Table of contents

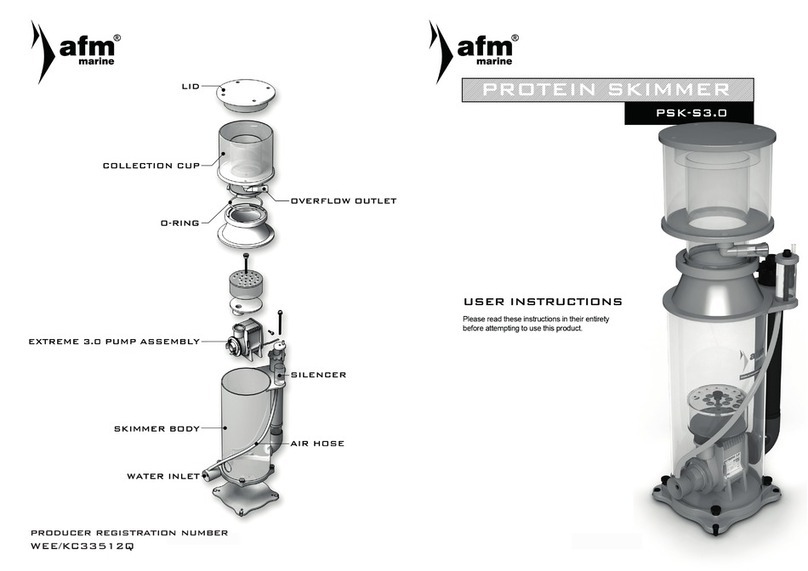

1About this product................................................................. 5

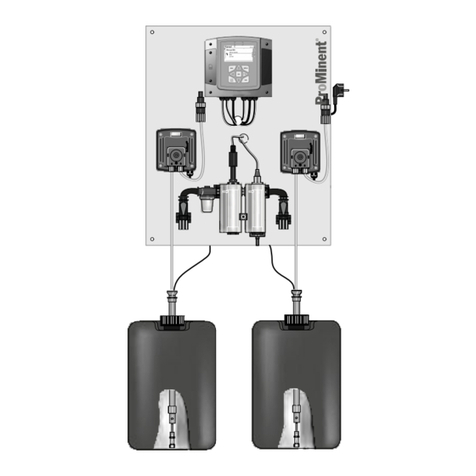

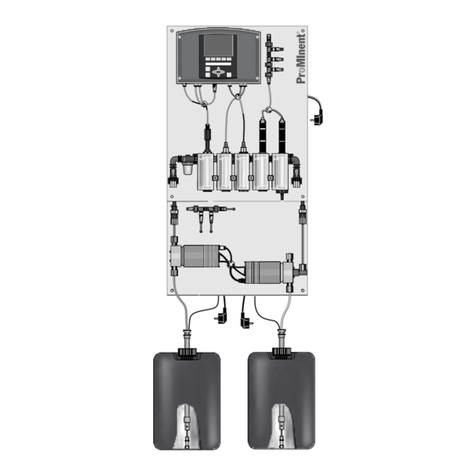

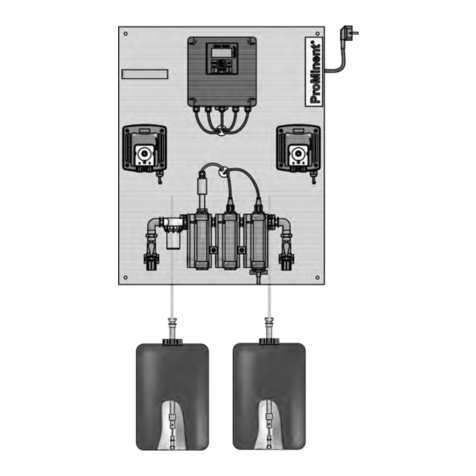

1.1 Overview of equipment................................................. 6

1.1.1 Control elements........................................................ 7

2 Identity code.......................................................................... 8

3Safety and responsibility..................................................... 10

3.1 User qualification........................................................ 10

3.2 Labelling of Warning Information................................ 11

3.3 General safety information.......................................... 12

3.4 Intended use............................................................... 13

4 Storage and transport......................................................... 14

5 Assembly............................................................................ 15

5.1 Scope of delivery........................................................ 15

5.2 Wall-mounted.............................................................. 15

5.3 Construction of the bypass fitting................................ 16

5.4 Hydraulic installation................................................... 18

5.4.1 Metering system...................................................... 20

5.4.2 Testing the hydraulic installation of the metering

system..................................................................... 21

5.4.3 Check the system for negative pressure................. 21

5.4.4 Assembly of the vent valve (optional)...................... 21

5.4.5 Installation of the sensors to determine the water

quality...................................................................... 22

5.5 Electrical installation................................................... 23

5.5.1 Cable Cross-Sections and Cable End Sleeves....... 24

5.5.2 Connecting the terminals......................................... 24

5.5.3 Installation (electrical).............................................. 24

5.6 Connecting sensors.................................................... 25

5.7 Potential-free switch connector, e.g. remote control... 25

5.8 Powered relay connector............................................ 27

5.9 Terminal diagram........................................................ 28

5.10 Cable Cross-Sections and Cable End Sleeves........ 29

5.11 Electrical fuses.......................................................... 29

5.12 Assembly of the potential equalisation and earthing

connector (optional accessories).............................. 29

5.12.1 Mounting kit........................................................... 29

5.12.2 Assembly of the potential equalisation.................. 30

5.12.3 Assembly of the earthing cable.............................. 30

6 Start up............................................................................... 31

6.1 Adjusting the setpoint for pH....................................... 32

6.2 Adjusting the setpoint for ORP................................... 32

6.3 Adjusting the flow sensor switching point................... 32

7 Replacing the chemical storage tanks................................ 33

8 Operation and user interface.............................................. 34

8.1 Settings in the header................................................. 34

8.1.1 Setting the date and time......................................... 35

8.2 Displaying the details of a measuring channel........... 35

8.3 Measuring channel settings........................................ 37

8.4 Digit input screen........................................................ 38

8.5 Programming screen.................................................. 38

Table of contents

3