Profab FDD- PRO V Operating manual

OPERATING AND MAINTENANCE INSTRUCTION

PROFAB MODEL FDD- PRO V

CD 66

2

2

INDEX

A. INTRODUCTION 4

B. WARRANTY 4

C. DESCRIPTION CAPACITOR DISCHARGE WELDING UNIT 5

1. Identification 5

2. Generality 6

3. Technical data 7

4. Welding control 8

5. Gun: Contact Black 9

D. CONDITIONS OF USE PROVIDED AND NOT PROVIDED 10

1. Intended used 10

2. Unintended used 10

E. PROCEDURE 10

F. COMMISSIONING 11

1. Connection to the electrical power 11

2. Machine adjustment 12

3. Combination of materials 14

4. Cable connecting 14

5. How to get a good weld 14

a. Characteristics of the working surface 14

b. Positioning the pieces 14

c. The gun using 14

6. Operations to avoid 16

G. SECURITY MEASURES 17

1. Safety devices installed on the welding machine 17

2. Verification of safety device 18

H. TROUBLESHOOTING 20

I. MAINTENANCE 20

1. Cleaning inside by professionals 22

2. Routine maintenance 23

3. Extraordinary maintenance and repairs 23

J. EMERGENCY SITUATIONS 24

1. For small fire 24

2. For equipment failure 24

K. TECHNICAL DOCUMENTATION 24

L. RESIDUAL RISKS 25

M. NOISE LEVEL 26

N. PARTS 26

O. INFORMATION ON DEMOLITION 26

P. INDICATIONS FOR UNDERSTANDING THE SAFETY REQUIREMENTS 27

ATTACHMENTS

N. 1 REGISTER OF PERIODICS CHECKS WELDER 28

N. 2 PARTS FOR WELDING CAPACITIVE DISCHARGE 29

N. 3 EXPLODED WELDER WIEW 30

N. 4 CIRCUIT DIAGRAM 31

N. 5 GUN SECTION 32

N. 6 LIST SPECIAL GUN IN CONTACT BLACK 33

CONTACT DETAIL 34

CD 66

3

3

A. Introduction

We want to thank you for your preference with the purchase of a welding

machine CRT Eurosaldature produced entirely in Italy, a guarantee of reliability,

ease of use, durability, with direct assistance and immediate availability of a wide

range of spare parts.

The machine, for the welding capacitor-discharge, provided of special stud

welding gun, is used in various sectors of manufacturing. Such a plant allows the

application of pins and metal inserts of various types.

This manual has been prepared to convey the necessary skills to enable safe

use of the machine. To this end, each user must read it carefully before starting

up the machine, respecting all indications, obligations and prohibitions.

The capacitive discharge welding machine has been designed and built to be

used in the method of welding capacitor-discharge, in combination with the

welding gun of the contact type, supplied.

Within the limits and conditions set out by the following manual, a different

use is contrary to the purpose for which the machine was built.

B. Warranty

Upon delivery of the welder capacitor discharge, the purchaser must verify the

absence of anomalies if any, to be reported within the statutory time limits.

The guarantee, which lasts TWO years from the day of delivery.

It should however be noted that any tampering of any kind, by the user or by

unauthorized personnel will void the warranty, CE marking and the manufacturer's

declaration, raising the manufacturer from any responsibility for any damage to

persons or property caused by such tampering.

The manufacturer is also relieved from liability arising from the following

cases:

•Incorrect maintenance.

•Lack of maintenance on schedule.

•Improper use of welding capacitor discharge.

This manual is provided by CRT EUROSALDATURE srl without any

responsibility. CRT EUROSALDATURE Inc. reserves the right to make this manual

at any time and without notice, changes resulting from typographical errors,

inaccuracies in the content, or improvements of programs and equipment.

Any changes will in any case incorporated into new editions of this manual. In

no event CRT EUROSALDATURE Ltd be liable for any direct, indirect, special,

CD 66

4

4

incidental or consequential, arising from the use or not ability to use the system

or documentation.

Copyright © 2018 C.R.T. EUROSALDATURE srl.

All rights reserved. Printed in Italy.

C. Description welding capacitor discharge

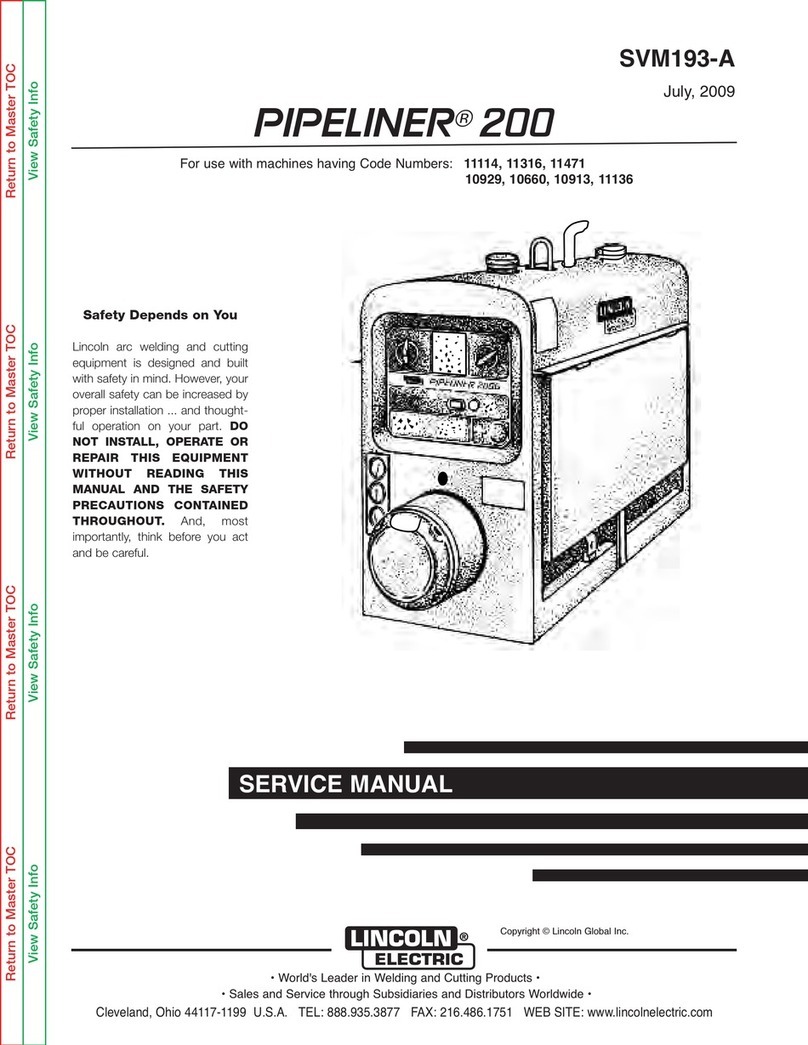

C.1 –Identification

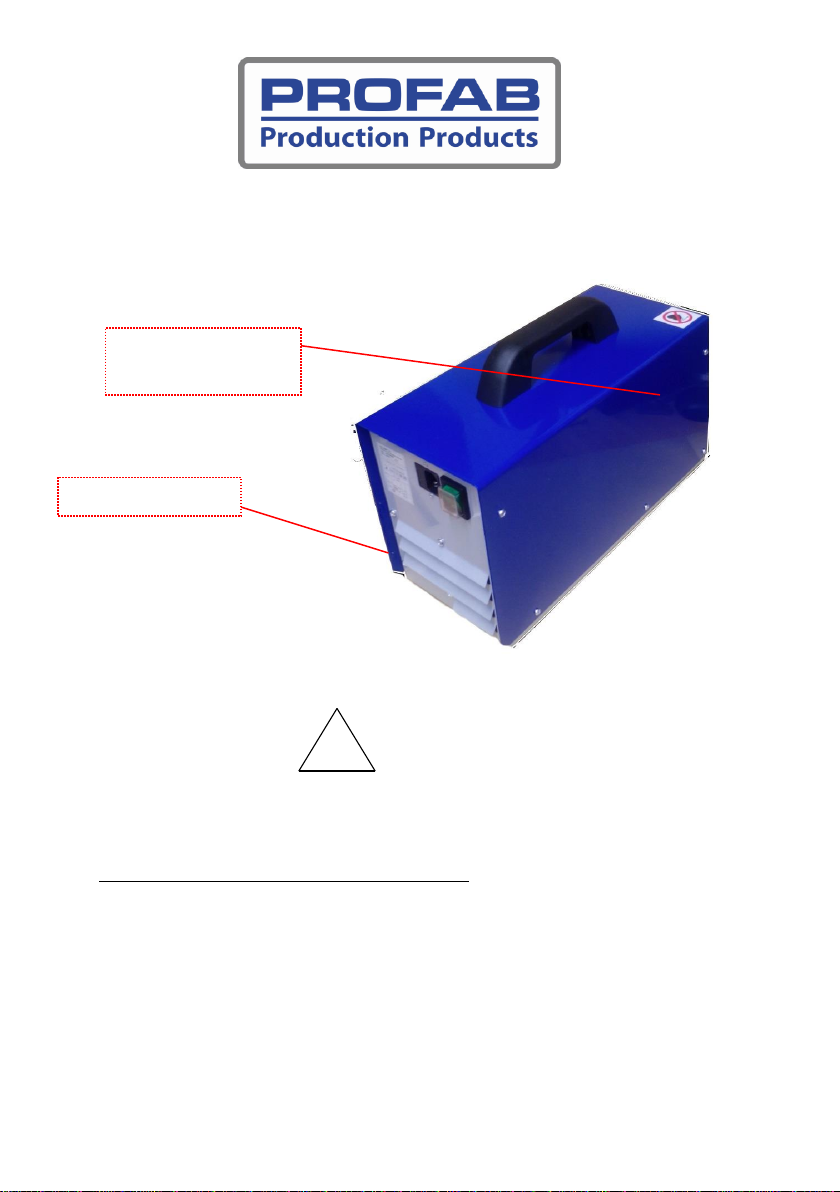

On the welding machine is fixed an

identification plate, on which in addition to the

CE marking shows the general characteristics

of the machine.

CD 66

5

5

C.2 –Generality

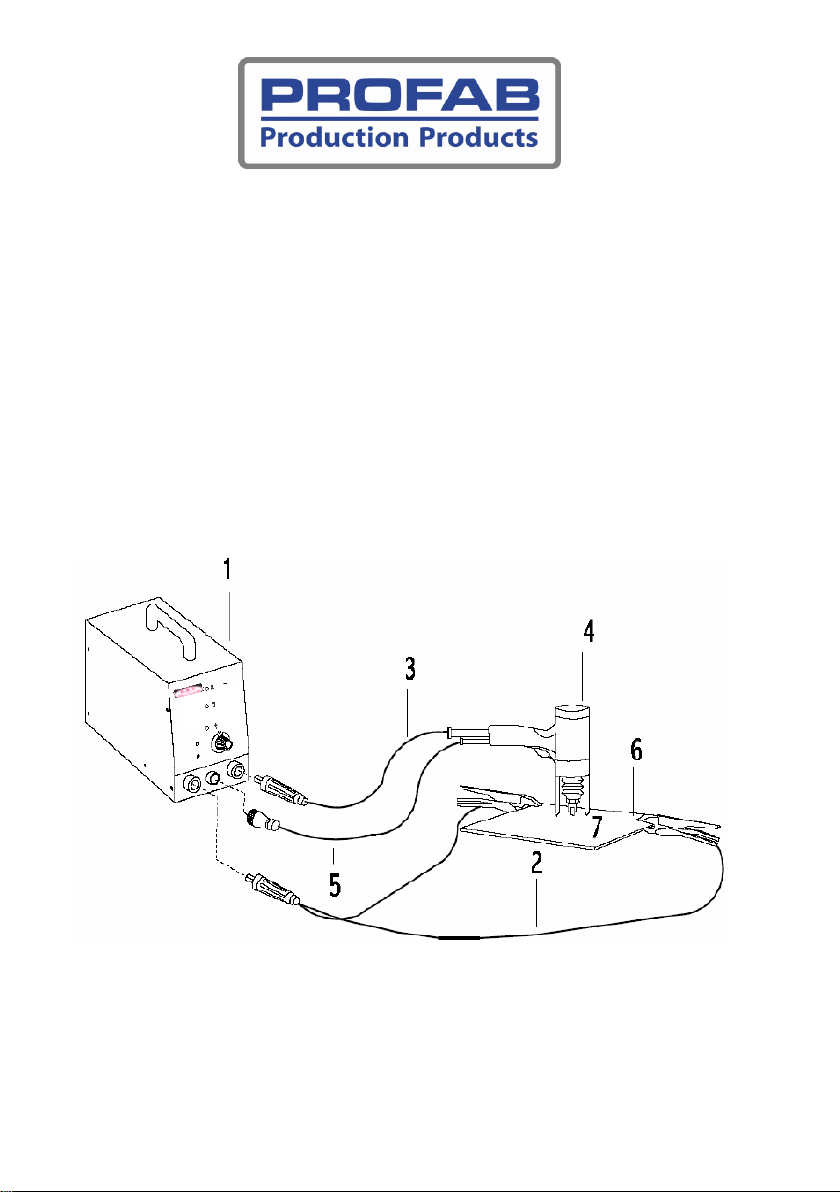

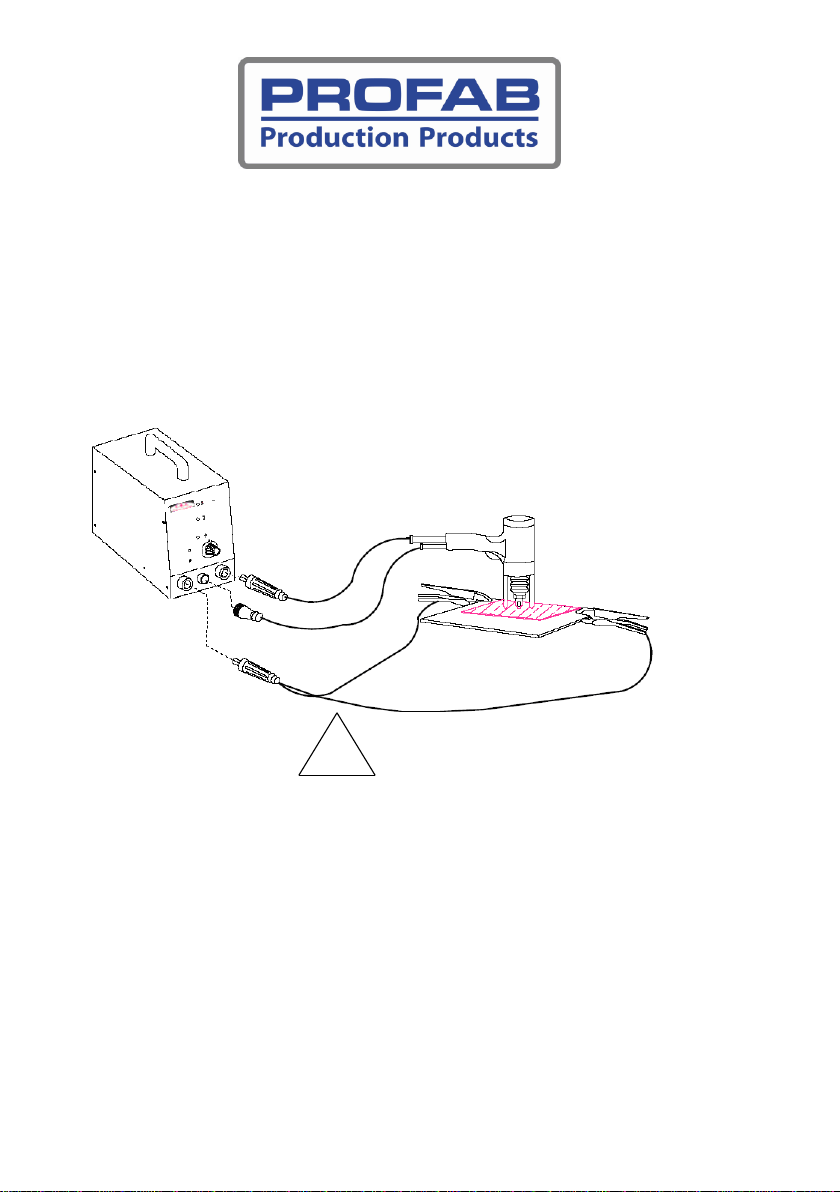

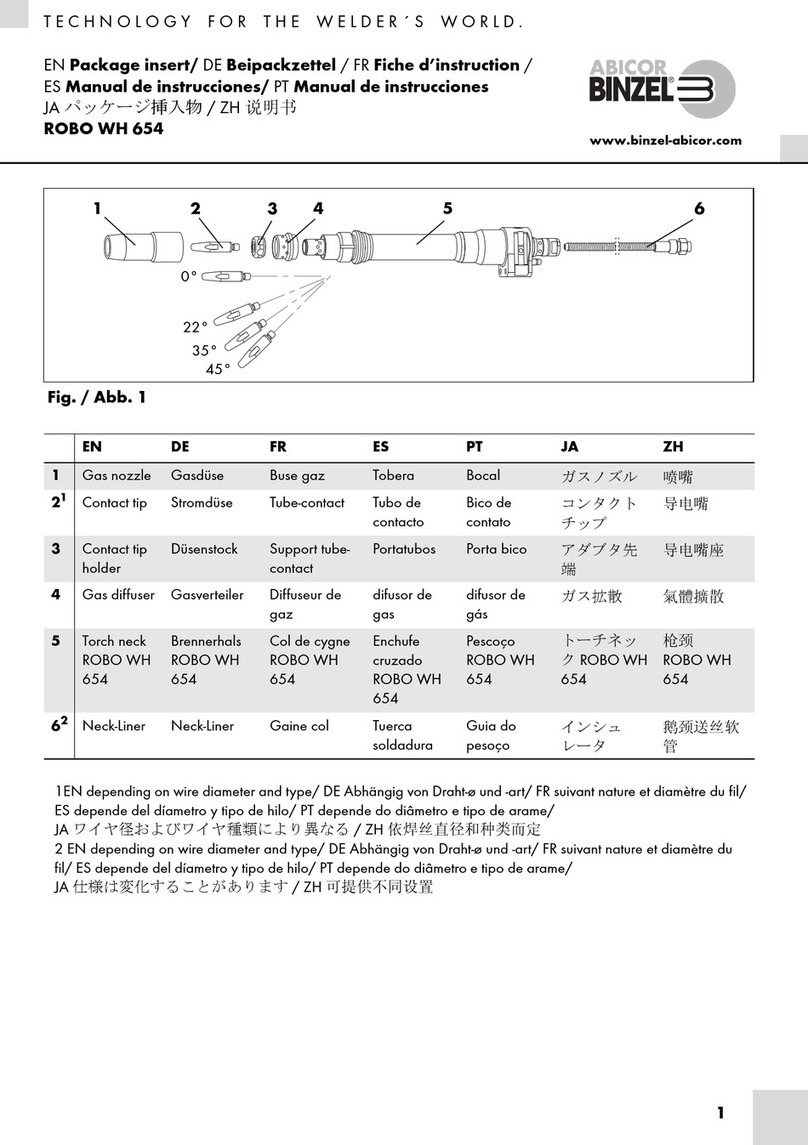

With reference to Figure 1, the welding machine must be combined with a gun

for welding so as to constitute a welding system comprising:

(1) capacitor discharge welding unit

(2) ground duble cable

(3) power cord

(4) contact gun

(5) control gun cable

(6) base plate

(7) stud

Fig. 1

CD 66

6

6

C.3 –TECHNICAL DATA

Equipment type

Capacitor discharge welding unit CD 66

CUPHEAD

Diameter pins ferrous

3 ÷ 8 mm

Diameter steel pins - aluminum

3 ÷ 6 mm

Weldable pieces minute

7 ÷ 20

Total capacity

66.000 uF

Energy

1320 Joule

Maximum recharge time

5,0 seconds

Voltage

115 V –50/60 Hz

Power max peak

600 Watt

Contact circuit voltage

15 V

Resistance max allowable contact

30

Charging voltage

30 ÷ 200 VDC

Protection

IP 23

Field working temperatures

0 ÷ 40 °C

Power cord

2 m detachable with plug 10A

Dimensions without handle

16x42x23 cm

Machine weight

14,0 kg

Single ground cable length

5 meters

Gun type

Contact black

Gun cable length.

5 meters

CD 66

7

7

C.4 - WELDING CONTROLS

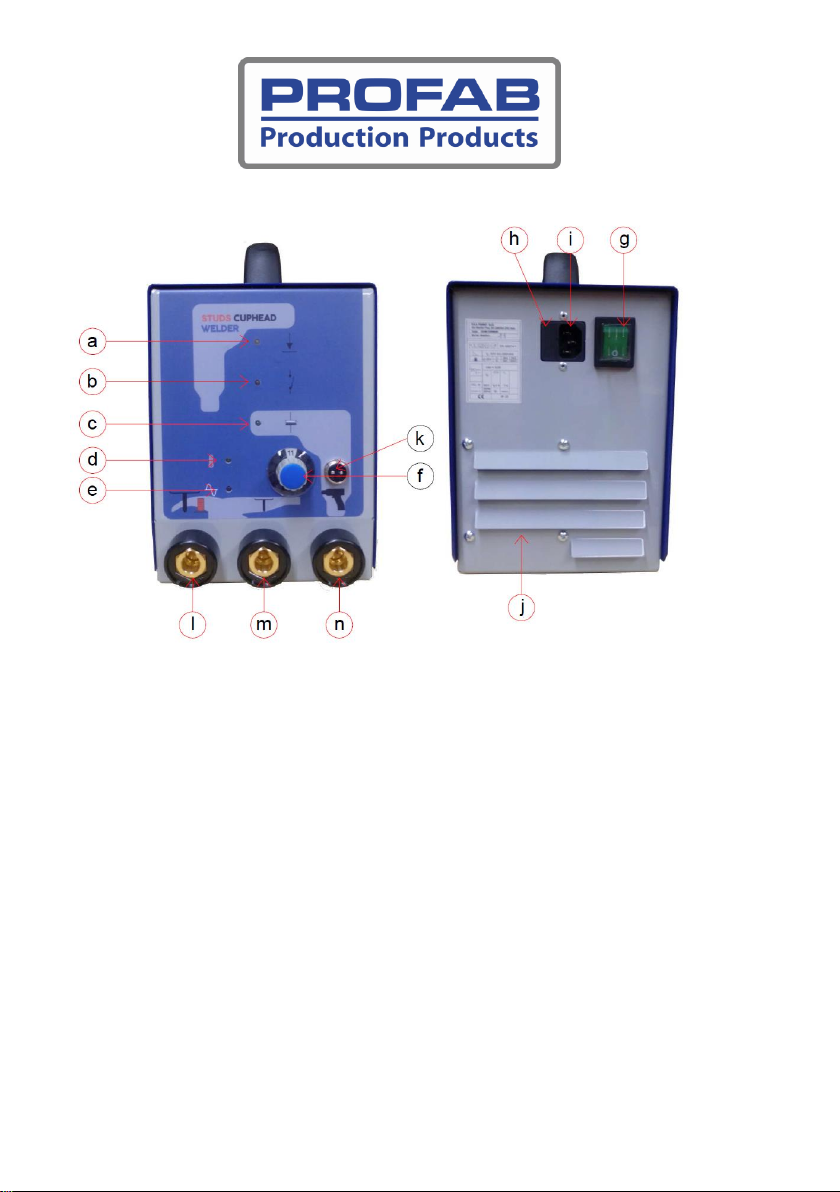

Fig. 2

a. Yellow LED indicator contact piece.

b. Red LED indicator start command.

c. Green LED indicator took charge of the capacitor.

d. Yellow LED indicator for over temperature protection.

e. Red LED indicator 115 V line.

f. Graduated knob adjustment charge voltage.

g. Lighted bipolar line switch.

h. Storage for two fuses (6,3 A delayed)

i. Socket line cable

j. Ventilation slots.

k. Control cable panel male

l. Ground cable socket for studs and big cuphead

m. Ground cable socket for small cuphead

n. Welding gun socket

CD 66

8

8

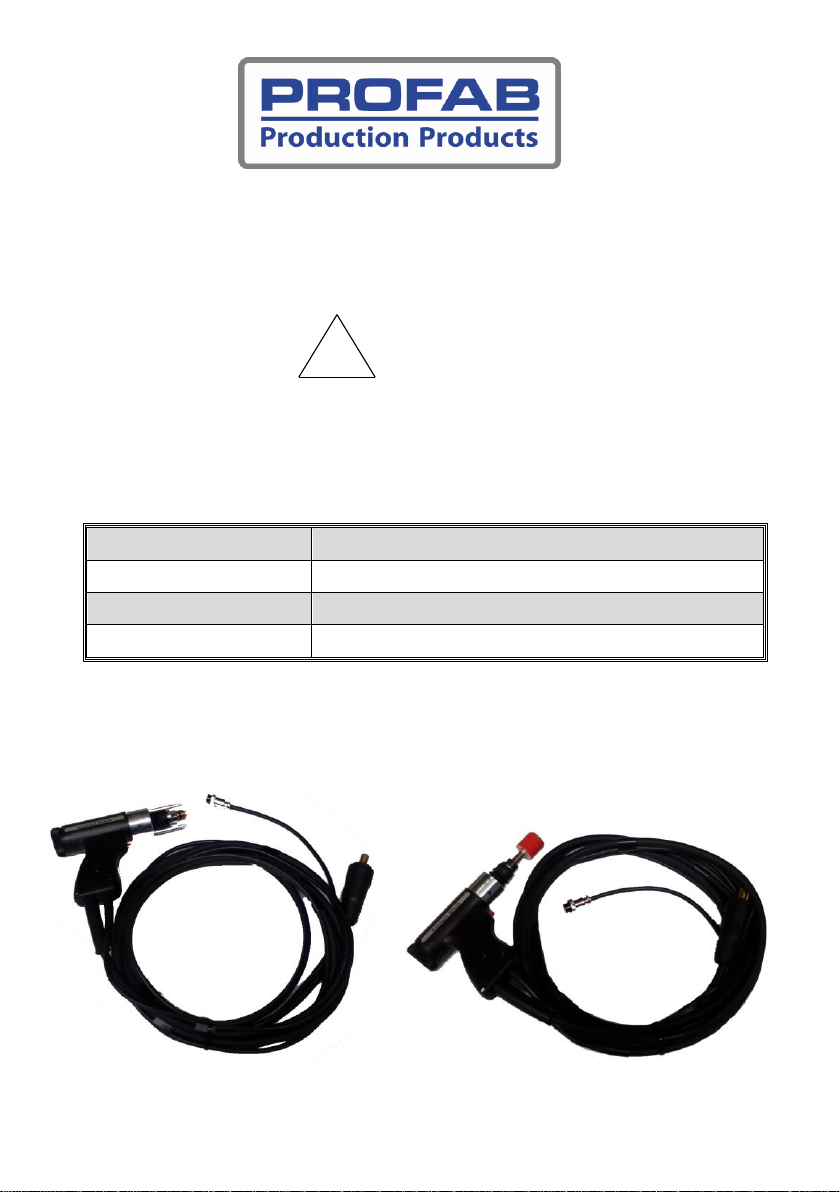

C.5- Gun: Contact Black

The welding contact gun is equipped with a magnet for Cuphead use or stud

holder for use with a threaded pin of maximum length 40 mm.

!

IS ABSOLUTELY FORBIDDEN TO MODIFY THE GUN

WITHOUT PRIOR VERIFICATION OF FEASIBILITY BY THE

MANUFACTURER.ANY ACTION CONTRARY TO THIS PROVISION

WILL VOID THE DECLARATION OF CONFORMITY.

Welding gun-type

Contact

Max diameter welded

6 mm Al/Inox - 8 mm Fe

Weight gun with cable

1,9 kg

Cable length

5 m

B.

The gun is equipped with a tripod which has the task of ensuring the

verticality.

CD 66

9

9

D. Conditions of use provided and not provided

D.1 - Intended uses

The capacitor discharge welding machine was built for stud welding.

!

CAUTION

THE CAPACITOR DISCHARGE WELDING MACHINE,WITH

PARTICULAR APPLICATIONS OR MODIFIED,MUST BE SUBJECTED

TO NEW COMPLIANCE VERIFICATION.

D.2 –Not provided

The capacitive discharge welder is not designed to be used at voltages and power

frequencies other than those indicated in the nameplate.

The standard welding gun must be used complete with tripod and spindles

original, there is no use of non-genuine or otherwise of different constitution or

measure.

The welding machine, as supplied, is not required for operation in automatic

cycles of welding.

Any tampering or welding gun will compromise safety.

E. Procedure

The welding process uses the fusion of a small cylindrical appendix, of basic

material, obtained under each pin, caused by the passage of a current of appropriate

intensity and for a suitable and predetermined welding time.

The solder thus obtained, due to the modest energy used not gives rise to

drawbacks of the arc welding or resistance, such as thermal stress or deformation of

the surfaces of the materials.

It will therefore be important that the appendix of the pin is not inserted into

small depressions or punch marks of the base material.

The welding machine is essentially constituted by an electronic circuit which

provides adjustment for the position of electrical capacitors to a voltage proportional

to the diameter of the pins to be welded.

A power module will, on operator command, to the provision of the discharge

current of the capacitor. On complex pin-piece basis, it will be achieved so the fusion

of the appendix of the pin and, for the slight pressure carried out on the same, the

welding, due to the solidification of the material brought to fusion.

CD 66

1

10

0

F. Commissioning

F.1- Connection to the electrical power

!

NOTICE

BEFORE POWERING THE WELDING MACHINE,MAKE SURE THAT

THE ELECTRICAL POWER SUPPLY SYSTEM,HAS BEEN

PERFORMED IN A WORKMANLIKE MANNER;THAT IS EQUIPPED

WITH A PROTECTIVE CONDUCTOR (PE YELLOW -GREEN)AND

DIFFERENTIAL SWITCH.

Do not use many extension cords and adapters.

Highlight with sign of danger wrappers containing live parts.

!

CAUTION

VOLTAGE OPERATING SYSTEM IS 115 V, 50/60 HZ,SINGLE

PHASE

!

CAUTION

BEFORE CONNECTING THE MACHINE TO THE POWER

SUPPLY IS NECESSARY TO ENSURE THAT THE

ELECTRICAL SYSTEM HAS BEEN PERFORMED ARULE OF

ART, AND IS EQUIPPED CIRCUIT PROTECTION ELECTRIC

(PE YELLOW GREEN) AND THE LINE IS PROTECTED BY A

DIFFERENTIAL SWITCH

•Connect the welding gun two poles control plug in the connector panel on

the front of the welding tightening the retaining ring.

•Insert the ground plug in the bush and tighten moderately turning it

clockwise, attach the clamps placed at the other end of the cable to the

base piece.

CD 66

1

11

1

•Connect the plug, marked with the symbol of the gun plug power,

connected to the gun itself and moderately tighten clockwise.

•Connect the machine to the 115 V line , making sure that the main switch

of the same is in the off position (0).

•Before turning on the machine, rotate fully counterclockwise adjustment

potentiometer.

•Switch on the system by bringing the power switch in the on position (on),

to ensure that the LEDs meet the following conditions:

yellow LED alarm overheating

Off

red LED 115 V line

On

green LED OK

On with charged capacitors.

yellow LED contact

Off

red LED button

Off

F.2 –Cable connecting

For smaller diameter Cuphead use, connect the ground cable in

the center bottom plug. For higher diameter Cuphead use, and also

threaded stud, connect the ground cable in the left bottom plug.

F.3 - Machine adjustment

Looking at the tables (tab. A-b) of combinations of voltage-diameter, adjust

accordingly the potentiometer on the values obtained from the table itself.

These values are indicative and will, from time to time, refined from practical

experience, in order to obtain good welds with respect to the processing in use.

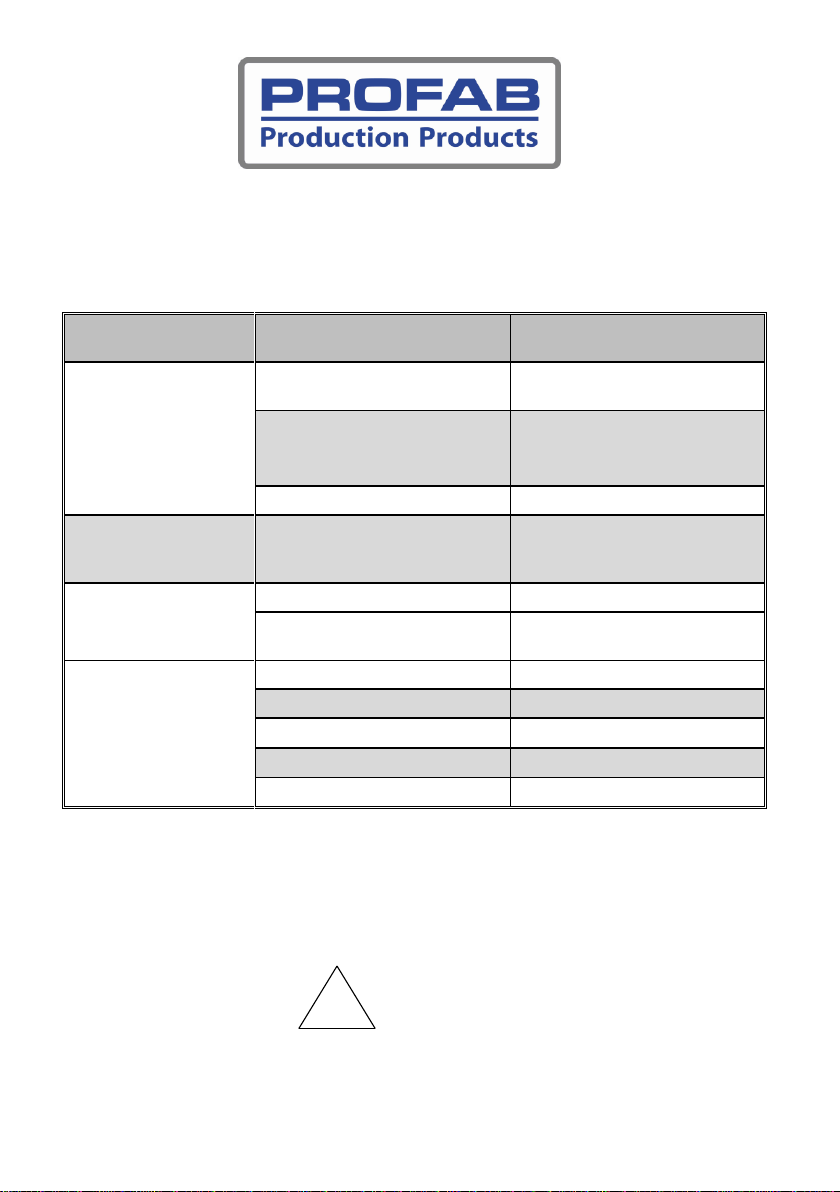

A) Tab. A –TABLE OF MATERIALS FERROUS (VOLTAGE REGULATION)

stud

Diameter

Fe 360 / 4.8

Galvanized steel sheet

/ 4.8

Alloy steel / 1.4301

3 mm

3

3

4

4 mm

5

4

5

5 mm

6

5

6

6 mm

8

8

8

8 mm

10

10

-

CD 66

1

12

2

B) TAB. B –TABLE OF MATERIALS NON-FERROUS (VOLTAGE

REGULATION)

Pins

Diameter

Cu Zn 37 / Cu Zn 37

Al Mg / Al Mg3

Al 99, 5 / Al 99,5

3 mm

2

3

3

4 mm

4

4

4

5 mm

5

7

6 mm

7

9

8 mm

9

-

The values in the table are indicative. Appropriate adjustments will be made case

by case

!

NOTICE

IN NO EVENT SHALL THE MANUFACTURER OF THE WELDER IS

RESPONSIBLE FOR ANY DAMAGE CAUSED TO PEOPLE OR TO THE

INEFFICIENCY OF THE WELDS MADE.

!

CAUTION

THE GUARANTEE OF AN EFFECTIVE WELDING WHICH

ENSURES THE MECHANICAL RESISTANCE VALUES

DESIRED, IT SHOULD ALWAYS BE VERIFIED BY

DESTRUCTIVE MECHANICAL TESTS

•Perform, then, a welding and verify visually and mechanically applying a

vertical traction on the pin welded.

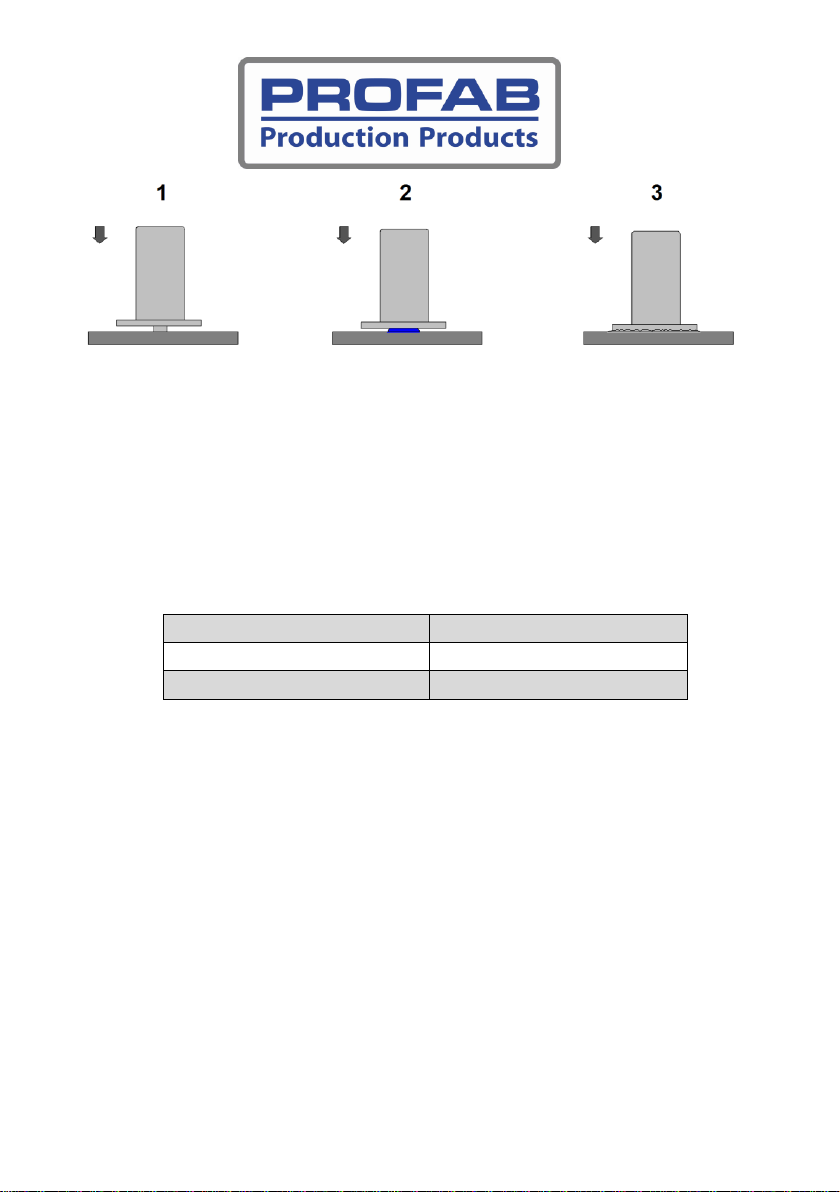

•The welding is developed through three phases summarized:

1. Positioning of the gun with pin inserted;

2. Start capacitive discharge, the current flow trough stud.

3. Diving stud in the melt.

CD 66

1

13

3

F.4 –Combination of materials (stud)

As indicated in the table c is possible to weld together materials having similar

compositions. The types of pairings most common are:

C) TAB. C –MATERIALS COMBINATION

F.5 –How to get a good weld

In order to get a good weld is essential that you meet some basic

requirements related to the work surface, positioning the pieces, provision of the

ground plane, use of the gun.

F.5 –a –Characterictis of the working surface

The final quality of a weld is strongly influenced by the characteristics of the work

surface.

The work surface must be:

• Unpainted

• Free of oils or chemicals

• Smooth or with limited roughness (less than or equal to approx. 70 x 10-6 m )

Ferrous materials

Ferrous materials

Type stainless steels

Type stainless steels

Type stainless steels

Ferrous materials

CD 66

1

14

4

F.5 - b -Positioning of the pieces

The workpieces must be placed on a surface and not deformable solid, to

ensure the perpendicularity of the gun and of welded pins, while also avoiding the

deformation of the workpiece, especially if of limited thickness.

F.5 - c - The welding gun used

You must first choose the appropriate PIN holding spindle to diameter welding

stud in planned measures and adjust the projection of about 2 mm from the copper

stud holder by adjusting the end stop screw which should then be blocked by the lock

nut.

You should then inserting the stud holder into the gun adjusted by tightening the nut

by means of socket wrench, while checking the tightness and stability of the

supporting feet.

Carrying, therefore, the pin into the exact point of work on the gun by applying a

vertical pressure and compressing, as well, the contrast spring until it rests stably

support feet on the workpiece.

Prestressing of the spring can be varied by turning the ring placed on the gun and

indicated by the index on the left (clockwise increases); thus it is varied the speed of

immersion of the pin into the molten bath welding. Adjust to get the best result.

Retaining the position thus achieved gun press starting the welding cycle and then

remove from the pin welded so absolutely vertical, without lateral bending that

would cause damage to the spindle.

Be sure the internal surface of copper stud holder are in best condition, for haven’t

stud damage.

!

CAUTION

ACHUCK WORN INTERNALLY FROM USE TOO,

COULD RESULT IN ABOW OF POWER BETWEEN SE

'ARMED AND PIN, DISPERSING ENERGY WELDING .

CD 66

1

15

5

F

F.

.6

6

-

-

Operations to avoid

GETTING TO AVOID

CONSEQUENCES

Use of the system without wearing

fireproof clothing, protective glasses,

insulated gloves and protective earplugs

-

Damage operator

Use of the system in humid

-

Damage to plant solder

- Hazardous electrical shock to the

operator

Operate on structures simultaneously

with other welding devices, especially if

high-frequency (inverter)

-

Dangerous interference

Connect the ground clamps away from

the place of welding

-

Damage to structures and systems

Operate in the vicinity of the plant with

electric grinders and grinding plant

-

Damage caused by the aspiration of

ferrous scrap

Make any changes to the stud holder or

the gun in general

-

Hazardous electrical shock to the

operator

Avoid welding in the vicinity and

especially through flammable

materials

-Fire

CD 66

1

16

6

G. Security measures

G.1 - Safety devices installed on the welding machine

The welding machine is equipped with a circuit for measuring the contact

resistance, which enables the flow of the welding current only when the value of

resistance is such as to reinforce a good contact between the pin to be welded, and

ground plate. In this way, during the phases of insertion of the pin in the gun or

manipulation of the same, away from the surface intended to receive the stud

welding and connected to the other pole of the welding circuit, the exposed metal

parts of the gun, are not in dangerous voltage.

During the step of positioning of the pin (pin contact), there is circulation of low

current is not dangerous for humans. In any case, always use suitable clothing to

protect themselves from the danger of electrocution, especially if in the presence of

moisture.

The moment in wich the button is pressed to start the welding cycle, the

resistance of the welding circuit is cheked, if this is lower than that provided by the

manufacturer is enabled by the passage of the arc current, which causes the welding

of the stud.

Are denied access to the internal parts of the welding leads, with power plug

inserted.

In case of use the welding machine is set in place appropriate gloves required PPE

for 'electrical insulation', DPI ear protection (earmuffs or earplugs) and DPI eye

(glasses).

MAKE SURE:

The electrical power supply of the welding machine equipped with differential

switch with high sensitivity (

=

N

I

30 mA), coordinated with an efficient earthing

system, protection against indirect contact.

On welding unit are affixed to the necessary warning information, as specified in

the following diagram.

CD 66

1

17

7

G.2 –Verification of safety

device

!

NOTICE

VERY IMPORTANT TO MAKE THE CHECKS PROVIDED

MANUAL CIRCUIT PROTECTION TO ENSURE THE

SECURITY LEVEL INTENDED BY THE MANUFACTURER.

And therefore essential to proceed as follows:

•welding unit is switched off, connect the ground plug and attach the clamps

to a metal base large enough to hold the plate with insulation resistance

test;

•connect the gun power cable;

•absolutely not connect the control cable

•turn on the system and check that:

•the red light is on (115 V line)

•the yellow light of overheating is off;

•the green light of the battery is charged is on;

•the yellow light contact is off

Indication "Caution

High Voltage"

Label CE marking

CD 66

1

18

8

•the red light button is off;

- insert a stud in a stud holder and push the gun on the metal support thus

verifying the yellow LED contact, is on.

- in the next stage to remove the gun and interpose between it and the metal

base plate (P) of insulation test provided, pushing the gun, the yellow LED of

contact must not light, thus verifying the inhibition of the welding unit to weld

with a value resistance just over 27and much less than that can occur for a

careless operator contact.

!

NOTICE

AND MUST WHEN USING THE MACHINE GLOVES TYPE DPI

ELECTRICAL INSULATION.

In case there is the last condition is essential not to use the system immediately

and contact the supplier or the manufacturer.

CD 66

1

19

9

H. Troubleshooting

FAULT

POSSIBLE CAUSES

REMEDIES

No welding takes

place

Button defective

Check the function through

the respective lamp

-Power cable interrupted

-Control cable interrupted

-Ground cable interrupted

Check the contact function of

the machine via the

respective lamp

Welding machine fails

Contact Technical Service

The welding machine

is in thermal

protection

Fan blocked by the presence

of foreign bodies

Removal of foreign bodies

Contact Technical Service

Welds uneven

Worn stud holder

Replace stud holder

Pliers ground loose or poorly

arranged

Check and replace

Detachment of studs

Insufficient spring pressure

Increase pressure

Loose cables

Cables clamping

Insufficient charging voltage

Adjust according to table

Vertical gun not

Check the height of the feet

Dirty surfaces

Cleaning of surfaces

I. Maintenance

!

CAUTION:

BEFORE ANY MAINTENANCE MAKE SURE THAT THE

POWER CORD, IS OFF.

CD 66

2

20

0

!

CAUTION

THE CAPACITIVE DISCHARGE WELDING UNIT, IS

EQUIPPED WITH A SYSTEM FOR AUTOMATIC DISCHARGE

OF THE CAPACITORS, WHEN POWER IS CUT.

WHEN THE WRAPPER PROTECTION, (TOP COVER)

ENSURE THAT THE RED LED ON THE ELECTRONIC BOARD

IS POWERED OFF, SECURITY DOWNLOAD OCCURRED.

Disconnect power

This manual suits for next models

1

Table of contents

Popular Welding System manuals by other brands

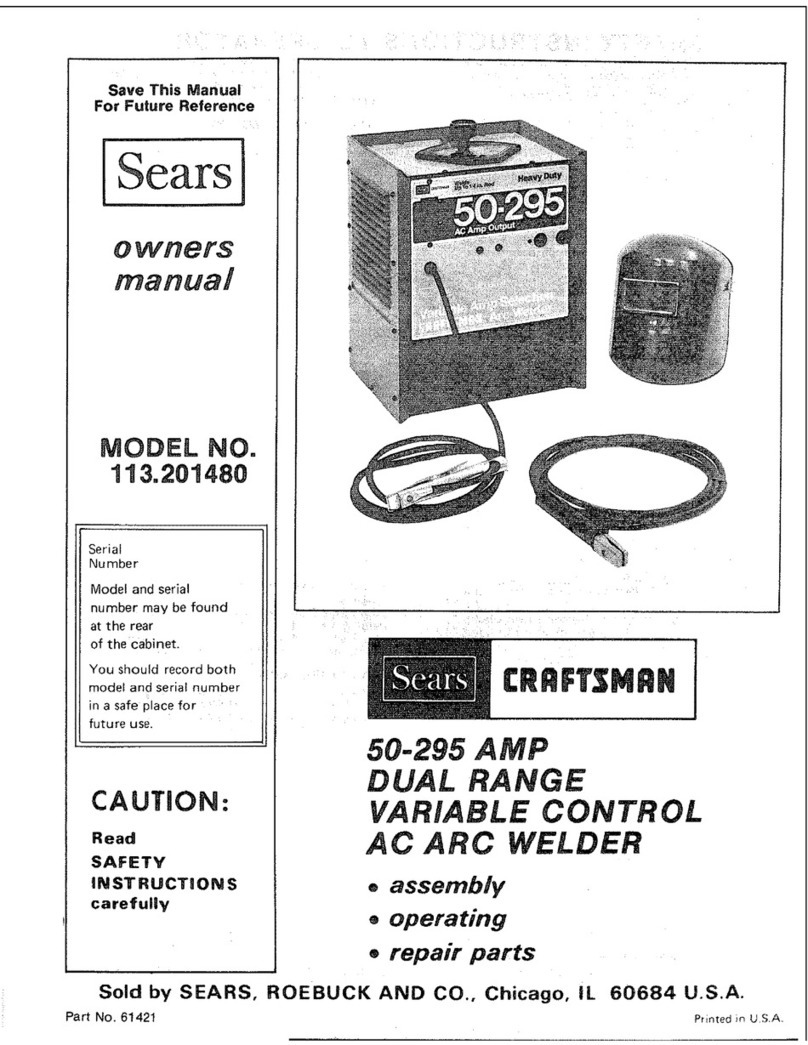

Craftsman

Craftsman 113.201480 owner's manual

MIDWEST FASTENERS

MIDWEST FASTENERS UA500 owner's manual

Abicor Binzel

Abicor Binzel ROBO WH 654 Package Guide

Saf-Fro

Saf-Fro DIGIPULS 320 W Use and maintenance manual

Miller Electric

Miller Electric STR 450 CE owner's manual

Furukawa

Furukawa ofs FITEL FITELS123M12 Quick reference guide

WELDKAR

WELDKAR WK TIG 320 AC/DC Pulse instruction manual

Hayes

Hayes HY PRO Series manual

Everlast

Everlast POWER MTS 200 Operator's manual

Miller

Miller Invision 352 MPa Auto-Line CE owner's manual

CARBONE

CARBONE Digi-Tig250ACDC Operator's manual

Lincoln Electric

Lincoln Electric WELDLINE PROTIG NG S 10 Instructions for safety, use and maintenance