promesstec UDA 100 User manual

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

user manual

digital display UDA 100

version 2.1.1

2

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Content

1. General ............................................................................................................... 3

1.1 For information .............................................................................................. 3

1.2 Signs and abbreviations................................................................................ 3

2. transport, packaging and storage......................................................................... 5

2.1 transport........................................................................................................ 5

2.2 packaging...................................................................................................... 5

2.3 storage .......................................................................................................... 5

3. Safety rules......................................................................................................... 6

3.1 Intended use of the product........................................................................... 6

3.2Personnel qualification .................................................................................. 7

3.3 Special hazards............................................................................................. 7

4. Commissioning and operation............................................................................. 8

4.1 Before mounting............................................................................................ 8

4.2 Calibration and adjustment / operation in normal mode ................................ 8

5. front- and back layout........................................................................................... 9

6. Programmable LED indicator UDA 100.............................................................. 10

7. Applications........................................................................................................ 11

8. Electrical specifications...................................................................................... 12

9. Connections....................................................................................................... 18

10. Block diagram .................................................................................................... 19

11. Routing diagram................................................................................................. 21

12. Scrolling help text............................................................................................... 22

13. configuration / operating the function keys......................................................... 25

13.1 documentation for routing diagram........................................................... 25

13.2 further explanations.................................................................................. 25

13.3 Graphic depiction of the relay function setpoint........................................ 26

14. Maintenance, Dismounting, Return, Liability, Cleaning and Disposal ............... 27

14.1 Maintenance, Dismounting....................................................................... 27

14.2 Return ...................................................................................................... 27

14.3 Liability..................................................................................................... 27

14.4 Cleaning................................................................................................... 27

14.5 Disposal ................................................................................................... 28

15. Installation.......................................................................................................... 28

16. order code.......................................................................................................... 29

3

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

1. General

1.1 For information

-These operating manual provides important information on handling the

measuring element. A prerequisite for safe working is compliance with all

specified safety notes and instructions for action.

-The qualified personnel must have read and understood these operating manual

before mounting and starting up the sensor.

-These operating manual is a component part of the product. Therefore, keep

them in a place that is accessible to all users at all times, close to the place of

use.

-The local regulations and safety rules applicable to the area of application of the

sensor must be observed.

-If the serial number on the type label is no longer readable (e.g. due to

mechanical damage), traceability is no longer ensured.

-The sensors described in the user manual are developed and manufactured

according to the newest findings. All components are subject strict quality and

environmental criteria during production.

-The manufacturer shall not be liable if damage is caused by improper use,

non-observance of these operating instructions, use of insufficiently qualified

personnel and unauthorized modifications to the sensor.

1.2 Signs and abbreviations

Warning!

Non-observance can lead to injuries to persons and/or destruction of

the device. There may be danger to life.

Attention!

Non-observance can lead to incorrect operation of the device or

damage to property.

Information!

Non-observance can influence the operation of the device or cause

undesired device reactions.

Danger!

If the safety instructions are not observed, there is a risk of serious or

fatal injury from electric current.

UDA 100

4

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Warning!

A dangerous situation may possibly occur, which can lead to burns

due to hot surfaces or liquids if they are not avoided.

Warning!

This device is designed for connection to hazardous electric

voltages. Ignoring this warning can result in severe personal injury or

mechanical damage. To avoid the risk of electric shock and fire, the

safety instructions of this manual must be observed and the

guidelines followed. The specifications must not be exceeded, and

the device must only be applied as described in the following. Prior to

the commissioning of the device, this manual must be examined

carefully. Only qualified personnel (technicians) should install this

device. If the equipment is used in manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Warning!

Until the device is fixed, do not connect hazardous voltages to the

device. The following operations should only be carried out on a dis-

connected device and under ESD-safe conditions:

Troubleshooting the device.

5

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Triangle with exclamation mark: Read the manual before installation

and commissioning of the device in order to avoid incidents that could

lead to personal injury or mechanical damage. Warning / demand.

Potentially lethal situations.

The CE-Mark proves the compliance of the device with the essential

requirements of the directives.

The double insulation symbol shows that the device is protected by

double or reinforced insulation.

2. transport, packaging and storage

2.1 transport

Inspect the device for any damage that may have occurred during transport. Report

obvious damage immediately.

2.2 packaging

Do not remove the packaging until immediately before assembly. Keep the packa-

ging, because it provides optimal protection during transport (e. g. changeable in-

stallation location, return).

2.3 storage

Avoid the following influences during longer storage:

-Direct sunlight or close to hot objects

-Mechanical vibration, mechanical shock (hard set up)

-Soot, steam, dust and corrosive gases

If possible, store the device in the original packaging or appropriate packaging.

6

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

3. Safety rules

Further important safety instructions can be found in the individual

chapters.

Definitions:

Hazardous voltages have been defined as the ranges: 75 to 1500 Volt DC, and

50 to 1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also

trouble-shoot technically correct and in accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate the

knobs or potentiometers during normal operation.

Receipt and unpacking:

Unpack the device without damaging it and check whether the device type

corresponds to the one ordered. The packaging should always follow with the

device until this has been permanently mounted.

3.1 Intended use of the product

Environment:

Avoid direct sun light, dust, high temperatures, mechanical vibrations and shock, rain

and heavy moisture. If necessary, heating is excess of the stated limits for ambint

tempertures should be avoided by way of ventilation. All devices fall under installation

categor II, pollution degree 2, and insulation class II.

7

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

3.2 Personnel qualification

Risk of injury due to insufficient qualification. Improper handling can

lead to considerable personal injury and property damage.

The activities described in these operating instructions may only be

performed by qualified personnel with the following qualifications

carry out.

Keep unqualified personnel away from the hazardous areas.

For mounting and commissioning of the sensor, these persons must be familiar with

the applicable country-specific directives and standards, and have the appropriate

qualification. You must have knowledge of measurement and control technology, be

familiar with electrical circuits and be able to carry out the work described and

recognize possible hazards independently. Depending on the operating conditions,

other knowledge may also be required, e.g. about aggressive media.

3.3 Special hazards

Observe the country-specific regulations (e.g. standards) and, in the

case of special applications, observe the applicable standards and

directives (e.g. for hazardous media such as Acetylene, flammable

or toxic substances as well as refrigeration plants and compres-

sors).

If the relevant regulations are not observed, serious personal

injury and damage to property may result!

Electrostatic discharge (ESD) protection is required. Proper use of

grounded work surfaces and personal wrist straps is required when

working with open circuits (printed circuit boards) to prevent damage

to sensitive electronic components from electrostatic discharge.

There is danger to life from electric current. There is an immediate

risk of death if live parts are touched. Installation and mounting of

electrical equipment may only be carried out by qualified electricians.

When operating with a defective power supply unit (e.g. short-circuit

from mains voltage to output voltage), life-threatening voltages can

result at the device.

Residual media in devices that have been removed can be

hazardous to persons, the environment and equipment. Sufficient

safety precautions are to be taken. This device must not be used in

safety or emergency stop devices. Incorrect applications of the de-

vice can lead to injuries. In the case of a fault, aggressive media at

extreme temperatures and under high pressure or vacuum may be

present at the device.

8

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

4. Commissioning and operation

4.1 Before mounting

Check whether a complete digital display has been supplied.

Inspect the device for any transport damage that may have

occurred. If such damage is present, notify the carrier and supplier

immediately. Keep the packaging, as it provides optimum protection

during transport. Make sure that the housing and the connection

contacts are not damaged.

4.2 Calibration and adjustment / operation in normal mode

Calibration and adjustment

During calibration and adjustment, the measuring and connection of external

voltages must be carried out according to the specifications of this manual. The

technician must use tools and instruments that are safe to use.

Normal operation

Operators are only allowed to adjust and operate devices that are safely fixed in pa-

nels injury and damage. This means there is no electrical shock hazard, and the de-

vice is easily accessible.

9

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

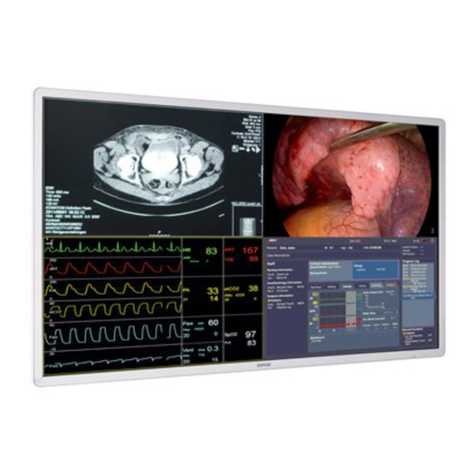

5. front- and back layout

front UDA 100:

back UDA 100:

10

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

6. Programmable LED indicator UDA 100

• 4-digit 14-segment LED indicator

• input for mA, V, potentiometer, Ohm, RTD and TC

• 2 relays and analog output

• universal voltage supply

• front key programmable

Application

•Display of digital readout of current, voltage, resistance, temperature or

potentiometer signals.

•Process control with 2 pairs of potential-free relays and / or analog output.

•For local readout in extremely wet atmospheres with a specially designed

splash-proof cover.

Technical characteristics

•4-digit LED indicator with 13,8 mm 14-segment characters. Max. display readout

-1999…9999 with programmable decimal point, relay ON / OFF indication.

•All operational parameters can be adjusted to any application by use of the front

keys.

•the UDA100 is available fully-configured acc. to specifications ready for process

control and visualisation.

•Help texts in eight languages can be selected via a menu item.

•Inputs, outputs, and supply are floating and galvanically separated.

•In versions with relay outputs the user can minimise the installation test time by

activating / deactivating each relay independently of the input signal.

Mounting

•To be mounted in front panel. The included rubber packing must be mounted

between the panel cutout hole and the display front to obtain a protection degree

of IP65. For extra protection in extreme environments, the UDA 100 can be

delivered with a speially designed splash-proof cover as accessory.

11

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

7. Applications

Input signals:

Output signals:

Supply:

12

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Order details

UDA 100-B-A = 2 relays

UDA 100-B-B = analog output and 2 relays

NB! Please order the splash-proof cover seperately.

8. Electrical specifications

Environmental conditions

Ambient operating temperature range. . . . . . . . . . . . -20°C to +60°C

Calibration temperature . . . . . . . . . . . . . . . . . . . . . . . 20°C…28°C

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< 95% RF (non-cond.)

Protection degree (mounted in panel) . . . . . . . . . . . .IP65

Mechanical specifications

Dimensions (HxWxD) . . . . . . . . . . . . . . . . . . . . . . . . .48 x 96 x 120 mm

Cutout dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . .44,5 x 91,5 mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 g

Wire size, pin 41...46 max. . . . . . . . . . . . . . . . . . . . . 0,05...1,31 mm2/ AWG

30...16 stranded wire

Wire size, other max. . . . . . . . . . . . . . . . . . . . . . . . . .0,05...3,31 mm2/ AWG

30...12 stranded wire

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IEC 60068-2-6

2...13,2 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±1 mm

13,2...100 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±0,7 g

Common specifications

Supply voltage, universal. . . . . . . . . . . . . . . . . . . . . . .21,6...253 VAC, 50...60 Hz

or 19,2...300 VDC

Type

International power dissipation

Max. required power

UDA 100-B-A

2,7 W

3,0 W

UDA 100-B-B

3,2 W

3,5 W

Isolation voltage, test /operation . . . . . . . . . . . . . . . . .2,3 kVAC / 250 VAC

Signal / noise ratio . . . . . . . . . . . . . . . . . . . . . . . . . . Min. 60 dB (0...100 kHz)

Response time (0...90%, 100...10%), programmable:

Temperature input . . . . . . . . . . . . . . . . . . . . . . . . . . . 1…60 s

Current / voltage input . . . . . . . . . . . . . . . . . . . . . . . . 0,4…60 s

Accuracy, the greater of the general and basic values:

General values

Input type

Absolute accuracy

Temperature coefficient

All

≤±0,1% of reading

≤±0,1% of reading / °C

13

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Basic values

Input type

Basic accuracy

Temperature coefficient

mA

≤ ±4 µA

≤± 0,4 µA / °C

Volt

≤ ±20 µV

≤± 2 µV / °C

Pt100

≤ ±0,2°C

≤ ± 0,01°C / °C

Linear resistance

≤ ± 0,1°Ω

≤ ± 0,01°Ω / °C

Potentiometer

≤ ± 0,1°Ω

≤ ± 0,01°Ω / °C

TC type:

E, J, K, L, N, T, U

≤± 1°C

≤ ± 0,05°C / °C

TC type: R, S,

W3, W5, LR

≤± 2°C

≤ ± 0,2°C / °C

TC type: B

85…200°C

≤ ± 4°C

≤ ± 0,4°C / °C

TC type: B

200…1820°C

≤± 2°C

≤ ± 0,2°C / °C

EMC - Immunity influence. . . . . . . . . . . . . . . . ≤ ± 0,5% of readout

Auxiliary supply:

2-wire supply, pin 46...45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25...15 VDC / 0...20 mA

TC input

Type

Min. value

Max. value

Standard

B

E

J

K

L

N

R

S

T

U

W3

W5

LR

0°C

-100°C

-100°C

-180°C

-200°C

-180°C

-50°C

-50°C

-200°C

-200°C

0°C

0°C

-200°C

+1820°C

+1000°C

+1200°C

+1372°C

+900°C

+1300°C

+1760°C

+1760°C

+400°C

+600°C

+2300°C

+2300°C

+800°C

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

IEC 60584-1

IEC 60584-1

IEC 60584-1

IEC 60584-1

DIN 43710

ASTM E988-90

ASTM E988-90

GOST 3044-84

Cold Junction compensation (CJC) via internal sensor. . . . . . . ±(2,0°C + 0,4°C * Δt)

Δt = Internal temperature –ambient temperature

14

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Sensor error detection, all TC types . . . . . . . . . . . . . . . . . . . . . Yes < ±1,0 °C

Sensor error current:

when detecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 2 μA

else. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 μA

RTD, linear resistance and potentiometer input

Input type

Min. value

Max. value

Standard

PT10…PT1000

Ni50…Ni1000

Cu10…Cu100

Lin. R

Potentiometer

-200°C

-60°C

-200°C

0 Ω

10 Ω

+850°C

+250°C

+260°C

10000 Ω

100 kΩ

IEC 60751

DIN 43760

= 0,00427

-

-

input for RTD types:

Pt10, Pt20, Pt50, Pt100, Pt200, PT250, Pt300, Pt400, Pt500, Pt1000

Ni50, Ni100, Ni120, Ni1000, Cu10, Cu20, Cu50, Cu100

Cable resistance pr. wire, RTD (max.) . . . . . . . . . . . . . . . .50 Ω

Sensor current, RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 0,2 mA

Effect of sensor cable resistance (3- / 4-wire), RTD . . . . . < 0,002 Ω / Ω

Sensor error detection, RTD . . . . . . . . . . . . . . . . . . . . . . . Ja

Short curcuit detection, RTD. . . . . . . . . . . . . . . . . . . . . . . < 15 Ω

Current input

Measurment range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0...23 mA

Programmable measurment ranges. . . . . . . . . . . . . . . . . . 0...20 and 4...20 mA

Input resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 20 Ω + PTC 25 Ω

Sensor error detection:

loop break 4...20 mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . Yes

Voltage input:

Measurment range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0...12 VDC

Programmable measurment ranges. . . . . . . . . . . . . . . . . .0...1 / 0,2...1 / 0...10 /

2...10 VDC

Input resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nom. 10 MΩ

Outputs

Display

Display readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -1999...9999 (4 digits)

Decimal point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Programmable

Digit height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13,8 mm

Display updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,2 times / s

Input outside input range is indicated by . . . . . . . . . . . . . .Explanatory text

15

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Current output

Signal range (span). . . . . . . . . . . . . . . . . . . . . . . . 0...23 mA

Programmable signal ranges . . . . . . . . . . . . . . . . 0...20 / 4...20 / 20...0 /20...4 mA

Load (max.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 800 Ω

Load stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 0,01% of span / 100 Ω

Sensor error detection . . . . . . . . . . . . . . . . . . . . . 0 / 3,5 / 23 mA / none

NAMUR NE 43 up / downscale . . . . . . . . . . . . . . 23 mA / 3,5 mA

Output limitation:

On 4…20 and 20…4mA signals. . . . . . . . . . . . . . 3,8…20,5mA

On 0…20 and 20…0mA signals. . . . . . . . . . . . . . 0…20,5mA

Current limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .≤ 28 mA

Relay outputs

Relay function. . . . . . . . . . . . . . . . . . . . . . . . . . . . Setpoint

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0...100%

On and Off delay. . . . . . . . . . . . . . . . . . . . . . . . . . 0...3600 s

Sensor error detection. . . . . . . . . . . . . . . . . . . . . .Make / Break / Hold

Max. voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 VAC / VDC

Max. AC current. . . . . . . . . . . . . . . . . . . . . . . . . . 2 A

Max. AC power. . . . . . . . . . . . . . . . . . . . . . . . . . . 500 VA

Max. DC current, resistive load:

@ URelay ≤ 30 VDC . . . . . . . . . . . . . . . . . . . . . . . . 2 ADC

@ URelay > 30 VDC . . . . . . . . . . . . . . . . . . . . . . . .[1380 x U-2Relay x 1,0085URelay] ADC

Graphic depiction of [1380 x U-2Relay x 1,0085URelay]:

16

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Sensor error detection / Sensor error detection outside range

Sensor error check in UDA 100 variants

Variant

Configuration

Sensor error detection

UDA 100-B-A

ERR1=NONE, ERR2=NONE:

OFF

else:

ON

UDA 100-B-B

ERR1=NONE, ERR2=NONE,

O.ERR=NONE:

OFF

else:

ON

Outside range readout (IN.LO, IN.HI):

If the valid range of the A/D converter or the polynomial is exceeded.

Input

Range

Readout

Limit

VOLT

0...1 V / 0,2...1 V

IN.LO

< -25 mV

IN.HI

> 1,2 V

0...10 V / 2...10 V

IN.LO

< -25 mV

IN.HI

> 12 V

CURR

0...20 mA / 4...20 mA

IN.LO

< -1,05 mA

IN.HI

> 25,05 mA

POTM

-

IN.LO

< -0,5%

IN.HI

> 100,5%

TEMP

TC / RTD

IN.LO

< temperature range -2°C

IN.HI

> temperature range +2°C

LIN. R

0...800 ohm

IN.LO

< 0 ohm

IN.HI

> 1 kohm

0...10 kohm

IN.LO

< 0 ohm

IN.HI

> 15 kohm

Sensor error detection (SE.BR, SE.SH)

Input

Range

Readout

Limit

CURR

Loop break (4...20 mA)

SE.BR

<= 3,6 mA; > = 21 mA

TEMP

TC

SE.BR

> ca. 750 kohm / (1,25 V)

RTD, 2-, 3- & 4-wire, No SE.SH for

Cuxx, Pt10, Pt20 and Pt50

SE.BR

> 12 kohm

SE.SH

< 15 ohm

LIN. R

0...800 ohm

SE.BR

> 875 ohm

0...10 kohm

SE.BR

> 12 kohm

17

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Display readout below min. / above max. (-1.9.9.9, 9.9.9.9)

Input

Range

Readout

Limit

CURR

VOLT

All

-1.9.9.9

Display readout <-1999

9.9.9.9

Display readout > 9999

LIN. R

All

-1.9.9.9

Display readout <-1999

9.9.9.9

Display readout > 9999

POTM

-

-1.9.9.9

Display readout <-1999

9.9.9.9

Display readout > 9999

Readout at hardware error

Error search

Readout

Cause

Text of Internal communication µC / ADC

HW.ER

Permanent error in ADC

Test of internal CJC sensor

CJ.ER

CJC sensor defect

Checksum test of the configuration in RAM

RA.ER

Error in RAM

Checksum test of the configuration in the EEPROM

EE.ER

Error in EEPROM

! Error Indications in the display blink once a second. The help text explains the error.

18

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

9. Connections

Inputs:

outputs:

Supply:

19

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

10. Block diagram

20

promesstec GmbH I Niedersachsenstraße 4 I D- 48465 Schüttorf I Tel.:+49 (0)5923/ 90 229 0 I Fax:+49 (0)5923/ 90 229 29

E-Mail: office@promesstec.com I Internet: www.promesstec.com

Table of contents

Other promesstec Monitor manuals