PROMIX RDS.01 User manual

16-07-2019

1

OPERATING MANUAL

Technical description. Installation manual. Certificate.

ПШБА.464415.101 РЭ

Check the completeness of the product upon purchase! The manufacturer will

not accept any further claims for completeness.

1.

PURPOSE

Remote control system Promix-RDS is designed for radio remote control of various actuators

(electromagnetic, electromechanical locks, latches; turnstiles, etc.).

The system includes: actuator, power supply unit, receiver, controller unit, remote controls. The

power supply unit, receiver, and controller unit are designed as a single unit (controller

Promix-

CR.RX.03, hereinafter – the controller). The receiver of the controller receives control signals of

remote controls

Promix-CR.TX.01. The power supply unit of the controller is used to control the

connected actuators.

2.

DELIVERY SET

Controller Promix-CR.RX.03 1 pc.

Remote control Promix-CR.TX.01 with a battery 2 pcs.

Operating manual 1 pc.

3.

CLIMATIC OPERATING CONDITIONS OF THE

CONTROLLER

•

resistance to climatic factors according to GOST15150-69:УХЛ4;

•

ambient air temperature: from -30 to +50 °С;

•

relative air humidity not more than 80% at +25 °С and lower temperatures without

condensation and frost formation.

REMOTE CONTROL SYSTEM

Promix-RDS.01

Promix-RDS.01

2

4.

TECHNICAL DATA

4.1 TECHNICAL DATA OF THE POWER SUPPLY UNIT

The power supply unit of the controller powers the receiver, controller unit, and actuator. The

power supply unit is a pulse type, with galvanic isolation of primary and secondary circuits. The

power supply unit has a built-in overcurrent and short-circuit protection for the load circuit.

Supply voltage (50 Hz), V 180-230

Output voltage (direct current), V 12

Rated output current, A

1.0

Maximum output current during 1 minute, А, not more than

1.5

Maximum load current (tripping current), A, not more than

2.0

4.2 TECHNICAL DATA OF THE CONTROLLER UNIT

The controller unit is designed on the same board as the receiver. The controller unit performs

the following functions:

•

programming of remote controls and control time of the actuator;

•

applying or removing supply voltage to/from the actuator for a specified time on the signals

of the programmed remote controls;

•

disconnecting the actuator from the power supply unit (protection) when the current

consumption by the actuator exceeds the preset level;

•

audible signaling of the controller current operations.

Supply voltage (direct current), V 12

Current consumption, mA 5

Protection tripping current (disconnection of the actuator), A

2.0

Memory capacity of the remote controls, pcs.

7

Range of programmed open lock time, s

1-15

4.3 TECHNICAL DATA OF THE RECEIVER

Supply voltage (direct current), V 12

Current consumption, mA 2

Operating frequency, MHz

433.92

Sensitivity, µV

7

Reception range of signals from the remote control Promix-CR.TX.01 (in

direct visibility and absence of interference), m, not less than

30

Promix-RDS.01

3

Since the controller can stay in this mode for an indefinite time, make sure that

actuator connected to the controller can be supplied with power for a long

time.

4.4 TECHNICAL DATA OF THE REMOTE CONTROL

PROMIX-CR.TX.01

Output power, мW, not more than 10

The length of the code, byte 4

Number of code combinations

16777216

Battery supply voltage (type 23А), V

12

Current consumption with pressed button, мА, not more than

5

5.

DESIGN AND PRINCIPLE OF OPERATION

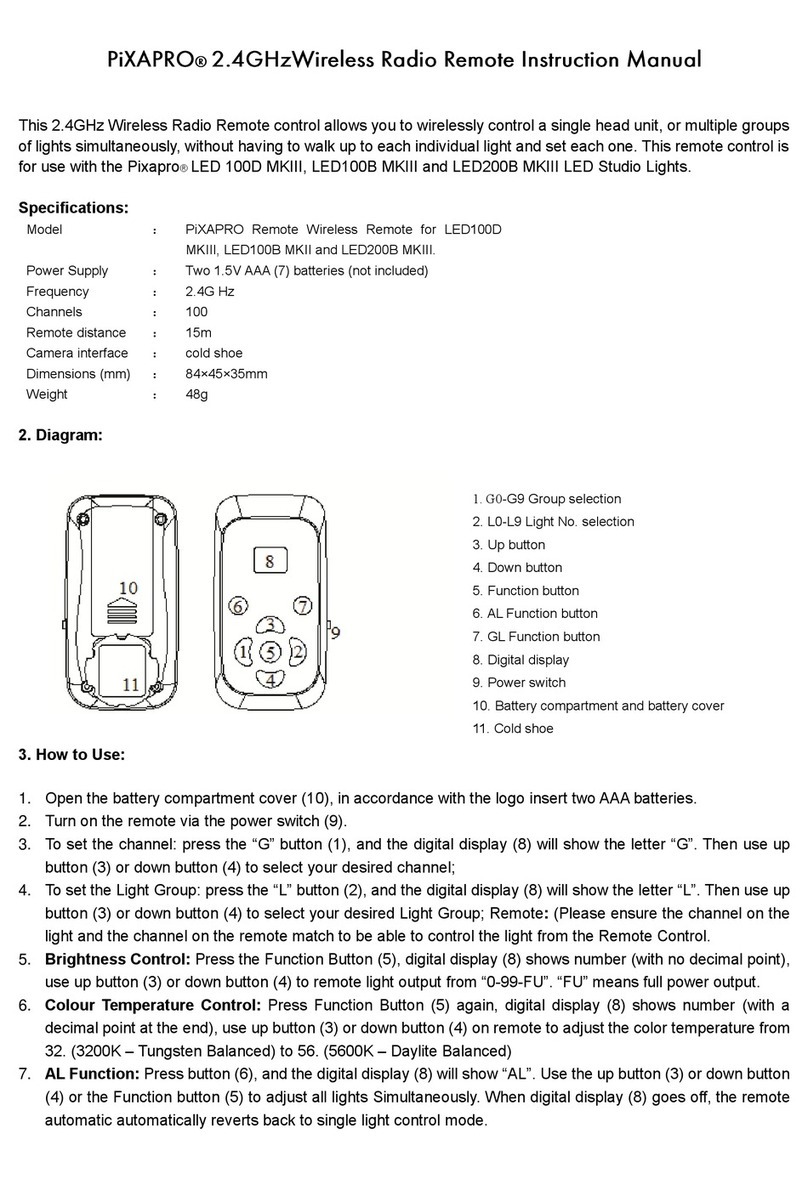

The controller Promix-CR.RX.03 contains: a connector for connection of the actuator, a mode

jumper J1, a power cord for connection to 220V power grid (1.4 m long), an antenna wire. The

overall dimensions of the controller Promix-CR.RX.03: 111x58x50 mm (LxWxH).

When pressing the control button on the remote control Promix-CR.TX.01, it sends a unique

code via a radio channel. The controller Promix-CR.RX.03 receives the sent code and, if this code

is recorded in the controller memory (see Section 7), activates its output contact for the

programmed time (the supply voltage is applied to or removed from the actuator), what is

accompanied by a continuous beep signal.

If the current in the circuit of the actuator exceeds the value of the tripping current, the power

supply will switch off. It can be restored by reconnecting the controller to the power grid. The state

of the controller after the current protection trips is indicated by short intermittent sound signals.

When holding down the remote control button for more than 7 seconds, the controller switches

into the permanently open actuator mode. The controller emits a short trill and then produces

single beeps. To close the actuator, press the remote control button. The controller will close the

actuator and emit a beep signal.

Promix-RDS.01

4

Avoid applying excessive supply voltage. Ensure reliable electrical contact.

Insulate connections to prevent short circuits.

6.

CONNECTION

Connect the actuator to the controller terminals, observing the polarity of the supply voltage: the

left terminal is positive, and the right one is negative. To do so, press the orange lever of the

terminal block with a screwdriver and, holding it pressed, insert the wire into the hole. To

disconnect the wire, perform the same procedure.

Connect the controller to 220V power grid.

Jumper J1 (see Fig. 1 in Section 5) on the side wall of the controller is to change its operating

modes:

Position 1 or 2

– control of normally open or normally closed actuator;

A normally open actuator is in the open state when there is no supply voltage and in the closed

state when the supply voltage is applied.

A normally closed actuator is in the closed state when there is no supply voltage and in the

open state when supply voltage is applied.

Position 3

– programming of the controller.

7.

PROGRAMMING THE CONTROLLER

The supplied remote controls are already recorded in the controller memory. The factory

setting of the controller parameters: control time is 5 seconds, control of the normally closed

actuator.

There are two ways of programming the controller: remote - carried out with the master remote

control Promix-CR.TX.01 M (supplied separately), non-remote - carried out by placing the jumper

J1 to position

3

.

Non-remote programming:

1. Place the jumper J1 to position

3

(see the figure in Section 5).

2. Connect the power cord to the power grid.

3. After a trill and then single beeps, proceed to programming

Fig.1. Diagramof the controller connection

Promix-RDS.01

5

After entering the programming mode all the previously recorded remote

controls will be deleted from the controller memory. The programmed time of

the open lock time remains saved.

While the controller is in the programming mode, the lock is turned off.

To avoid accidental reprogramming of the controller and deleting of the

database of programmed remote controls, make sure you move the jumper J1

from position 3 to position 1 or 2 after programming is complete.

4. Press the remote control button, wait for a sound signal, confirming recording of the remote

control number into the controller memory.

5. Program next remote control by repeating step 4. When 7 remote controls are recorded you

will hear a trill. If fewer remote controls are to be programmed, wait until the end of single

beeps and confirmation of the end of remote controls programming.

6. Wait for 5 seconds. In 5 seconds the controller switches into the actuator control time

programming mode what is confirmed by two beeps. Then the controller emits double short

beeps, during which the programming is carried out.

7. Pressing the button of the programmed remote control increases the open lock time by 1

second. The set time (in seconds) corresponds to the number of beeps.

8. If no action is performed during 5 seconds, the controller switches from the programming

mode into the operating mode, confirming it with three beeps.

9. Determine the type of the connected actuator (normally open or normally closed) (see

Section 6).

Remote programming:

1. Connect the power cord to the power grid.

2. Press the button of the master remote control Promix-CR.TX.01 M (supplied separately)

within 5 seconds.

3. After a trill and then single beep sounds, proceed to programming according to the

aforementioned algorithm, starting from step 4.

8.

FUNCTIONAL CHECK USING THE EXAMPLE

OF ELECTRICALLY-CONTROLLED LOCK

Connect the controller to 220V power grid and close the door with an installed electrically-

controlled lock.

1. Try to open the door. It should not open.

2. Press the button of the remote control Promix-CR.TX.01 programmed in the controller, after

a beep sound the lock will be open for the programmed time. The door should open. After

the beep ends, the lock will be closed again.

Promix-RDS.01

6

9.

MAINTENANCE

The controller: special maintenance is not required.

The remote control: if the LED does not light up or glows dimly it is necessary to replace the

battery of the remote control. To replace the battery, unscrew the screw on the back of the remote

control and disassemble the body.

10.

REQUIREMENTS OF SAFETY AND

ENVIRONMENTAL ENGINEERING

Promix-RDS set meets the safety requirements as per GOST R IEC 60065-2009.

Installation and operation of the controller Promix-CR.RX.03 must meet the safety

requirements as per GOST 12.2.003-91.

The controller Promix-CR.RX.02 meets the fire safety requirements as per GOST 12.1.004-91.

Promix-RDS.01 set is not hazardous for life and health of people and for environment. After the

expiration of the service life, the set can be disposed of without any special environmental

protection measures.

10.1 ELECTRICAL SAFETY REQUIREMENTS

Due to low supply voltage the remote control Promix-CR.TX.01 is electrically safe.

Electrical safety requirements for the controllers Promix-CR.RX.02 meet the requirements of

protection against electric shock according to class II as per GOST R IEC 60065-2009.

The insulation strength between the current-carrying circuits of the mains supply and the

secondary circuits with a low-voltage complete device must withstand an AC voltage of 3750V of

practically sinusoidal form with a frequency of 50±1 Hz. The electrical insulation resistance

between the current-carrying circuits of the mains supply and the secondary circuits, depending on

the climatic operating conditions, must be at least of the following values:

- with a low-voltage complete device - 10 MOhm;

- at the highest value of temperature - 4 MOhm;

- at the highest value of relative humidity (98% at 25°С) - 1 MOhm.

The residual voltage between the pole contacts of the power cord must not exceed 31V one

second after disconnecting from the power grid.

In the controller Promix-CR.RX.02 there are no circuits that lead to leakage currents.

11.

STORAGE AND TRANSPORTATION

Prior to putting into operation, the products must be stored in the manufacturer’s packing, in

rooms with ambient air temperature of -30 to +50 °С and relative humidity not higher than 98% at

25 °С according to the storage conditions as per GOST 15150-69.

The products transportation conditions must comply with group C under GOST 23216-78 in

terms of exposure to mechanical factors, and Ж2 under GOST 15150-69 in terms of exposure to

climatic factors.

Promix-RDS.01

7

The warranted operation period of the products is 12 months from the date of

sale but not longer than 18 months from the day of acceptance by the

manufacturer’s QCD.

The warranty does not cover the batteries included in the set.

Faulty products are accepted for repair only complete, with the compulsory

preservation of the factory labels on the body of the products.

To improve the quality of the product, the manufacturer reserves the right to

make changes in the design of products without prior notice.

12.

WARRANTY LIABILITIES

The manufacturer, ETC PROMIX LLC, warrants conformity of the products to requirements of

current technical specifications provided that the transportation, storage, installation and operation

rules established in this Manual are followed.

Within the period of warranty, ETC PROMIX LLC undertakes to eliminate defects of the system

components, caused by the Manufacturer's fault, or to replace defective components and units

free of charge. Costs of delivery to and from the place of repair shall be borne by the Buyer.

Warranty liabilities do not cover any defects and damages caused by:

•

Improper maintenance by the Buyer;

•

Use of the products under conditions that do not comply with the operation requirements;

•

Mechanical damages or disassembly of the products by the Buyer;

•

Non-observance of the transportation and storage rules.

After the expiration of the warranty service period, the manufacturer provides post-warranty

service of the product on a contractual basis.

13.

ACCEPTANCE AND PACKING CERTIFICATE

The remote control system

PROMIX-RDS.01

in quantity of ___ pieces (1 peace by default) bearing the

manufacturing date and QCD mark on the body is manufactured and accepted according to

ПШБА.464415.101 ТУ, meets the obligatory requirements of state standards and current technical

documentation, is recognized fit for operation and packed by ETC PROMIX LLC.

Engineering and Technical Center PROMIX LLC

Russia, 214030, Smolensk, Krasninskoye shosse, 35, letter A

Tel. (4812) 619-330

www.promix-center.com

www.facebook.com/Promixcenter

mail@promix-center.com

This manual suits for next models

2

Table of contents