5

EN – ENGLISH (Original instructions)

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new machine. This

manual has been prepared for the owner and operators of a PROMAC sander to promote safety

during installation, operation and maintenance procedures. Please read and understand the

information contained in these operating instructions and the accompanying documents. To obtain

maximum life and efficiency from your machine, and to use the machine safely, read this manual

thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

General safety notes

Remaining hazards

4. Machine specifications Technical data

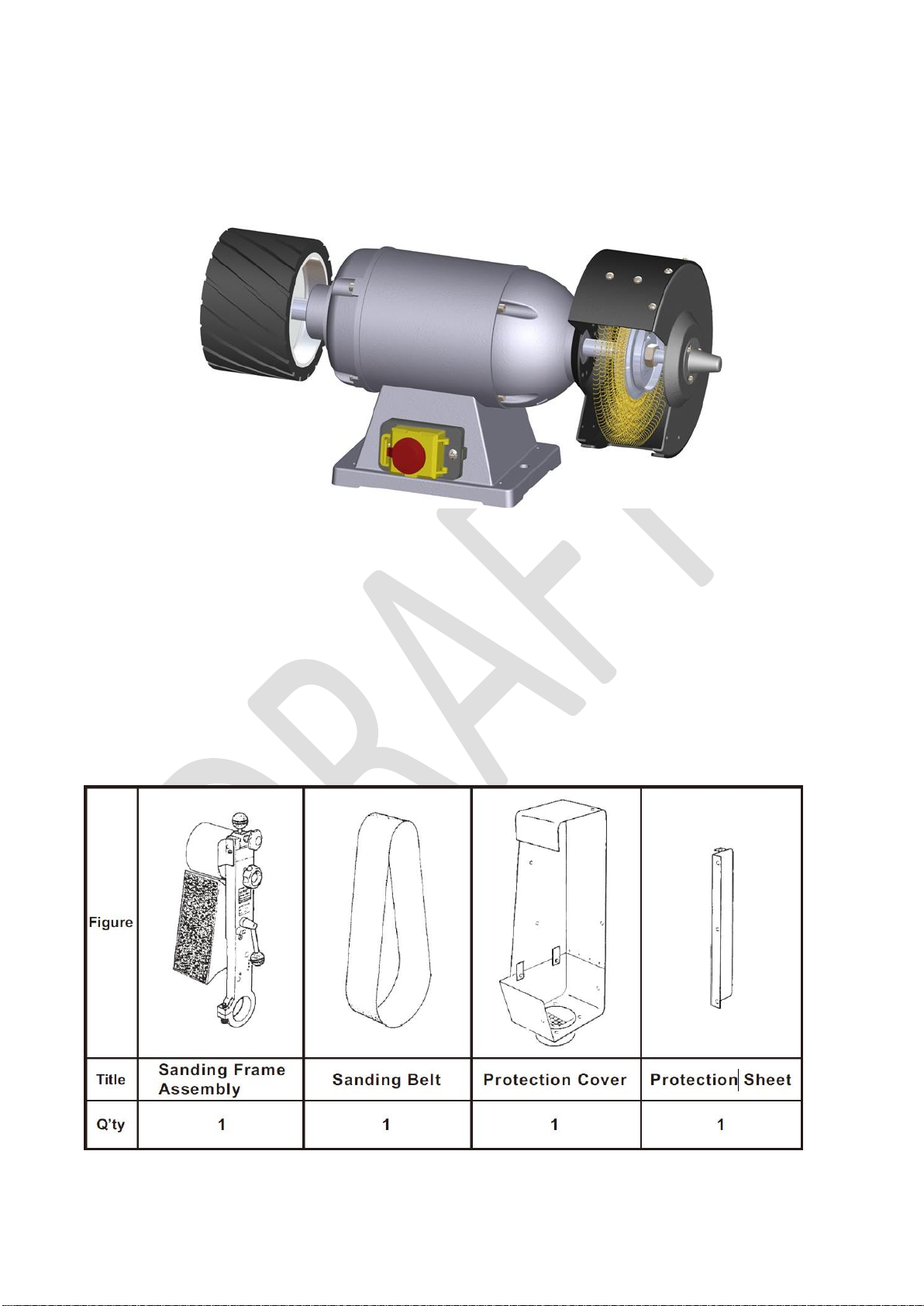

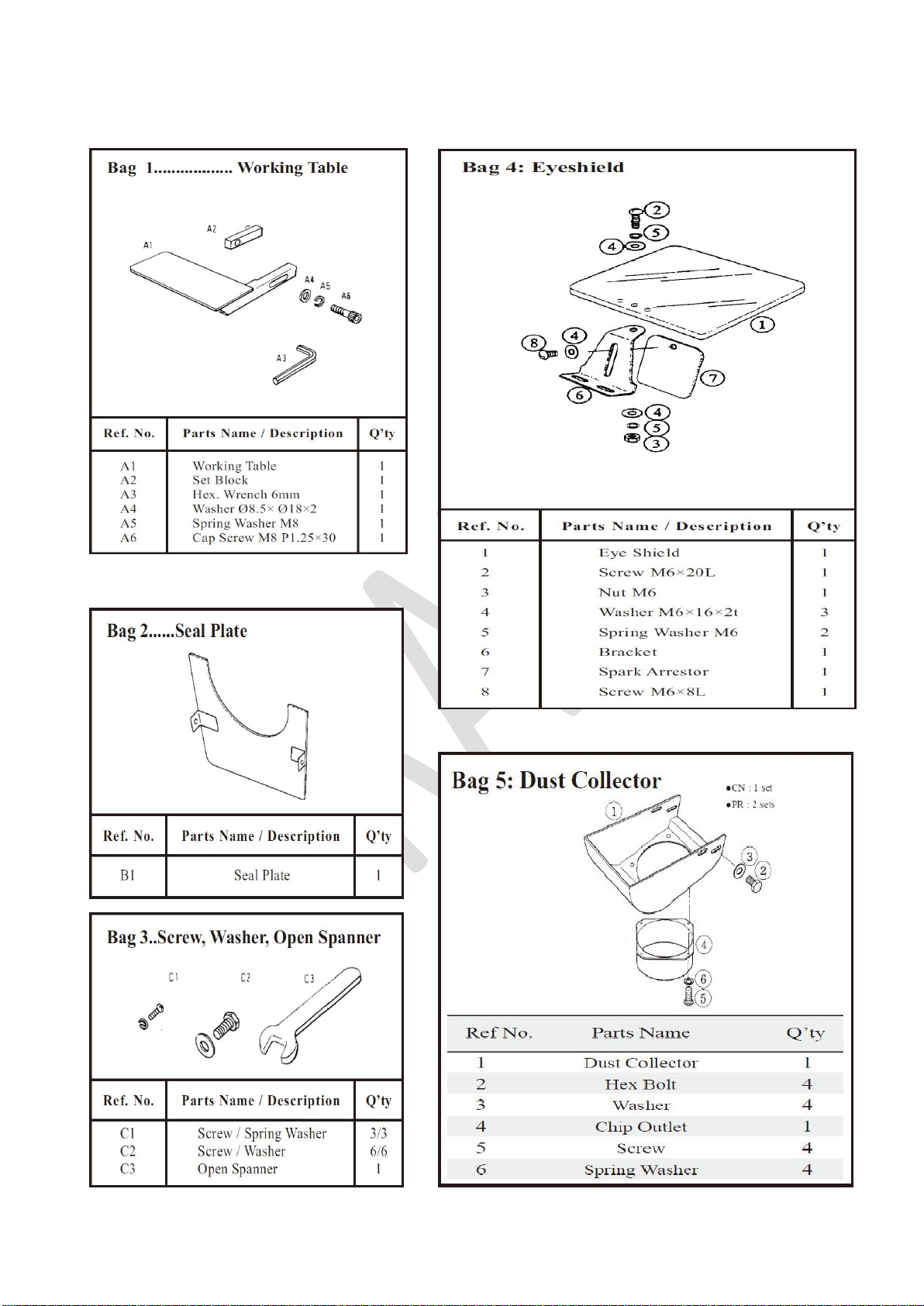

5. UNPACKING AND CHECKING LIST

6. 323BF-BP Exploded View

7. 323BF-BP Part List

1. Declaration of conformity

On our own responsibility we hereby declare that

this product complies with the regulations* listed

on page2.

Designed in consideration with the standards**.

2. Warranty

Tool France guarantees that the supplied

product is free from material defects and

manufacturing faults.

This warranty does not cover any defects which

are caused, either directly or indirectly, by

incorrect use, carelessness, accidental damage,

repair, inadequate maintenance or cleaning and

normal wear and tear.

Any warranty details (i.e. warranty period) can

be found in the General Terms and Conditions

(GTC) that are integral part of the contract.

These GTC can be viewed at the website of your

dealer or sent to you upon request.

Tool France reserves the right to make changes

to the product and accessories at any time.

3. Safety

3.1 Authorized use

This sander is designed for sander metal and a

similar sander only. Machining of other materials

is not permitted and may be carried out in

specific cases only after consulting with the

manufacturer.

The proper use also includes compliance with

the operating and maintenance instructions

given in this manual.

The machine must be operated only by person’s

familiar with its operation and maintenance and

who are familiar with its hazards.

The required minimum age must be observed.

The machine must only be used in a technically

perfect condition.

When working on the machine, all safety

mechanisms and covers must be mounted.

In addition to the safety requirements contained

in these operating instructions and your

country’s applicable regulations, you should

observe the generally recognized technical rules

concerning the operation of metalworking

machines.

Any other use exceeds authorization.

In the event of unauthorized use of the machine,

the manufacturer renounces all liability and the

responsibility is transferred exclusively to the

operator.

3.2 General safety notes

Metalworking machines can be dangerous if not

used properly. Therefore, the appropriate

general technical rules as well as the following

notes must be observed.