Profoscope Proceq User manual

profoscope

www.proceq.com

...more than 50 years of know-how you can measure!

Operating Instructions

Rebar Detector

and Covermeter

Getting Started

A start-up test kit is provided with the packaging to help

you familiarize yourself with the instrument.

i

First time user: Complete the tutorial OR see a

demo by a qualified Proceq representative.

1. Verify that there are no metal items on hands, fingers,

or in the vicinity of test area, (metal trolleys etc.)

2. Power on: Press the ON/OFF button on the top

panel.

3. Reset the instrument.

4. Check the location of the Measurement Center (MC)

which indicates the center of the probe.

MC

5. Checktheoperationwiththestart-uptestkitandconfirm:

- The location and orientation of the rebars

- The position between two rebars

- Cover depths 15mm / 0.59” and 60 mm / 2.36”

- Diameter 16 mm / #5

Congratulations! Your new Profoscope is fully operational

and you can now continue with your measurements.

Performing a Reset

The pulse induction measuring principle is liable to drift

with temperature and other external influences. Performing

a reset corrects for any drift and ensures accurate meas-

urements. We recommend a reset every 5 minutes or so.

On power on, the Profoscope re-

minds the user to perform a reset.

Hold the Profoscope in free space (no metal within a

40cm / 16” sphere) and press the reset key. The dis-

play rotates for approximately 2.5s while the reset is car-

ried out.

2© 2008 by Proceq SA

© 2008 by Proceq SA 5

Table of Contents

Getting Started 2

Overview of the Profoscope 3

The Profoscope Display 4

1 Safety and Liability 6

1.1 Safety and Usage Precautions 6

1.2 Liability 6

1.3 Safety Instructions 6

1.4 Labelling Used in the Manual 6

2 Tutorial 7

2.1 The Measurement Principle 7

2.2 The Measuring Range 8

2.3 Factors Affecting the Measurement 8

2.3.1 Errors due to Neighboring Bars 8

2.3.2 Resolution 9

2.3.3 Effect of Setting Incorrect Bar Diameter 10

2.3.4 Factors Affecting Diameter Determination 11

2.3.5 Orientation 11

3 Real Tests 12

3.1 Preparation 13

3.2 Locate a Rebar 13

3.2.1 Finding a Rebar 13

3.2.2 Check the Orientation 16

3.2.3 Verification 17

3.2.4 Locate a Mid Point 17

3.2.5 Map out the Rebar Grid 17

3.2.6 Advanced Settings (Measuring Range) 18

3.3 Measure Cover Depth 18

3.3.1 Set the Rebar Diameter 18

3.3.2 Read the Cover Depth 19

3.3.3 Advanced Settings (Neighboring Rebar Correction) 19

3.3.4 Advanced Settings (Minimum Cover Alert) 19

3.4 Measure Rebar Diameter 20

3.4.1 Determining Unknown Rebar Diameter 20

3.4.2 Create a Rebar Grid 20

3.4.3 Work with a Default Value 21

3.4.4 Drill Inspection Hole 21

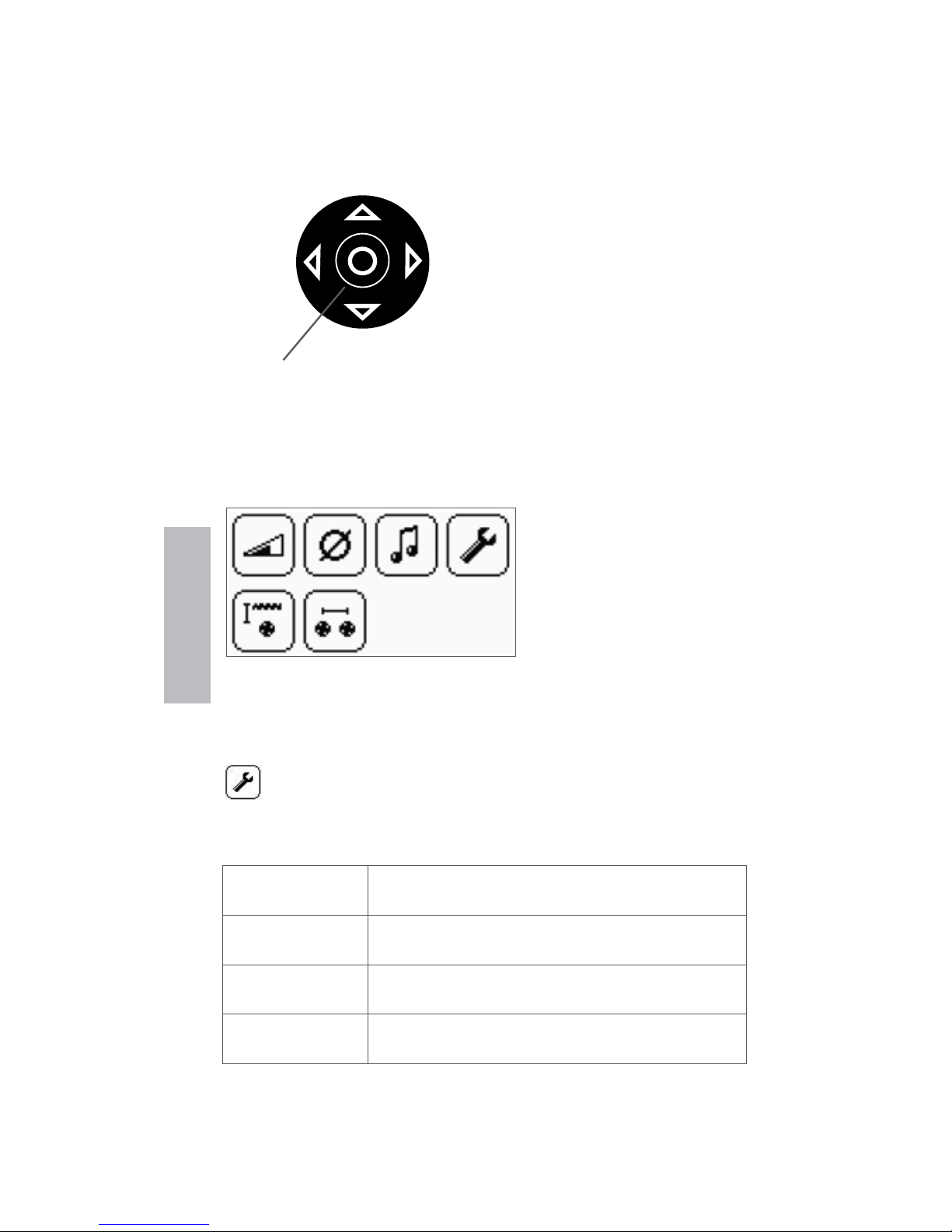

4 General Settings 22

4.1 Navigating 22

4.2 Regional Setting 22

4.3 Bar Diameter 23

4.4 Measuring Range Selection 23

4.5 Audio Setting 24

4.6 Minimum Cover 24

4.7 Neighboring Bar Compensation 24

5 Technical Specifications 25

6 Part Numbers and Accessories 26

7 Maintenance and Support 27

7.1 Replacing the Protective Cover 27

7.2 Support Concept 27

Subject to change without notice.

820 39 101E ver 09 2008

6© 2008 by Proceq SA

1 Safety and Liability

1.1 Safety and Usage Precautions

This manual contains important information on the safety,

use and maintenance of the Profoscope. Read through

the manual carefully before the first use of the instrument.

Keep the manual in a safe place for future reference.

1.2 Liability

Our “General Terms and Conditions of Sale and Delivery”

apply in all cases. Warranty and liability claims arising from

personal injury and damage to property cannot be upheld

if they are due to one or more of the following causes:

Failure to use the instrument in accordance with its•

designated use as described in this manual.

• Incorrectperformancecheckforoperationandmainte-

nance of the instrument and its components.

• Failuretoadheretothesectionsofthemanualdealing

with the performance check, operation and mainte-

nance of the instrument and its components.

• Unauthorized structural modications to the instru-

ment and its components.

• Serious damage resulting from the effects of foreign

bodies, accidents, vandalism and force majeure.

All information contained in this documentation is pre-

sented in good faith and believed to be correct. Proceq

SA makes no warranties and excludes all liability as to the

completeness and/or accuracy of the information.

1.3 Safety Instructions

The instrument is not allowed to be operated by children

or anyone under the influence of alcohol, drugs or phar-

maceutical preparations. Anyone who is not familiar with

this manual must be supervised when using the instru-

ment.

1.4 Labelling Used in the Manual

i

Note: This symbol indicates important infor-

mation.

Safety

© 2008 by Proceq SA 7

2 Tutorial

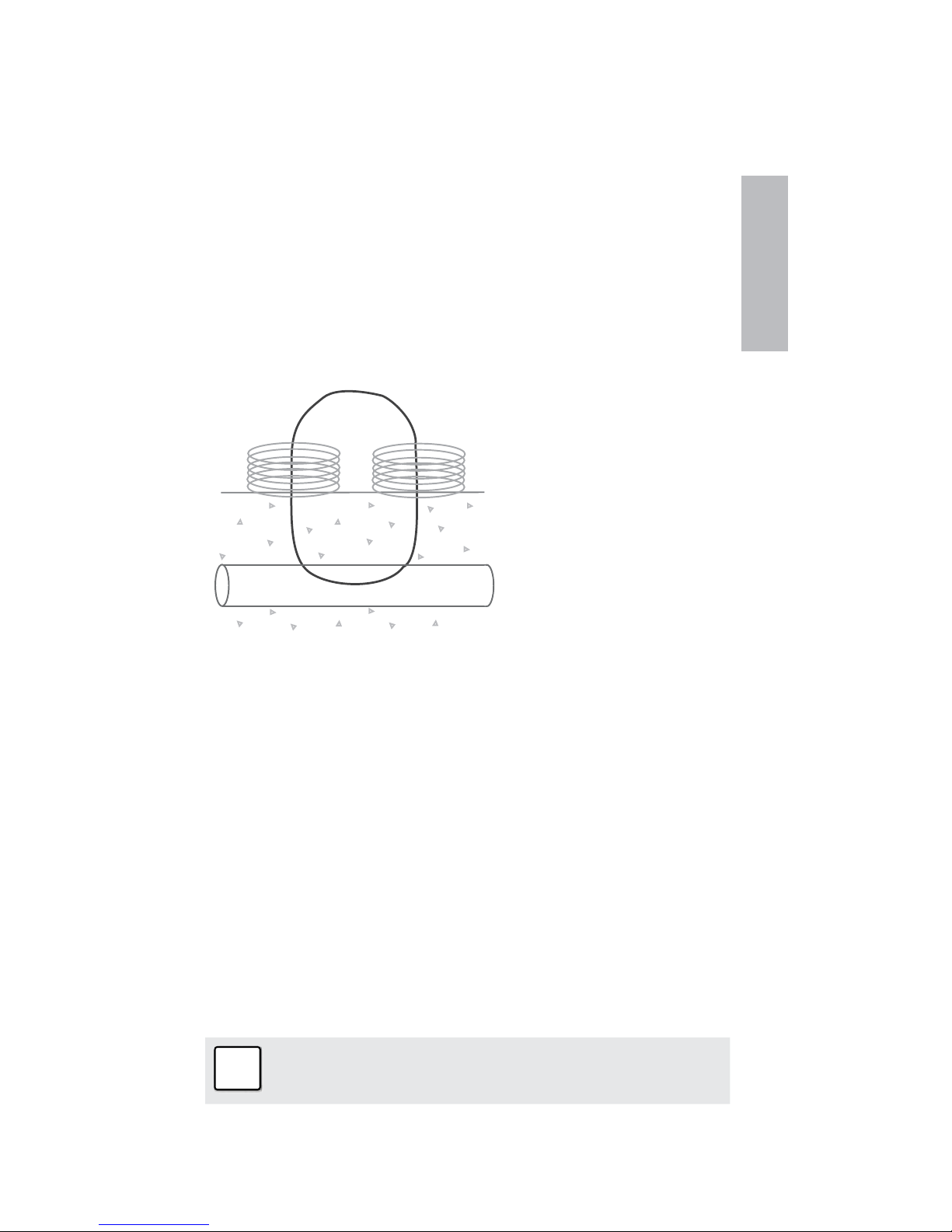

2.1 The Measurement Principle

The Profoscope uses electromagnetic pulse induction

technology to detect rebars.

Coils in the probe are periodically charged by current

pulses and thus generate a magnetic field.

On the surface of any electrically conductive material

which is in the magnetic field eddy currents are produced.

They induce a magnetic field in opposite direction. The

resulting change in voltage can be utilized for the meas-

urement.

Coils

Concrete Magnetic Field

Rebar

The Profoscope uses different coil arrangements to gene-

rate several magnetic fields. Advanced signal processing

allows

1. Localization of a rebar

2. Localization of the mid-point between rebars

3. Determination of the cover

4. Estimation of the bar diameter

This method is unaffected by all non conductive materials

such as concrete*, wood, plastics, bricks etc. However

any kind of conductive materials within the magnetic field

(approx. 400 mm / 16” sphere) will have an influence on

the measurement.

i

Note: Remove all metallic objects such as rings

and watches before you start measuring.

* Some concrete types and other structural materials may

have metallic content.

Tutorial

8© 2008 by Proceq SA

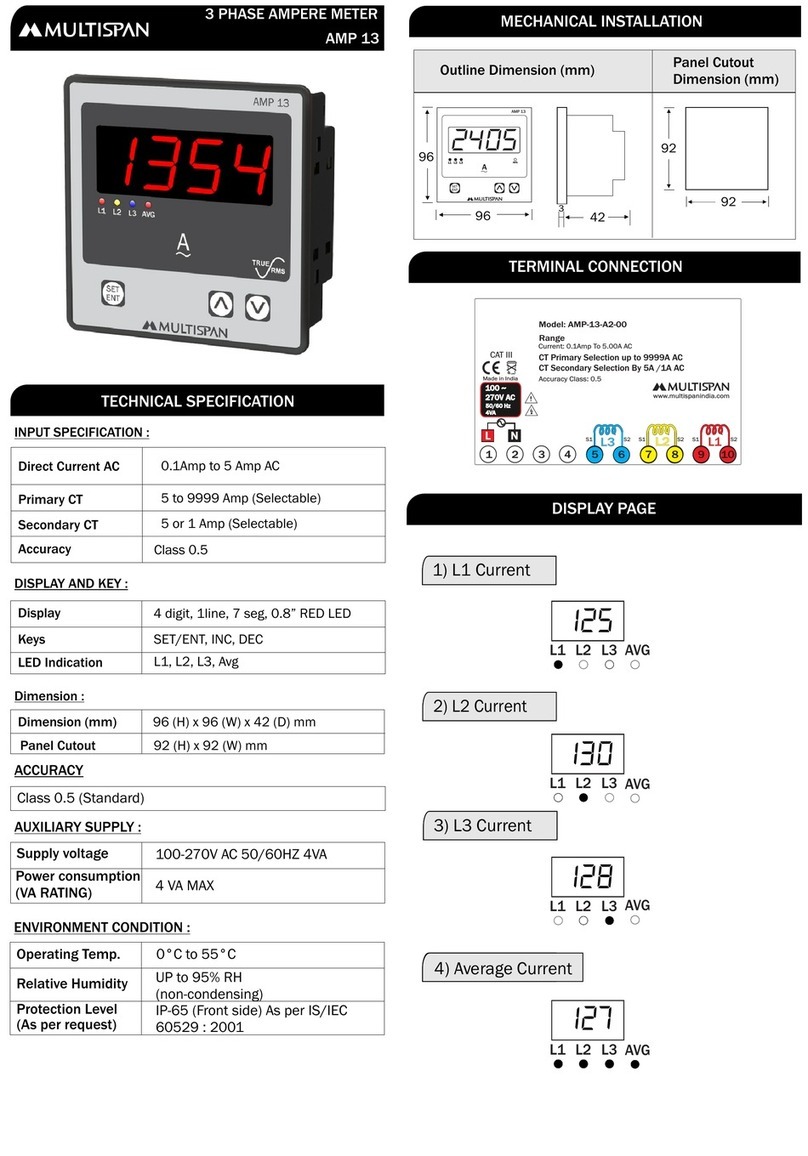

2.2 The Measuring Range

The pulse induction principle used by Profoscope has a

defined range of operation.

The measuring range is dependent on the bar size. The

expected accuracy of the cover measurement is indicated

in the graphic below. (Complies with BS1881 part 204, for

a single rebar with sufficient spacing).

long measuring

range

Cover depth

measuring accuracy

short measuring

range

Bar size

2.3 Factors Affecting the Measurement

2.3.1 Errors due to Neighboring Bars

All rebars within the sphere of influence affect the reading.

Sphere of influence

400 mm /16 inch

MC

Neighboring bars close to the target bar result in an under-

estimated cover value and an overestimated bar dia-

meter.

i

Note: This effect can be reduced by the neigh-

boring bar correction implemented in the Profo-

scope.

Tutorial

© 2008 by Proceq SA 9

2.3.2 Resolution

There is a limit on the minimum spacing of bars depend-

ing on the cover depth. It is impossible to distinguish be-

tween individual bars below these limits.

(For the depth at which bars of different sizes can be de-

tected at all – see 2.2)

short measuring

range

Cover depth

Bar spacing

long measuring

range

rebars can be

separated

Cover

Bar spacing

Tutorial

10 © 2008 by Proceq SA

2.3.3 Effect of Setting Incorrect Bar Diameter

The accuracy of the cover measurement is also depend-

ent on setting the correct bar diameter.

The following two charts give an estimation of the error in

percentage of the cover reading for different rebar sizes if

a default size of 16mm (#5) is set.

For the short range:

Cover depth

Error

For the long range:

Cover depth

Error

Tutorial

© 2008 by Proceq SA 11

2.3.4 Factors Affecting Diameter Determination

Two factors affect the determination of the rebar diameter.

One is the cover depth. Diameter can be determined for

rebars with cover not exceeding 80% of the small range.

(64 mm, 2.5”)

The second is the separation between neighboring bars.

The separation between the bars must be greater than the

limits shown in the drawing below (with reference to the

MC) for accurate determination of diameter.

2.3.5 Orientation

The strongest signal results when the center line of the

probe is parallel to a bar. The center line in the Profoscope

is the long axis of the instrument. This property is used to

help determine the orientation of the rebars.

Tutorial

12 © 2008 by Proceq SA

3 Real Tests

Overview

Read the

Tutorial

Understanding the boundaries of the pulse induction principle

Complete

Getting Started Check the operation of your Profoscope with

the start-up test kit

Regional Settings Change default settings to your regional standard

What Do You

Want to Do?

3.2

Locate a Rebar No further

Settings necessary Locate the Rebar Check the

Orientation Place center line directly over rebar•

3.3

Measure

Cover Depth

Key-in Rebar

Diameter Place Center Line

Directly over Rebar Read off Cover Depth

An accurate rebar diameter setting will•

give an accurate cover depth result

Activate neighboring bar correction if•

necessary

Create Rebar Grid Check minimum bar spacing•

3.4

Measure Rebar

Diameter

Determining

Unknown Rebar

Diameter

Work with Default Known error tolerances given in the•

Tutorial section

Drill Inspection Hole Remove all doubt•

Real Tests

© 2008 by Proceq SA 13

3.1 Preparation

See chapter 4 for advice on selecting your regional setting

and on navigating around the menus.

Measuring Screen Short Cuts

UP

RIGHT

DOWN

SELECT

LEFT

Pressing the up arrow

will switch the back-light

on/off.

Pressing the right arrow

toggles between meas-

uring ranges.

3.2 Locate a Rebar

☺Switch on the Profoscope and perform a reset as ex-

plained in “Getting Started”. The Profoscope can im-

mediately be used to locate a rebar.

i

Note: The Profoscope is able to locate a rebar

and also the mid-point between two rebars. It is

important to be able to recognize which is which.

3.2.1 Finding a Rebar

Step 1 – Place the Profoscope on the test surface and

move it slowly in a chosen direction. The Profoscope re-

acts differently depending on its orientation relative to the

rebars. There are three scenarios.

Scenario A)

Sweeping Parallel to the Rebars

☺Try it out on the start-

up test kit.

Real Tests

14 © 2008 by Proceq SA

Arrows indicate proximity of rebars off screen.

Continue sweeping in the chosen direction.

As you get closer, the rifle scope indicates either:

The presence of a rebar beneath the instrument or,•

The mid-point between two rebars beneath the instru-•

ment.

It is very simple to differentiate between the two.

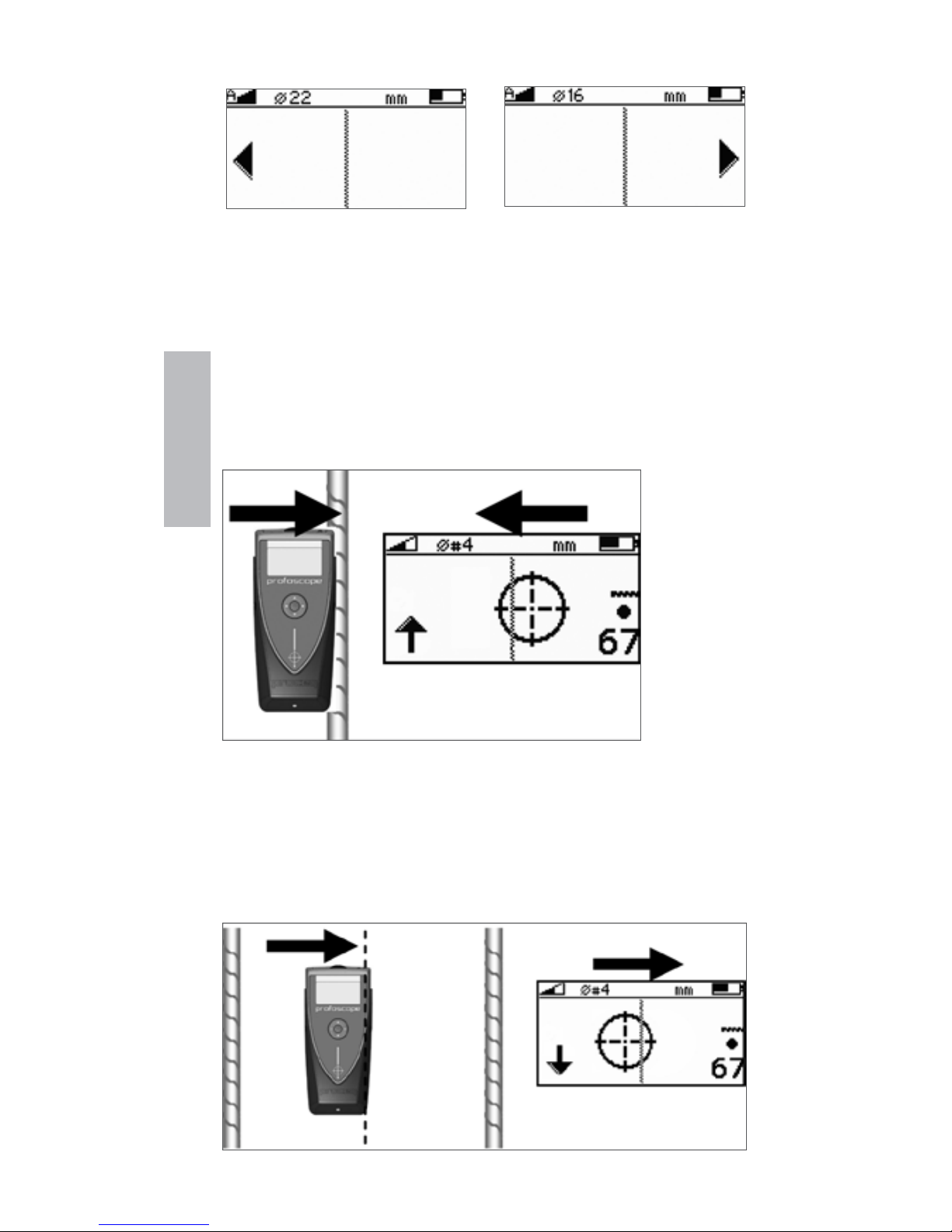

Approaching a Rebar

Rifle scope moves in opposite direction to the Profo-

scope.

The signal strength is increasing as the rifle scope

moves towards the center line.

Approaching a Mid-point

Real Tests

© 2008 by Proceq SA 15

Rifle scope moves in the same direction as the Profo-

scope.

The signal strength is decreasing as the rifle scope

moves towards the center line.

i

Confirm that you are approaching a rebar.

Continue sweeping until the rifle scope is in the center of

the screen. When it is centered exactly, the LED indicator

will light. (If the acoustic signal is activated it will sound

as long as the LED is lit). The rebar is directly beneath the

measurement center.

Rebar centered

Scenario B)

Sweeping Perpendicular to the Rebars

☺Try it out on the start-

up test kit.

If there are rebars within range, the rifle scope will remain

close to the center of the screen and move very little.

Little or no movement of

the rifle scope.

In this case turn the Profoscope by 90° and continue

sweeping as described in the previous section.

Real Tests

16 © 2008 by Proceq SA

Scenario C)

Sweeping at an Angle to the Rebars

☺Try it out on the start-

up test kit.

The response on the screen will be similar to the case

when you are sweeping parallel, but the movement of the

rifle scope will be slower.

3.2.2 Check the Orientation

Step 2 – Once you have located the rebar, you need to

check the orientation of the bar by rotating around the

measurement center.

☺Try it out on the start-

up test kit.

i

Note: Ensure that the rifle scope remains cen-

tered as you rotate.

Rotate until you get the minimum cover value and the LED

indicator is lit.

i

Note: The signal strength arrow can also be

used as an aid here. The signal strength will in-

crease as you rotate towards the correct orienta-

tion and decrease as rotate away.

Real Tests

© 2008 by Proceq SA 17

The center line of the Profoscope is now directly above

the rebar and pointing in the same direction. Mark at either

end of the instrument with chalk or similar.

3.2.3 Verification

Step 3 – Verify by moving the Profoscope in the direction

of the rebar and observe that the cover depth reading dis-

plays a constant value.

3.2.4 Locate a Mid Point

Step 4 – Continue sweeping with the center line of the

Profoscope parallel to the rebar you have just located. As

you approach the mid-point between two rebars the rifle

scope will appear on the screen again. This time:

• Theriescopewillmoveinthesamedirectionasthe

Profoscope.

• The signal strength will be decreasing as the rifle

scope moves towards the center line.

Center the rifle scope as described previously to locate

the exact position of the mid point.

☺ You may want to mark the mid-points as well as a

guide to drilling holes.

3.2.5 Map out the Rebar Grid

Step 5 – “Reset” the Profoscope again and then start

the process once more to locate further rebars.

Sweep in one direction first and then at 90° to build up

the grid.

You will soon have a good representation the rebar con-

figuration to help you begin drilling or to conduct further

measurements of cover depth and rebar diameter and so

forth.

Real Tests

18 © 2008 by Proceq SA

3.2.6 Advanced Settings (Measuring Range)

short, long, auto, auto

This symbol in the top left corner of the screen indicates

the measuring range set. Toggle between ranges with the

short cut describe in chapter 3.1.

The range can also be set in the main menu by

selecting the following icon.

Choose the short range to accurately detect rebars that

are embedded closer to the concrete surface.

The long range setting will allow rebars embedded deeper

in the concrete structure to be detected. However, it will

create a larger sphere of influence which in turn means

that neighboring rebars may affect the reading.

Alternatively, choose the automatic setting that will au-

tomatically toggle between the short range and the long

range.

3.3 Measure Cover Depth

Once the rebar grid has been located the cover can be

measured.

3.3.1 Set the Rebar Diameter

☺An accurate knowledge of the rebar diameter will also

give best cover depth results.

The default reference rebar diameter set in the instrument

is 16 mm or #5. This can be seen in the status row at the

top of the display screen.

Step 1 - If you already know the actual rebar dia-

meter, select the icon in the menu to set this as

the reference.

i

Note: If you DO NOT know the rebar diameter,

then proceed to chapter 3.4.

Real Tests

© 2008 by Proceq SA 19

3.3.2 Read the Cover Depth

Step 2 - Place the centre line of the Profoscope directly

over the rebar and read off the cover depth.

e.g.

Cover depth = 15 mm

i

Note: Ensure that the measurement centre is not

placed over a horizontal/vertical intersection in

the rebar grid.

3.3.3 Advanced Settings

(Neighboring Rebar Correction)

As described in the tutorial neighboring rebars

that are within the sphere of influence will also be

detected by the Profoscope and will affect cover

depth results. The effects of neighboring rebars can be

mitigated by keying-in a correction value.

i

Note: This works for rebars of the same layer run-

ning in parallel to the rebar under test.

Measure the distance from the rebar under test to a

neighboring rebar. (See 3.2.5)

Enter the settings menu, select the icon and input this

value. Verify that neighboring rebar correction symbol

is active in the status line at the top of the display. Repeat

step 2.

3.3.4 Advanced Settings

(Minimum Cover Alert)

This is particularly useful for detecting insuffi-

cient concrete cover depth when conducting

large scale checks on structures after removing

the formwork or large scale building inspections and so

forth.

Real Tests

20 © 2008 by Proceq SA

Enter the settings menu, select the icon and set the re-

quired cover depth limit. Verify that minimum cover alert

symbol is active in the status line at the top of the

display.

Move the Profoscope over the test surface. Whenever the

cover depth is less than the programmed minimum the

LED indicator will light and if it is enabled, an acoustic

alarm will be given.

i

Note: In this mode the LED will not light to indi-

cate that a rebar has been located.

3.4 Measure Rebar Diameter

3.4.1 Determining Unknown Rebar Diameter

☺ The Chapter “Getting Started” shows that under the

right conditions the Profoscope can accurately deter-

mine the diameter of a rebar.

The Tutorial chapter on the pulse induction principle de-

scribes the limitations of the technology and clearly out-

lines the conditions whereby accurate readings of rebar

diameter CANNOT be made if there is too much inter-

ference from neighboring rebars or other metallic objects

within the sphere of influence.

We present 3 working methods which are recommended

to obtain the best results.

3.4.2 Create a Rebar Grid

Method 1 To map out a rebar grid on a test surface and

then to select one rebar from the grid that has sufficient

spacing from other rebars.

Step 1 - Create a rebar grid as described in chapter

3.2.5.

Step 2 - Select one rebar that has the largest spacing

from neighboring rebars.

Step 3 - Use a ruler and confirm that the spacing is at

least 150 mm (6”). If not, redo Steps 1 and 2 until a rebar

Real Tests

© 2008 by Proceq SA 21

is located with at least 150 mm (6”) spacing to a neigh-

boring rebar.

Step 4 - Place the centre line of the Profoscope over the

rebar and click the function key on the left side.

The measured rebar

diameter replaces the

signal strength arrow.

Note down the rebar diameter.

☺Try it out on the start-up test kit.

3.4.3 Work with a Default Value

Method 2 The purpose of this approach is to work with

a default value with known error tolerances.

From the menu item “Bar diameter” select the default

value 16mm or #5 for the diameter.

Use the chart in section 2.5 of the tutorial to understand

the errors that can be expected in the cover readings if the

actual rebar diameters differ from the reference value.

3.4.4 Drill Inspection Hole

Method 3 The purpose of this approach is to accurately

determine the rebar diameter through destructive means.

If neither of the methods 1 and 2 are feasible for what-

ever reason and you are still in doubt (this could be the

case when rebars are bunched too close together or are

too small in diameter), then drill an inspection hole wide

enough to allow the use of a caliper to measure the re-

bar diameter. Program this value into the Profoscope and

proceed.

Real Tests

22 © 2008 by Proceq SA

4 General Settings

4.1 Navigating

UP

RIGHT

DOWN

SELECT

LEFT

The settings menu can

be entered by pressing

the select button. Use

the navigation keys to

select the desired menu

icon and press the se-

lect button again.

Scroll within the menus to the setting you wish to make

and press the select button to implement it. Exit the main

menu by pressing either the reset or function button.

Each menu item is de-

scribed in detail below.

4.2 Regional Setting

The Profoscope supports 4 regional settings. This

setting affects all other displays and should be

done prior to making other selections.

Metric Cover and bar diameters in mm accord-

ing to table in 4.3

ASTM inch Cover in inch, bar diameters according

to table in 4.3

ASTM mm Cover in mm, bar diameters according

to table in 4.3

Japanese Cover in mm, bar diameters according

to table in 4.3

General Settings

Table of contents