Promotech Mini Spider User manual

JEI DRILLING & CUTTING SOLUTIONS LTD

Unit 21 Empire Business Park, Enterprise Way

Burnley, Lancashire, BB12 6LT

Tel: 00 44 1706 229490 Email: sales@jeisolutions.co.uk

OPERATOR’S MANUAL

M

Mi

in

ni

i

S

Sp

pi

id

de

er

r

WELDING CARRIAGE

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Operating................................................................................................................... 9

3.2. Troubleshooting........................................................................................................11

4. MAINTENANCE...............................................................................................................12

5. ACCESSORIES...............................................................................................................13

5.1. Battery 5.2 Ah...........................................................................................................13

5.2. Battery charger .........................................................................................................13

5.3. Power supply and power cord...................................................................................14

5.4. Auxiliary magnet blocks ............................................................................................15

5.5. Cable anchor ............................................................................................................16

6. WIRING DIAGRAM..........................................................................................................17

7. DECLARATION OF CONFORMITY.................................................................................18

8. QUALITY CERTIFICATE..................................................................................................19

9. WARRANTY CARD..........................................................................................................20

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

3

1. GENERAL INFORMATION

1.1. Application

The Mini Spider is a battery-powered welding carriage designed to make fillet welds

by using MIG/MAG torches. It is clamped to the surface with permanent magnets.

An optional magnet blocks increase the clamping force. An optional power supply

can be used to connect the carriage to a 110–240 V power source.

1.2. Technical data

Voltage

18 V DC, 5.2 Ah

Power

25 W

Welding position (according to EN ISO 6947 and AWS/ASME)

PA / 1F

PB / 2F

Torch type

MIG/MAG

Torch diameter

16–22 mm (0.63–0.87″)

Maximum allowed cable weight for horizontal work

8 kg (18 lbs)

Minimum workpiece thickness

4 mm (0.16″)

Ground clearance

4 mm (0.16″)

Horizontal pulling force

150 N

Cross slides adjustment range

0–21 mm (0–0.83″)

up-down, left-right

Horizontal speed*

5–110 cm/min

(2–44 in/min)

Weight (without the battery)

7.6 kg (16.8 lbs)

* When the battery is fully charged.

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

4

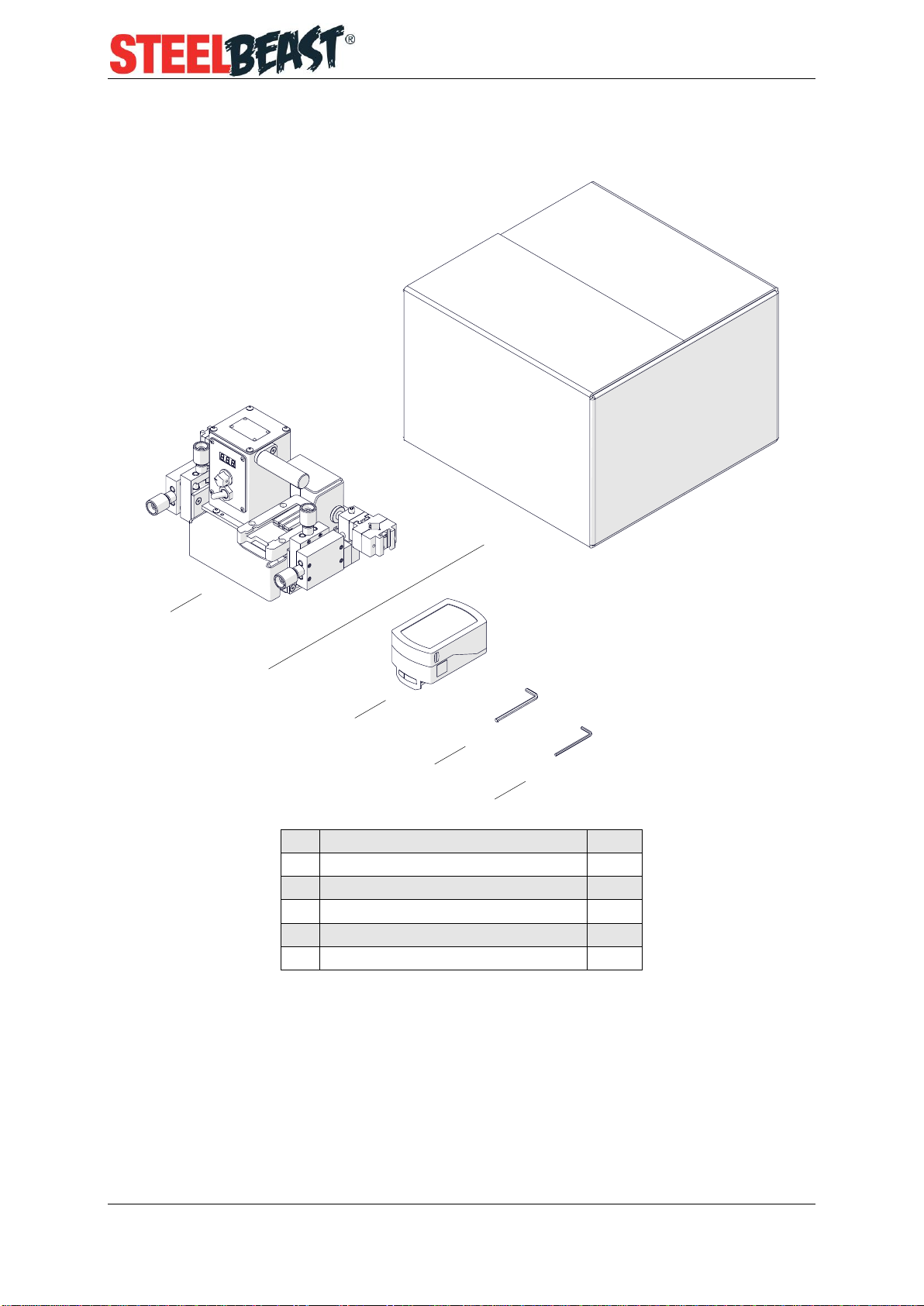

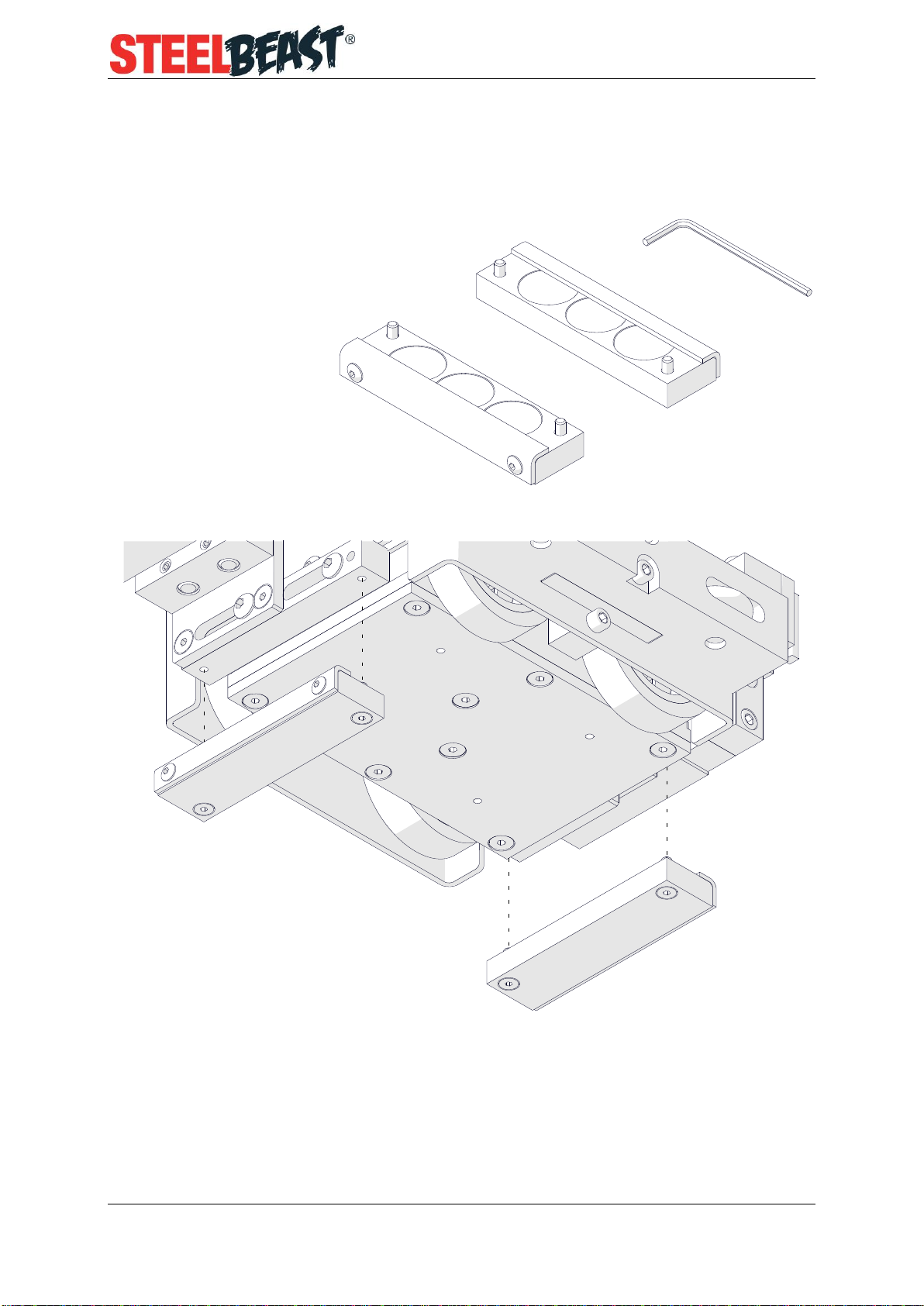

1.3. Equipment included

1

Carriage

1 unit

2

Cardboard box

1 unit

3

Battery

1 unit

4

4 mm hex wrench

1 unit

5

3 mm hex wrench

1 unit

–

Operator’s Manual

1 unit

2

3

4

1

5

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

5

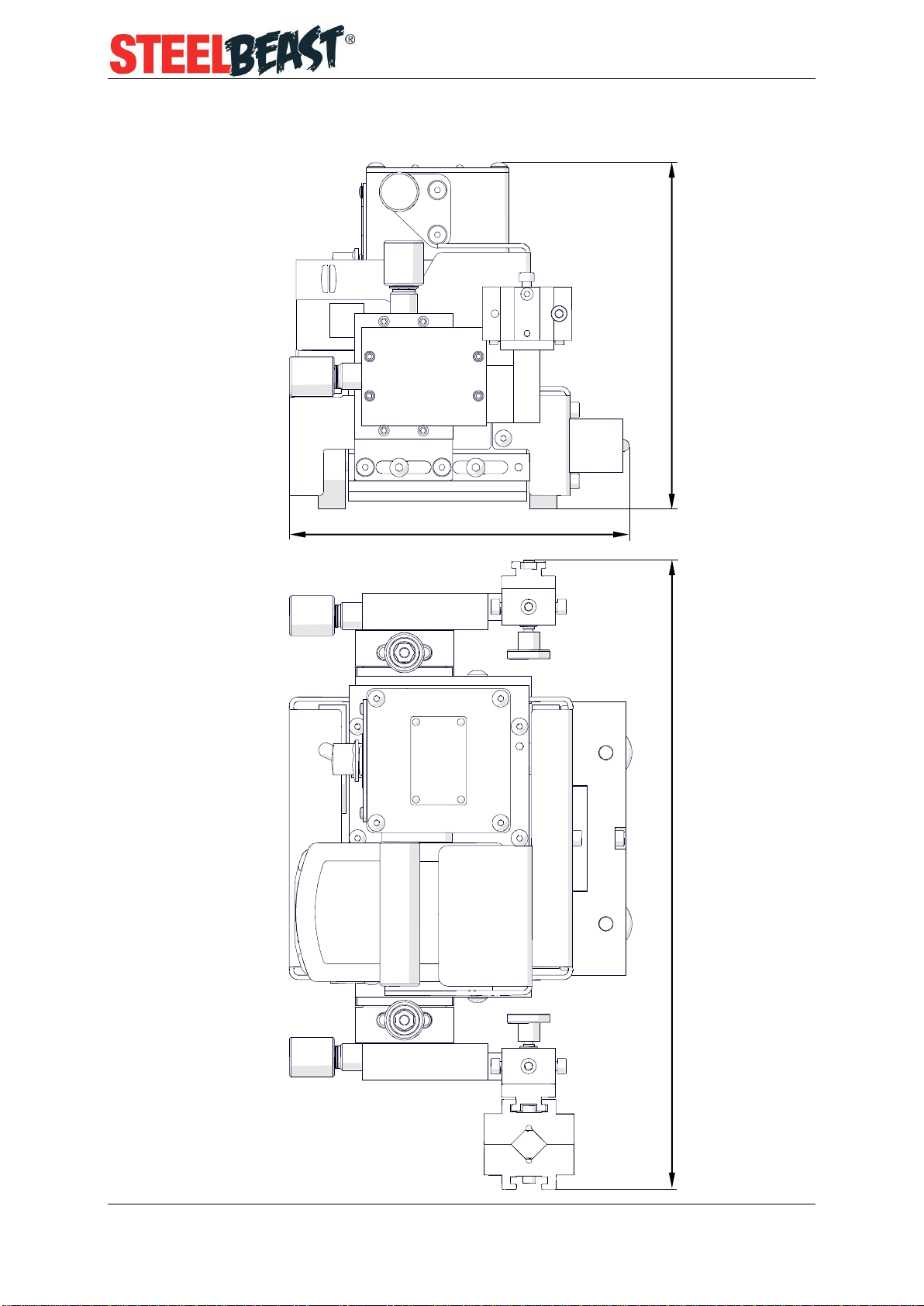

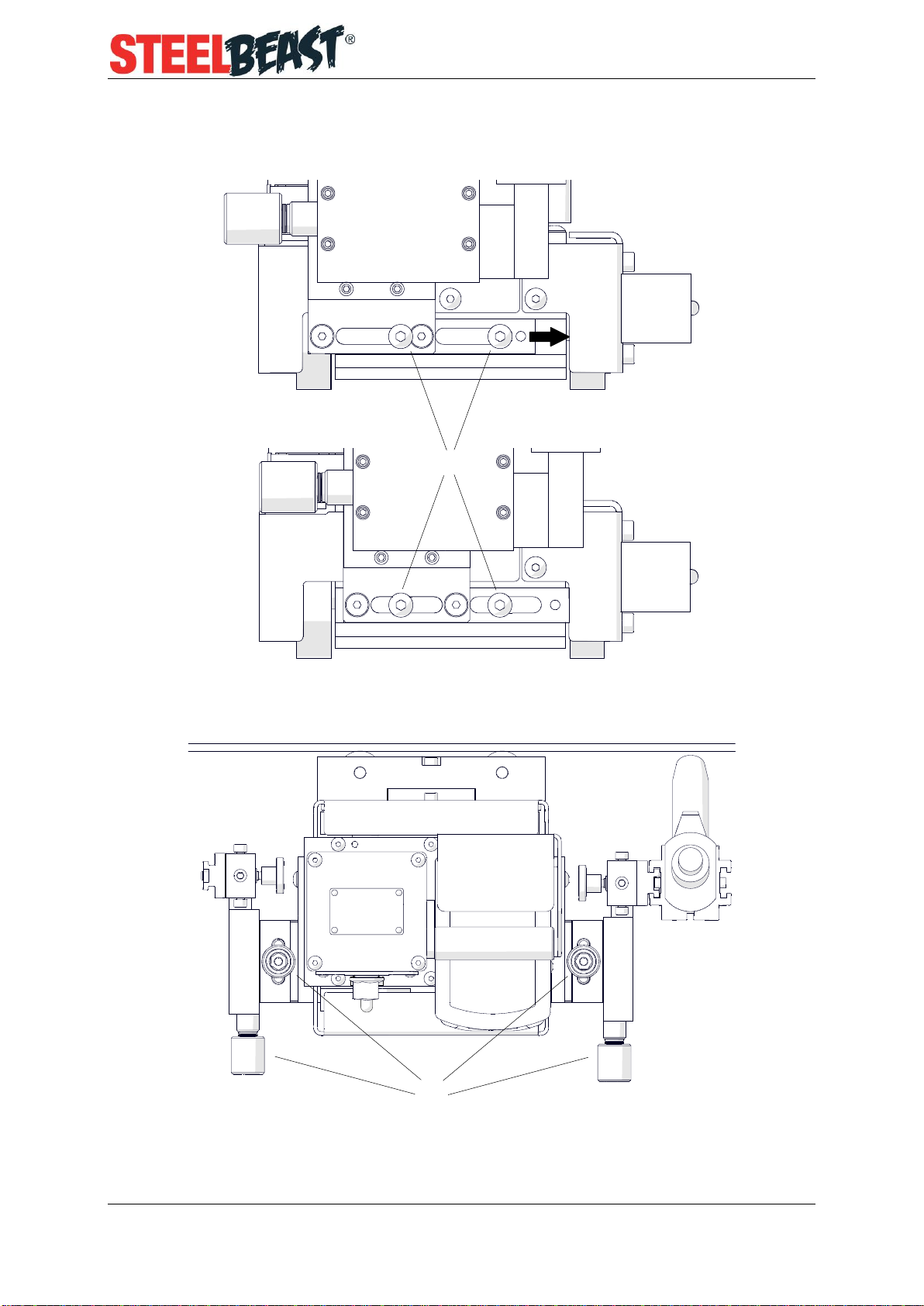

1.4. Dimensions

350 mm (13.8″)

194 mm (7.6″)

191 mm (7.5″)

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

6

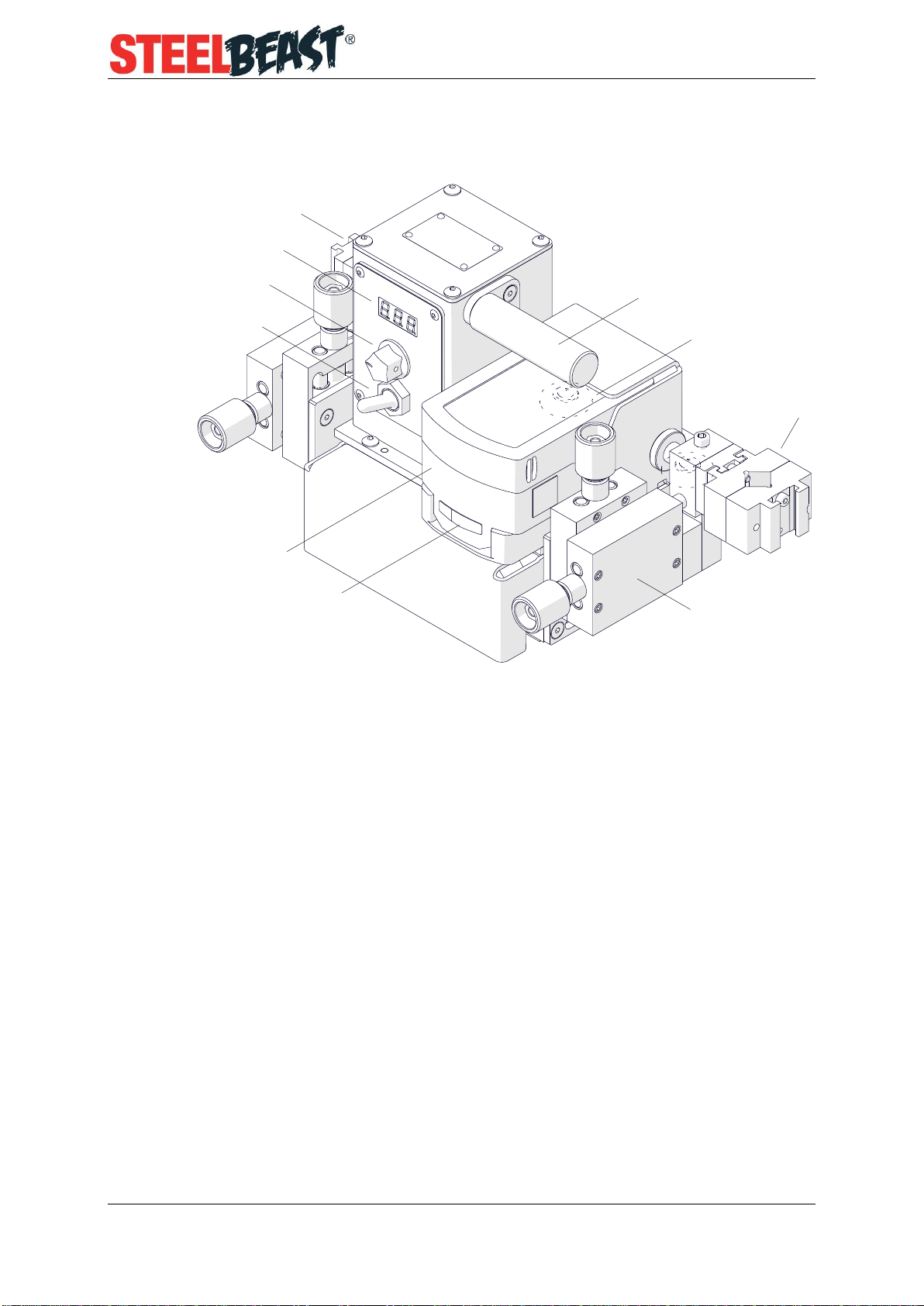

1.5. Design

Travel direction switch

(Left / O / Right)

Guide roller (×2)

LED display

Carrying handle

Cross slide (×2)

Speed knob

Battery

Torch holder

Torch holder bracket (×2)

Charge indicator

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

7

2. SAFETY PRECAUTIONS

1. Before you start, read this Operator’s Manual and complete occupational safety

and health training.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the carriage has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. When you use a power supply, connect it to a correctly grounded power source.

6. Do not carry the carriage by the cords, and do not pull them. This can cause

damage and electric shock.

7. Keep untrained bystanders away from the carriage.

8. Before each use, ensure the correct condition of the carriage, battery, power supply,

power source, cords, control parts, rollers, and wheels.

9. Before each use, make sure that no part is cracked or loose. Make sure to maintain

correct conditions that can have an effect on the operation of the carriage.

10. Keep the carriage dry. Do not expose it to rain, snow, or frost.

11. Keep the work area well lit, clean, and free of obstacles.

12. Do not use near flammable materials, or in explosive environments.

13. Move and put the carriage by using the carrying handle.

14. Put the carriage so that all four wheels are on the surface. Make sure that no

contact is between the surface and chassis.

15. Install the battery / power supply only after you set the travel direction switch to the

middle position.

16. Install only torches whose diameter matches the diameter of the torch holder.

17. Make sure that the torch cables are not on the surface. Hang them to decrease the

load on the carriage. Use only cables whose weight is not more than 8 kg (18 lbs).

18. At heights, use a protection to not let the carriage fall.

19. Do not stay below the carriage that is put at heights.

20. Use ear and eye protection (helmet, shield, and screen), gloves, and protective

clothing. Do not use loose clothing.

21. Do not try to stop the travel by hand. To stop, set the travel direction switch to the

middle position.

22. Maintain only after you remove the battery / power supply.

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

8

23. Repair only in a service center appointed by the seller.

24. If the carriage falls, is wet, or has any damage, stop the work and promptly send

the carriage to the service center for check and repair.

25. Do not leave the carriage unattended during work.

26. If you are not going to use the carriage, remove it from the worksite and keep it in

a safe and dry place.

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

9

3. STARTUP AND OPERATION

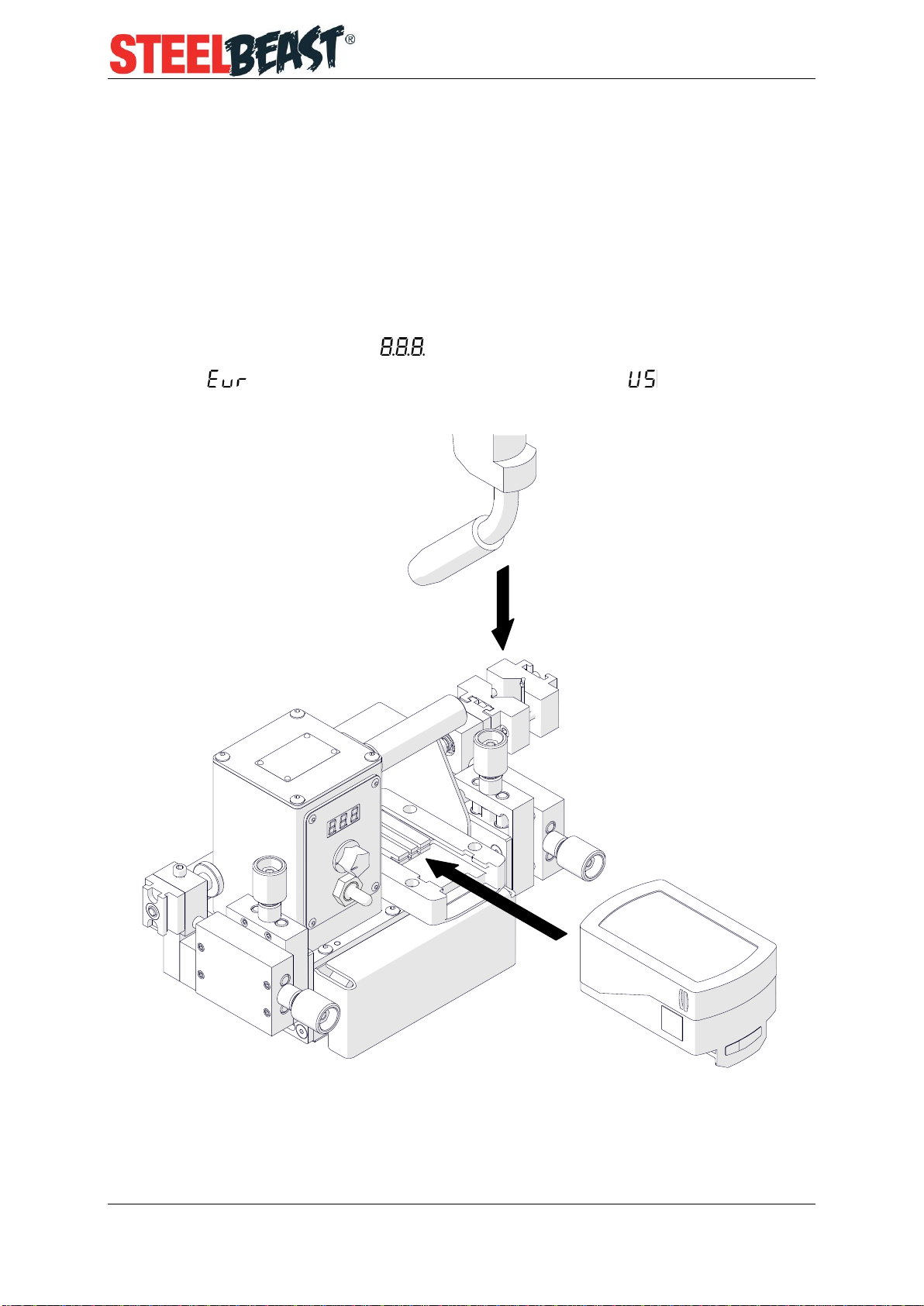

3.1. Operating

Put the battery into the charger. Let the battery charge until the light on the charger

stops flashing and stays on.

Use the carrying handle to move the carriage to the worksite. Set the travel

direction switch to the middle position (1) and put the battery onto the carriage (2).

Then, the display comes on ( ). Next, if the unit of speed is set to centimeters

per minute, shows. If the unit is set to inches per minute, shows.

Use the 3 mm and 4 mm hex wrenches to tighten the torch in the holder (3).

3

2

1

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

10

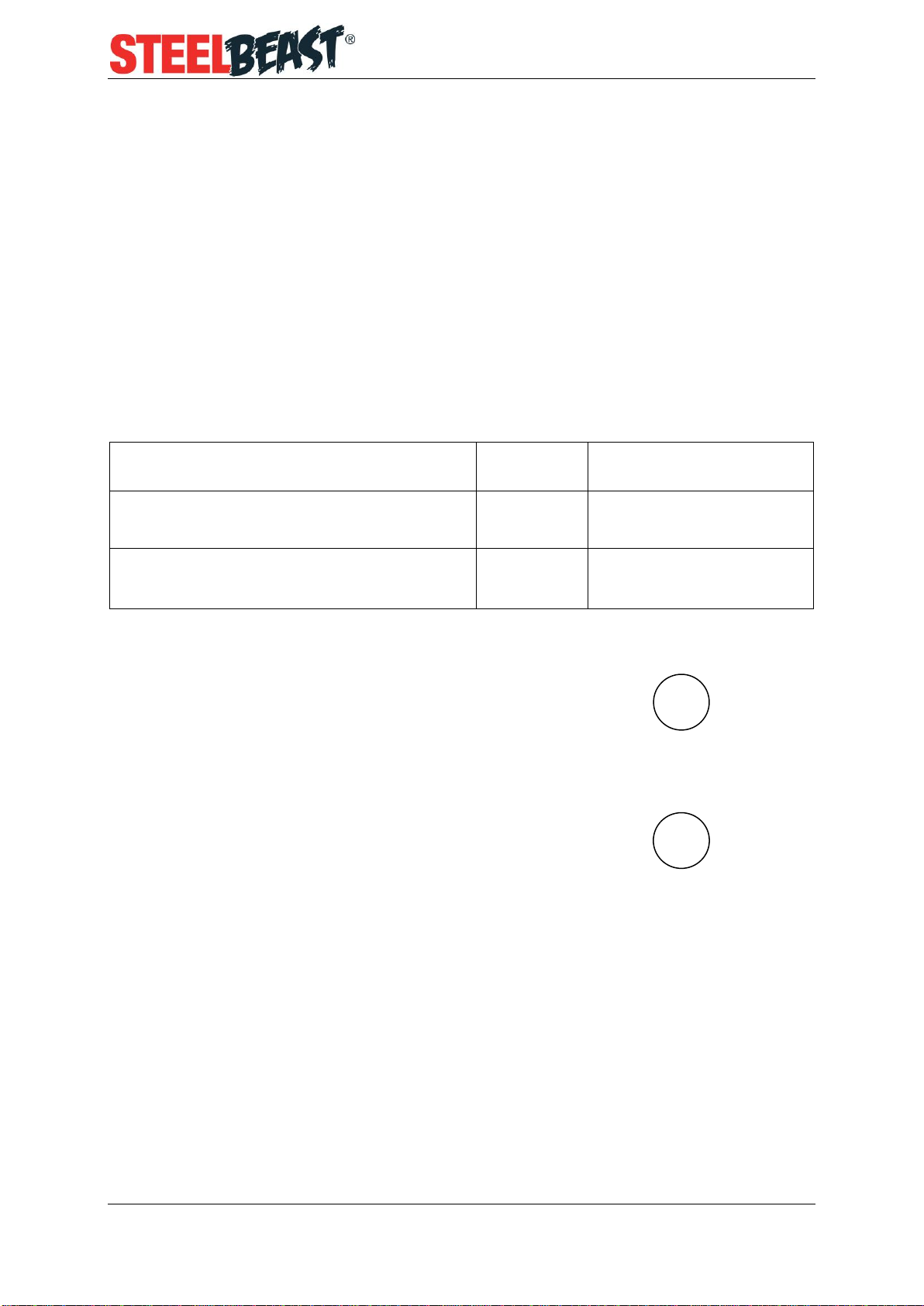

To work in narrow spaces, adjust the position of the cross slides. On the two sides,

loosen the screws (4). Then, move the cross slides (5) and tighten the screws (4).

Put the carriage so that the rollers are on the workpiece. Then, use the knobs (6) to

put the torch in the welding joint.

4

5

6

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

11

Use the speed knob to set the required speed. Use the travel direction switch to

select a direction of travel. This will start the travel with the speed that is shown.

To stop the travel, set the travel direction switch to the middle position.

If you do not use the carriage for 2.5 minutes, it goes to the sleep mode. To go

back from the sleep mode, use a travel direction switch. When the battery is

discharged, the travel stops. Then, recharge the battery. To check the charge level,

press the button on the charge indicator.

After the work is finished, remove the battery / power supply.

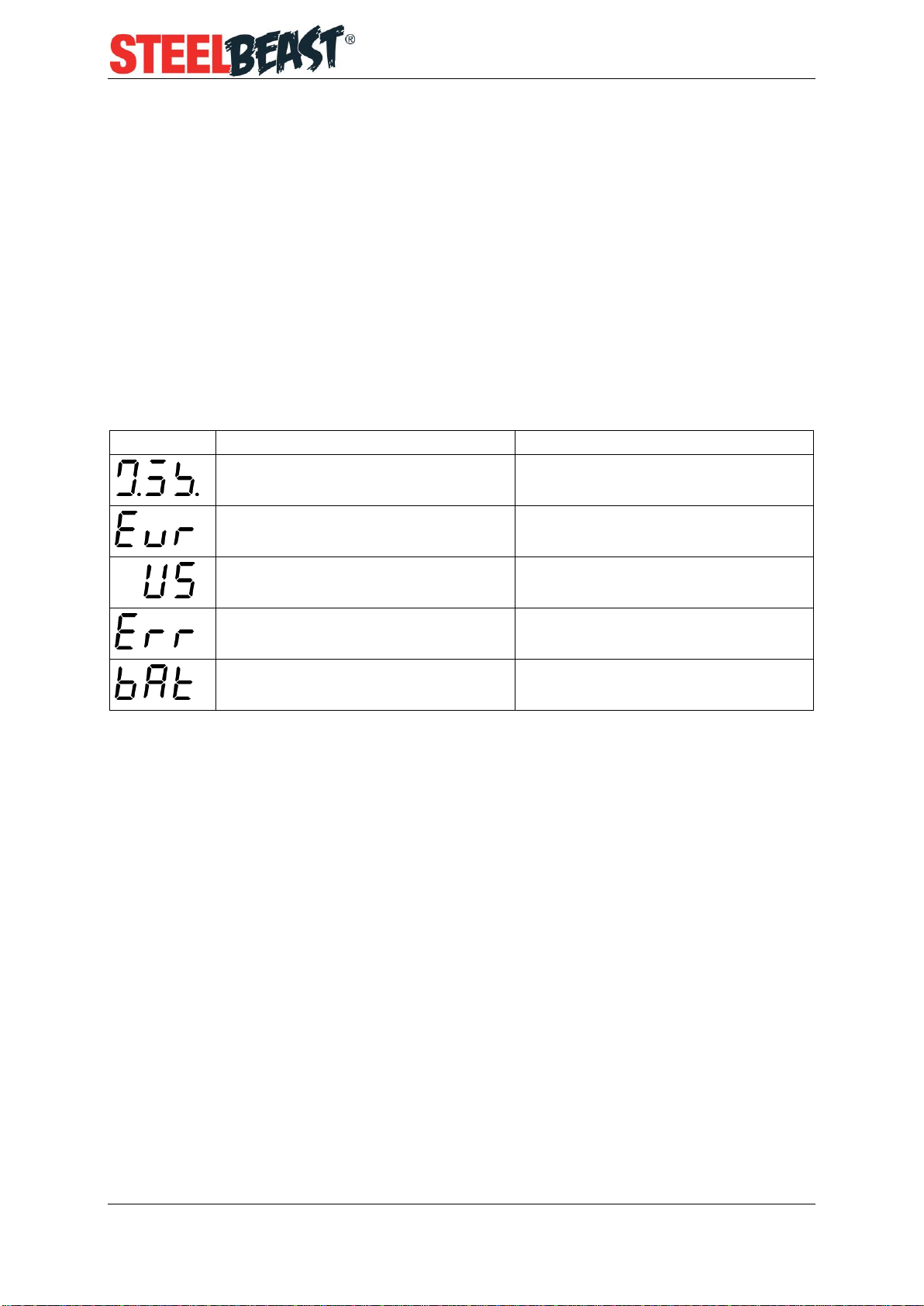

3.2. Troubleshooting

Message

Problem

Solution

Not all display segments are on after

powering.

Contact service center for check

and repair.

Speed is shown in centimeters per

minute instead of inches per minute.

Contact service center.

Speed is shown in inches per minute

instead of centimeters per minute.

Contact service center.

Travel direction switch is not set to the

middle position when powering.

Set the travel direction switch to

the middle position.

Battery discharged. The carriage

stops.

Charge the battery or replace to

a fully charged.

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

12

4. MAINTENANCE

Each day:

1. Clean the chassis, rollers, and wheels.

2. Make sure that the rollers rotate freely.

3. Clean the torch nozzle. Replace if damaged.

4. Examine the battery. Replace if damaged.

Each month:

1. Make sure that the knob and the switch work as intended. Replace if loose or

damaged.

2. Examine cables and cords. Replace if damaged.

3. Tighten screws if loose.

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

13

5. ACCESSORIES

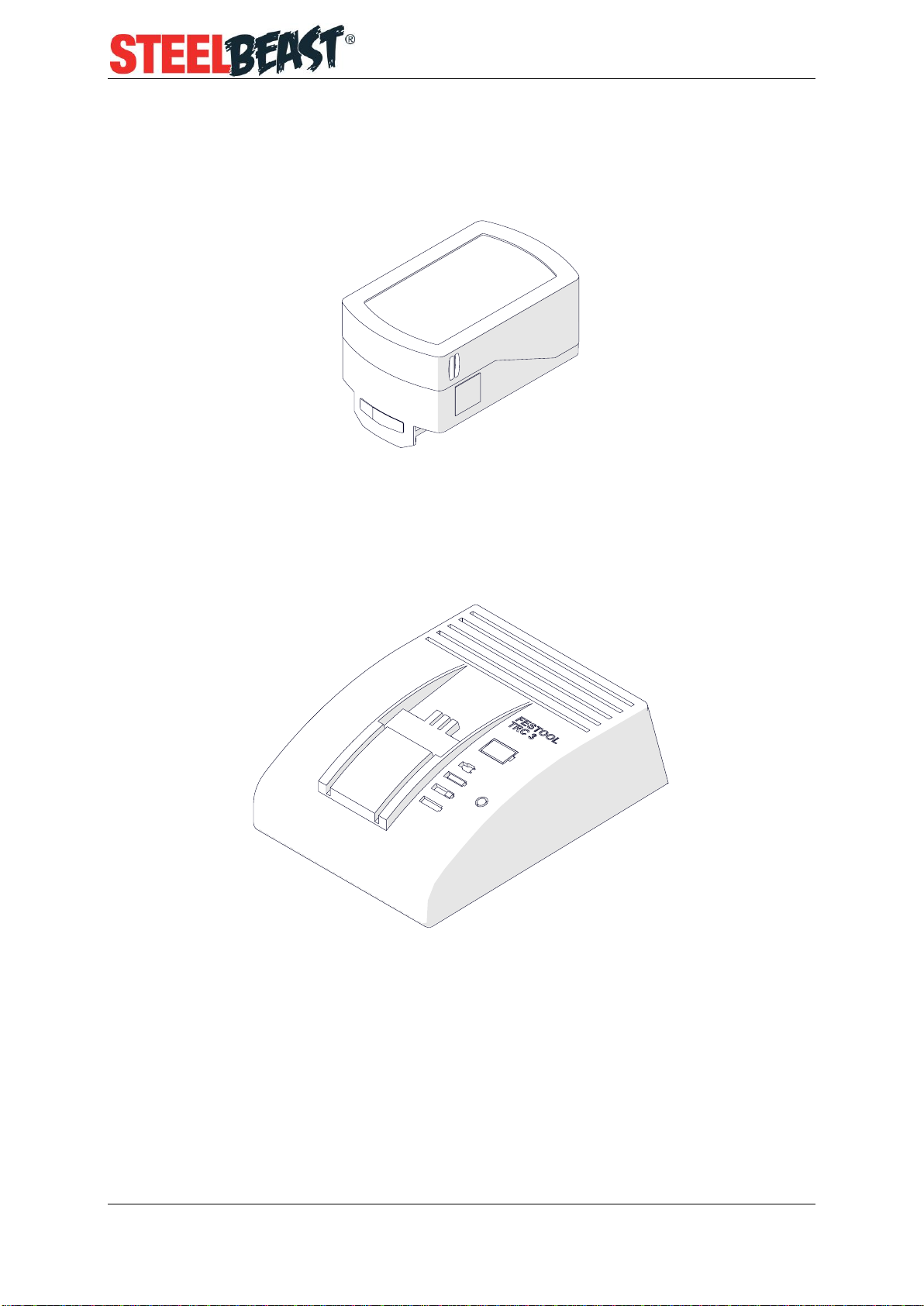

5.1. Battery 5.2 Ah

5.2. Battery charger

Recharges the battery from 220–240 V or 120 V power source.

Part number:

LDW-000006 (220–240 V, 50/60 Hz)

LDW-000007 (120 V, 60 Hz)

Part number:

AKM-000086

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

14

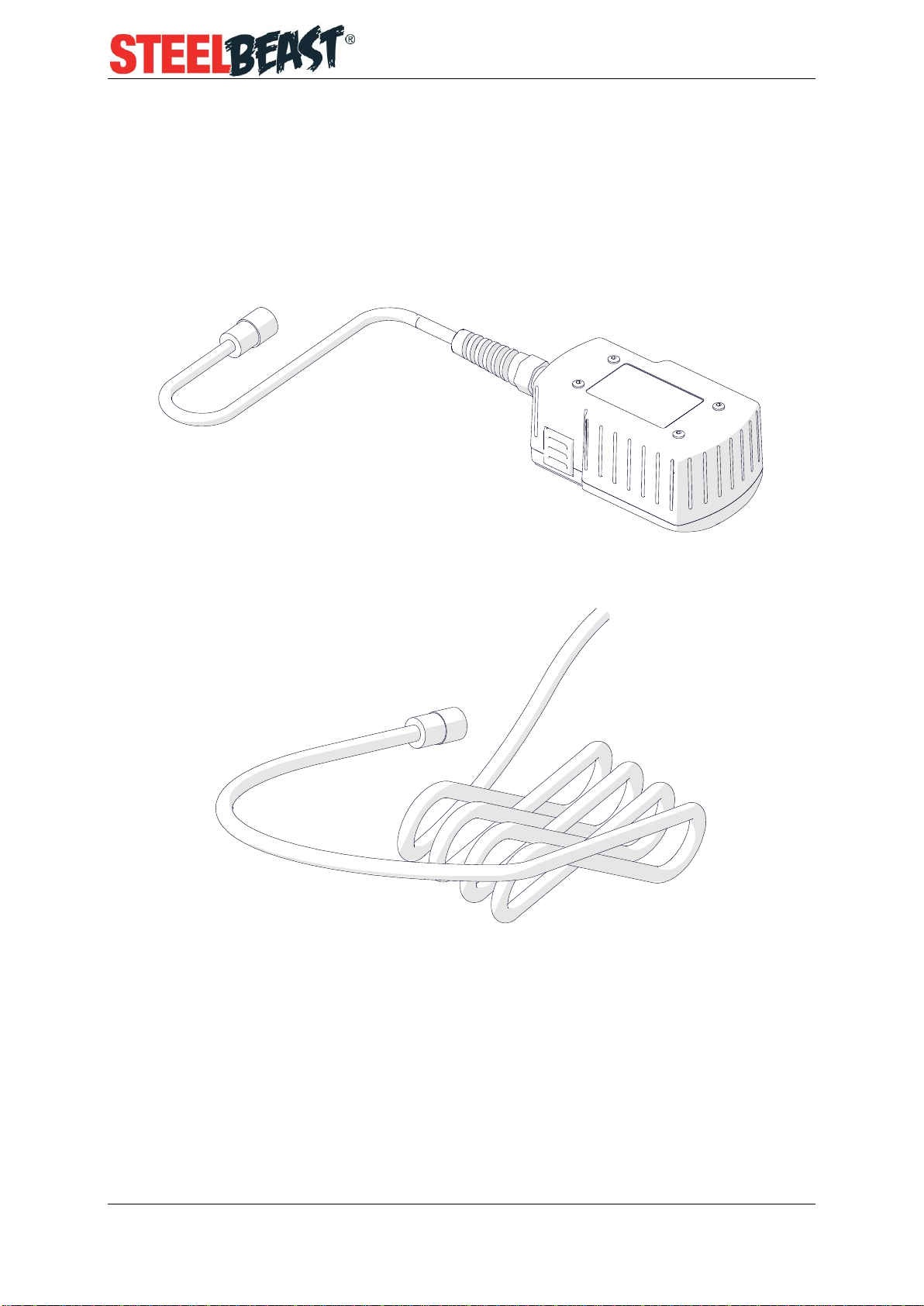

5.3. Power supply and power cord

Allows connecting the carriage to a110–240Vpower source instead using the

battery. The length of the power cord is 3 m (10 ft).

Part number (power supply):

ZSL-0526-20-00-00-0

Part number (power cord):

PWD-0466-18-00-00-0 (230 V CEE)

PWD-0466-21-00-00-0 (230 V AU)

PWD-0466-31-00-00-0 (230 V IN)

PWD-0466-16-00-00-0 (115 V USA)

PWD-0466-28-00-00-0 (115 V UK)

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

15

5.4. Auxiliary magnet blocks

The blocks increase the clamping force of the carriage.

Use the 2.5 mm hex wrench to attach the blocks to the carriage.

Part number:

ZST-0655-09-00-00-0

(holding force: 2×50 N)

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

16

5.5. Cable anchor

Attaches the gas cables and the power cord to decrease the load applied on the

torch holder. Install the anchor on the carrying handle.

Part number:

PDT-0526-21-00-00-0

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

17

6. WIRING DIAGRAM

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

18

7. DECLARATION OF CONFORMITY

EC Declaration of Conformity

We

JEI Group Ltd

T/A JEI Drilling & Cutting Solutions Ltd

Unit 21 Empire Business Park

Enterprise Way, Burnley

Lancashire, BB12 6LT

declare with full responsibility that:

Mini Spider Welding Carriage

is manufactured in accordance with the following standards:

•EN 12100

•EN 60204-1

•EN 60974-10

and satisfies safety regulations of the guidelines: 2014/30/EC, 2014/35/EC, 2006/42/EC.

Person authorized to compile the technical file:

David McFadden, Managing Director

Burnley, 11 October 2018 ___________________________

David McFadden

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

19

8. QUALITY CERTIFICATE

Machine control card

Mini Spider Welding Carriage

Serial number .....................................................................

Electric test

Type of test

Result

Name of tester

Insulation electrical strength test

(1000 V, 50 Hz)

...................................

Date

Continuity test of the protective earth system

…........ Ω

...................................

Signature

Quality control .................................................

Adjustments, inspections

Quality control .................................................

Mini Spider

This document is protected by copyrights.

Copying, using, or distributing without permission of JEI Group Ltd is prohibited.

20

9. WARRANTY CARD

WARRANTY CARD No...........

.......................................................................... in the name of Manufacturer warrants

the Mini Spider Welding Carriage to be free of defects in material and workmanship

under normal use for a period of 12 months from the date of sale.

This warranty does not cover wheels as well as damage or wear that arise from

misuse, accident, tempering, or any other causes not related to defects in workmanship

or material.

Date of production.........................................................................................................

Serial number................................................................................................................

Date of sale ...................................................................................................................

Signature of seller..........................................................................................................

1.00 / 22 October 2018

WE RESERVE THE RIGHT TO MAKE CHANGES IN THIS MANUAL WITHOUT NOTICE

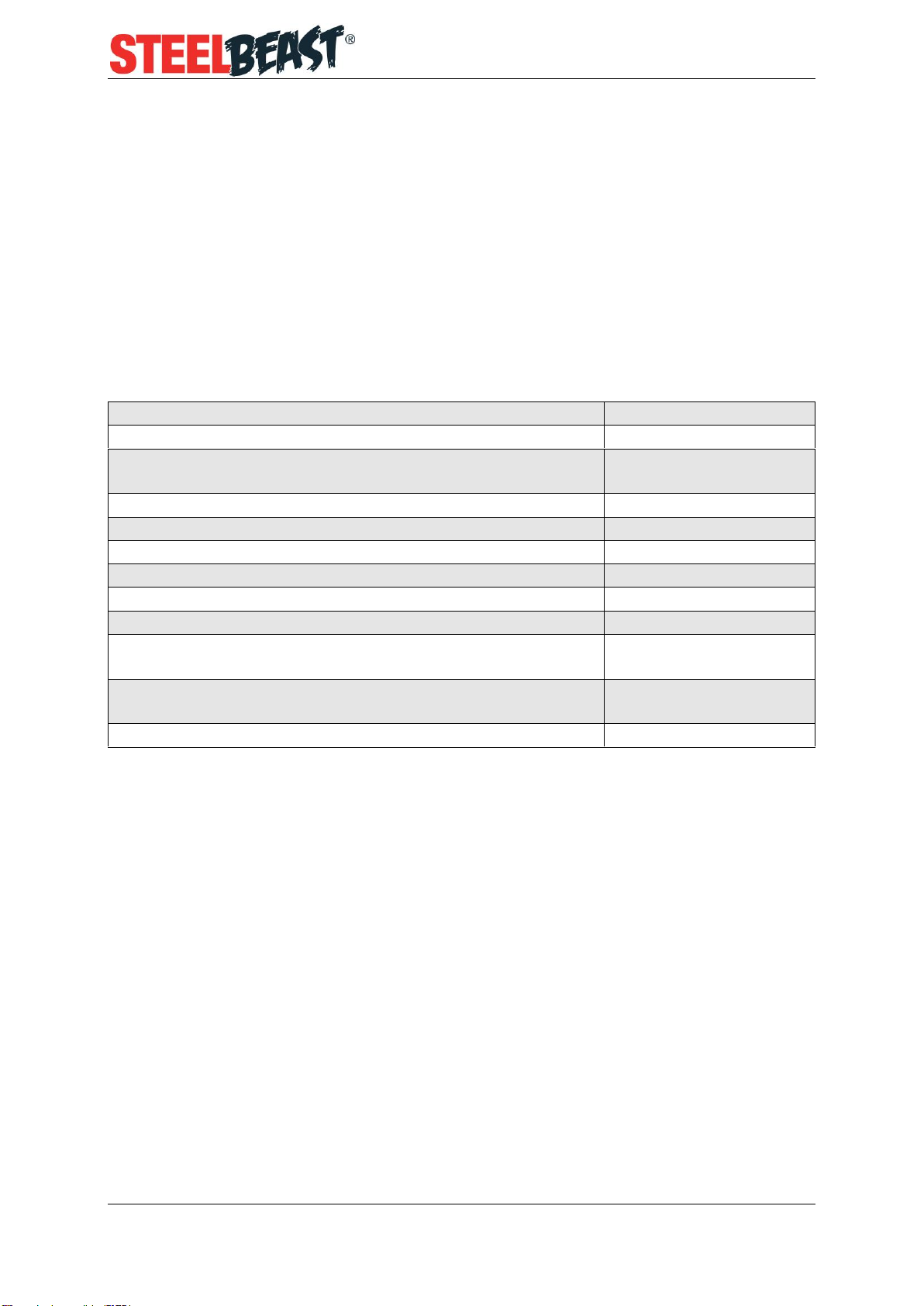

Table of contents

Other Promotech Welding System manuals

Popular Welding System manuals by other brands

Migatronic

Migatronic OMEGA2 300 user guide

Oerlikon

Oerlikon CITOTIG 250 AC/DC Safety Instructions for Operation and Maintenance

Everlast

Everlast Power i-MIG 315 Operator's manual

Longevity

Longevity ForceCut LP-100 operating manual

Thermal Arc

Thermal Arc FABRICATOR 210 Service manual

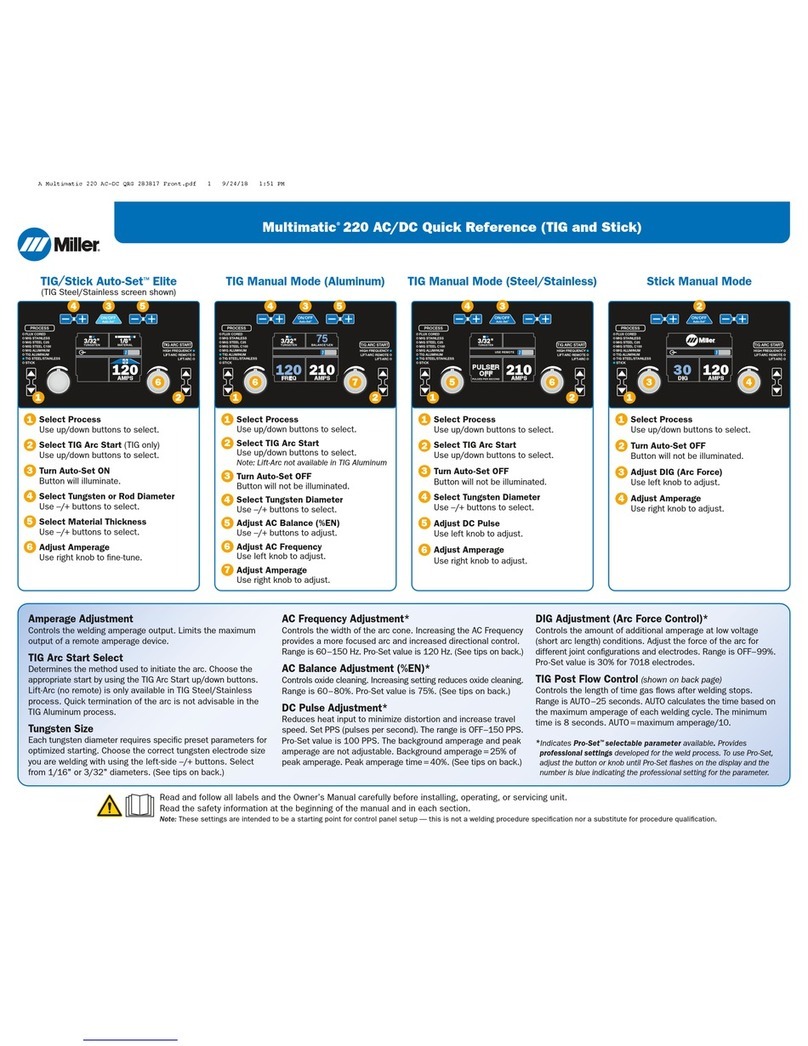

Miller

Miller Multimatic 220 AC/DC quick reference

BOC

BOC Smoothcut Plasma 40 operating manual

Badger Welder

Badger Welder M22 Operation manual

Everlast

Everlast POWERARC 141STL Operator's manual

Lincoln Electric

Lincoln Electric Power Wave C300 Operator's manual

Abicor Binzel

Abicor Binzel TIG ABITIG MT operating instructions

Rothenberger

Rothenberger ROWELD P 250 A Instructions for use