PRODEM PDS Series Instruction Manual

A Force You Can Depend On

PDS RANGE

OPERATING

INSTRUCTIONS

MANUAL

VERSION 2.0 / 2018

www.prodem-attachments.com

www.prodem-attachments.com

INTRODUCTION INSTALLATION

Transport and handling

Storage

Coupling check

Mounting

Use on construction cranes

Connections

Stopping and dismounting

GENERAL INFORMATION

Attachment identification plate and data

Safety standards

Preparation by the customer responsible for

General guarantee conditions

USE OF THE ATTACHMENT

Putting into operation

Operating cycle

Stopping

Taking out of service

Waste disposal

Dismantling

SAFETY

General instructions

Safety instructions

Danger zones

Attachment stickers

Safety pictograms

Individual Protection Devices (IPD)

Residual risks

MAINTENANCE

Attachment insulation

General

Routine maintenance

Scheduled maintenance

Extraordinary maintenance

Diagnostics and troubleshooting

ATTACHMENT DESCRIPTION

Attachment description

Permitted uses

Prohibited uses

Environmental conditions

Technical data

Sticker position

Illumination

Vibrations

Noise

Standard supply

REPLACEMENT PARTS

Assistance

Replacement parts

Replacement parts request Form

TABLE OF

CONTENTS

2Translated by the original

3

4

4

4

5

6

7

8

9

9

10

11

14

15

16

17

18

19

24

25

25

26

27

27

29

30

30

30

31

31

31

32

32

33

34

37

43

44

44

45

20

21

21

21

22

23

23

23

23

23

Purpose of the operation instruction and

maintenance manual

Preserving the instruction manual

Updating the instruction manual

Recipients

Glossary and symbols

Copyright

Manufacturer's identification plate and data

INTRO

SECTION

www.prodem-attachments.com

PURPOSE OF THE OPERATION INSTRUCTION AND MAINTENANCE MANUAL

This Manual is an integral part of the attachment and its purpose is to provide all the information necessary for:

Correctly alerting the operators to safety problems;

Safely handling the packed and unpacked attachment;

The correct installation of the attachment;

In-depth knowledge of its operation and limits;

Its correct use in safe conditions;

Performing maintenance correctly and safely;

Safely dismantling the attachment in observance of rules protecting worker health and the environment.

Under current law, the persons responsible for using this attachment are obligated to read the contents

of this document carefully and to have the operators and maintenance technicians read the parts

within their competence. You will be amply rewarded for the time spent through the safe and correct

operation of the attachment.

This document assumes that current laws regarding safety and occupational hygiene are observed in the

places where the attachment is to be used. The instructions, drawings and documentation contained in

this Manual are of confidential technical nature and may not be reproduced in whole or in part.

The limits of this Manual are:

The Manual can never be a substitute for an adequately experienced user;

For particularly demanding operations, the Manual can only provide a summary of the main steps.

The Manual is to be considered a part of the attachment and must be preserved for future reference until

the latter's final dismantling. The Manual must be available for consultation in the vicinity of the operating

machine and correctly preserved. This Manual reflects the machine's technical state at the time it was sold

and cannot be considered inadequate only because it was later updated based on new experience. The

maker reserves the right to update its production and Manuals without any obligation to update previous

production and Manuals.

The PRODEM Group will not be liable in the following cases:

Improper use of the attachment;

Use contrary to specific national law;

Incorrect installation (in the case where the attachment was installed by unauthorized personnel);

Power supply defects;

Serious failures to perform the required maintenance;

Unauthorized service of modifications;

Use of replacement parts or materials not specific to the model;

A total or partial failure to follow the instructions provided;

Use of the attachment with an incompatible machine;

Exceptional events.

3Translated by the original

www.prodem-attachments.com

PRESERVING THE INSTRUCTION MANUAL

UPDATING THE INSTRUCTION MANUAL

RECIPIENTS

The Manual must be carefully preserved and must accompany the attachment every time its ownership

changes throughout its life.

You must help preserve the Manual by using it carefully with clean hands and not laying it down on dirty

surfaces.

Parts of it must not be removed, torn or arbitrarily changed.

The Manual should be stored in an environment protected from heat and humidity and near the attachment

to which it refers.

The manufacturer can supply additional copies of the Manual upon the user’s request.

The manufacturer reserves the right to change the design of, and make improvements to, the attachment

without informing the customer and without updating Manuals that have already been delivered to the user.

Moreover, when the manufacturer makes changes to the attachment installed at a customer that require

changes to one or more chapters of the Manual, the manufacturer will be responsible for sending the holders

of the Manual involved the chapters affected by the change, with a new global revision form.

The manufacturer is responsible for the descriptions in Italian; translations cannot be fully checked and, for this

reason, if an incongruence is detected, you must follow the Italian version and, if necessary, contact our sales

office, which will make any changes considered appropriate.

This Manual is addressed to: Installers, Operators and Technicians qualified to maintain the attachment.

It should be clarified that Operator refers to the person assigned to operate, adjust, clean and perform

ordinary maintenance of the attachment.

By Qualified Person or Qualified Operator, we mean those persons who have attended courses of

specialization, training, etc. and have experience in the installation, operation and maintenance, repair or

transport of the attachment.

By Dangerous Area, we mean any area inside and/or near an operating machine in which the presence of a

person constitutes a risk for the safety, health or well-being of that person.

The attachment is intended for industrial use and, therefore, professional and not generalized; for this reason

its use must be entrusted to qualified persons and, in particular, who:

Are adults;

Are physically and mentally able to perform work of particular technical difficulty;

Have been adequately instructed in the use and maintenance of the attachment;

Have been judged suitable by the employer to perform the work entrusted to them;

Are capable of understanding and interpreting the Manual and the safety instructions;

Are familiar with the emergency procedures and how to implement them;

Are able to operate the specific type of attachment;

Are familiar with the specific rules of the case;

Have understood the operating procedures defined b the manufacturer of the attachment.

INTRO

SECTION

4Translated by the original

www.prodem-attachments.com

GLOSSARY AND SYMBOLS

This paragraph explains the abbreviations used and the meaning of the symbols used to indicate the

operator qualifications and the state the attachment. Their use allows the information necessary for the

correct and safe use of the attachment to be communicated quickly and unequivocally.

DANGEROUS AREA:

An area inside and/or near the attachment in which the presence of an exposed person constitutes a risk

for the health of that person (See safety rules cited).a

EXPOSED PERSON:

Any person wholly or partially inside a dangerous area (See safety rules cited).

OPERATOR:

A person appointed to install, operate, adjust, perform maintenance on, clean, repair or transport the

attachment (See safety rules cited).

MAN-OPERATING MACHINE INTERACTION:

Any situation in which an operator interacts with the attachment in any of the operational phases at any

time in its life.

OPERATOR QUALIFICATION:

Minimum skill level that the operator must have to perform the operation described.

NUMBER OF OPERATORS:

The number of operators sufficient to perform the operation described and derived from a careful analysis

performed by the manufacturer for which the use of a different number of employees could prevent

obtaining the expected result or place the safety of the personnel involved in danger.

STATE OF THE OPERATING MACHINE:

The state of the operating machine includes its mode of operation, for example, automatic, jog, stopped,

etc., the condition of the safety features on the operating machine, such as protections included,

protections excluded, emergency stop pressed, type of insulation of the sources of energy, etc.

RESIDUAL DANGER:

A danger that cannot be eliminated or sufficiently reduced through design, against which the protections

are not (or are not totally) effective; the Manual provides information of its existence and instructions and

warnings to allow it to be overcome (See safety rules cited).

SAFETY COMPONENT:

This is a component used to provide a safety function and who failure or poor operation has a negative

effect on the safety and/or health of exposed persons (such as lifting equipment, fixed, mobile or

adjustable protections, or an electrical, electronic, optical, pneumatic or hydraulic device that is

interlocked with a protection, etc.).

INTENDED USE:

The operation with Interchangeable attachment must be in accordance with the information reported

into the instructions for use (Directive 2006/42/EC Annex I, 1.1.1) .

INTRO

SECTION

5Translated by the original

www.prodem-attachments.com

GLOSSARY AND SYMBOLS

COPYRIGHT

Descriptions in this purple text contain very important information/instructions regarding safety. Failure to

observe them can involve:

Danger for the operator's well-being;

Loss of the contractual guarantee;

Denial of the manufacturer’s liability.

SYMBOLS RELATIVE TO OPERATOR QUALIFICATIONS

INTRO

SECTION

6Translated by the original

Symbol Description

Generic unskilled worker: an operator with no specific skills only capable of

performing simple duties on the instructions of a qualified technician.

Driver of lifting and handling equipment: an operator qualified to use vehicles to lift

and handle materials and machinery (scrupulously following the manufacturer’s

instructions) in observance of current law in the country of use of the machinery.

1st level machine operator: an operator with no specific skills, only capable of

performing simple duties, i.e., operating the machine through the use of the buttons

on the pushbutton pad and loading and unloading the materials used during

production with the protections installed and active; not qualified to use the machine

in jog mode.

2nd level machine operator: personnel capable of performing the tasks of a 1st level

operator plus capable of operating the machine in jog to perform typically simple

functions of starting production and restoring it follow a pause and adjustment.

Maintenance mechanic: a qualified technician capable of operating the machine

under normal conditions, operating it with the jog command with the protections

deactivated, working on mechanical components to perform the necessary

adjustments, maintenance and repairs. Typically not qualified to work on electrical

systems under voltage.

Manufacturer’s technician: a technician provided by the manufacturer to perform

complex operations in particular situations or, in any case, in agreement with the

user. Depending on the case, he may have mechanical, electrical, electronic and/or

software skills.

Agenda

This Manual is copyrighted by PRODEM. This Manual is intended for operating and maintenance personnel. It

contains instructions and technical diagrams that may not be copied, in whole or in part, distributed or

examined by unauthorized persons for competitive purposes or divulged to any other third party.

www.prodem-attachments.com

MANUFACTURER’S IDENTIFICATION DATA

INTRO

SECTION

7Translated by the original

MANUFACTURER

PRODEM Global Ltd

10 Gillmans Industrial Estate,

Natts Lane, Billingshurst,

West Sussex, RH14 9EZ, UK

CONTACTS

Tel.: +44 (0) 1403 787 949

Fax.: +44 (0) 845 017 6973

sales@prodem-attachments.com

www. prodem-attachments.com

OPENING HOURS

8am - 5.30pm Mon-Fri

www.prodem-attachments.com

ATTACHMENT IDENTIFICATION PLATE AND DATA

GENERAL

INFORMATION

8Translated by the original

Each attachment is identified by a CE plate (Fig. 1.2.1) on which the reference data is indelibly printed.

Always provide this information in any communications with the manufacturer.

Fig. 1.2.1

ATTENTION!

The plate is attached to the attachment in a protected, easy to reach place. This place can vary from

model to model.

The identification plate contains the following information:

Model

Serial num.

Production year

Weight in kg.

Max. operating pressure

Max. operating capacity

Max. operating pressure (rotation)

Max. operating capacity (rotation)

Coupling with operating machine

PRODEM Global Ltd,

10 Gillmans Industrial Estate, Natts

Lane, Billingshurst, West Sussex,

RH14 9EZ, UK

Tel.: +44 (0) 1403 787 949

sales@prodem-attachments.com

www. prodem-attachments.com

A Force You Can Depend On

www.prodem-attachments.com

SAFETY RULES

PREPARATIONS THE CUSTOMER IS RESPONSIBLE FOR

GENERAL

INFORMATION

9Translated by the original

The attachment has been constructed in conformity with the safety standards listed below:

UNI EN ISO 12100

Machine safety - Fundamental Concepts, General design principles, Risk assessment and risk reduction.

UNI EN ISO 13857

Safe Distances from Machinery - Safe distances for preventing the upper limbs from reaching dangerous

areas.

UNI EN 349

Safe Distances from Machinery - Minimum distances to avoid crushing parts of the human body.

UNI EN 474-1

Machine Safety - General Requirements.

UNI EN 474-5

Machine Safety - General Requirements - Requirements for hydraulic excavators.

ATTENTION!

The standards in this manual may not protect from specific situations that may arise during different

stages of work.

Except where contractually agreed otherwise, the customer is normally responsible for:

Preparing the environment / work area and work equipment in accordance with specific safety and

required by the applicable laws in the country to use the equipment;

Check in accordance with specific safety and required by the applicable laws in the country to use the

equipment correctly matched to the machine;

Power hydraulic equipment, in accordance with the regulations in the country of use and the

specifications in this manual;

ATTENTION!

It is a customer / end user responsibility to integrate the instructions contained in this user manual and

system maintenance / assembly and provide any additional information to the operator.

www.prodem-attachments.com

GENERAL GUARANTEE CONDITIONS

GENERAL

INFORMATION

10 Translated by the original

The guarantee does not include parts subject to normal consumption and/or wear and to breakage due to

improper use of the attachment supplied by PRODEM Global Ltd. In this case, the customer will have to

provide for delivery to, and pick up from, our workshop at its own expense; if the customer wishes the repair to

be performed at its office, so long as this is possible, it will be required to pay the seller’s transport and travel

expenses. In the event of the customer’s carelessness and/or negligence or any other fact not dependent on

PRODEM Global Ltd., the latter is not able to intervene in a timely manner during the guarantee period

immediately after the occurrence of the breakage or deficiency, the customer will be responsible for the

worsening of the breakage or damage deriving from the additional use of PRODEM products. This additional

damage is excluded from the guarantee.

PRODEM Global Ltd. will not be responsible for any expenses for repairs performed, or ordered performed, by

the customer in workshops other than those authorized or in the case in which the service was not agreed to.

The customer may not claim compensation for any damages deriving from the stoppage of the machinery

during the guarantee period.

ATTENTION!

This guarantee is exclusively valid when the product has been entirely paid for in conformity with the

required conditions of supply and the “Guarantee Card” (on the last page of this manual) has been

returned within 2 weeks from the purchase. Failure to pay for the products within the agreed terms will

void this guarantee, even in the case where the goods in question are entirely paid for later.

www.prodem-attachments.com

GENERAL INSTRUCTIONS

SAFETY

11 Translated by the original

The operator’s safety is one of the manufacturer’s principal concerns.

In constructing a new attachment,we attempt to foresee all possible situations of danger and, obviously,

adopt suitable safety measures, paying a great deal of attention to operations that are especially dangerous.

The manufacturer will not be liable for the failure to follow the safety and accident prevention instructions in

this manual.

Before making the attachment operational, the instructions contained in this manual must be carefully

read and the information given carefully followed.

The manufacturer has provided the attachment with all the protections and safety devices considered

necessary and, in addition, has accompanied it with sufficient information for its safe and correct use.

To this end, when necessary, every chapter contains the following information for every man-attachment

interaction:

Minimum required operator qualifications;

Number of operators necessary;

State of the attachment;

Residual risks;

Necessary or recommended individual protective devices;

Prevention of human errors;

Prohibitions/obligations relative to reasonably foreseeable incorrect behavior.

ATTENTION!

This information must be scrupulously obeyed.

www.prodem-attachments.com

GENERAL INSTRUCTIONS

SAFETY

12 Translated by the original

The user may supplement the manufacturer’s information with additional instructions that, obviously, do not

conflict with what is shown in the manual to contribute to the safe use of the attachment.

Anyone working on the attachment must pay attention to the clothing he is wearing.

Avoid the use of clothing with parts that could get snagged in the attachment;

Avoid wearing ties or other flapping articles of clothing;

Avoid wearing rings or bracelets that could catch ones hands in the components of the attachment.

When necessary, the manual will provide additional recommendations for preventive measures to taken by

the user, individual protection devices, helpful information for avoiding human errors and prohibitions against

reasonably foreseeable prohibited behaviors.

In any case, it is indispensable to follow the following instructions diligently:

It is absolutely forbidden to operate the attachment with the fixed protections dismounted;

It is absolutely forbidden to inhibit the safety devices installed on the attachment;

Washing must be performed with the hydraulic separation devices disconnected;

Do not modify any parts of the attachment;

The manufacturer will not be responsible for the consequences of malfunctions caused by a failure to

respect the above. We recommend requesting any modifications directly from the manufacturer.

IMPORTANT !

The manufacturer will not be liable for personal injury or damage caused by the attachment in the case

of:

Use of the attachment by inadequately trained personnel;

Improper use of the attachment;

Defects in the hydraulic power supply;

Incorrect installation;

Lack of the required maintenance;

Unauthorized service or modifications;

Use of replacement parts that are not original or not specific to the model;

A total or partial failure to follow the instructions provided;

Use contrary to specific national law;

Disasters or exceptional events.

CONTROLS AND CHECKS

Checks must be made by an expert; they must be visual and functional, with the purpose of guaranteeing

the safety of the attachment. They include:

A check of all the load-bearing structures, which must not have any cracks, breakage, damage,

deformation, corrosion, wear or alteration with respect to their original characteristics;

A check of all mechanical components;

A check of all the safety devices installed on the attachment;

A check of all connections with pins and screws;

www.prodem-attachments.com

GENERAL INSTRUCTIONS

SAFETY

13 Translated by the original

Functional check of the attachment;

A check of the state of the attachment;

A check of the seal and efficiency of the hydraulic system.

ATTENTION!

If anomalies are found, they must be eliminated before putting the attachment back into operation.

If the person performing the check finds dangerous cracks or anomalies, he must notify the manufacturer of

the attachment in a timely manner.

Take the attachment out of service whenever operating anomalies occur and see to suitable checks and/or

repairs.

Make sure that there are no objects between the parts of the attachment.

After any maintenance service, check that there are no objects remaining between moving parts.

In any case, to guarantee the maximum safety when transporting the attachment it is FORBIDDEN:

To tamper with any part of the attachment;

Leaving moving parts unguarded;

Use attachment that is working but not with complete efficiency;

Modify the attachment to change its original use without explicit authorization from the manufacturer or

with assuming complete liability in conformity with directive 2006/42/CE (the Machine Directive);

Manually moving mobile parts in the absence of energy.

The attachment may not be used to lift or transport persons, animals or objects.

Do not use the attachment to lift or extract parts stuck in the ground.

Do not climb on the structure of the attachment.

During demolition, depending on the structure to be crushed, do not begin from lower points that could

cause the upper part to collapse way.

Do not use the attachment to pound on structures to be demolished.

The arm must be moved safely, with slow, precise movements. Avoid brusque movements.

Do not use the attachment to: pull, push on the front or side, pound or hit.

Make sure that the floor can support the load of the operating machine.

Do not bring the operating machine closer than 10 meters from aerial power lines under voltage.

To avoid the development and diffusion of dust while working, it is necessary to the work area damp

using jets of water.

Do not make any adaptations or changes that the manufacturer has not previously agreed to and

approved in writing.

All regulation, maintenance, repairs or cleaning must be performed with the engine stopped and the

attachment stably support on the ground and not residual hydraulic pressure. The residual hydraulic

pressure must be discharged by activating the opening and closing controls of the attachment several

times with the motor stopped and depressurizing the oil tank. The intervention must be marked on the

card in the cabin.

Do not come closer than 20 meters to range of action of

an operating machine that is working with the

attachment.

Use the appropriate individual protection devices

(gloves, goggles, hard hat and safety shoes) during both

work and maintenance.

The attachment may only be operated by a qualified

operator who has read and understood the contents of

this manual.

Do not allow unauthorized personnel to operate the

attachment or perform any type of maintenance.

The operator must quickly release his grip on the

attachment in case of danger.

Do not use the attachment if it is not working properly.

The attachment can only be used when it is installed on

the operating machine using the upper bracket and the

pins provided.

www.prodem-attachments.com

SAFETY INSTRUCTIONS

SAFETY

14 Translated by the original

During overhead work, fragments or blocks of material can fall. Make sure that the machine on which the

attachment is installed has the necessary protections for performing this time of work and has a FOPS

cabin (Fig. 2.2.1).

Fig. 2.2.1

www.prodem-attachments.com

SAFETY INSTRUCTIONS

DANGER ZONES

SAFETY

15 Translated by the original

When performing cleaning, mounting, dismounting, maintenance and transport, take care to place the

attachment in a condition of perfect stability and lock its rotation with the pins provided. The movements of

its various parts must be inhibited by external constraints (such as slings or supports).

Any service of the rotation thrust block must only be performed by a specialized technician equipped with

a torque wrench for tightening the screws.

For the hydraulic connections, only and exclusively use hydraulic hoses and fittings conforming to the

SAEJ517 or DIN20066 standards for the specified pressures. Failure to observe the above could compromise

the safety of the attachment.

Always check the integrity of the hoses to make sure they have not been damaged. If so, have them

replaced immediately. Search for leaks using small pieces of paper or cardboard and never with your

fingers to avoid possible subcutaneous injections of oil under pressure.

The oil can reach very high temperatures. Before performing any service on external surfaces, wait for them

to completely cool.

Only use original replacement parts to replace worn parts.

OPERATOR POSITIONING

When the operating machine is working, the operator must pay particular attention to his own position in

other to avoid possible danger to himself and persons nearby. The area adjacent to the attachment is

divided into two areas:

OPERATOR AREAS

These are areas in which the operator must work during normal operation of the attachment. The “operator

areas” are to be considered potentially dangerous areas. In these areas, which are indicated on the

following drawing, the operator should pay the maximum attention while working to protect the well-being

of persons near to him; it is extremely important to follow all the accident prevention rules described to this

point.

DANGER ZONES

These are the areas that unauthorized personnel must not approach during work.

OPERATOR POSITION MAP

1 = Command area

2 = Person is safe area

3 = Person in danger area

4 = Range of action of the

machine

5 = Safe area limit

Fig. 2.3.1

www.prodem-attachments.com

ATTACHMENT STICKERS

SAFETY

16 Translated by the original

Stickers are applied on the attachment with the main warnings and instructions to keep in mind during use.

Symbol Description Symbol Description

“Read the manual”

Carefully read this Use and

Maintenance Manual.

“Greasing points”

Indicates points to be lubricated.

“Safe distance”

Stay at a safe distance from

the range of operation of the

operating machine.

“Oil output”

Power/rotation oil input.

“Burn hazard”

Surfaces that can reach high

temperatures with the risk of burns.

Wait for the attachment to cool

before performing any type of

service.

“Oil return”

Power/rotation oil output.

“Danger material projection”

Stay at a safe distance from

the range of operation of the

operating machine.

“Direction rotation”

Direction in which the attachment

must rotate.

“Cut hazard”

Don’t approach the operating

machine during the work cycle. In

the case of maintenance, wear

individual protective devices.

“Drainage”

Overflow point of excess oil.

“Crushing hazard”

Don’t approach the operating

machine during the work cycle.

“Lifting points”

Use the indicated points for

handling the attachment.

Table 2.4.1

www.prodem-attachments.com

SAFETY PICTOGRAMS

SAFETY

17 Translated by the original

Pictograms in a triangle indicate DANGER.

Pictograms in a circle are PROHIBITIONS.

Symbol Description

Attention to your hands

Crushing limbs

Getting tangled

Dragging

Generic hazard

Removing safety devices prohibited

Prohibited to clean, grease, repair or adjust moving parts by hand

Table 2.5.1

www.prodem-attachments.com

INDIVIDUAL PROTECTIVE DEVICES (IPD)

SAFETY

18 Translated by the original

Pictograms in a blue circle are OBLIGATIONS.

Symbol Description

It is obligatory to use protective goggles

It is obligatory to wear work clothing

It is obligatory to protect your hearing

It is obligatory to wear protective gloves

It is obligatory to wear protective shoes

It is obligatory to wear a hard hat

Table 2.6.1

www.prodem-attachments.com

RESIDUAL RISKS

SAFETY

19 Translated by the original

DEFINITION OF RESIDUAL RISK:

“A hazard that cannot be totally reduced through design and protective techniques or a potential hazard

that is not obvious.”

Attention must be paid to the following residual risks that are present when the attachment is used and that

cannot be eliminated.

Operating safely and maintaining the attachment require knowing and following the general safety rules in

the country of use and, in any case, always obeying these instructions:

Before operating the attachment,the operator must carefully read this manual and have through

knowledge of the operating machine’s technical specifications and controls.

The operator should be trained to make the best use of the attachment.

Maintenance must only be performed by qualified personnel.

Unauthorized and unqualified personnel are prohibited from operating, adjusting or repairing the

attachment.

Do not use your hands instead of the proper tools to work on the attachment.

In the case of a malfunction of the attachment or damage to its components, contact the maintenance

manager without attempting to repair it.

Never perform hasty or makeshift repairs that could compromise the good operation of the attachment. In

the case of doubt, always request service by specialized personnel.

It is forbidden to perform checks and/or replace parts during work.

All checks and maintenance require the removal of the safety protections and must only be performed

under the user’s complete responsibility. We, therefore, recommend that these operations be exclusively

performed by specialized and authorized technicians.

To avoid personal risks, only use electrical devices that are correctly connected to the grounding system

and conform to the national safety standards in the country of use.

In the case of operations or repairs to be performed in positions that are not directly reachable from the

ground, use ladders or lifting means that are secure and conform to national safety regulations.

In the case of repairs near or below the attachment,make sure that there are no moving parts that can

start working and that parts that are, by their nature, unstable are not positioned on, or near, the

attachment ; in any case, see to blocking them with adequate tools.

Unless expressly specified by this manual, avoid repairing or adjusting the attachment (or parts of it) during

work, in order to avoid being hooked by moving parts.

Pay the maximum attention to the table (Table 2.6.1) that indicates the Individual Protection Devices to be

used when working on, or near, the attachment.

Everyone but the operator is severely prohibited from pausing or working in the area of the attachment

when it is operating.

Before putting the attachment in operation, warn persons in its vicinity.

Do not remove the safety devices or protective guards.

It is absolutely prohibited for anyone to use the attachment for any purpose other than that expressly

allowed and documented. The attachment must always be used in the manner and at the times and

places required by good practice and in conformity with the current laws of every country, even if there are

no laws regulating the sector in the country of use.

www.prodem-attachments.com

RESIDUAL RISKS

ATTACHMENT DESCRIPTION

ATTACHMENT

DESCRIPTION

20 Translated by the original

ATTENTION!

These safety standards supplement and do not replace current local safety standards.

ATTENTION!

Any tampering by the user will release the manufacturer from all liability and will make the user solely

responsible to the competent authorities for the prevention of accidents.

IMPORTANT!

PRODEM declines all liability for any accidents or personal and property damage deriving from a failure

to obey the general safety instructions and the standards listed here.

The ProDem PDS Shear range is an attachment entirely designed and constructed by PRODEM. It is intended

for modern industrial demolition job sites that need significant cutting force at considerable heights and

professionals that recycle ferrous scrap and materials.

The geometry of the mouth and the arrangement of the interchangeable blades cut scrap clean and straight,

simplifying loading and reducing the costs of handling and transport and, as a consequence, limiting

machine stoppages.

The use of a “speed multiplication” valve, where foreseen, allows recovering and reusing the drained oil. The

presence of this regeneration circuit in the majority of PRODEM demolition equipment significantly reduces

the closing time of the jaws approaching to the material to be cut.

The closing power is produced by the thrust of a hydraulic cylinder to allow the cutting of the most resistant

materials.

The load-bearing structure and claw jaws are made of anti-wear steel with a high elastic limit. This confers

great anti-abrasion characteristics together with exceptional mechanical strength.

The hinges are made of thermally-treated alloy steel and rotate on hardened and ground bushings with

grooves for internal lubrication. The dust abatement system with which they are equipped extends the life of

surfaces in contact.

All the attachments of the PDS range are equipped with a continuous rotation system, which reduces

repositioning to a minimum and allows gripping pieces with greater precision.

This manual suits for next models

13

Table of contents

Other PRODEM Power Tools manuals

Popular Power Tools manuals by other brands

Parker

Parker Karrykrimp 82C-061L Operation and technical manual

Briteq

Briteq ALU CLAMP Series Operation manual

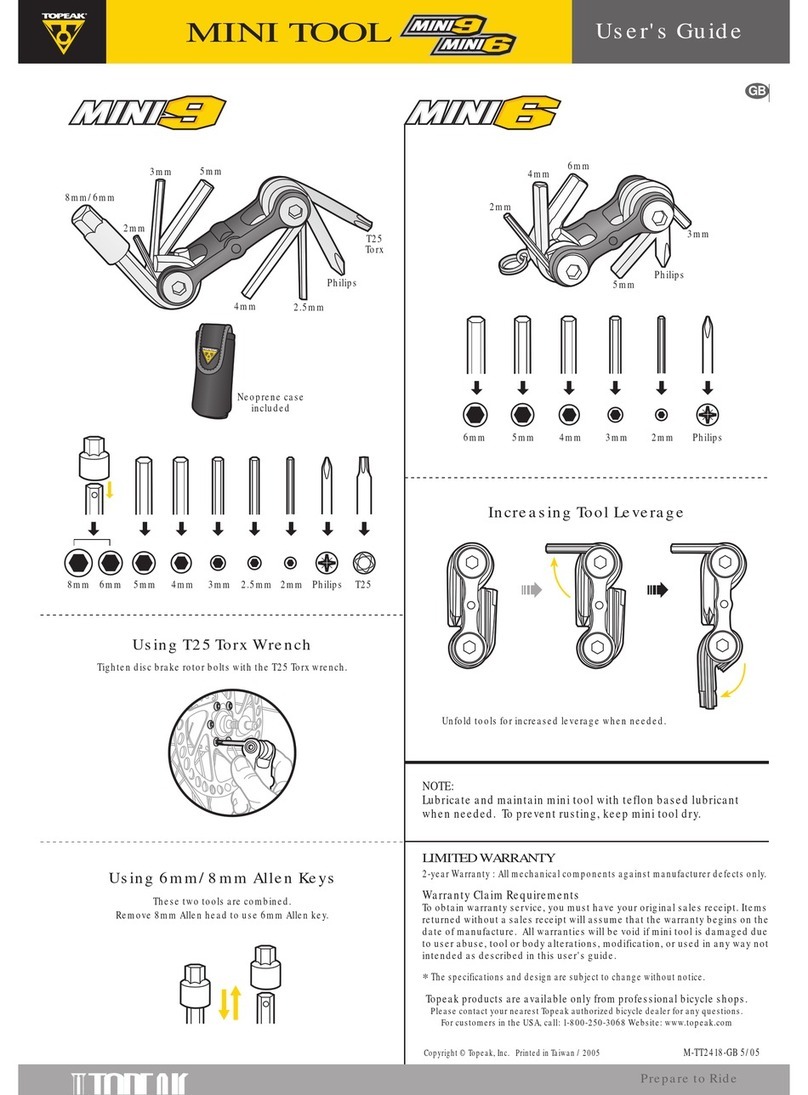

Topeak

Topeak Mini Tool Mini6 user guide

Makita

Makita JS3200 instruction manual

Eaton

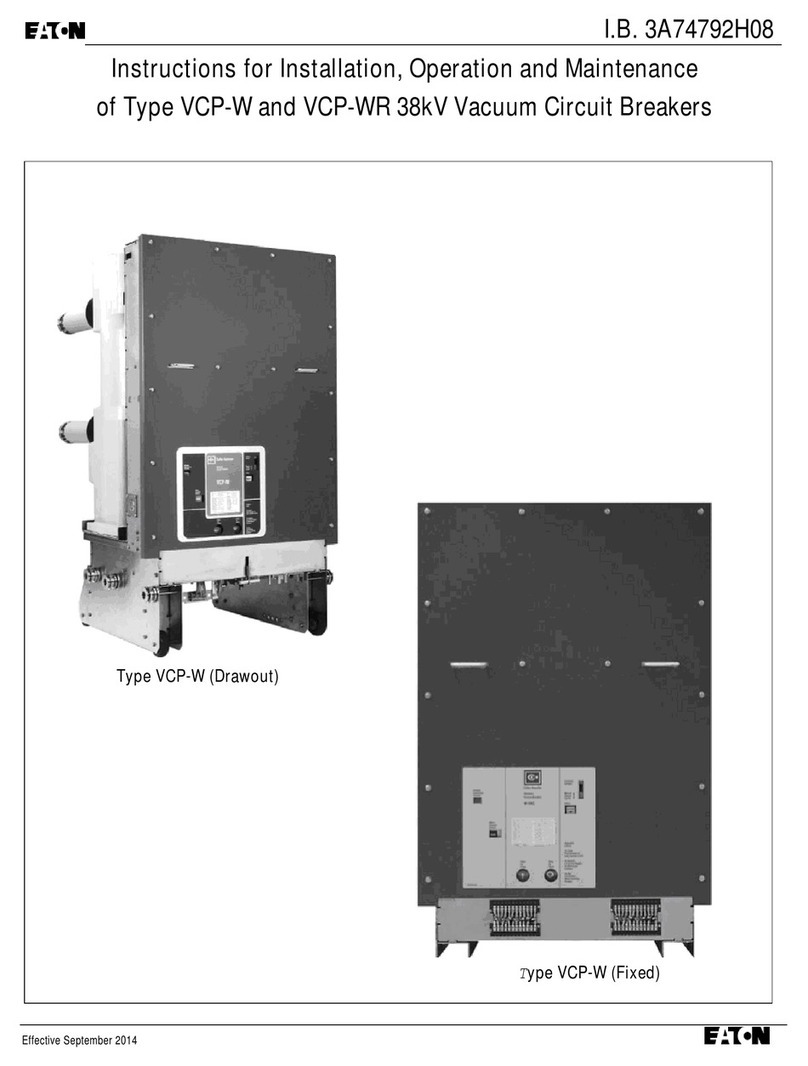

Eaton 380 VCP-W 16 Instructions for installation, operation and maintenance

Makita

Makita DTW300 instruction manual