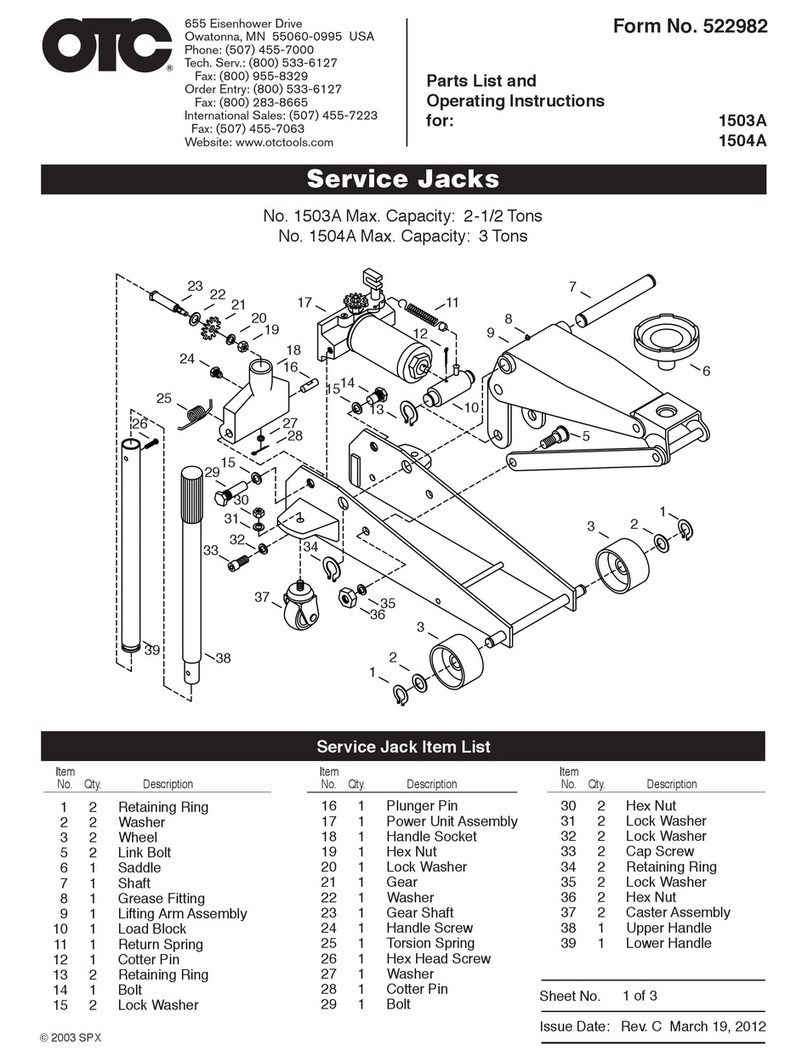

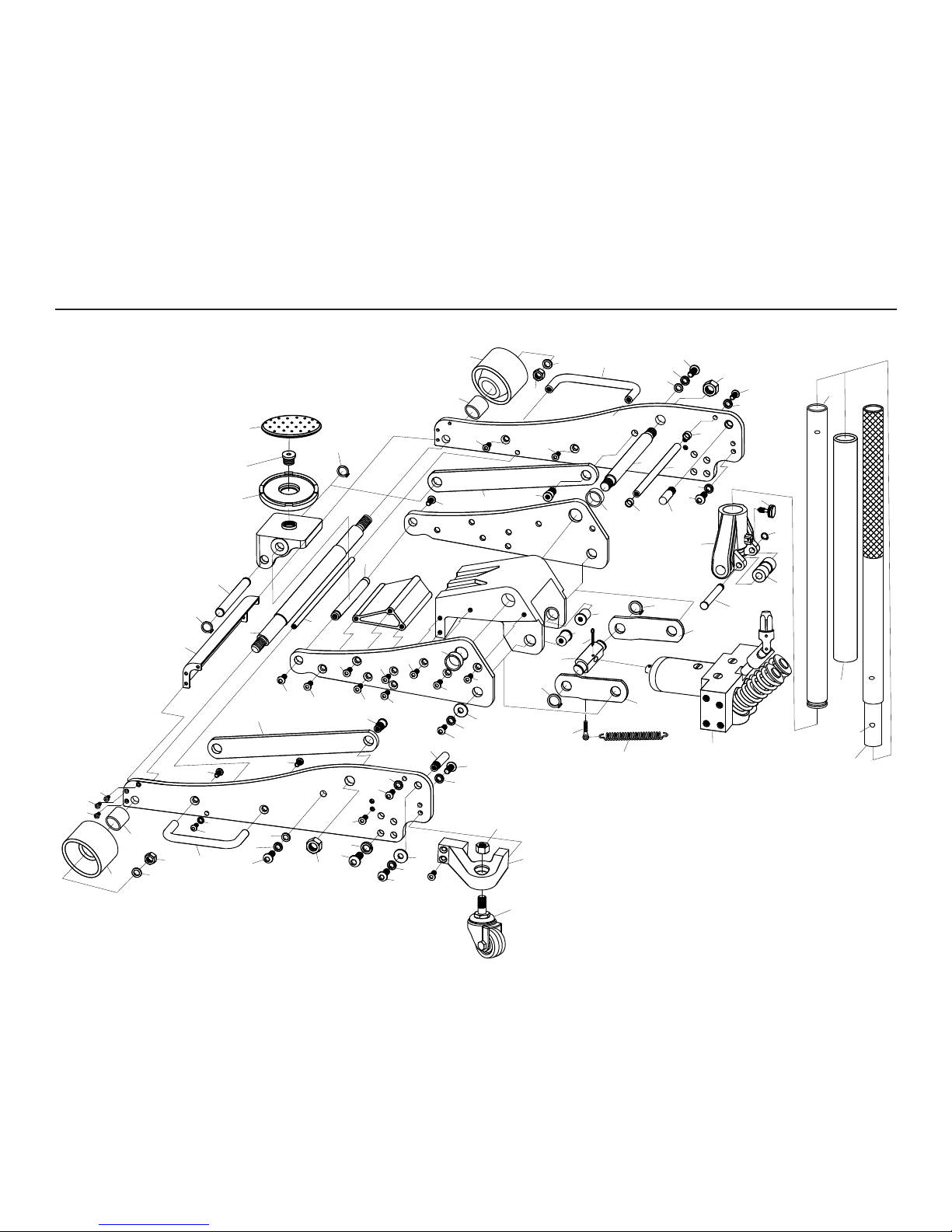

Setup

Assemble the Handle

1. Loosen the thumb screw on the back of the handle socket.

2. Grease the socket opening. Insert the handle.

3. Hand tighten the thumb screw.

Bleed Air from the Service Jack

Air can accumulate within a hydraulic system during shipment or after prolonged use.

This entrapped air causes the jack to respond slowly or feel “spongy.”

To remove the air:

1. Open the release valve by turning the handle all the way counterclockwise.

2. Pump the jack handle six full strokes.

3. Close the release valve by turning the handle all the way clockwise.

4. Pump the jack handle until the lift arm is fully extended.

5. Lower the lift arm by turning the handle counterclockwise. If the jack does not

immediately respond, repeat Steps 2–4.

Operating Instructions

1. Close the release valve by turning the handle completely clockwise.

2. Position the jack under the vehicle using the manufacturer’s recommended lifting

points on the chassis. The jack must be free to roll without obstruction while lifting

or lowering the vehicle. The wheels of the vehicle must be in the straight-ahead

position, with the emergency brake released.

3. Pump the jack handle until the saddle touches the vehicle. Check the placement

of the jack; the load must be centered on the jack saddle.

CAUTION: To prevent personal injury, avoid wheel obstructions such

as gravel, tools, or uneven expansion joints.

4. Finish lifting the vehicle by pumping the handle. Do not attempt to raise the jack

beyond its travel stops.

5. Place approved support stands under the vehicle at points that will provide stable

support. Before working on the vehicle, SLOWLY lower the vehicle onto the support

stands by turning the handle counterclockwise.

Preventive Maintenance

CAUTION: Dirt is the greatest single cause of failure in hydraulic units. Keep

the jack clean and well lubricated to prevent foreign matter from entering the

system. If the jack has been exposed to rain, snow, sand, or grit, it must be

cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive

vapors, abrasive dust, or any other harmful elements.

2. Regularly (at least once per month) lubricate the moving parts in the wheels, arm,

and handle.

3. Replace the oil in the reservoir at least once per year. To check the oil level, place

the jack on level ground and lower the lift arm completely. Remove the oil screw. The

oil level should be at the bottom of the ller plug hole. If necessary, add approved

anti-wear hydraulic jack oil, and install the ller plug again. CAUTION: The use of

alcohol, hydraulic brake uid, detergent motor oil, or transmission oil could

damage the seals and result in jack failure.

4. Inspect the jack before each use. Take corrective action if any of the following

problems are found:

Cracked or damaged housing; excessive wear, bending, or other damage; leaking

hydraulic uid; scored or damaged piston rod; malfunctioning swivel heads or

adjusting screws; loose hardware; or modied or altered equipment.

Parts List & Operating Instructions Form No. 577597, Sheet 3 of 4, Back