ProLite LD1 User guide

Installation, Servicing and User Instructions for

LD1 & LD2 BOILING TOPS

CAUTION: Read the instructions before using the appliance.

Important Installation Information

The installer must ensure that installation of the unit(s) is in conformity with regulations in force at the

time. For the UK, particular attention requires to be paid to:-

BS7671 IEE Wiring Regulations

Electricity at Work Regulations

Health and Safety at Work Act

Fire Precautions Act

The unit has been CE-marked on the basis of compliance with the Low Voltage and EMC Directives for the

voltage stated on the data plate.

WARNING: THIS APPLIANCE MUST BE EARTHED!

Preventive Maintenance Contract

In order to obtain maximum performance from the equipment, we would recommend that a

maintenance contract be arranged with Serviceline. Visits may then be made at agreed intervals to carry

out adjustments and repairs. A quotation for this service will be provided upon request. Contact

Serviceline as detailed below:-

Tel: 01438 363 000 Fax: 01438 369 900

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts in a safe manner, via a

licenced waste handler.

Units are designed to be dismantled easily and recycling of all material is encouraged

whenever practicable.

Falcon Foodservice Equipment

Wallace View, Hillfoots Road, Stirling. FK9 5PY, Scotland

e-mail: info@falconfoodservice.com T100317 Ref 8

IMPORTANTINFORMATION

Warranty Policy Shortlist

Warranty does not cover :-

•Correcting faults caused by incorrect installation of a product.

•Where an engineer cannot gain access to a site or a product.

•Repeat commission visits.

•Replacement of any parts where damage has been caused by misuse.

•Engineer waiting time will be chargeable.

•Routine maintenance and cleaning.

•Gas conversions i.e. Natural to Propane gas.

•Descaling of water products and cleaning of water sensors where softeners/ conditioners are not

fitted,

or are fitted and not maintained.

•Blocked drains

•Independent steam generation systems.

•Gas, water and electrical supply external to unit.

•Light bulbs

•Re-installing vacuum in kettle jackets.

•Replacement of grill burner ceramics when damage has been clearly caused by misuse.

•Where an engineer finds no fault with a product that has been reported faulty.

•Re-setting or adjustment of thermostats when unit is operating to specification.

•Cleaning and unblocking of fryer filter systems due to customer misuse.

•Lubrication and adjustment of door catches.

•Cleaning and Maintenance

•Cleaning of burner jets

•Poor combustion caused by lack of cleaning

•Lubrication of moving parts

•Lubrication of gas cocks

•Cleaning/adjustment of pilots

•Correction of gas pressure to appliance.

•Renewing of electric cable ends.

•Replacement of fuses

•Corrosion caused by use of chemical cleaners.

Electrical Safety and Advice Regarding Supplementary Electrical Protection

Commercial kitchens and foodservice areas are environments where electrical appliances may be located

close to liquids, or operate in and around damp conditions, or where restricted movement for installation

and service is evident.

The installation and periodic inspection of the appliance should only be undertaken by a qualified, skilled

and competent electrician; and connected to the correct power supply suitable for load as stipulated by the

appliance data label.

The electrical installation and connections should meet the necessary requirements to local electrical

wiring regulations and electrical safety guidelines.

We recommend:-

Supplementary electrical protection with use of a residual current device (RCD).

Fixed wiring appliances incorporate a locally situated switch disconnector to connect to, which is

easily accessible for switching off and safe isolation purposes. The switch disconnector must meet

the specification requirements of IEC 60947.

SECTION 1 - SITING

Dimensions

LD1 - 300mm (W) x 645mm (D) x 240mm (H) Power Rating –2.76kW

Weight - 10kg Fuse Rating - 13A

LD2 - 600mm (W) x 645mm (D) x 240mm (H) Power Rating –6.44kW

Both Models - Side/Rear Clearance - 20mm Vertical Clearance - 900mm

The LD1 and LD2 have been designed in modular form to allow countertop use or base unit

mounting.

Free-standing and base models should be installed upon a firm, level surface and adjustable feet are

provided for levelling purposes.

Counter units must be positioned upon a table, counter or similar surface.

Vertical and horizontal clearances required from the top and sides of a particular unit to any

overlying combustible surface (ie wall, partition, etc) are listed above. Relevant fire regulations must

be complied with.

Mounting Counter Units on the Oven

When mounting a counter unit upon a light duty oven, it is recommended that units which carry

liquids, i.e. fryers and bains marie, are secured as follows:

Remove oven outer back panel and crown plate.

Position unit(s) which require to be secured upon the oven.

Secure hob unit(s) to oven through side flange centre holes into the threaded inserts in the base(s)

of the hob unit(s). Use fixings provided (packed separately) and replace oven back panel.

The unit is now ready for electrical connection.

Figure 1 Front View

Mounting Counter Units on a Cupboard

Light duty hot cupboards are designed to be used in conjunction with counter models. Assembly is

achieved by means of two shouldered fixings being applied to the underside of a top unit from inside

a base appliance as detailed in Figure 1.

SECTION 2 - ELECTRICAL SUPPLY AND CONNECTION

Electrical ratings are as stated on the unit data plate. This is based on standard UK specification at

230V - 240V~ as appropriate. Wiring must be executed in accordance with the regulations listed in

this booklet.

WARNING! - Each individual appliance must be earthed!

The appliance is also provided with a terminal for the connection of an external

equipotential conductor. This terminal is in effective electrical contact with all fixed

exposed metal parts of the appliance, and shall allow the connection of a conductor

having a nominal cross-sectional area of up to 10 mm². It is located on the rear panel and

is identified by the following label and must only be used for bonding purposes.

After completion of installation, the method of operation should be demonstrated to the kitchen

staff. The isolating switch location, for use in an emergency or during cleaning should also be

pointed out.

LD1 Boiling Top

This model is designed to be connected to a single phase AC supply using the 2 metre mains lead

fitted as standard.

Check that no damage has occurred to the appliance, power cable and plug top during transit. If

damage has occurred do not use the appliance.

Ensure that the mains power cable is routed free from the appliance to avoid damage.

We recommend supplementary electrical protection with the use of a residual current device (RCD).

Periodic testing, repair and fixed wiring connection should only be undertaken by a skilled and

competent electrician.

Wires are coloured in accordance with the following code and should be connected to the plug as

follows:

EARTH to terminal marked Eor coloured GREEN or GREEN/YELLOW.

NEUTRAL to terminal marked Nor coloured BLACK.

LIVE to terminal marked Lor coloured RED.

Units which receive power from a plug, adaptor or distribution board must be individually protected

by a fuse with an appropriate rating.

For models with two mains leads, each lead requires to be protected by a fuse with an appropriate

rating.

Any replacement supply cable must be 1.5mmŽ2•, cord code designation 245 IEC 57 (CENELEC H05

RN-F).

For internal connection, outer sheathing must be stripped 140mm from the cable end. The live and

neutral conductors must be trimmed so that the Earth conductor is longer by 50mm. Pass inlet cable

through the rear panel cord grip and ensure that the cable is routed without leaving excessive free

length inside the appliance.

LD2 Boiling Top

This model is designed to be connected to a single phase AC supply. Electrical supply must be

installed using a suitable isolating switch with a minimum contact separation of 3mm in all poles.

SECTION 3 - USE and CLEANING

IMPORTANT: GENERAL NOTES ON CLEANING

Disconnect unit from electricity supply prior to cleaning.

Never use a coarse abrasive to clean exterior panels. A soft cloth with a warm

water and detergent solution is sufficient.

Never attempt to steam clean or hose down with a jet of water.

Plate Control Switch

Each hotplate is controlled by a switch which offers six individual heat settings. The LD2 front plates

have a built-in cut-out device to automatically reduce heat if the plates are left uncovered at a high

setting. Always switch plate settings to OFF position when not in use.

Rear to left Front to right

Rear Front

Figure 2 - LD1 Model

LH Front LH Rear RH Rear RH Front

Figure 3 - LD2 Model

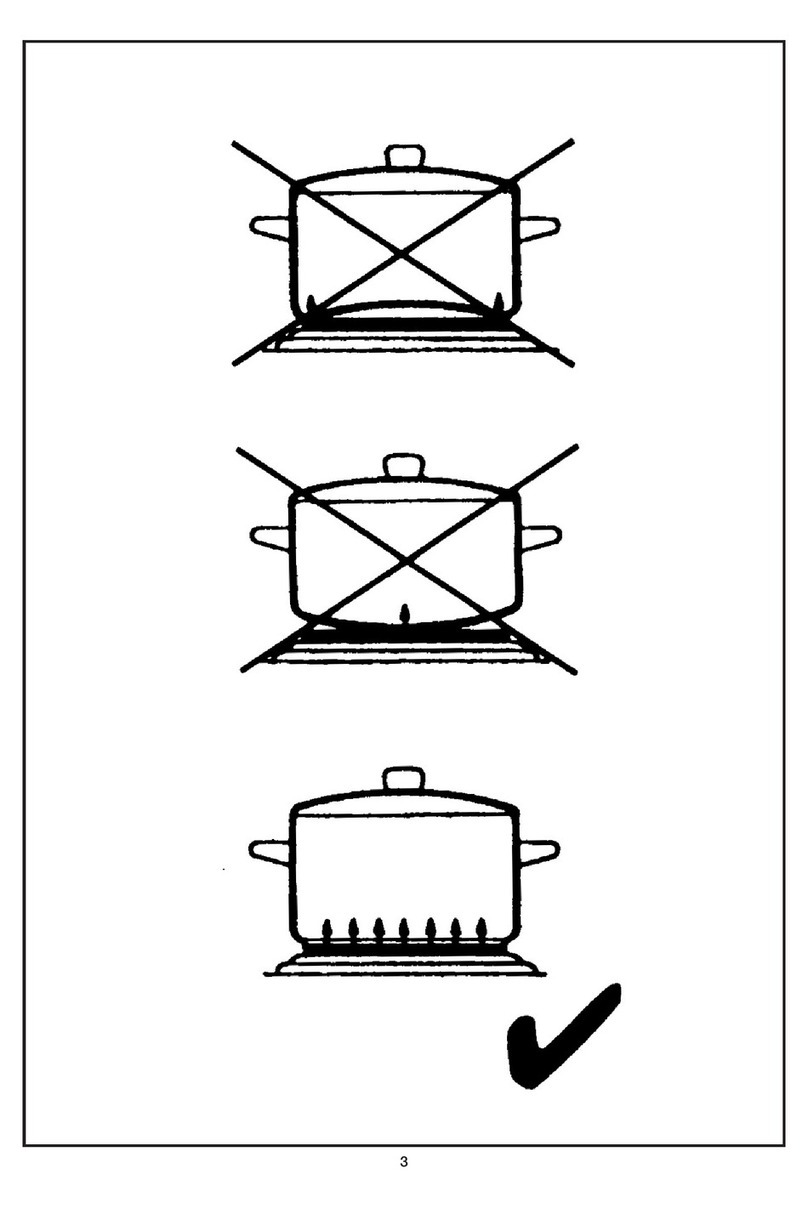

For efficient operation, it is important that good contact be established between the plate and

utensil. Ground based pots should be used and the plate surface must be clean. For maximum

efficiency, the pot diameter should be the same as that of the plate. This is not always possible but,

in the interest of fuel economy, using very small or large pots should be avoided.

Spillage should never be allowed to accumulate around the edge of a plate as this will burn on and

become difficult to remove.

Cleaning a Boiling Top

Allow the unit to cool before cleaning.

Use a detergent/water solution, take care to rinse and dry all surfaces thoroughly. Stubborn stains

may be removed with a soap-filled pad. Be careful, NEVER use a harsh abrasive on stainless steel.

SECTION 4 - SERVICING

SERVICE ACCESS

Base Plate

Upturn unit and rest it at the edge of a worksurface with rear upstand overhanging the edge.

Undo base plate fixings to remove base plate.

FUNCTIONAL COMPONENTS

Control Switch

Remove base.

Remove control knob.

Remove electrical connections, noting their positions.

Undo fixings which secure control to panel and remove.

Replace in reverse order.

Elements

Remove base plate.

Undo electrical connections, noting their positions.

Undo element fixings and remove.

Replace in reverse order.

Terminal Block

Remove base plate.

Remove electrical connections at terminal block, noting their positions.

Undo fixings which secure the block to the unit and remove.

Replace in reverse order.

Neons

Remove base plate.

Remove electrical connections at terminal block, noting their positions.

Remove and replace neon.

Replace in reverse order.

Cable

Remove base plate.

Undo mains cable cord grip at unit rear.

Undo electrical connections at terminal block and remove cable.

Replace in reverse order. Ensure cable is fed through the securing clamp and pulled taut before

tightening the clamp.

Short Spares List

735110010 Round Hotplate (1.5kW)

730960050 Round Hotplate (2kW)

735110050 Control Knob

735110030 Control Switch

730962040 Neon (Amber)

730962010 Neon (Red)

LD1 WIRING DIAGRAM

LD2 WIRING DIAGRAM

Other manuals for LD1

1

This manual suits for next models

1

Table of contents

Popular Cooktop manuals by other brands

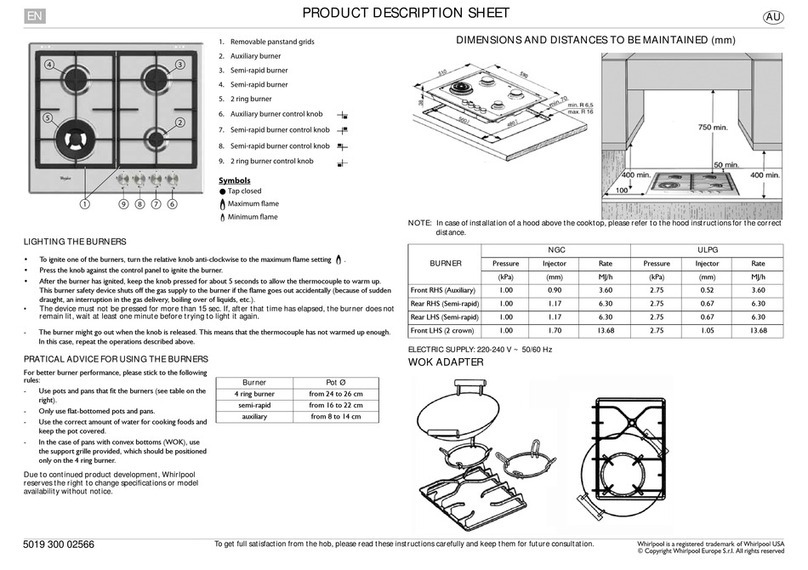

Whirlpool

Whirlpool GMF6422 Product description sheet

Wolf

Wolf CT36I/S Planning information

Thermador

Thermador Professional P24WK Care and use manual

Jenn-Air

Jenn-Air JDS9865 Use and care guide

American Range

American Range ARSCT-354GD installation manual

Electrolux

Electrolux E36GC70FSS - Icon 36 Inch Drop-In Gas... Specifications