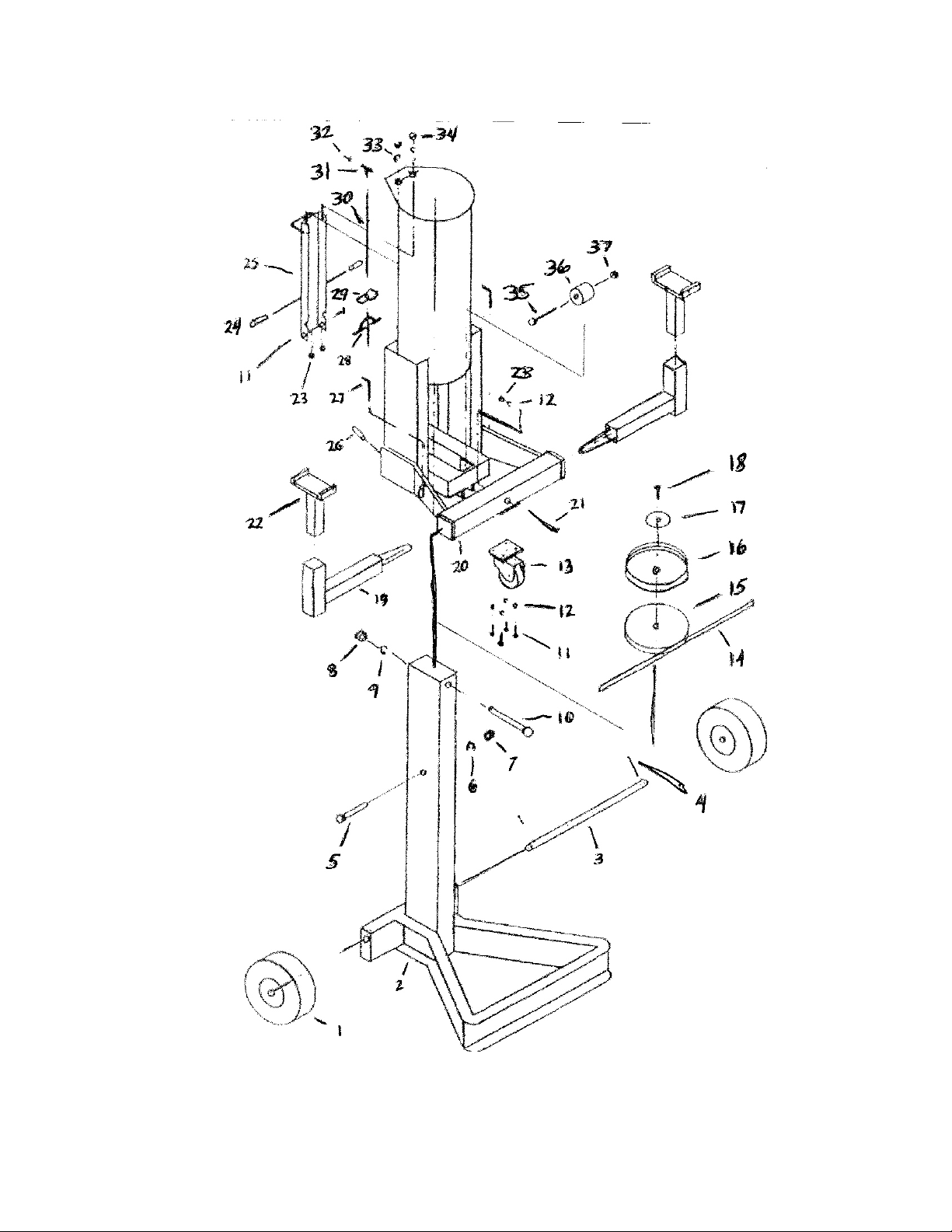

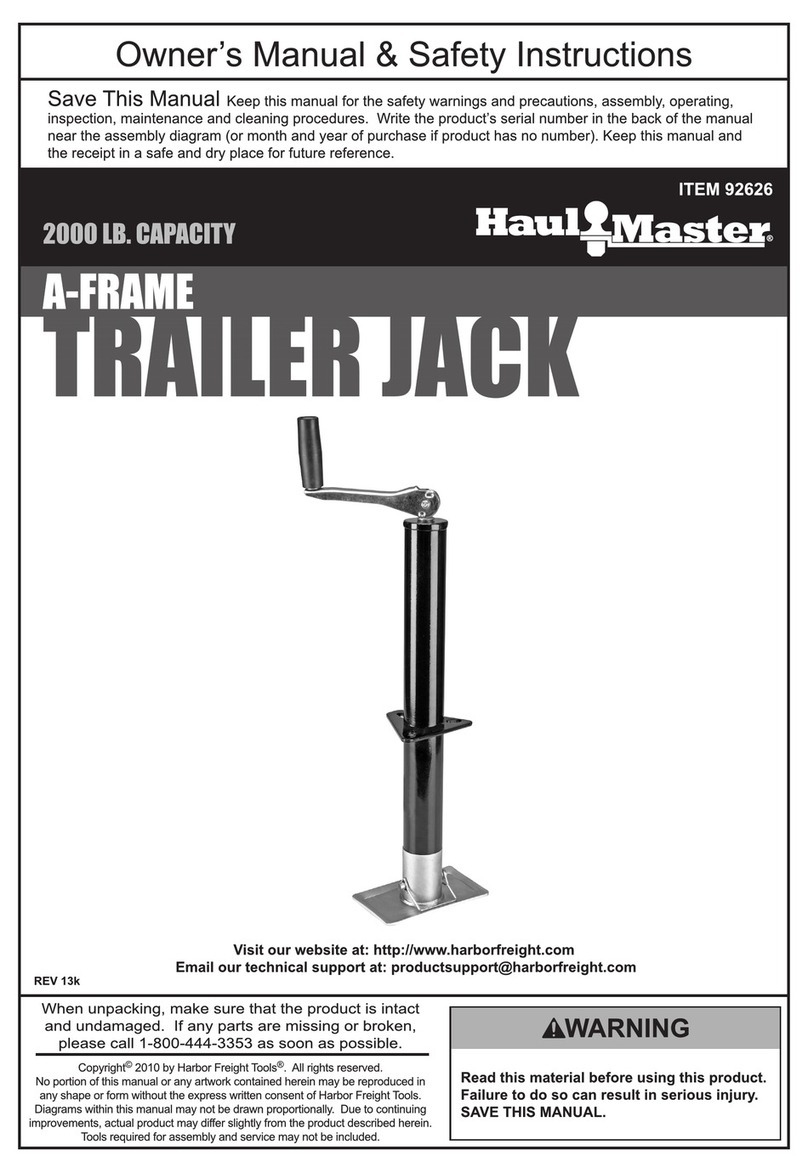

Assembly

Your bumper jack will require no assembly.

It is important that you read the entire manual to become familiar with the unit BEFORE you use it. Be

sure that you have all parts described in the Parts List.

Air Connection

Step 1 - You will need a Union fitting (sold separately) before you can connect your bumper jack to an air

compressor. Attach the Union fitting to the air inlet and tighten the fitting.

Step 2 - Attach and air coupler (sold separately) to the Union fitting if desired. This is a useful accessory

as it allows quick-coupling action when using a variety of tools with the same air compressor. Your

bumper jack is now ready to use.

Before Operating

Before operating your bumper jack, check for damaged parts. You should also do the following:

DO NOT exceed the tools maximum capacity of 5 Tons. Do not exceed maximum PSI (200psi)

Check for damaged parts. Before using any tool, any part that appears damaged should be carefully

checked to determine that it would operate properly and perform its intended function.

Operation

Never force the tool or attachment to do the work of a larger industrial tool. It is designed to do the job

better and more safely at the rate for which it was intended.

Setup: Frequent, but not excessive, lubrication is required for best performance. Oil added through the

airline connection will lubricate internal parts. An automatic airline oiler is recommended but oil may be

added manually before every operation or after about one (1) hour of continuous use. Only a few drops of

oil at a time are necessary. Too much oil will collect inside of the tool and be blown out during the

exhaust cycle. Use only pneumatic tool oil. Do not use detergent oil or additives as these lubricants will

cause accelerated wear to the seals in the tool.

Dirt and water in the air supply are major causes of pneumatic tool wear. Use a filter/oiler for better

performance and longer life of the tool. The filter must have adequate flow capacity for the specific

application. Consult the manufacturer’s instructions for proper maintenance of your filter.

Using the Bumper Jack

The bumper jack should be tested often and whenever it is suspected of working improperly. Do not use if

working improperly.

Step 1 - Position the vehicle you are working with on a hard, level surface. Make certain the parking

brakes are “ON”, when lifting trailers; lower any landing gear for support.

Step 2 - Position the lift saddle under the frame at locations recommended by the vehicle manufacturer.

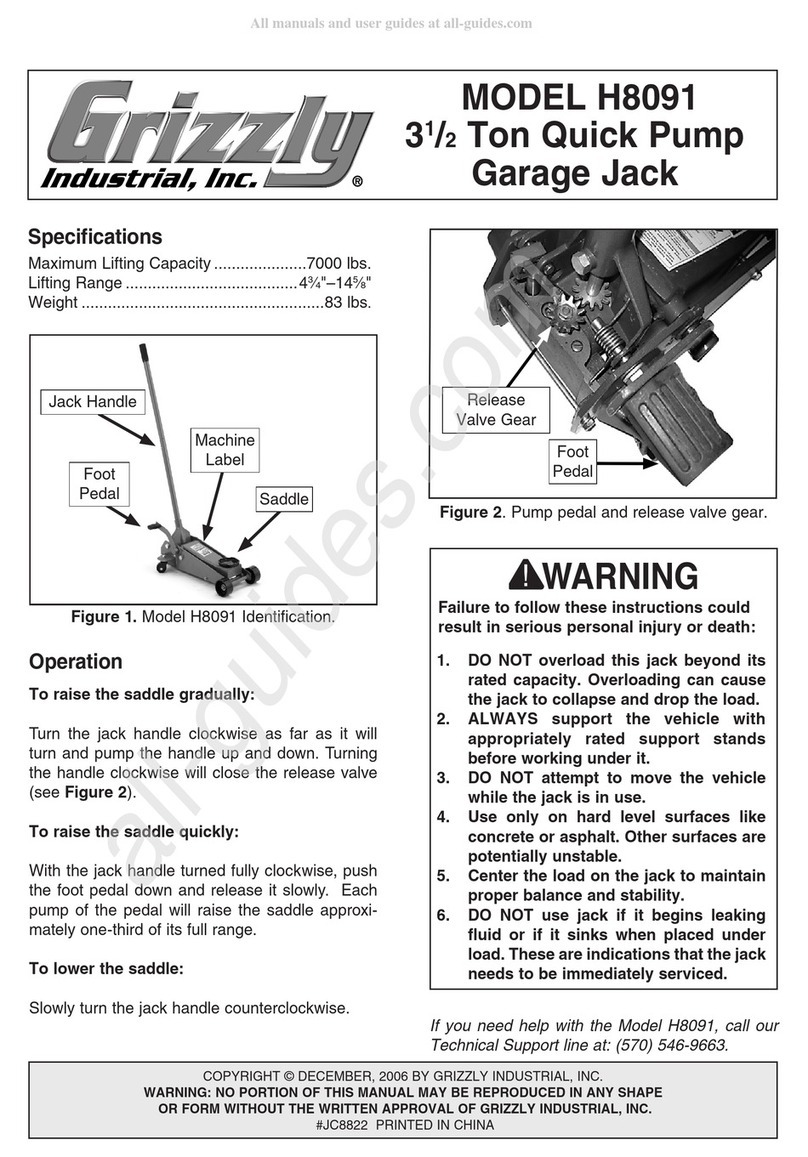

Step - Connect the air compressor hose to the air inlet. Turn on the compressor. Turn the valve to the

direction marked “UP” to raise the lift saddle so that it makes contact with the frame of the vehicle. Make

certain that the load is centered with the lift saddle and positioned to prevent load slippage.

Step 4 - Continue to lift the load to a height needed. Making certain that the vehicle stands are in place

under the load, lower the jack by pushing up the lock handle and turning the valve to the direction marked

“DOWN”.

WARNING: Before doing any work, make certain that the load and stands are stable.