Table of contents

1Identity code.......................................................................... 5

2 About This Product............................................................... 7

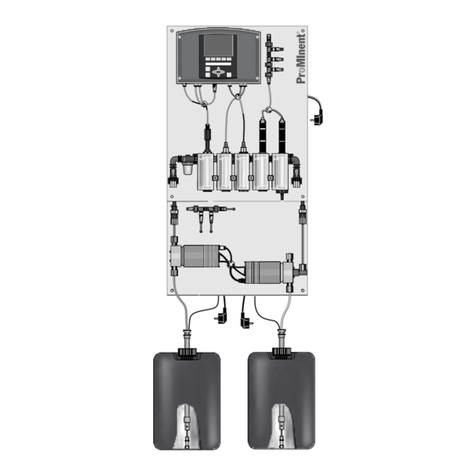

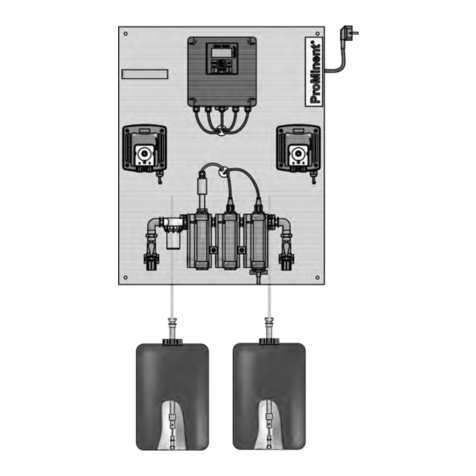

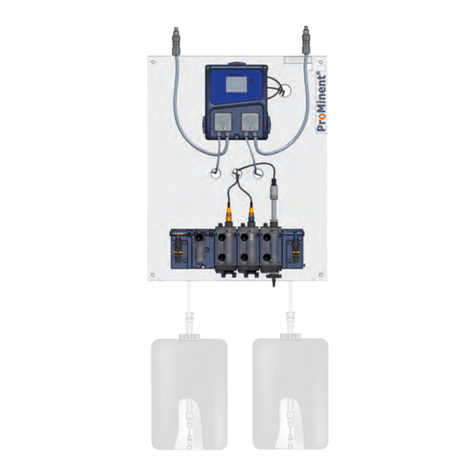

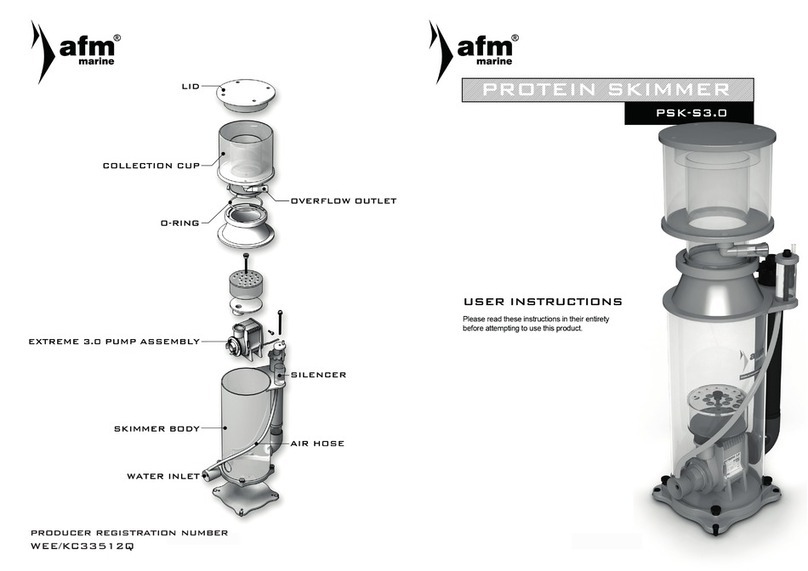

2.1 Overview of Equipment................................................. 7

3 Safety and Responsibility...................................................... 9

3.1 Users' qualifications...................................................... 9

3.2 Explanation of the safety information.......................... 10

3.3 General Safety Information......................................... 11

3.4 Intended Use.............................................................. 13

4 Operating Concept.............................................................. 14

4.1 Functions of the keys ................................................. 16

4.2 Changes the set operating language.......................... 17

4.3 Acknowledge fault or warning message .................... 17

4.4 Key Lock .................................................................... 18

5 Storage and transport......................................................... 19

6Assembly............................................................................ 20

6.1 Wall-mounting............................................................. 20

6.2 Fit the antikink device for the bleed line...................... 21

6.3 Hydraulic Installation................................................... 22

6.3.1 Metering system...................................................... 23

6.3.2 Sensors.................................................................... 26

6.4 Electrical Installation................................................... 27

6.4.1 Connect power supply............................................. 27

6.4.2 Install external signal inputs and signal outputs...... 27

6.4.3 Electrical Installation of the Sensors........................ 28

6.4.4 Cable Cross-Sections and Cable End Sleeves....... 28

7 Start Up............................................................................... 29

7.1 Priming and bleeding (with an alpha or Beta pump)... 30

7.2 Adjust the flow sensor switching point........................ 30

7.3 Calibration................................................................... 31

7.3.1 Calibration................................................................ 32

8

[Diagnostics]

....................................................................... 45

8.1 Displaying

[logbooks]

.................................................. 45

8.1.1 Displaying the

[Calibration Log Book]

...................... 45

8.1.2 Reading the

[Error Log Book]

.................................. 46

8.2 Displaying

[simulation]

................................................ 46

8.3 Displaying

[Device Information]

.................................. 47

8.4 Error messages and warning alerts............................ 47

8.5 Help texts.................................................................... 52

9 Maintenance Work.............................................................. 53

9.1 Replacing the chemical storage tanks........................ 54

9.2 Troubleshooting.......................................................... 55

9.3 Disposal of Used Parts............................................... 55

10 Technical Data.................................................................... 56

10.1 Wiring Diagram......................................................... 57

10.2 Drawings, Drilling and External Dimensions of the

DULCODOS®............................................................ 59

11 Spare Parts and Accessories.............................................. 62

Table of contents

3