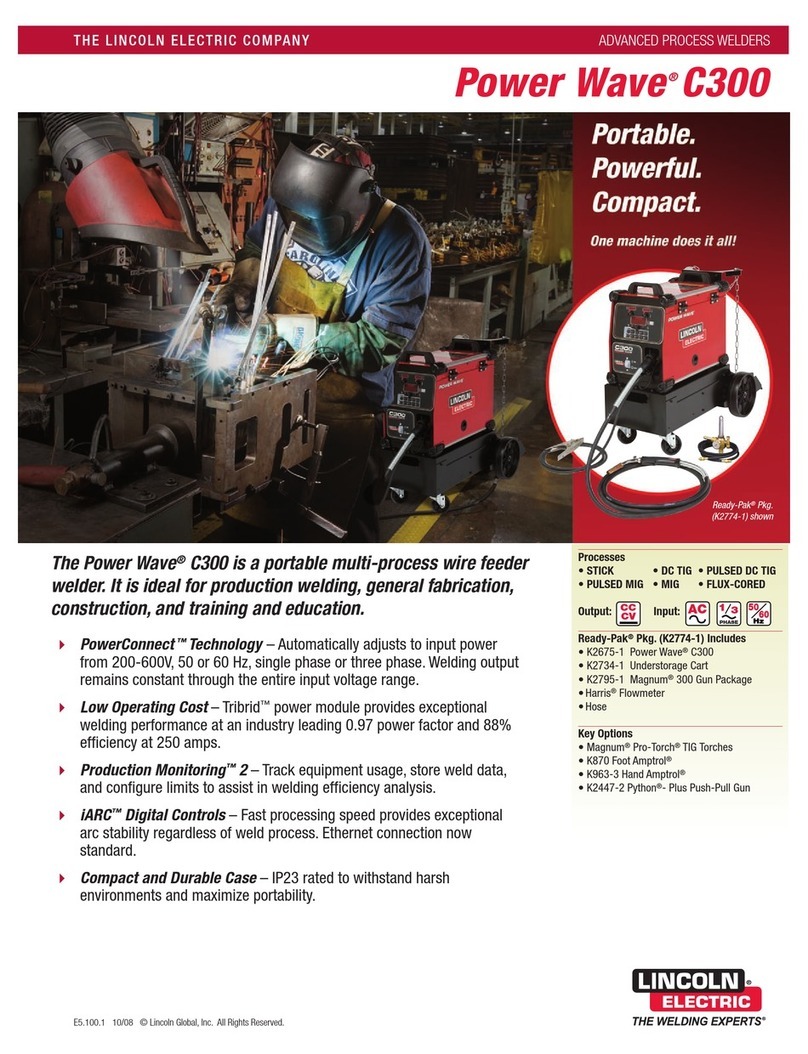

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

RECOMMENDED OPTIONS

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company®is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of

our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to

inquiries to the best of their ability based on information provided to them by the customers and the knowledge they may have concerning the application. Our employees, however, are not

in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume

any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or

implied warranty that might arise from the information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is

specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. lease refer to www.lincolnelectric.com for any updated information.

Idealarc®250 (208/230/460/1/60) K1053-7

Idealarc®250 (230/460/575/1/60) K1053-8

Idealarc®250 (208/230/460/1/60) with Power Factor Capacitors K1053-9

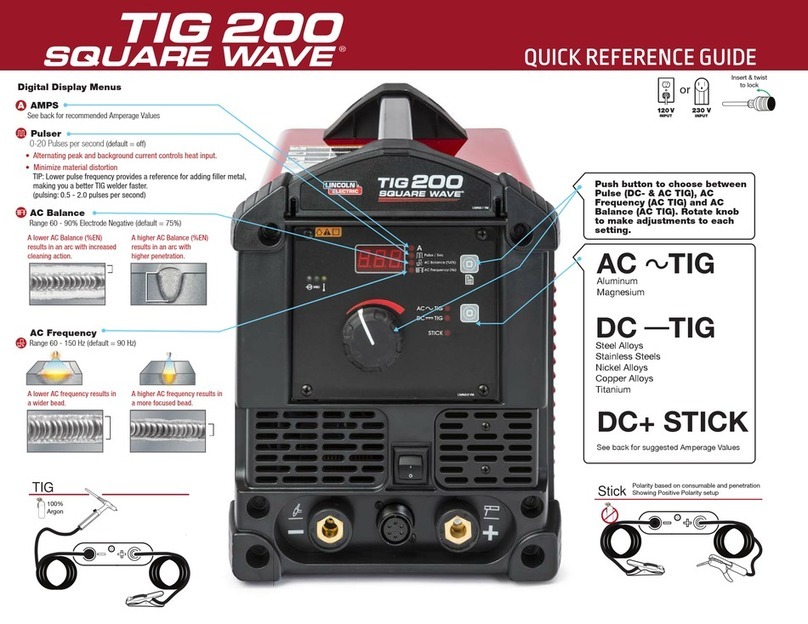

Recommended General Options

ower Factor Capacitor Kit K1894-1

Undercarriage K866

2-Year Extended Warranty - U.S. Only X1053

Recommended Stick Options

Accessory Kit, 400 Amp K704

Accessory Kit, 150 Amp K875

Recommended TIG Options

TIG Module K930-2

Contactor Kit K938-1

Control Cable K936-4

TOTAL:

IDEALARC®250 ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

GENERAL OPTIONS

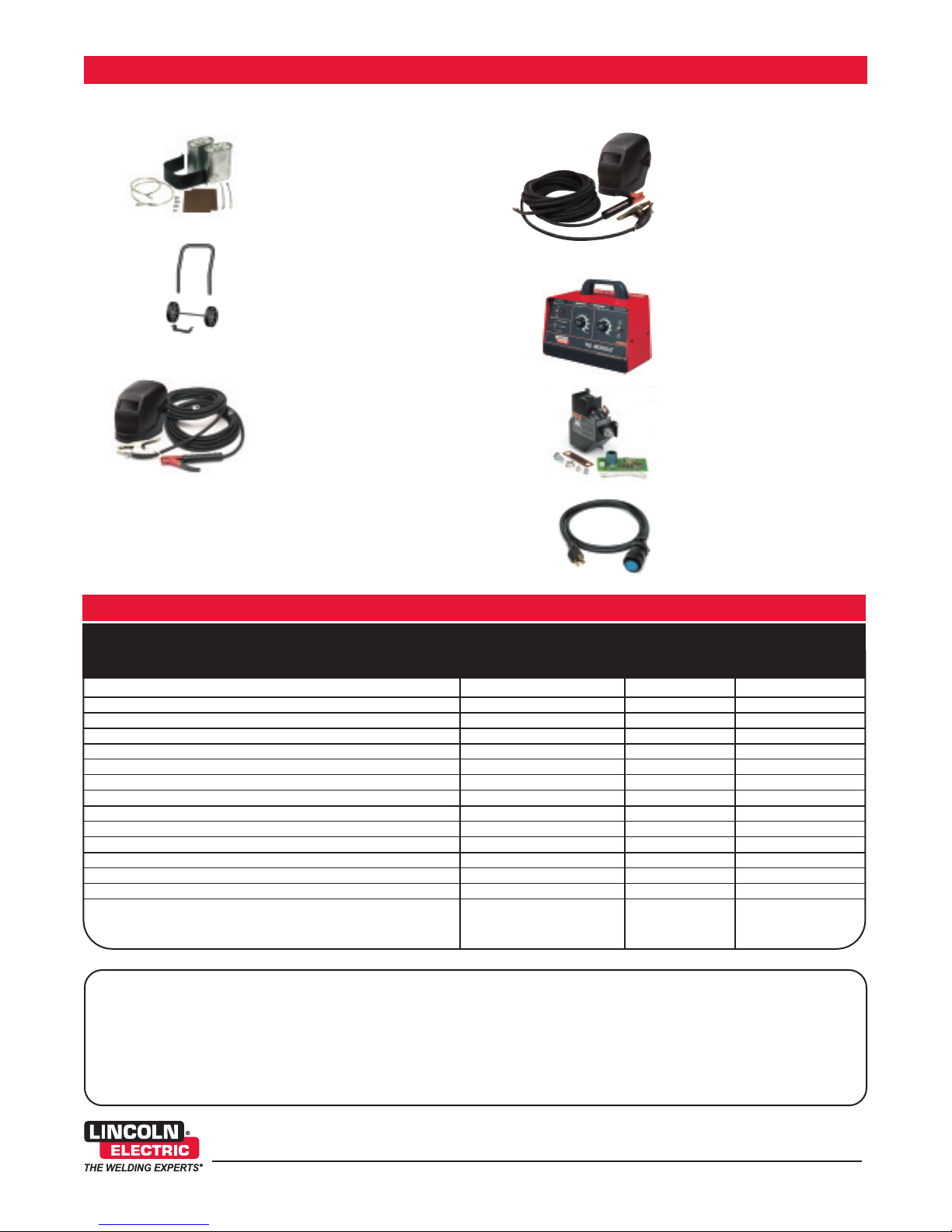

Power Factor Capacitor Kit

Used to reduce current draw and

keep electricity cost to a minimum

when machine is routinely operated

at high outputs. Reduces input amps

by approximately 20% at rated load.

Order K1894-1

Undercarria e

For hand moving. Includes handle,

axle, wheels, front bracket and

mounting hardware

Order K866

STICK OPTIONS

Accessory Kit, 400 Amp

For stick welding. Includes 35 ft.

(10.7 m) #2/0 electrode cable with

lug, 30 ft. (9.1 m) #2/0 work cable

with lugs, headshield, filter plate,

work clamp, and electrode holder.

Order K704

STICK OPTIONS, CONT.

Accessory Kit, 150 Amp

For stick welding. Includes 20 ft.

(6.1 m) #6 electrode cable with lug,

15 ft. (4.6 m) #6 work cable with

lugs, headshield, filter plate, work

clamp, electrode holder and sample

pack of mild steel electrode.

Order K875

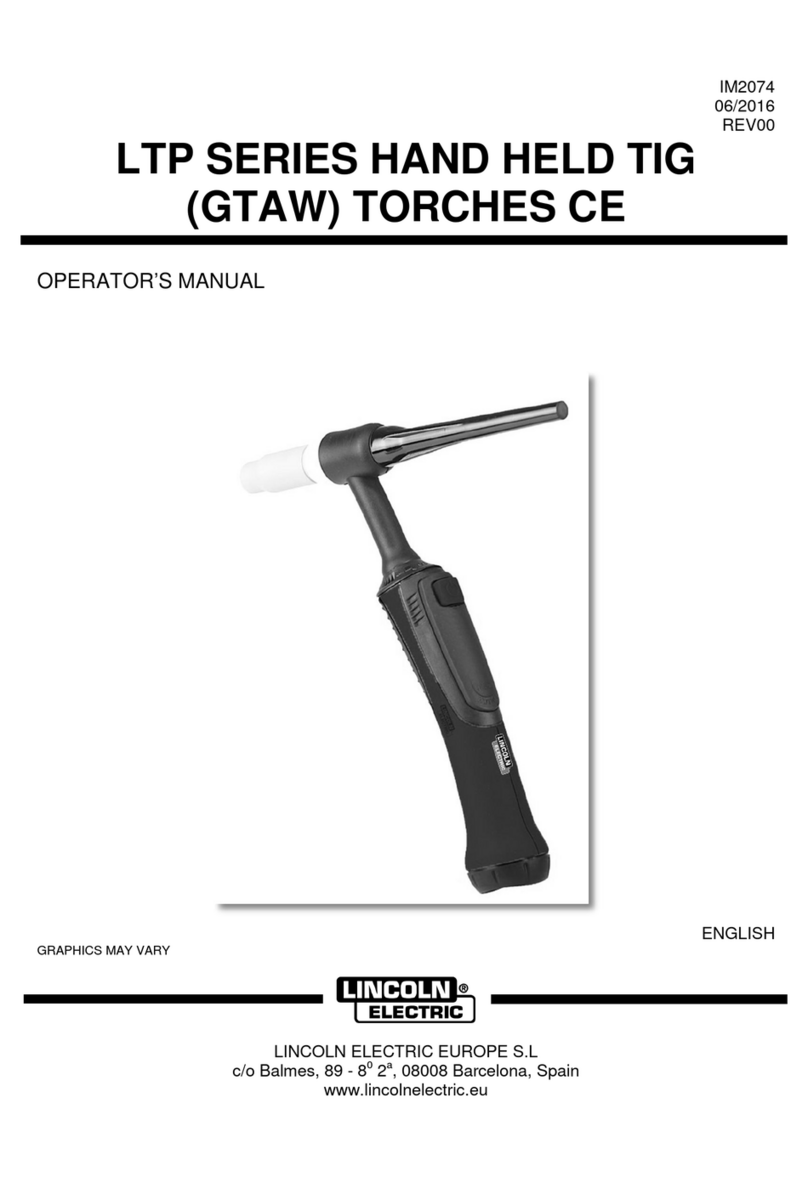

TIG OPTIONS

TIG Module

ortable, high frequency unit with

gas valve for TIG welding. Rated at

300 amps/60% duty cycle.

Order K930-2

Contactor Kit

Installs in the K930-2 TIG Module for

use with welders without a contactor.

Makes the TIG torch electrode

electrically “cold” until the Amptrol®

is activated.

Order K938-1

Control Cable

Connects TIG Module to power

source. 9-pin to 115V.

Order K936-4