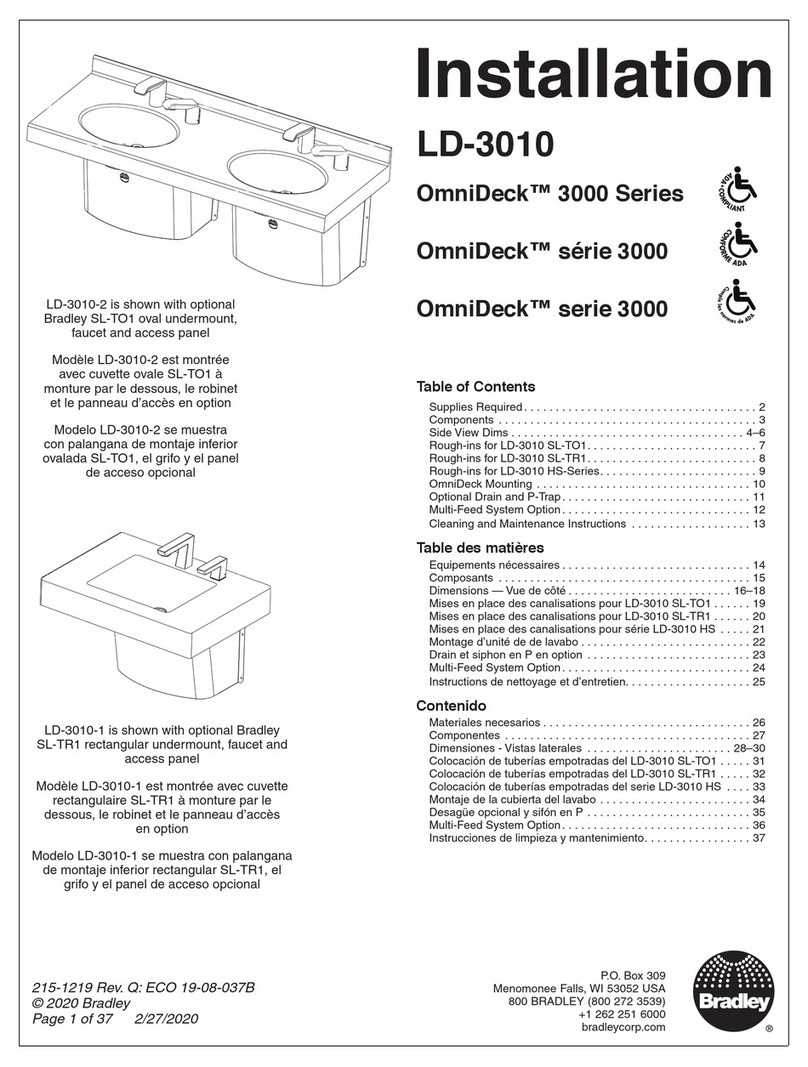

Bradley OmniDeck 3000 Series User manual

Bradley

Bradley Sentry SN2004/IR User manual

Bradley

Bradley WS-1X User manual

Bradley

Bradley Terreon TDB3104 User manual

Bradley

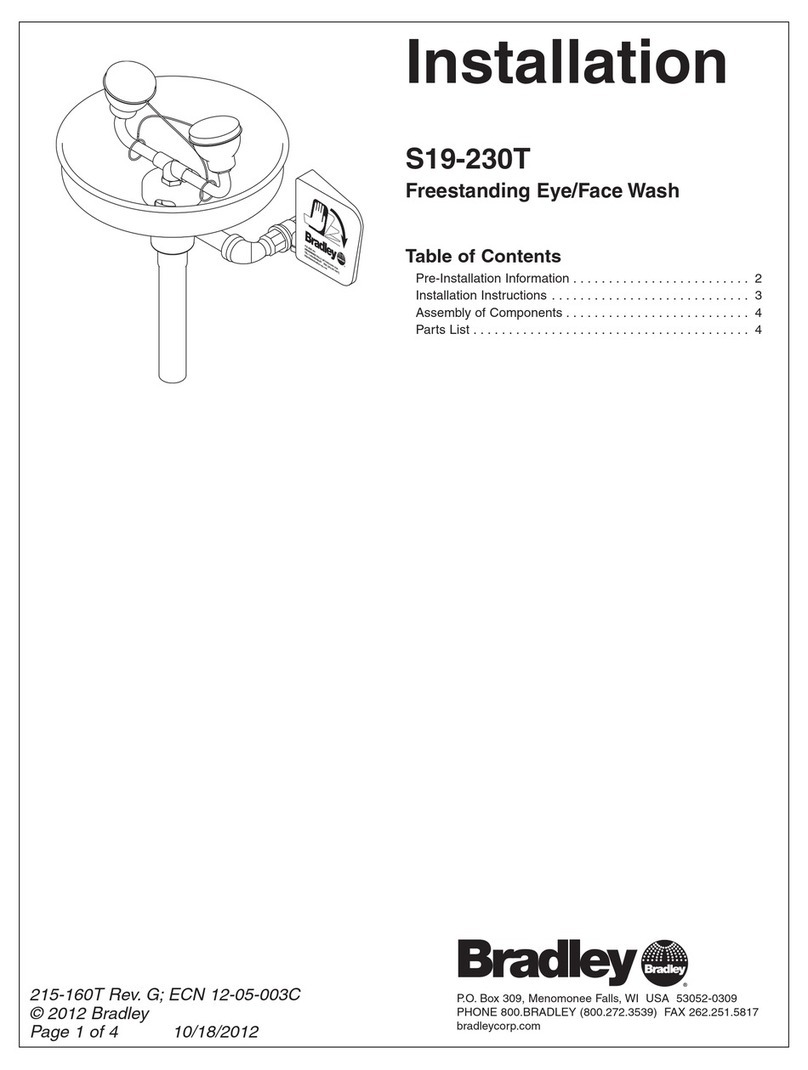

Bradley S19-230T User manual

Bradley

Bradley TouchTime MG Series User manual

Bradley

Bradley 1C TouchTime User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide