Prosense QPSL-AP-42 User manual

P.1

P.1

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

Digital Pressure Switch /

Transmitter

Compact combination Pressure Switch / Transmitter with 2 digital outputs (NPN or PNP)

which may be set individually and an analog 4-20mA output. Perfect for the factory floor

or installed in a control cabinet. The unit comes with a 2 meter cable for easy installation

and has 2 optional mounting brackets available.

Models:

QPSL-AP-42

QPSL-AN-42

QPSH-AP-42

QPSH-AN-42

Box Contents and Unpacking Instructions

• Unpack the QPS Pressure Switch from its

shipping carton. Included in the carton is the

switch, cable and pressure units label and these

instructions.

• Inspect all equipment for completeness. If any-

thing is missing or damaged, immediately call

the AutomationDirect returns department @

1-800-633-0405.

• Inspect the part number to ensure the model

received matches the output type required.

WARNING: To minimize the risk of potential safety problems, you should follow all applicable local

and national codes that regulate the installation and operation of your equipment. These codes vary

from area to area and it is your responsibility to determine which codes should be followed, and to

verify that the equipment, installation, and operation are in compliance with the latest revision of

these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for your product design, installation,

or operation.

If you have any questions concerning the installation or operation of this equipment, or if you need

additional information, please call us at 1-800-633-0405 or 770-844-4200.

This publication is based on information that was available at the time it was printed. At

Automationdirect.com® we constantly strive to improve our products and services, so we reserve the

right to make changes to the products and/or publications at any time without notice and without

obligation. This publication may also discuss features that may not be available in certain revisions of

the product.

WARNING! Electric shock danger

ProSense QPS is a pressure measurement device. DO NOT use it out of its specification. Improper

pressure or incorrect wiring may cause injuries to staff or damages to other devices.

1. Keep away from high-voltage and high-frequency environment during the installation to prevent

interference. Avoid using the device in environments which contain: (a) dust or corrosive gas; (b)

high humidity and high radiation; (c) shock and vibration

2. QPS can only be used for air pressure measurement and should avoid corrosive, inflammable or

toxic gas measurement.

3. Make sure the input power is switched off when installing or uninstalling the QPS and the pres-

sure source is off to prevent harm to personnel or equipment.

4. Before switching on the input power, check the signal connection, e.g. the input voltage and

polarity. Voltage that is too high may cause damage to the QPS.

5. Use dry cloth and DO NOT use acid or alkaline liquid to clean the device.

6. Outputs remain active in Setup Mode.

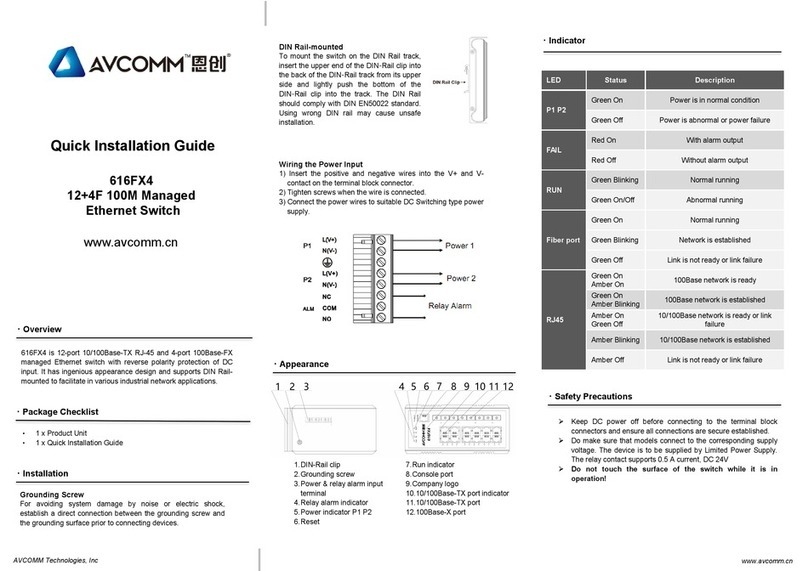

x

QPSL-AN-42

QPSH-AN-42

QPSL-AP-42

QPSH-AP-42

QPS-CBL (Included with each QPS switch/transmitter)

1 - Positive input power (brown)

2 - Digital output 1 signal (black)

3 - Digital output 2 signal (white)

4 - Analog output signal (orange)

5 - Negative power supply input (blue)

12

3

4

5

2

OUT

1

OUT

ANALOG

1

2

3

4

5

678

9

10

1 - Analog output indicator

2 - Digital output 1 indicator

3 - Digital output 2 indicator

4 - Pressure Value (PV)/parameter display (8mm digits)

5 - Setpoint Value (SV)/setup item display (4mm digits)

6 - Increment UP button

7 - SET or Enter button

8 - Increment DOWN button

9 - Cable connection

10 - Pressure connection

Load Load

Load

Load

Load

Load

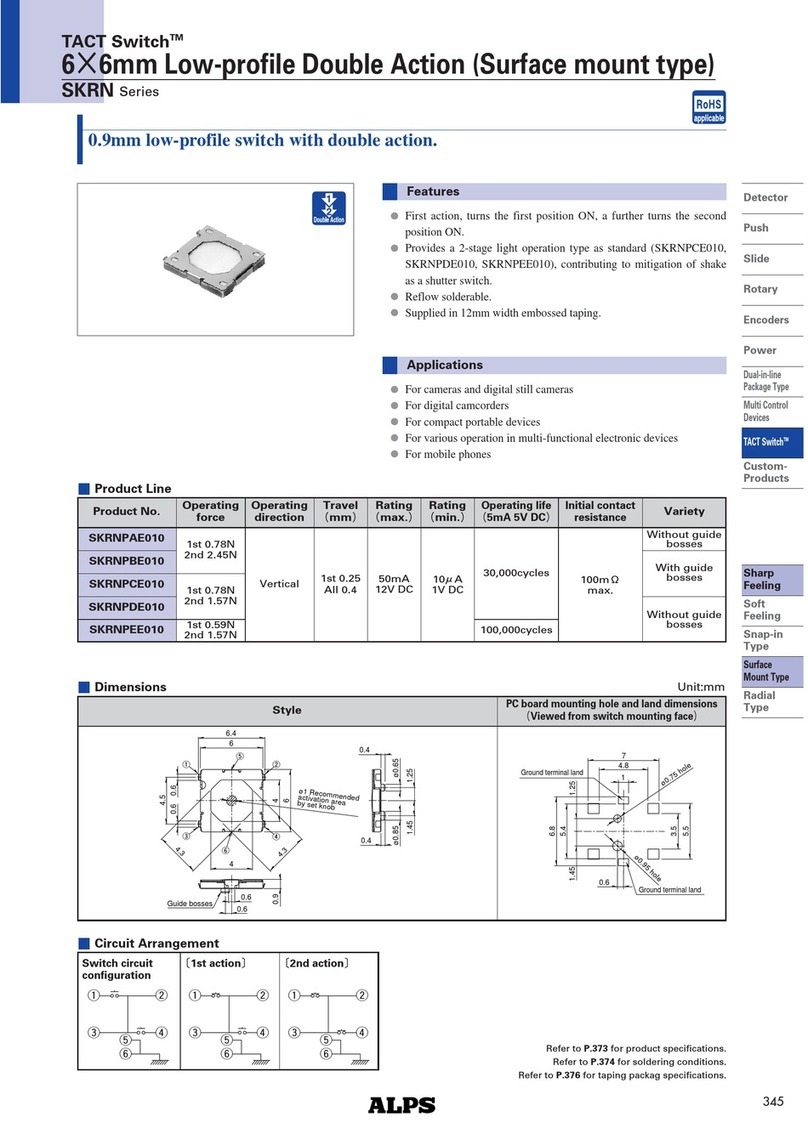

Wiring

Dimensions

mm [in]

Display, KeyPad and Connections

cmHg

inHg

KPa

MPa

kgf/cm

bar

psi

Pressureunit label

Instructions

Dimensions

mm [in]

M3.5 x 14mm

QPS-PMK - Optional Panel Mount Kit

QPS-FMK - Optional Frame

Mount Kit

Input Power

10.8 to 26.4VDC

PNP

(4-20mA output)

M3-.5 x 6mm

NPN

(4-20mA output)

Input Power

10.8 to 26.4VDC

ProSense QPS Digital Pressure Switch / Transmitter Specifications

Model QPSL-AP-42 QPSL-AN-42 QPSH-AP-42 QPSH-AN-42

Rated Pressure -14.5 to +14.5 psi -14.5 to +145 psi

Maximum Pressure (Proof) 29psi 217psi

Maximum Vacuum -14.5 psi

Pressure Accuracy w3% of full scale

Temperature Influence @ 25°C w2% of full scale

Fluid Measured Air, Non-corrosive gas, Non-flammable gas

Input Power 10.8 to 26.4 VDC

Power Consumption 260mA maximum

Digital

Outputs

Output Type 2-PNP 2-NPN 2-PNP 2-NPN

Maximum Current 100mA each

Response Time 2ms, 4ms, 10ms, 30ms, 50ms, 100ms, 250ms, 500ms, 1,000ms, 5,000ms

selectable

Residual Voltage 1.5 VDC

Analog

Output

Output Type 4-20mA

Maximum Output

Load Resistance 400ΩΩ

Linear Accuracy < w2% of full scale

Process Connection 1/8” NPT outer / M5 inner bore (Nickel Plated Brass)

Case Materials Case = ABS Plastic, Lens = Polycarbonate

Shock Immunity 10 ~ 500 Hz, 10mm 3 axes for 2 hours

Vibration Immunity Max. 100m / s2 3 axes 6 directions, 3 times each

Operating Temperature 0°C to +50°C (32°F to 122°F)

Storage Temperature -20°C to +65°C (-4°F to 149°F)

Altitude < 2,000m

Ambient Humidity 35% ~ 80% (non-condensing)

Approvals cULus - UL 508 (E157382), CE, RoHS

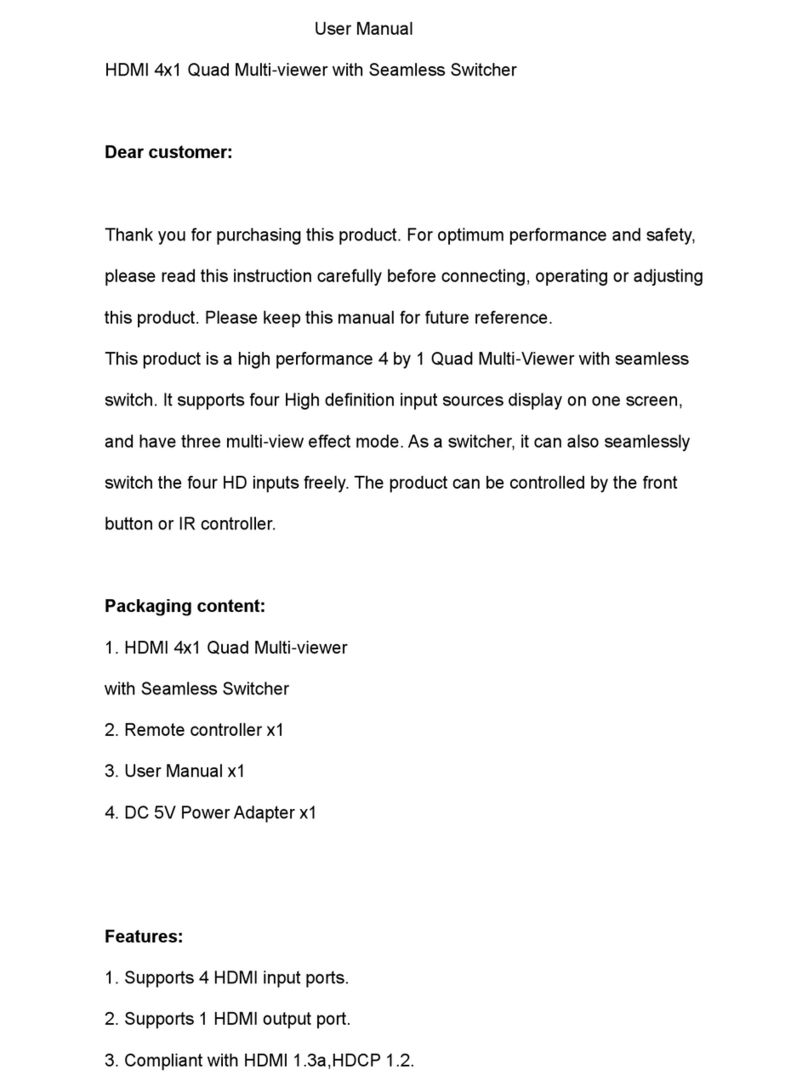

Changing modes:

The QPS will be in the “Run Mode” when it is powered on, displaying PV and SV. Press ;

for more than 2 seconds in this mode to switch to the “Quick Setup Mode”. Press ;for

more than 4 seconds in the “Run Mode” to switch to “Pro Setup Mode”. Press ;more than

2 seconds in the “Quick Setup Mode” or “Pro Setup Mode” to return to the “Run Mode”.

Setting up parameters:

In the three modes, press ;once to select the parameter to set up. When you find the

parameter to set up or modify, use , . to modify the setting.

Menu Navigation

Resetting the ProSense QPS to factory default values:

Hold ;button for 4-5 seconds until display changes to read Pro. Press the ;button 9

times until the display shows off

rst

Using the ,. buttons change the value to on and press ;

When complete the display will read

std

sub

Caution: Outputs remain active in Setup Mode

Pro Setup Mode Quick Setup

Mode

QPS Powered ON

Run Mode

Press ;> 4 secs.

Press ;> 2 secs.

Press

;

> 2 secs.

Press ;> 2 secs.

Accessing QPS Setup Modes:

;

;

;

;

;

Run Mode

Upper limit of OUT1

Lower limit of OUT1

Upper limit of OUT2

Lower limit of OUT2

SV

SV

–1-h

–2-h

–2-l

–1-l

–1-p

–2-p

OUT1 set to

Hysteresis or Window

Mode

OUT2 set to

Hysteresis or Window

Mode

OUT2 set to

Easy Mode

OUT1 set to

Easy Mode

Run Mode

Run Mode

1-H Output 1 high setpoint for hysteresis or window modes

1-L Output 1 low setpoint for hysteresis or window modes

1-P Output 1 high setpoint for easy mode

2-H Output 2 high setpoint for hysteresis or window modes

2-L Output 2 low setpoint for hysteresis or window modes

2-P Output 2 high setpoint for easy mode

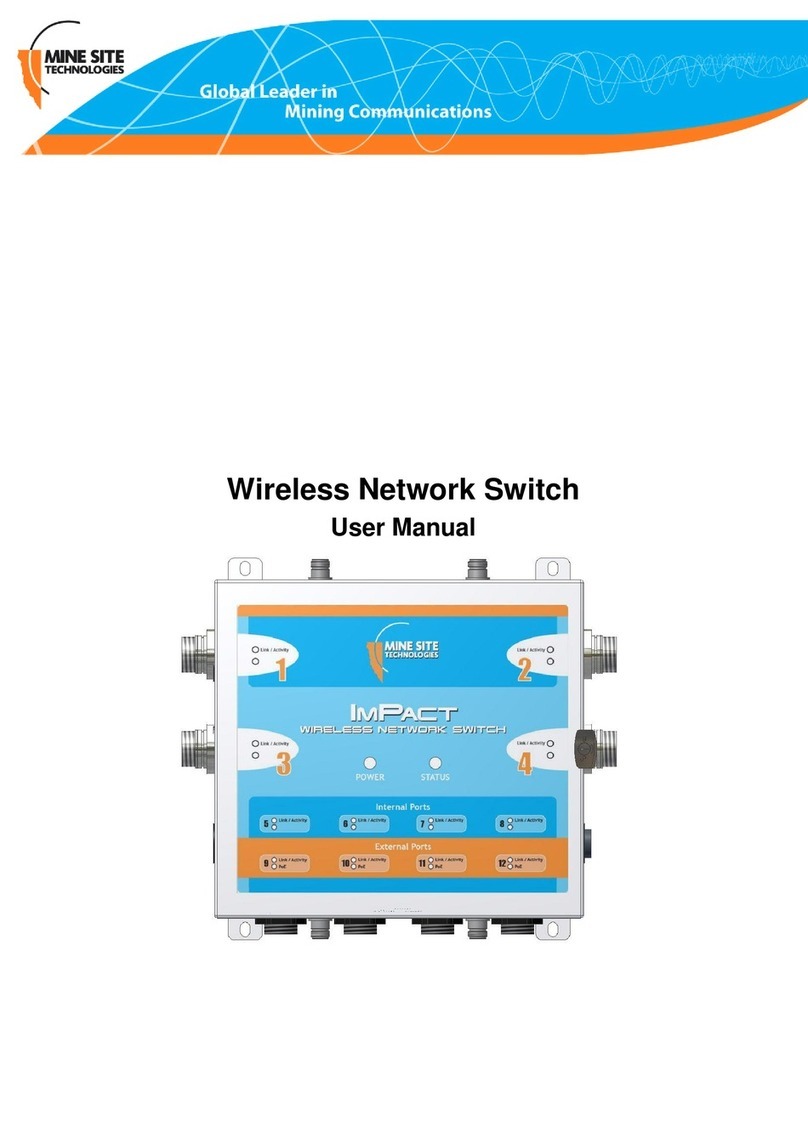

;

;

;

;

;

Quick Setup

Mode

OUT1 mode

OUT2 mode

NO/NC of OUT1, OUT2

Output response time

Unit

PV display color

;

;

easy

–ot1

.

,

.

,

–hys

–ot1

WCMp

–ot1

easy

–ot2

.

,

.

,

–hys

–ot2

WCmp

–ot2

1o2o

–noC

.

,

.

,

1C2o

–noC

1o2C

–noC

.

,

1C2C

–noC

Easy Hysteresis Window

Easy Hysteresis Window

–––2

–spd

.

,

.

,

–––4

–spd

––10

–spd

.

,

––50

–spd

OUT1 N.O.

OUT2 N.O.

OUT1 N.C.

OUT2 N.O.

OUT1 N.O.

OUT2 N.C.

OUT1 N.C.

OUT2 N.C.

.

,

––30

–spd

.

,

–100

–spd

.

,

–250

–spd

.

,

–500

–spd

.

,

1000

–spd

.

,

5000

–spd

Unit: ms

r-on

–Clr

.

,

.

,

6-on

–Clr

–red

–Clr

.

,

6ren

–CLr

–Mpa

–unt

.

,

.

,

–Kpa

–Unt

–K6f

–unt

.

,

–psi

–unt

.

,

–bar

–unt

.

,

mmh6

–unt

.

,

cmh6

–unt

.

,

inh6

–unt

MPa* kPa** kgf/cm² bar psi

mmHg** cmHg* inchHg

* Will not be displayed in low pressure type sensor. (QPSL)

** Will not be displayed in high pressure type sensor. (QPSH)

Quick Setup Mode

Additional Help and Support

• For additional technical support and questions, call our Technical

Support team @ 1-800-633-0405 or 770-844-4200

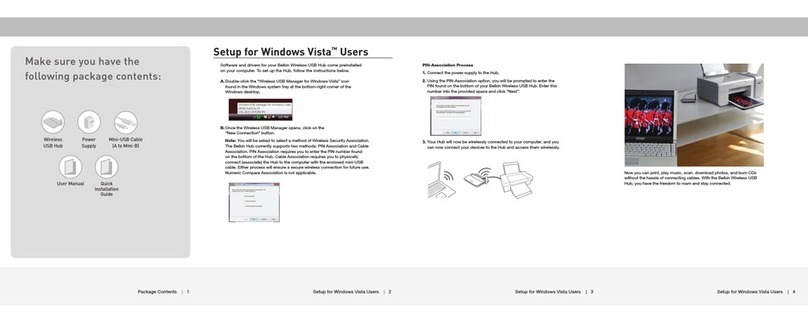

;

;

;

;

Pro Setup

Mode

SV/Setup Item Display

;

;

–std

–sub

.

,

.

,

–off

–sub

unit

–sub

–100

–dsp

.

,

.

,

–250

–dsp

–500

–dsp

Display SV Off Display unit

–––1

–hys

.

,

.

,

–––2

–hys

–––3

–hys

.

,

–––5

–hys

.

,

–––4

–hys

.

,

–––6

–hys

.

,

–––7

–hys

.

,

–––8

–hys

–off

–pWs

.

,

––on

–pws

out1

–dpy

.

,

.

,

out2

–dpy

–and

–dpy

.

,

––or

–dpy

0000

–Cod

.

,

0000

–002

–Pro

–set

Display Response Time

Switching Color Display

1000

–dsp

.

,

.

,

Cp-m

–Cpy

Power Saving

Hysteresis

Code

–off

–Cpy

.

,

Cp-5

–Cpy

Copy Mode

–off

–Asw

.

,

––on

–asw

Analog Output Enable

–off

–rst

.

,

––on

–rst

Reset to Default Settings

;

;

;

;

Slave mode Master mode

Pro Setup Mode

Copyright 2017, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Data Sheet: QPS-QSG P.2

See “Code” for details

Quick Setup Mode

ot1 Mode Selection for Output 1

ot2 Mode Selection for Output 2

EASY Easy Mode (Default) (see examples on Page 4)

HYS Hysteresis Mode (see examples on Page 4)

WCmP Window Mode (see examples on Page 4)

noC Normally Open /Normally Closed output selection

1o2o Output 1 Normally Open & Output 2 Normally Open (Default)

1C2o Output 1 Normally Closed & Output 2 Normally Open

1o2C Output 1 Normally Open & Output 2 Normally Closed

1C2C Output 1 Normally Closed & Output 2 Normally Closed

Spd Output Response Time in milli-seconds - use to minimize digital output fluctuations due to pressure variations

(Default = 2)

CLr Color - set how display color will change based on parameter dPY in Pro Setup Mode

r-on PV display turns red based on output status as set by parameter dPY in Pro Setup Mode (Default)

6-on PV display turns green based on output status as set by parameter dPY in Pro Setup Mode

rEd PV display is always red regardless of Out1 and/or Out2 state

6rEn PV display is always green regardless of Out1 and/or Out2 state

Unt Select Engineering Units

Engineering Units Display Resolution

QPSH QPSL

MPa MPa available only on QPSH-Ax-42 0.001 -

Kpa kPa- available only on QPSL-Ax-42 -0.1

k6f kgf/cm² 0.01 0.001

bAr bar 0.01 0.001

PSi psi (Default) 0.1 0.01

MMH6 mm Hg available only on QPSL-Ax-42 - 1

CMH6 cm Hg avalialbe only on QPSH-Ax-42 1 -

InH6 inch Hg 10.1

Pro Setup Mode

Pro Pro Setup Mode - Displays when entering Pro Setup Mode

Set Setup - Displays when entering Pro Setup Mode

sub SV / Setup Item Display selection

std Display shows SV (Default)

off OFF

unit Display shows Engineering unit, set by Unt in Quick Setup Mode

dsp Display response time rate in milli-seconds (Default = 100)

Hys Hysteresis setting for outputs in EASY and WINDOW modes (Default = 3), applies to both outputs

QPSH

MPa(MPa)1 = 0.001 MPa thru 8 = 0.008 MPa -

kPa(KpA)-1 = 0.1 kPa thru 8 = 0.8 kPa

kgf/cm²(k6f)1 = 0.01 kgf/cm² thru 8 = 0.08 kgf/cm² 1 = 0.001 kgf/cm² thru 8 = 0.008 kgf/cm²

bar(bAr)1 = 0.01 bar thru 8 = 0.08 bar 1 = 0.001 bar thru 8 = 0.008 bar

psi(PSI)1 = 0.1 psi thru 8 = 0.8 psi 1 = 0.01 psi thru 8 = 0.08 psi

mm Hg(MMH6)-1 = 1 mm Hg thru 8 = 8 mm Hg

cm Hg(CMH6)1 = 1 cm Hg thru 8 = 8 cm Hg -

In Hg(InH6)1 = 1 in Hg thru 8 = 8 in Hg 1 = 0.1 in Hg thru 8 = 0.8 in Hg

pWs Power Saving Mode - Turns display back light off. Display values can be viewed momentarily by

pressing the ;button

dpy Switching color display - sets when display changes colors (as set by parameter CLr) based on output

status

out1 Color changes when Output 1 is ON (Default)

out2 Color changes when Output 2 is ON

and Color changes when Output 1 and Output 2 are ON

or Color changes when Output 1 or Output 2 is ON

Cod Code - quick reference to determine the settings of the QPS device (See Code Reference Table - Page 3)

CPY Copy - used to select master and slave when copying settings to other QPS devices

CP-s Copy Slave Mode

CP-m Copy Master Mode

Asw Analog Output Enable (Default = ON)

rst Reset QPS to Factory Defaults

P.3

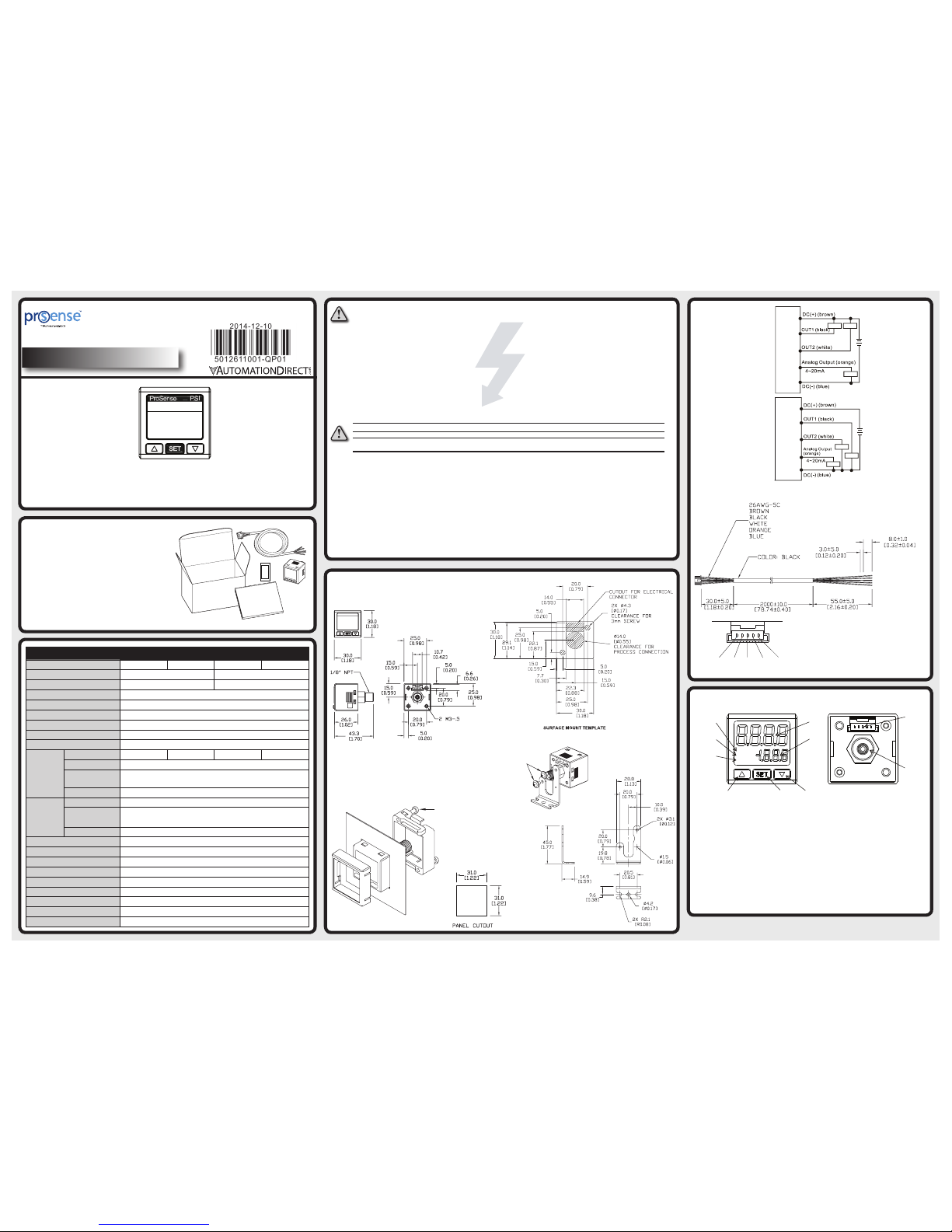

Analog Output

The analog output is directly proportional to the process pressure over the full range of the device. For example if the process pressure is 0 psi

the 4-20 mA output of a QPSL will be approximately 12 mA or for the QPSH the pressure at 12 mA would be 65.3 psi and for 0 psi the output

would be 5.45 mA. The analog output is enabled as the factory default. It can be disabled with the “Analog Output Enable” parameter in Pro

Setup Mode.

4mA

12mA

20mA

-14.5psi 14.5psi 4mA

12mA

20mA

-14.5psi 145psi

QPSL-xx-42 QPSH-xx-42

0psi 65.3psi

5.45mA

0psi

Process Connection

Use a suitable thread sealant Teflon® tape. Do not use liquid thread

sealant. Always tighten with an open end or adjustable wrench on

the wrench flats. Never use any part of the pressure gauge to tighten

other than the wrench flats that are on the gauge socket. Failure to

do so will severely damage the pressure gauge.

OK

SET

ProSense PSI

CODE (Pro Setup Mode Parameter Cod)

CODE provides a quick method to determine the settings of the QPS parameters (Factory Default 0000 302)Locking the Keys

Lock On: Press ; and .together for 2 seconds until

lock

on

is

displayed. You will then see the display of pressure value (PV) and

setpoint value (SV).

Lock Off: Press ; and ,together for 2 seconds until

lock

off

is

displayed. You will then see the display of pressure value (PV) and

setpoint value (SV).

Lock Display: Press any key in the key locking mode, and you will see

the display of pressure value (PV) and lCk (SV). Release the key and

the PV and SV will return to original values.

QPS is able to copy the parameters from one

device to another.

Electrical connection for copying parameters:

Connect Pin 2 (black) on master to Pin 3 (white) on slave; Pin 3

(white) on master to Pin 2 (black) on slave; Pin 5 (blue) on master

and slave to COM on power supply; Pin 1 (brown) on master and

slave to +24V on power supply.

Setup for copying paramters:

Slave device: In the “Run Mode”, press ;for more than 4 seconds

and release the key after you see

pro

set

. You are now in “Pro Setup

Mode”. Press ; 7 times and find the parameter for setting up the

copy function (See Pro Setup Mode chart). Use ,. to select

Cp-s

Cpy (CP-S refers to Copy-Slave).

Master device: In the “Run Mode”, press ; for more than 2

seconds and release the key after you see

pro

set

. You are now in the

“Pro Setup Mode”. Press 7 times and find the parameter for setting

up the copy function (See Pro Setup Mode chart). Use ,. to

select

Cp-m

Cpy (CP-M refers to the Copy-Master).

Next, press ;for more than 2 seconds and return to the “Run

Mode”.

Now you will see Cp-m on the display and CP-S on the slave

device, indicating that the two devices have been connected. In the

lower display int you will see numbers counting up, referring to

the number of parameters transmitted successfully between the two

devices.

Once the copy of parameters completes, you will see

Cp-m

ok

on the master device and

Cp-s

ok

on the slave device.

After the copy is complete, power the units off and re-connect them

according to the wiring diagram.

Resetting Zero Pressure:

Remove pressure from device before starting.

In the “Run Mode”, press ,. simultaneously, and you will see

0000

adj. The zeroing will start. Release the keys to end the zeroing

sequence.

Code

1st digit 2nd digit 3rd digit 4th digit

OUT1 mode N.O./N.C. OUT2 mode N.O./N.C. Output Response

Time Color Switching Color Display

0Easy N.O. Easy N.O. 2ms

Red when ON

OUT1

1N.C. N.C. 4ms OUT2

2Hysteresis N.O. Hysteresis N.O. 10ms OUT1 and OUT2

3N.C. N.C. 30ms OUT1 or OUT2

4Window N.O. Window N.O. 50ms

Green when ON

OUT1

5N.C. N.C. 100ms OUT2

6– – – – 250ms OUT1 and OUT2

7– – – – 500ms OUT1 or OUT2

8– – – – 1,000ms

Red

OUT1

9– – – – – OUT2

A– – – – – OUT1 and OUT2

B– – – – – Red OUT1 or OUT2

C– – – – –

Green

OUT1

d– – – – – OUT2

E– – – – – OUT1 and OUT2

F– – – – – OUT1 or OUT2

Code 6th digit 7th digit 8th digit

Pressure Unit Display Response Time SV/Setup Item Display Hysteresis Setting

0kPa or MPa

100ms

Standard 1

1kgf/cm² Off 2

2bar Unit 3

3psi

250ms

Standard 4

4mm Hg or cm Hg Off 5

5inch Hg Unit 6

6–

500ms

Standard 7

7–Off 8

8–Unit –

9–

1,000ms

Standard –

A–Off –

B–Unit –

QPS Display

P.4

Data Sheet: QPS-QSG

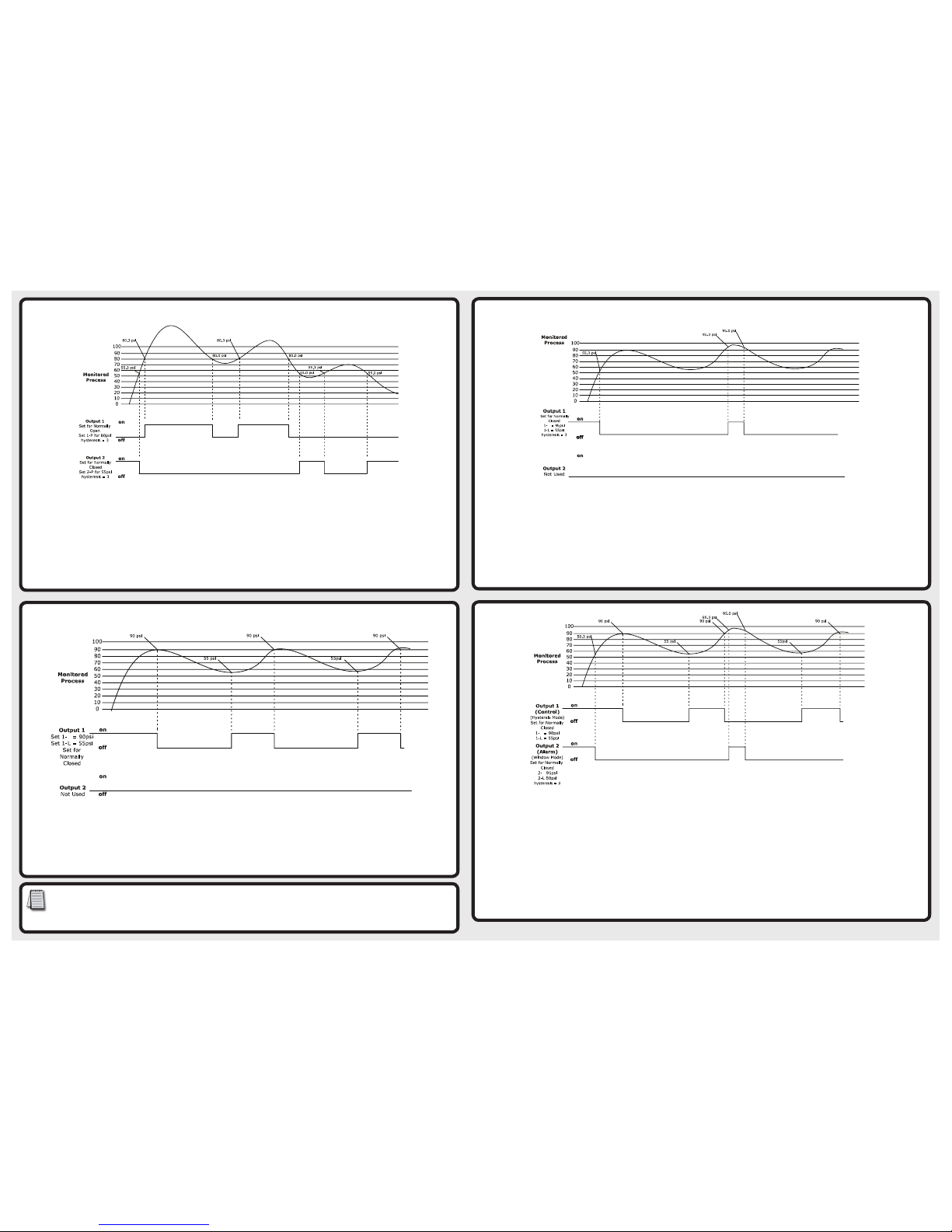

Window Mode: In the example below the output will change state when the measured pressure increases to 55.3psi (1-L SV + HYS)and will

change state again when the pressure increases to 90.3psi (1-H SV + HYS). As the measured pressure decreases back to 90psi (1-H SV) the output

will change state and will change state again when the pressure decreases to 55psi (1-L SV). Each digital output can be individually set.

Using Hysteresis Mode to control the pressure in a tank

Hold ;button for 2-3 seconds until display changes.

Verify 0T1 is set to HYS, if not use the ,. to change and press ;button.

Verify 0T2 is set to EASY, if not use the ,. to change and press ;button.

Verify noC is set to 1C2o, if not use the ,. to change and press ;button.

Press and hold the ; button until the display changes to show the Setpoint and Process values.

Using the ,. set the output 1 1-H level to 90psi.

Briefly press and release the ;button to change to 1-L and set it to 55psi.

Hysteresis Mode: When the measured pressure is greater than the Hi setpoint, the output will change state. When the measured pressure

is less than the Lo setpoint, the output will change state. Each digital output can be individually set.

Using EASY Mode to Set up a Simple Alarm

Hold ;button for 2-3 seconds until display changes.

Verify 0t1 is set to easy, if not use the ,. to change and press ;button.

Verify 0T2 is set to EASY, if not use the ,. to change and press ;button.

Verify noC is set to 1o2C, if not use the ,. to change and press ;button.

Press and hold the ; button until the display changes to show the Setpoint and Process values.

Using the ,. set the output 1 ON level for 1-P to 80psi.

Briefly press and release the ;button to change to 2-P and set the output 2 ON level to 55psi.

Hold ;button for 4-5 seconds until display changes to Pro.

Press the ;button 3 times so that HYS is on the display.

Verify the value 3 is in the lower display, if not use the ,. to change and press ;button

Press and hold the ;button until the display changes to show the Setpoint and Pressure copy values.

Easy Mode: When the measured pressure is greater than pressure setpoint plus the hysteresis setting (SV+hysteresis), the output will

change state. When the measured pressure is less than the pressure setpoint (<SV), the output will change state. Each digital output can

be individually set.

Copyright 2017, Automationdirect.com Incorporated/All Rights Reserved Worldwide

H

H

Hysteresis is defined as: The lag in response of the output in reacting to changes in the process affecting it. For example Setpoint

1-P is set to 80 PSI for output 1 but the output does not change state when the pressure is increasing until the actual pressure

reaches 80.3 PSI (1-P+hysteresis), the output will then change back to its neutral state once the pressure drops below the Setpoint

of 80 PSI. This function known as Hysteresis is used to prevent the outputs from chattering if the process pressure were to hover

close to the Setpoint.

H

H

Using Hysteresis mode to control the pressure in a tank and window mode to generate an alarm

Wire the QPS using the connection diagrams supplied.

Hold ;button for 2-3 seconds until display changes.

Verify 0T1 is set to Hys, if not use the ,. to change and press button.

Verify 0T2 is set to WCMP, if not use the ,. to change and press button.

Verify noC is set to 1C2C, if not use the ,. to change and press button.

Press and hold the ;button until the display changes to show the Setpoint and Process values.

Using the ,. set the output 1 1-H level to 90psi.

Briefly press and release the ;button to change to 1-L and set it to 55psi.

Briefly press and release the ;button to change to 2-H and set it to 95psi.

Briefly press and release the ;button to change to 2-L and set it to 50psi.

Hold ;button for 4-5 seconds until display changes to Pro.

Press the ;button 3 times so that Hys is on the display.

Verify the value 3 is in the lower display, if not use the ,. to change and press ;button.

Press and hold the ;button until the display changes to show the Setpoint and Process values.

Hysteresis & Window Modes of operation for control and alarming

Using Window Mode to create alarm condition

Hold ;button for 2-3 seconds until display changes.

Verify 0T1 is set to wCmp, if not use the ,. to change and press ;button.

Verify 0T2 is set to EASY, if not use the ,. to change and press ;button.

Verify noC is set to 1C2o, if not use the ,. to change and press ;button.

Press and hold the ;button until the display changes to show the Setpoint and Process values.

Using the ,. set the output 1 1-H level to 95psi.

Briefly press and release the ;button to change to 1-L and set it to 55psi.

Hold ;button for 4-5 seconds until display changes to Pro.

Press the ;button 3 times so that Hys is on the display.

Verify the value 3 is in the lower display, if not use the ,. to change and press ;button

Press and hold the ;button until the display changes to show the Setpoint and Process values.

This manual suits for next models

3

Popular Switch manuals by other brands

Savant

Savant PAV-SIPA50SM quick start guide

steute

steute Ex 61 Z Mounting and wiring instructions

Harris

Harris IconMaster Installation and configuration manual

AAVARA

AAVARA PB9000W user guide

Siemens

Siemens SCALANCE X-300EEC Compact operating instructions

Korenix

Korenix JetNet 701 Quick installation guide