Contents

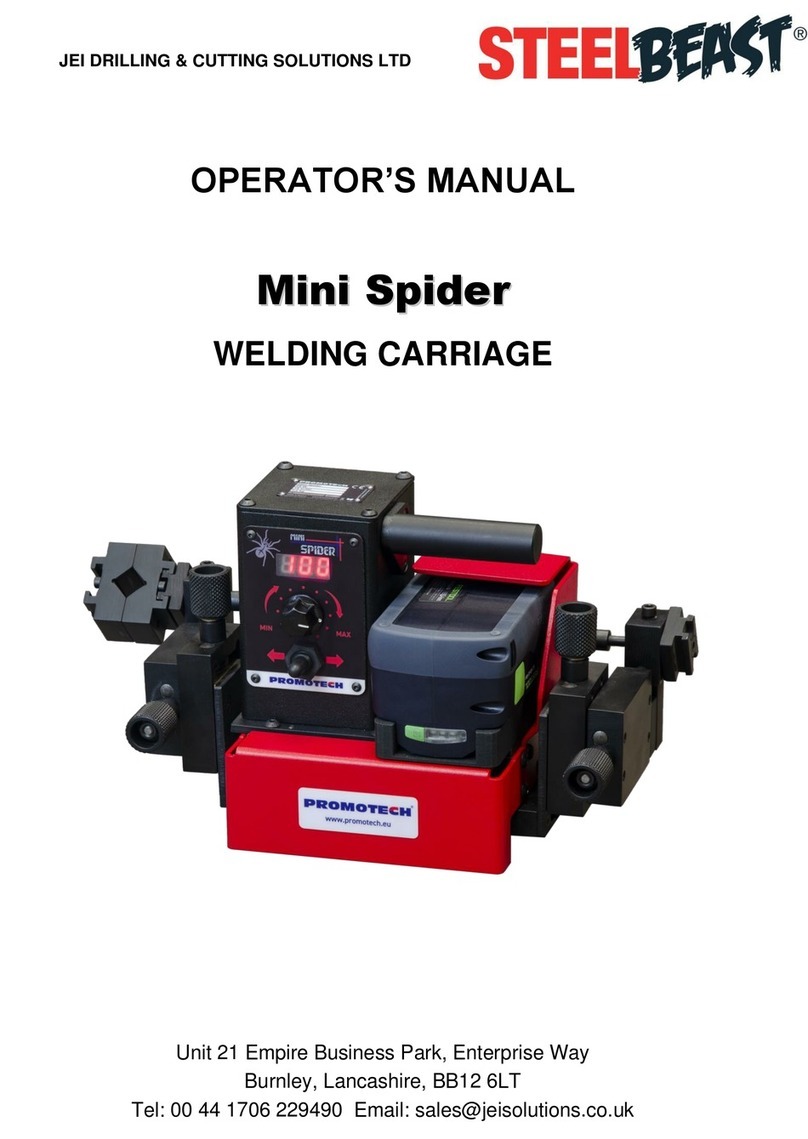

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Design ....................................................................................................................... 5

1.4. Equipment included ................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Preparing................................................................................................................... 9

3.2. Connecting to welding circuits...................................................................................10

3.3. Positioning at the worksite ........................................................................................11

3.4. Starting .....................................................................................................................12

3.5. Programming ............................................................................................................12

3.6. Welding procedure....................................................................................................14

3.7. Operating..................................................................................................................15

3.8. Using oscillator (accessory) ......................................................................................16

3.8.1. Installing..........................................................................................................16

3.8.2. Welding with oscillation...................................................................................17

3.8.3. Operating........................................................................................................18

3.9. Troubleshooting........................................................................................................19

4. MAINTENANCE...............................................................................................................20

5. ACCESSORIES...............................................................................................................21

5.1. Oscillator...................................................................................................................21

5.2. 16–22 mm torch clamp..............................................................................................23

5.3. 16–22 mm torch clip..................................................................................................23

5.4. 22–35 mm torch clamp..............................................................................................23

5.5. Short rod...................................................................................................................24

5.6. Long rod....................................................................................................................24

5.7. Short rod torch holder with clamp..............................................................................24

5.8. Short rod torch holder with clip..................................................................................25

5.9. Short rod low torch holder with clip............................................................................25

5.10. Long rod torch holder with clamp ............................................................................25

5.11. Long rod torch holder with clip.................................................................................26

5.12. Torch extension arm ...............................................................................................26

5.13. Edge following guide arms......................................................................................27

5.14. Adjustable guide arms.............................................................................................28

5.15. Magnet guide arms .................................................................................................29

5.16. Dual torch mount.....................................................................................................32

5.17. Guiding set..............................................................................................................33

5.18. Guide adjustment tool .............................................................................................35

5.19. 76 mm cross slide...................................................................................................36

6. WIRING DIAGRAM..........................................................................................................37

7. DECLARATION OF CONFORMITY.................................................................................38

8. QUALITY CERTIFICATE..................................................................................................39

9. WARRANTY CARD..........................................................................................................40