Proheat M Series User manual

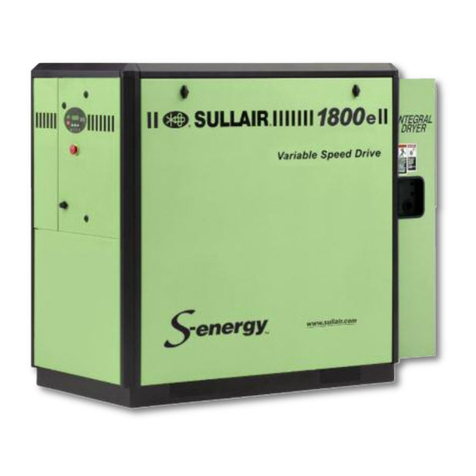

M-SERIES DIAPHRAGM

COMPRESSOR REBUILD KIT

Part# 200690K

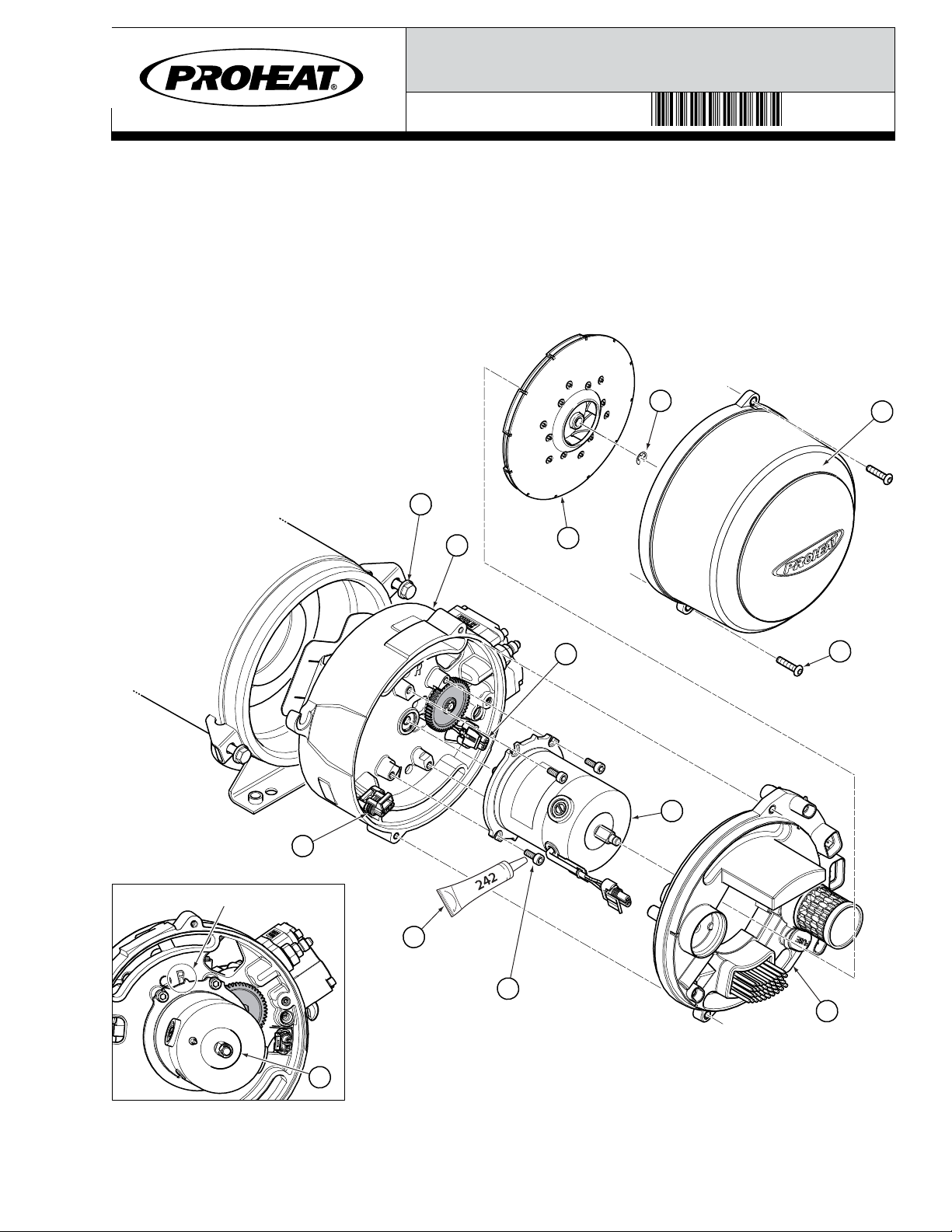

Disassembly Instructions

4

11

1

5

2

3a

9

10

8

15

7

6

3

4

4

SHOWN IN "R" POSITION

6

To avoid the risk of shock, ensure to

disconnect power to the heater unit

during disassembly/reassembly.

WARNING

Copy Part# 206000, Rev. E Page 1 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

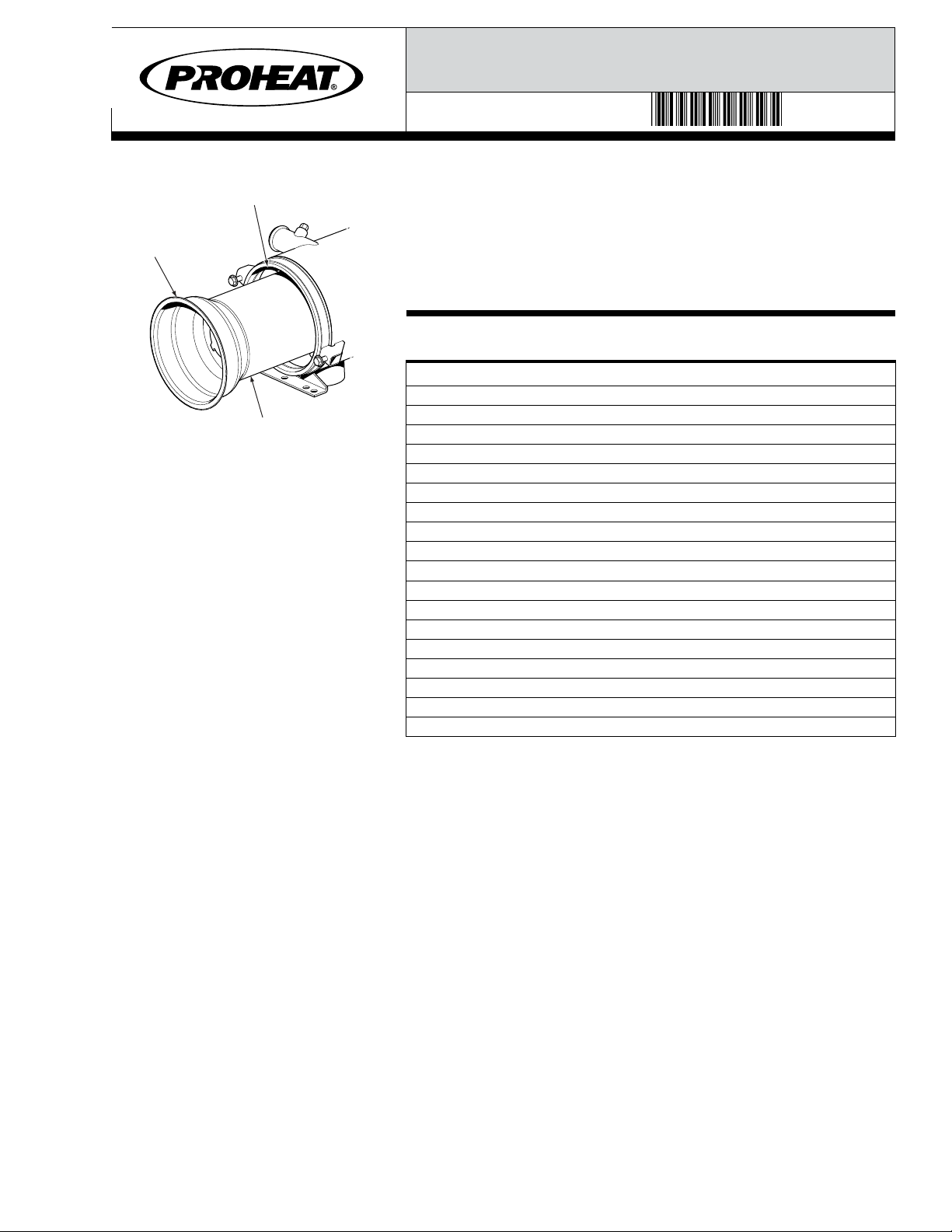

INSTALLATION INSTRUCTIONS

Figure A.

DO NOT discard any component unless

directed to do so. All mounting hardware

will be re-used during the installation

of the compressor kit.

NOTICE

1. Disconnect all harnesses at the PCM.

2. Disconnect the fuel supply line.

3. Referring to figure A, loosen and back out the burner head mounting

bolts (item 1) allowing enough room to rotate the burner head 15°

counter-clockwise and remove.

4.

Remove the blower housing (item 3) by removing the two M6 screws

(item 2). Item 3a may vary in appearance depending on the type of

heater model. Note initial orientation of blower housing.

5.

Remove the combustion air blower (item 5) by removing the retaining

ring (item 4).

6. Disconnect the motor (item 6), fuel solenoid (item 7), and ignition

module (item 8) at the PCM (item 9), then carefully slide off the PCM

to avoid damaging the motor wires.

7.

Remove the motor (item 6) by removing the four M6 screws (item 10).

Note initial orientation of motor for reassembly (refer to figure A inset).

8. Remove and discard the Motor Gear (item 11) by removing the

retaining ring (item 4). Ensure Motor Shaft and retaining ring

groove are thoroughly cleaned and free from all green Loctite®

adhesive before reassembly.

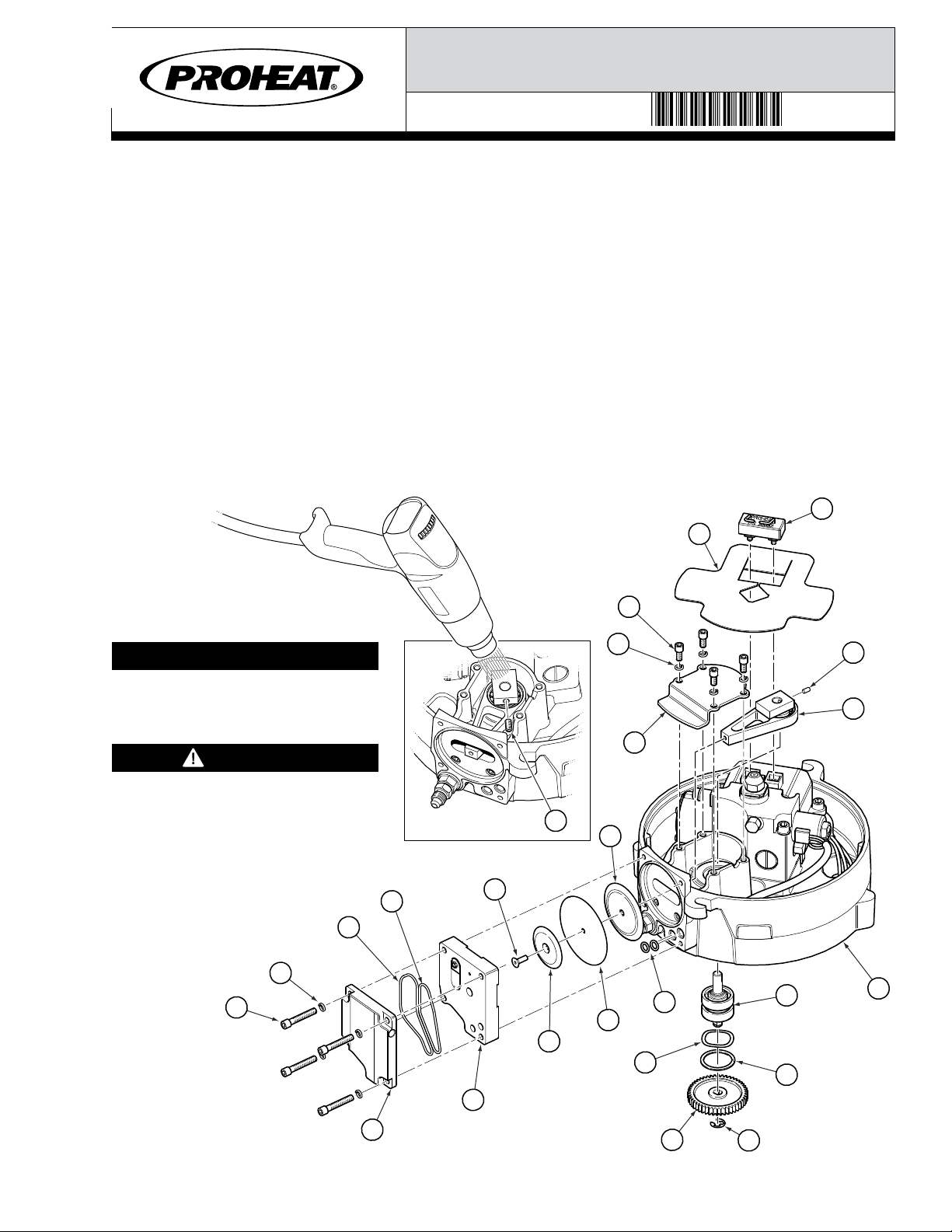

9. Turn the Burner head over as shown in figure B. Remove the

ignition electrode (item 28) then the flame shield (item 29).

10. Remove the valve cover (item 18) by removing the four M5 screws

(item 16) and lock washers (item 17).

11. Remove and discard the two O-rings (item 19 & 20) and cylinder

head assembly (item 21).

12. Remove the #8 screw (item 22) from the connecting rod assembly

(item 23), then remove the intake disk (item 24), diaphragm (item

25) and compression disk (item 26).

13. Remove and discard the two O-rings (item 27) from the burner head

flange (item 15).

28

29

31

18

19

21

22

27

12

14

4

13

33

26

15

25

23

32

24

20

30

17

16

17

Figure B.

Heat may be required. Use a heat gun

directed at the screw head (item 32) to

loosen the Loctite®bond.

NOTICE

32

Area must be free from any combustible

fuels when using a heat gun.

WARNING

Copy Part# 206000, Rev. E Page 2 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

Disassembly Parts Checklist

14. Remove the compressor cover (item 31) by removing the four M5

screws (item 30) and lock washers (item 17).

15. Remove and discard the compressor gear (item 12) by removing

the retaining ring (item 4). Ensure the Compressor Shaft and

retaining ring groove are thoroughly cleaned and free from all

green Loctite®adhesive before reassembly.

16. Remove the internal retaining ring (item 13) and spring washer

(item 14) from the burner head flange (item 15).

17. Remove the #10 set screw (item 32) from the connecting rod

assembly. NOTE:heat may be required. Use a heat gun directed at

the screw head to loosen the Loctite®bond (See figure B inset).

18. Referring to figure C, remove the compressor shaft assembly

(item 33). NOTE: heat may be required. Use a heat gun directed at

bearings to loosen the Loctite®bond, then tap out with a hammer

being careful not to damage the burner head flange (item 15).

19. Slide the connecting rod assembly (item 23) out from the

compressor crankcase.

20. Discard all of the remaining components as per the disassembly

parts checklist.

ITEM RE-USE DISCARD DESCRIPTION QTY UOM

1 X Screw, M8 x 1.25 x 30, HWHCS 2 ea

2 X Screw, M6 x 1 x 1.25, BHSCS SS 2 ea

3 X Blower Housing 1 ea

4 X Retaining Ring 3 ea

5 X Combustion Air Blower 1 ea

6 X Motor 1 ea

7 X Fuel Solenoid 1 ea

8 X Ignition Module 1 ea

9 X Proheat Control Module (PCM) 1 ea

10 X Screw, M6 x 1 x 16, SHCS SS 4 ea

11 X Motor Gear 1 ea

12 X Compressor Gear 1 ea

13 X Snap Ring 1 ea

14 X Spring Washer 1 ea

15 X Burner Head Flange 1 ea

16 X Screw, M5 x 0.8 x 30 SHCS ZP 4 ea

17 X Lockwasher, #10 SS 8 ea

18 X Valve Cover 1 ea

19 X O-Ring, 2-035 1 ea

20 X O-Ring, 2-031 1 ea

21 X Cylinder Head 1 ea

22 X Screw, #8-32 x 1/2, FHSCS SS 1 ea

23 X Connecting Rod Assembly 1 ea

24 X Intake Disk 1 ea

25 X Diaphragm 1 ea

26 X Compression Disk 1 ea

27 X O-Ring, 2-010 2 ea

28 X Ignition Electrodes 1 ea

29 X Flame Shield 1 ea

30 X Screw, M5 x 0.8 x 10, SHCS SS 4 ea

31 X Compressor Cover 1 ea

32 X Set Screw, #10-32 x 3/8, SHSS 1 ea

33 X Compressor Shaft Assembly 1 ea

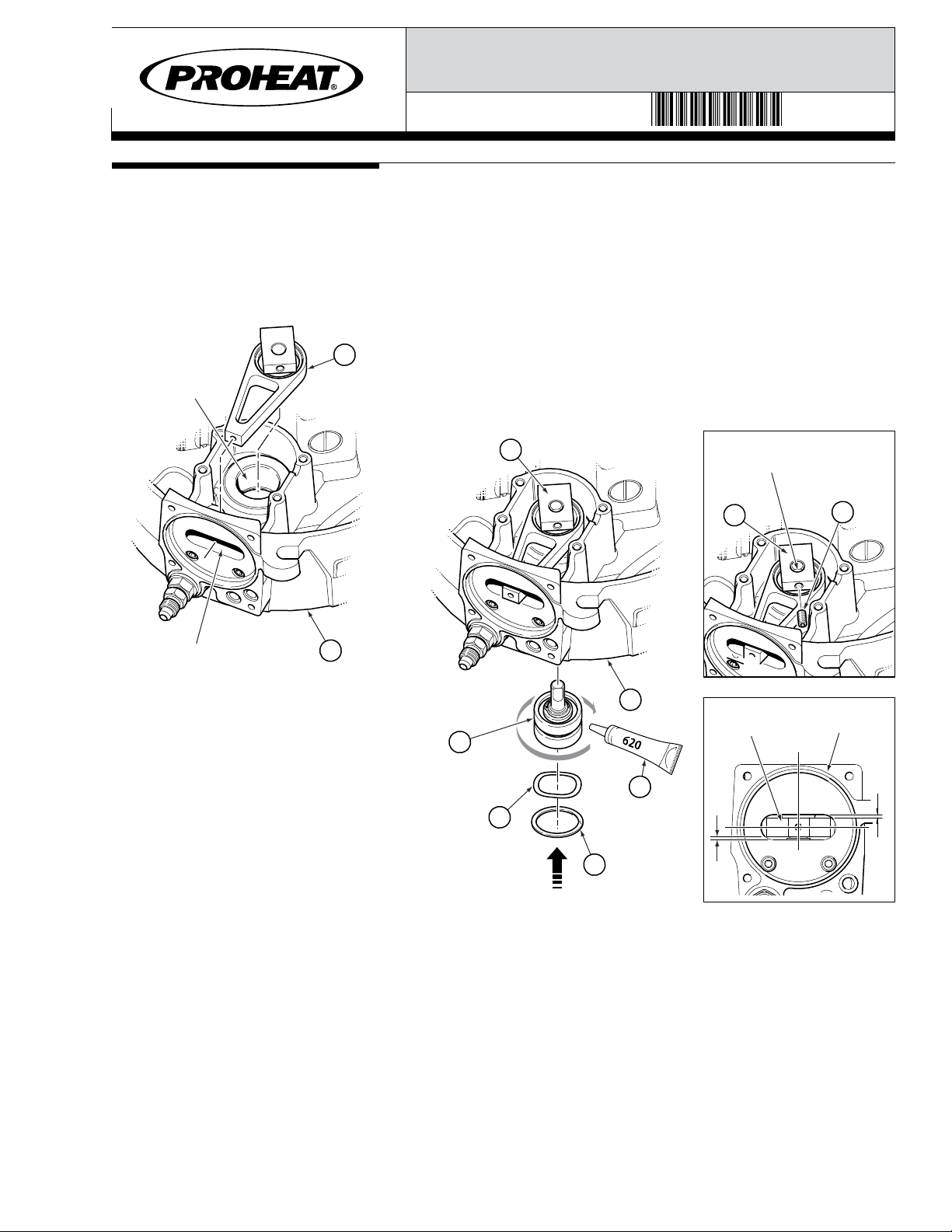

33

15

Figure C.

Copy Part# 206000, Rev. E Page 3 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

50

15

34

36

35

37

37

38

FLAT FACE OF

COMPRESSOR

SHAFT TORQUE:

25 ± 3 IN-LBS

GAP

GAP

CONNECTING

ROD

DIAPHRAGM

OPENING

15

37

DRIVE HUB

DIAPHRAGM

OPENING

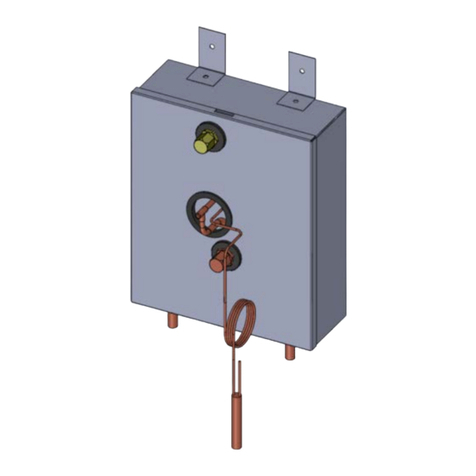

Reassembly Instructions 1. Prep drive hub to ensure it is clean and free from any debris and/

or contaminants. Use of a Scotch Bright pad is permitted.

2. Apply Loctite®620 (item 50) to the outer race of the bearings in

item 34. Ensure no Loctite®contacts the sealing surfaces.

3. Place the connecting rod assembly (item 37) in position as

shown in figure E FIRST. Insert the compressor shaft assembly

(item 34) into the drive hub SECOND. NOTE: the order of this

operation is important.

4. Install the spring washer (item 35) and snap ring (item 36). Ensure

the spring washer sits evenly against the bearing surface, and the

snap ring is properly seated in the groove in the drive hub.

5. Install set screw into the connecting rod assembly ensuring that it

mates flush to flat face of compressor shaft after tightening. If

positioned correctly, the areas marked “gap” will be equal in size

(see figure E insets).

Copy Part# 206000, Rev. E Page 4 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

figure E.

Figure D.

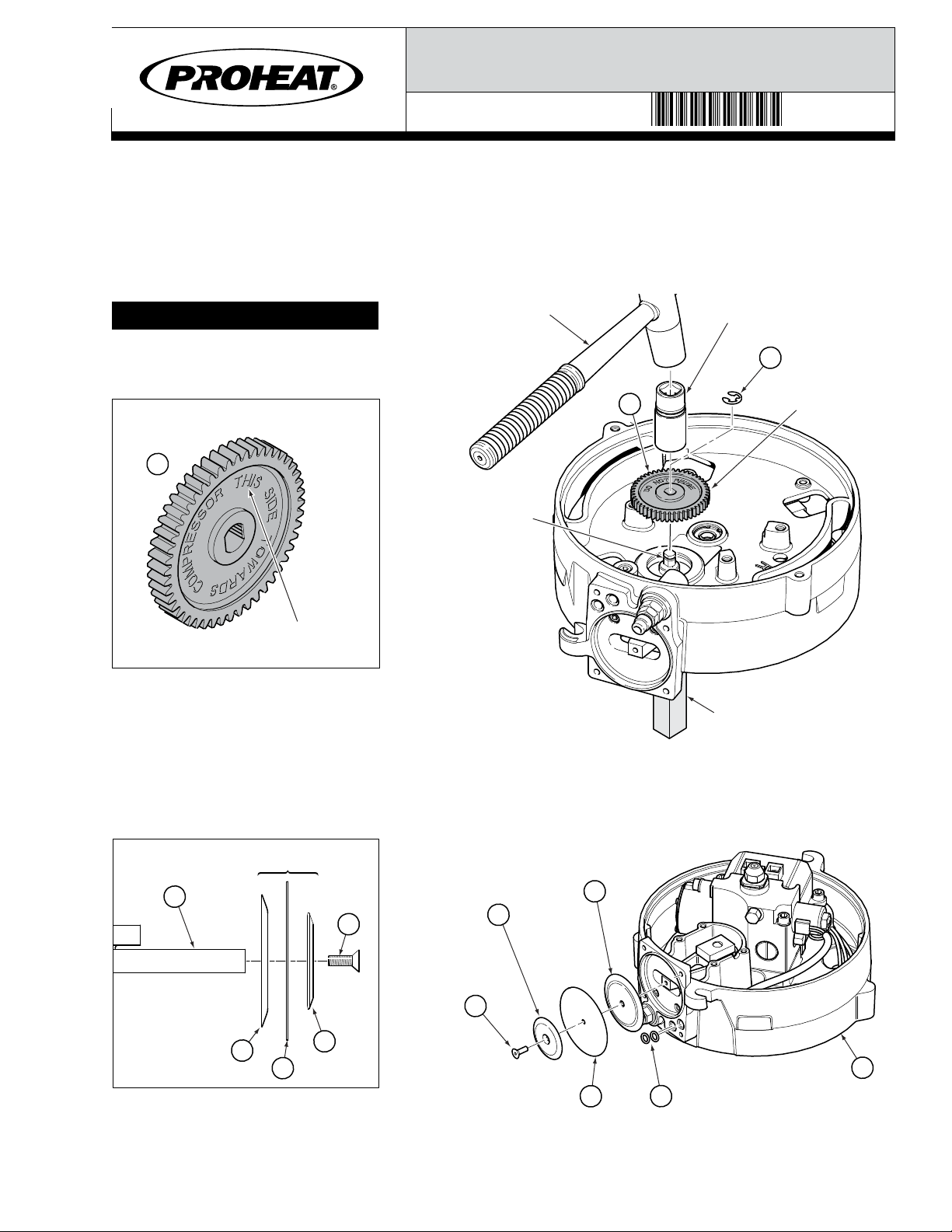

48

47

SHAFT TO BE

FREE OF ALL

ADHESIVES/

LUBRICANTS

NOTE GEAR

ORIENTATION

SEE INSET

SOFT HAMMER 13 mm DEEP SOCKET

WOOD BLOCK TO

SUPPORT SHAFT

48

TEETH

47

Compressor Gear.

NOTE: ORIENTATION

AS

PER TEXT ON GEAR

39

39

43

42

42

37

15

41

41

40

40

TORQUE:

25 ± 3 IN-LBS

NOTE

ORIENTATION

NOTE ORIENTATION NOTE

ORIENTATION

DO NOT apply lubricants or Loctite®to

compressor shaft or gear during

installation.

NOTICE

Figure F.

6. Orient the compressor gear (item 47) as noted in figure F. with

appropriate side facing compressor as per gear text. Install by hand

and secure to the compressor shaft with a new retaining ring

(item 48). If gear cannot be installed by hand, remove the four screws

securing the compressor cover in place and support the compressor

shaft as shown in figure C. A 13 mm deep socket and soft hammer

can then be used to lightly tap gear onto shaft.

7. Install the diaphragm assembly (items 39–42) onto the connecting

rod as shown in figure G. NOTE: orient the intake disk (item 40)

and compression disk (item 42) with the beveled side pointing

away from burner head flange (see figure G inset).

Figure G.

8. Install two O-rings (item 43) into the burner head flange (item 15).

9. Install two O-rings (items 44 and 45) into the valve cover (item 18).

Copy Part# 206000, Rev. E Page 5 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

37

TDC

ENSURE COUNTER-WEIGHT IS ALIGNED BOTTOM

DEAD CENTER (BDC) BEFORE INSTALLATION

BDC

17

44

46

45

16

18

31

30

17

1

2

3

4

TORQUE SEQUENCE

ENSURE CONNECTING

ROD IS CENTERED IN

DIAPHRAGM OPENING

TORQUE:

27 ± 3 IN-LBS

TORQUE: 27 ± 3 IN-LBS

Figure I.

Figure H.

49

49

48

6

Black Motor Gear

with 38 Teeth.

NOTE: ORIENTATION

AS

PER TEXT ON GEAR

38 TEETH

SHAFT TO BE

FREE OF ALL

ADHESIVES/

LUBRICANTS

WOOD BLOCK

TO

SUPPORT SHAFT

13 mm

DEEP

SOCKET

SOFT

HAMMER

Figure J.

10. Position the connecting rod assembly (item 37) so that it is in

BDC (see figure H), and ensure the diaphragm (item 41) is

concentric to the “diaphragm opening”.

NOTE: this operation is CRITICAL prior to proceeding onto step 11.

11. Install the cylinder head assembly (item 46) and valve cover (item

18) and secure with four M5 screws (item 16) and lock washers

(item 17). Torque the screws according to the torque sequence

shown in figure I inset.

12. Install the compressor cover (item 31) and secure with four screws

(item 30) and lock washers (item 17).

13. Orient the Motor Gear (item 49) as noted in figure J. (Inset) with

appropriate side facing Motor flange as per gear text. Install by hand

and secure to the Motor Shaft with a new retaining ring (item 48).

If gear cannot be installed by hand, a 13 mm deep socket and soft

hammer can be used to lightly tap gear onto shaft. Support Motor

shaft from combustion air blower side as shown in figure J.

Copy Part# 206000, Rev. E Page 6 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

48

7

1

5

2

9

10

51

APPLY LOCTITE® 242

TO THREADS

TORQUE: 75 ± 7 IN-LBS

6

3

TORQUE:

100 ± 10 IN-LBS

TORQUE:

75 ± 7 IN-LBS

SHOWN IN "R" POSITION

6

15

8

Figure K.

14. Referring to figure K, install the motor (item 6) onto the burner

head flange and secure with four M6 screws (item 10). Ensure to

apply Loctite®242 (item 51) to the screw threads prior to

installation. NOTE: Motor (item 6) must be re-installed according

to its original position (see orientation marks item figure K inset).

15. Install the PCM (item 9), then reconnect the motor (item 6), fuel

solenoid (item 7) and ignition module (item 8) to their respective

terminals. NOTE: Ensure the PCM is reinstalled in its original

orientation.

Copy Part# 206000, Rev. E Page 7 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

Ensure to rotate combustion air blower

(item 5) by hand until it spins freely.

This seats the fuel pump gear pack

and avoids a Code 12 on startup. For

more information, refer to the manual

at www.proheat.com

NOTICE

PK0036 Digital Manometer or PK0067

Pressure Test Gauge (not shown) is

required to complete the rebuild. It is

NOT supplied in the rebuild kit.

Go to www.proheat.com for more

information.

NOTICE

16. Install the combustion air blower (item 5) and secure with a new

retaining ring (item 48). Spin the combustion air blower by hand

after installation to ensure it spins freely.

17. Install the blower housing (item 3) ensuring correct orientation,

and secure with two screws (item 2).

18. Set Compressor Pressure (refer to figure L).

Refer to M-Series Service Manual at www.proheat.com for detailed

instructions. Air filter and nozzle must be clean for compressor

setting. Inspect air passages of fuel block and clean as required.

MODEL AIR PRESSURE (DIAPHRAGM COMPRESSOR)

M50 6.0 ± 0.1 PSI (41.4 ± 0.7 kPa)

M80/M90 2.9 ± 0.1 PSI (20.0 ± 0.7 kPa)

M105/M125 3.65 ± 0.1 PSI (25.1 ± 0.7 kPa)

19. Install the heat shield (item 29) and ignition electrodes (item 28).

20. Inspect and Clean Heat Exchanger and Combustion Tube.

Remove combustion tube to access the inside of the heat exchanger.

Clean any combustion deposits that may have accumulated on

the heat exchanger fins with a wire brush. Use a vacuum to suck

the combustion deposits out. Ensure that the exhaust pipe is

clean and free from restriction.

Clean the combustion tube with a wire brush. Reinstall combustion

tube into the heat exchanger ensuring that the orientation boss

is at the 12 o’clock position as shown in figure M.

PRESSURE ADJUSTMENT SCREW

DECREASE

PRESSURE

INCREASE

PRESSURE

FLAME

SHIELD

IGNITION

ELECTRODE

ASSEMBLY

DIAPHRAGM

COMPRESSOR

DIGITAL

MANOMETER

(P/N PK0036)

PRESSURE

ADJUSTMENT

SCREW

Figure L.

Flammable. Point Nozzle away from face, open sparks and flames.

WARNING

Copy Part# 206000, Rev. E Page 8 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

ITEM DESCRIPTION QTY UOM

34 Compressor Shaft Assembly 1 ea

35 Spring Washer 1 ea

36 Snap Ring 1 ea

37 Connecting Rod Assembly 1 ea

38 Set Screw, #10-32 x 3/8, SHSS 1 ea

39 Screw, #8-32 x 1/2, FHSCS SS 1 ea

40 Intake Disk 1 ea

41 Diaphragm 1 ea

42 Compression Disk 1 ea

43 O-Ring, 2-010 2 ea

44 O-Ring, 2-035 1 ea

45 O-Ring, 2-031 1 ea

46 Cylinder Head 1 ea

47 Gear, Compressor, 48 Teeth, Black 1 ea

48 Retaining Ring 3 ea

49 Gear, Motor, 38 Teeth, Black 1 ea

50 Loctite®620 (.5 ml Tube) 1 ea

51 Loctite®242 (.5 ml Tube) 1 ea

Reassembly Parts Checklist

ORIENTATION

BOSS

HEAT EXCHANGER

FLANGE NOTCH

COMBUSTION TUBE

Figure M. 21. Install the burner head back onto the heat exchanger and secure

with two screws (item 1).

22. Operate heater for a minimum of two cycles to ensure functionality.

Inspect for fuel leaks around the exterior of the burner head and

heat exchanger.

Copy Part# 206000, Rev. E Page 9 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Tel: 604.270.6899 Web: www.proheat.com

INSTALLATION INSTRUCTIONS

Other manuals for M Series

2

This manual suits for next models

1

Table of contents

Popular Air Compressor manuals by other brands

Sullair

Sullair 185 Operators manual and parts lists

Fieldmann

Fieldmann FDAK 901521 instruction manual

GEA

GEA HG76e/1620-4 Assembly instructions

AEROTECNICA COLTRI

AEROTECNICA COLTRI MCH-5/EM CNG Use and maintenance manual

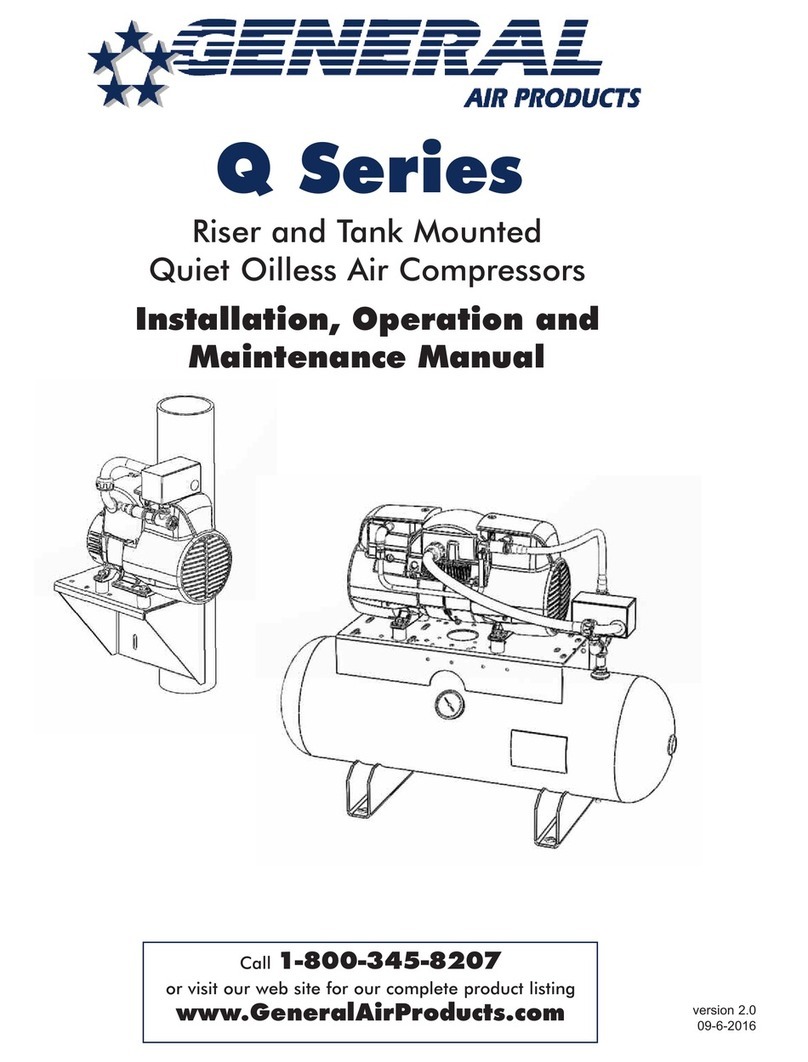

General Air Products

General Air Products Q Series Installation, operation and maintenance manual

GLENCO

GLENCO AIRMAC FU SHENG T20 owner's manual