PROCRAFT PAE600 User manual

EN|ENGLISH

1

Bench Grinders

PAE600, PAE900, PAE1050, PAE1250, PAE1350

INSTRUCTIONS

Carefully read the instructions before first use of the product. Please keep

the manual for future use.

Grinder (hereinafter - sharpener) is designed for sharpening chains, knives,

scythes, and other household and professional tools. The product is equipped

with a grinding wheel abrasive wheel, the rotational motion is combined with

suitable materials allows the best way to handle a necessary tool. The

product is intended for domestic use, not for commercial use.

GENERAL SAFETY RULES

• For every 15 minutes of operation, the device shall be at 15 minutes of rest.

• The mains power must match the value specified on the nameplate of the

tool.

• Repairs should be performed only by qualified personnel at authorized

service centers.

• Opening or dismantling the tool terminates the free warranty service

• Please, before first use of the product, carefully read and follow these

instructions. It is specially designed for your safety and the safety of others,

as well as to ensure a long and trouble-free service life of your equipment.

Warning

It is strongly recommended not to make any changes in the design of the

power, or use it for other purposes, as well as the use of any devices or

accessories other than those recommended in this manual - it may cause

damage to the tool or injury to the operator.

• Use the tool exactly as prescribed

• Do not use the tool for the job for which it was not designed (for heavy

work needs a tool designed for the harsh conditions of work; for the light

work sufficiently low power tool). Do not use the tool for the purpose for

which it was not designed. This instrument applies to domestic class and is

not intended for commercial use.

Working area

• Cluttered benches and work areas provoke accidents. Benches should be

kept in a neat condition. Floors should be clean and free of debris. Special

precautions should be taken in areas where the floor is slippery due to the

presence of sawdust or wax.

Work environment

EN|ENGLISH

2

•Do not expose your power tools to rain or use it in damp or wet locations.

Maintain a well-lit work area. Do not use power tools in areas where there

is risk of fire or explosion due to the presence of combustible materials,

flammable liquids, paints, varnishes, gasoline, etc., flammable gases and

dust having explosive. As a precaution, it is recommended to consult with

a specialist in respect of a suitable fire extinguisher and the methods of its

application.

Private security

• Clothing: Do not wear loose clothing, jewelry or anything that could get

caught in moving elements (mechanisms) tool.

• Hair: Avoid getting hair in the moving parts of the power tool. To keep the

long hair wear protective headgear.

• Eye protection: it is imperative Goggles (regular glasses are not sufficient to

protect the eyes).

• Hearing Protection: It is recommended to use hearing protection during

periods of continuous operation.

• Shoes: in cases where there is a risk of foot injuries from heavy objects or

the risk of slipping on wet or slippery floor, should wear appropriate

protective skid shoes.

• Head protection: in cases where there is a risk of falling objects or hitting

the speakers or low-lying obstacles should wear a hard helmet.

• Respiratory protection: when machining operations generate dust, wear a

dust personal protective equipment.

Avoid accidental start

• Before inserting the plug tool into an AC outlet, make sure that the switch is

in the OFF.

Unplug power tools

• Upon completion of work, provide a disconnection of the power from the

power supply. Disconnect the plug from the power supply before performing

maintenance also, grease or when making adjustments and when changing

accessories such as blades, drill bits and chisels.

Extension cords and reels

• Do not use extension cords or two-wire coils on the power tools with a

grounding circuit. Always use a three-wire extension cords or coils with

protective conductor is connected to ground.

• If necessary, use power tools outdoors, use only extension cords intended

for outdoor use and marked accordingly («W» or «WA»).

EN|ENGLISH

3

• For extension cords with lengths up to 15 meters using wire cross-section

of 1.5 mm2.

• For the extension cords with a length of over 15 meters, use the cross-

section of 2.5 mm2.

• Protect your extension cords from sharp objects, excessive heat and placing

in a damp or wet location. Before use, remove all damaged extension cord

instrument and, if damaged, contact an authorized service center for

replacement. Work dry, clean and free from oil and grease hands.

Remain alert

Before using the tool, check all the parts and components for damage.

Check the integrity of the housing of the power tool, properly set up the

moving parts, make sure that they are not binding.

Check the availability and performance of all switches (especially ON/OFF)

and parts. If necessary, contact an authorized service center for repair or

replacement. • If devices require mounting, make sure that it is securely

attached to a suitable workbench.

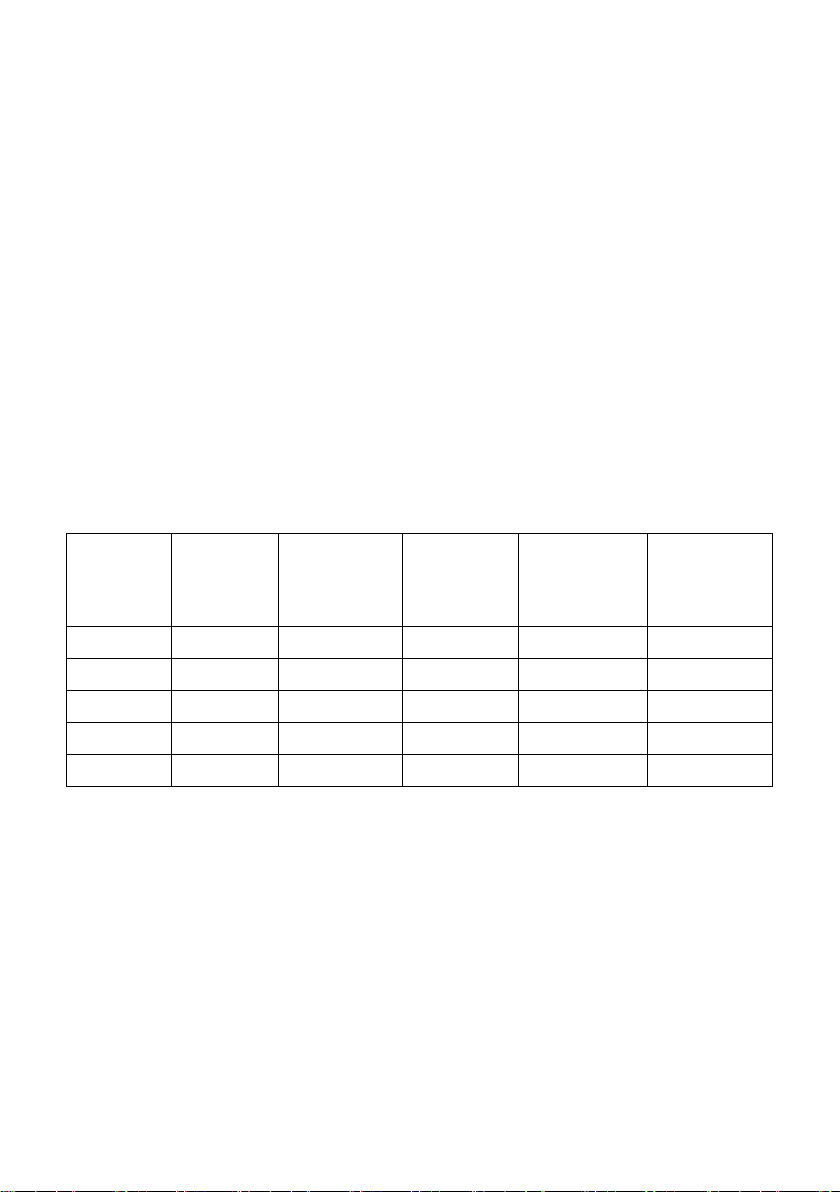

DESCRIPTION AND CHARACTERISTICS

Model Voltage,

V

Frequency,

Hz Power, W

Disc

diameter,

mm

No-load

speed, rpm

РАЕ600

220

50

600

150

2950

РАЕ900

220

50

900

150

2950

РАЕ1050

220

50

1050

150

2950

РАЕ1250

220

50

1250

200

2950

РАЕ1350

220

50

1350

200

2950

EN|ENGLISH

4

1. Abrasive circle

2. Metal-bearing area

3. On / off key (ON / OFF)

4. The protective cover

5. Protective Screen

6. Lock the shield

7. The motor housing

8. Lock-site support

WARNING!

Due to the constant improvement of the design, power may have changes in

design and specifications without notice users.

Appearance of the device in the picture may vary in shape and dimensions of

the housing.

EN|ENGLISH

5

BEFORE START

Unpacking

Carefully unpack the instrument and the necessary parts. Retain the

packaging for future storage. Remove the remaining packages of moving

parts (if any).

GETTING STARTED

Before you start, be sure to check that the mains voltage and power values,

being on the technical label on the unit.

Be sure to install protective screens and reference sites. Securely attached

and check the lock before each start.

This grinder has in its design a high power motor that when you start to

consume a lot of current (inrush current). Verify the ability to connect to your

high-power electrical appliances electricity (consult the appropriate service).

If the tool is used in winter, it is necessary to sustain power at room

temperature for 2 hours at a temperature not lower 18-20 C°. In the case of

condensation, power tools include smoking, until it is completely dry.

SWITCH ON (ON)

Gently press on the Power button (ON / OFF) to turn on the power tool. See

figure describing the details of the power tool. Perform the required

operation.

NOTE

Models with soft start function, gradually gaining momentum, the work in

this case should begin only after the motor is completely dispersed and reach

full operating speed.

During operation, it is necessary to follow the work tool. Remember careless

handling of the power tool may result in injury to the operator.

TURNING OFF (OFF)

To turn off the tool and stop the execution of the power key (ON / OFF). See

figure describing the details of electronic instruments.

WARNING!

During operation, prevents jamming moving parts. To compare with the

required level of work capacity of the power tool. Wedging can damage the

tool.

PROCESS OF OPERATING A POWER TOOL

Power tool designed for easy and safe operation, but in the process it is

necessary to observe the following rules.

Before you start, make a trial without turning the power load to ensure

correct operation of the tool.

EN|ENGLISH

6

Start processing material only when reliable locking of the processed material

(workpiece).

Perform work smooth confident movements.

WARNING!

Some sites and cutting parts in the process can be heated. Exclude contact

with hot parts before and after work.

Be careful not to put your hands on the path or on the axis of the cutting or

working elements in the process - this can lead to injury.

Apply even pressure, how to rotation speed remained stable. Do not press

hard on the workpiece - this may damage it. Move sharpened material

(blank) evenly and smoothly, without jerks, without stopping, then

sharpened edge is quality and level.

WARNING!

Never use a power tool, it can cause injury to the operator. Contact an

authorized service center in the event of faults.

REPLACING SUPPLIES

During operation of the power tool working surfaces consumables wear.

Timely replacement of consumables guarantees correct, trouble-free and

safe operation of the power and quality handling of material required. The

user should periodically replace the consumables (discs, grinding wheels and

the like). The brushes with the design of fast access is permitted to replace

the user without going to a service center.

MAINTENANCE

During operation, you must take good care of the appliance. Check the power

before starting the work. Visually inspect and check the reliability of fastening

removable custom nodes.

Do not disassemble the tool body inside the shell does not contain

components / parts for the service user.

CLEANING

Clean power tool from pollution brought about by the operation. When

cleaning the power tool is prohibited to use abrasive cleaners, as well as

alcohol and solvents. This may damage the body of the appliance.

Use a cloth moistened with water. If very dirty, use soapy water.

WARRANTY CONDITIONS

To avoid confusion, we kindly ask you before working with the product

carefully read the conditions of use specified in this data sheet. Please note

tool is used only in domestic purposes. Lifetime warranty on the product is 12

months. This period is calculated from the date of sale at retail.

EN|ENGLISH

7

Our warranty applies only to defects discovered within the warranty period,

and due to the industrial, technological and structural defects, ie. admitted

the fault of the manufacturer.

The warranty does not apply to:

А) Product malfunction resulting from:

1. non-compliance with the requirements of the operating manual;

2. mechanical damage caused by external influence or any other reason;

3. misuse of the machine;

4. the impact of adverse weather and external factors on the product, such as

rain, snow, high humidity, heat, aggressive media, supply mismatched

electrical requirements of the manual;

5. the use of accessories, consumables and spare parts not covered by the

technological structure of the model;

6. ingestion of foreign objects or products clogging the vents a lot of waste,

such as dust, sawdust, shavings, etc.

B) The items, that were subjected to stripping, repair or modification by

unauthorized persons.

C) Failures caused by improper handling or storage of the machine, signs of

which are:

1. the presence of rust on the metal elements of the product;

2. the presence of oxides of the engine manifold;

3. breaks and cuts of the supply cord;

4. chips, scratches, strong abrasions of housing.

D)Malfunctions caused by overloading the product which caused the failure

of the motor or other components and parts.

To definite signs of overload refers:

- deformation or melt plastic parts and assemblies of the machine;

- emergence of scale on the collector of motor or on carbon brushes;

- simultaneous failure of armature and stator;

- darkening or charring of the wire insulation.

Attention! When buying a product require a verification completeness and

serviceability.

EN|ENGLISH

8

CE DECLARATION OF CONFORMITY

We Vega Trade Company Limited as the responsible manufacturer declare

Bench Grinders TMProcraft:

PAE600, PAE900, PAE1050, PAE1250, PAE1350

are of series production and сonfirms to the following European Directives:

2006/42/EC

And are manufactured in accordance with the following standards or

standardised documents:

EN 60745-1:2009/A11:2010

EN 60745-2-3:2011/A13:2015

…………………………

Technical documentation has been supported by: VEGA TRADE COMPANY

LIMITED, add.: Room 1009, Distrii Zhangjiang Keyuan Office: 6-11 / F, No.5

Bibo Road, Zhangjiang Innopark, Pudong, Shanghai.

Made in P.R.C

This manual suits for next models

4

Table of contents

Other PROCRAFT Grinder manuals