PS Motor Manet Korado User manual

·~

·

moped

Owner's

Manual

moped

Owner's

Manual

The moped KORADO is a vehicle used for transport on roads with reinforced sur-

face

to

bring you to work

or

to

spend free time for leisure and sports.

The vehicle is driven with a reliable PUCH motor which is built under licence and

together with easy operation guarantees safe, comfortable and economic driving. It

has a massive frame, good ergonomical parameters and a modern design. Among its

other advantages belong long life, high performance, economical operat

io

n and a

reasonable price.

Read this ma

nu

al

before your fi

rs

t drivi1g

to

learn how

to

operate the moped and

respect recommendations included

in

this manual.

Th

e KORADO moped went thro-

u

gt

·,

t

or1g-

tirn~

t~st

ing

and its modern production technology a

nd

tr

ad

ition is a

gu

aran-

tee of its high European quality standard. •

We wish you many troublefree and safe kilometers on your new moped.

PS MOTOR MANET a. s.

Povazska Bystrica

The producer reserves the right to change the text and pictures

in

this manual.

2

CONTENT

Main partsi ..

..

..........

..

......

...

..

....

..

. 5

Introduction.................................. 6

Technical data

..

............

.

..

........

..

. 7

Control elements ...............

......

..

. 8

Instructions for driving ................ 10

Maintenance and adjustment

..

..

. 12

Maintenance chart

....

......

..

.....

....

. 24

Lubrication chart

..

..............

..

....

..

.

25

Troubleshooting ............

....

.......

..

. 26

Electrical equipment diagram

....

. 27

Tools and outfit

..

........

..

........

..

....

. 28

Spare parts

..

..

......

..

....

..

..........

..

..

. 28

3

22

21

zo

12

f1

fO

8

l3

14

15

16

11

23

18

2~

19

1 2 3

4

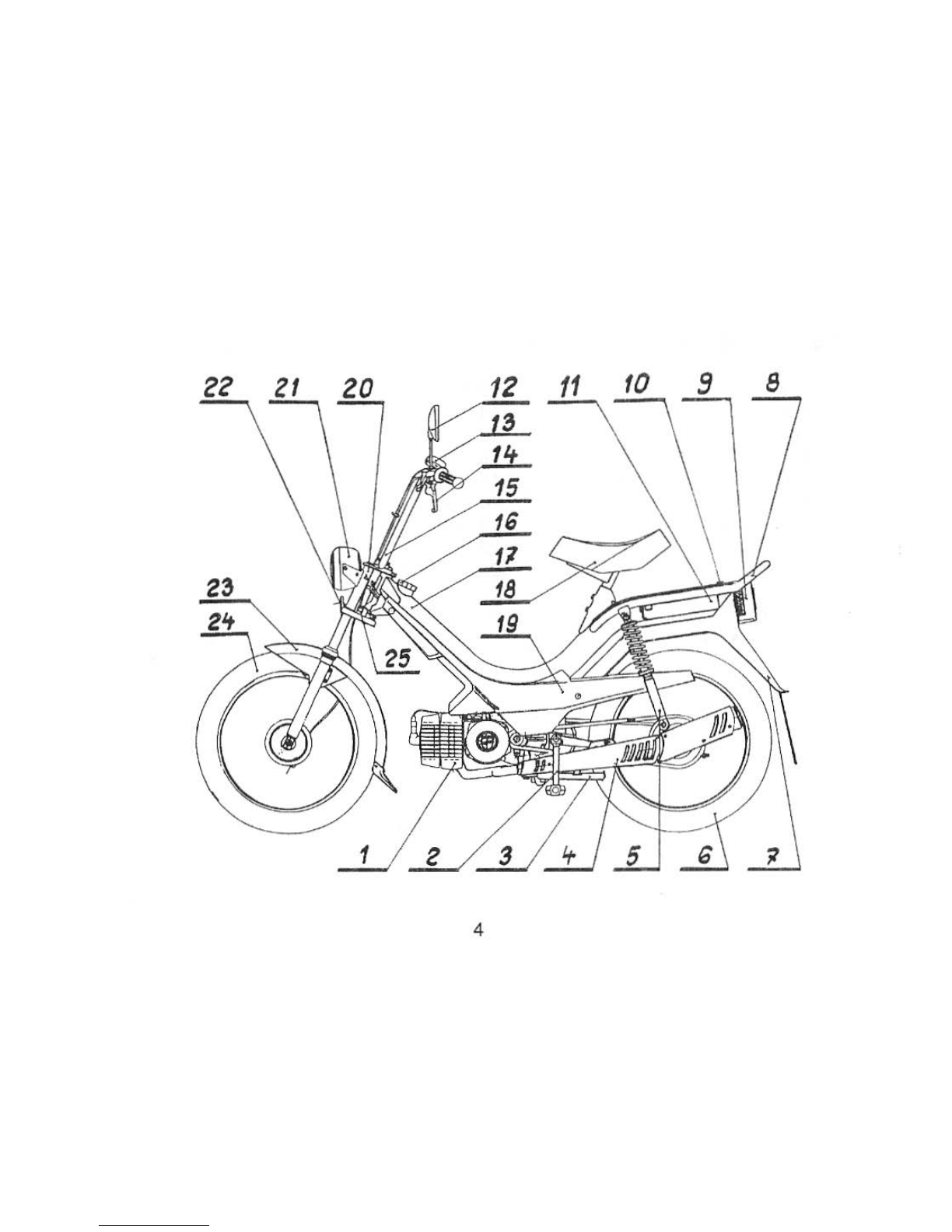

Fig. 1 KORADO

Moped-

ma

in parts

1.

Engine

2. Pedals

3.

Stand

4.

Exhaust silencer

5.

Telescopic rear suspension

6. Rear wh

ee

l

7.

Rear mudguard

8. Luggage rack

9. Rear light

1

0.

Air-release valve

11. Tool kit

12.

Rear-view mirror

13. Be

ll

14. Cont

ro

l levers

1

5.

Handlebars

1

6.

Filler cap

1

7.

Frame

18. Saddle

19. Side covers

20. Teleskopic front suspension

21

. Headlight

22. Front reflecting glass

23. Front

mu

dguard

24. Front wheel

25.Lock

5

1.

In

troduction

-Takeover of the motorcycle

Control the outfit for completeness according to the documentation when taking

over the motorcycle.

-Control the serial number if

it

coincides with the documentation-the serial num-

ber

is

located on the upper part of the frame and is readable from

th

e right side of the

motor. The motor number need not be identical with the number of the chassi

s.

Get

acquainted with the main parts and control elements before your first drive (fig. 1).

-AT

T E

NT

I 0 N -You have bought a two-stroke engine. It is therefore neces-

sary

to

mix the main fuel -gasoline with oil

in

the ratio 1:33 when breaking-in and

1:40 after breaking-

in

the engine. Use fuel with octane number 95 and oil SHELL-

SUPER

2T

. When using synthetic oil SHELL SUPER 2TX the mixing ratio is 1:50.

6

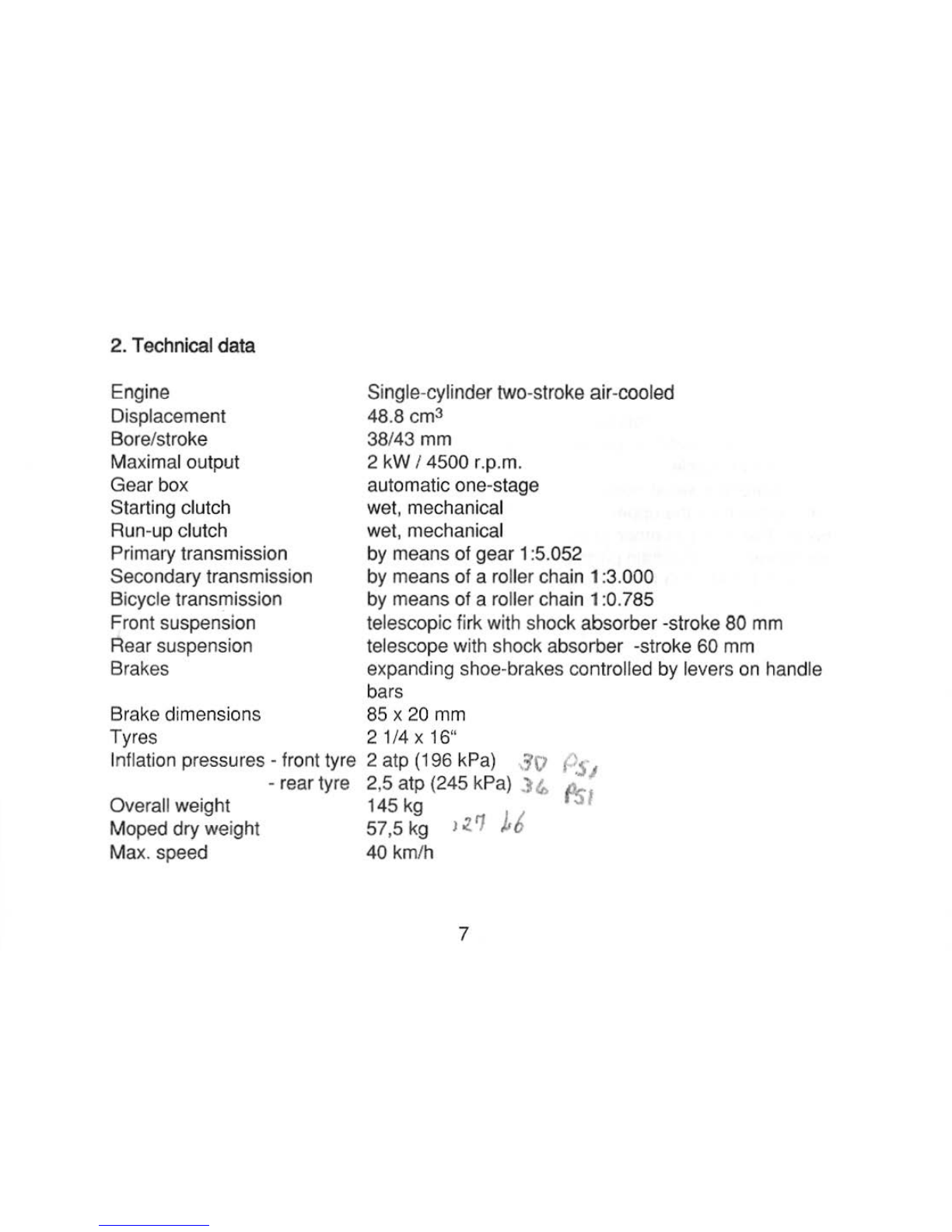

2. T

ec

hni

ca

ldata

Engine

Displacement

Bore/stroke

Maximal output

Gear box

Starting clutch

Run-up clutch

Primary transmission

Secondary transmission

Bicycle transmission

Front suspension

Rear suspension

Brakes

Brake dimensions

Tyres

Inflation pressures

-front

tyre

-reartyre

Overall weight

Moped dry

we

i

ght

Max

. speed

Single-cylinder two-stroke air-cooled

48.8 cm3

38/43 mm

2

kW

I 4500 r.p.m.

automatic one-stage

wet, mechanical

wet, mechanical

by means of

gea

r 1:5.052

by means of a roller chain 1:3.000

by means of a roller chain 1:0.785

telescopic firk with shock absorber -stroke

80

mm

telescope with shock absorber -stroke 60 mm

expanding shoe-brakes controlled by levers

on

handle

bars

85 x20 mm

2 1/4 X 16"

2 atp (196 kPa)

30

1

~!i!

2,5

atp

(245 kPa) .l

~

f's

1

145 kg

57,5 kg )

.z.

tJ

t6

40

km/h

7

Fuel tank capacity

Hill-climbing capacity

Noise

Basic fuel consumption

Carburettor

Power supply

Ignition

Spark advance

Spark plug

Head

lamp

Tail

lamp

41

14%

72

dB

(A)

1,7 1/100

km

at 27 km/h

BING 18/

14

/

108

alternator 6 V/

20

W

flywheel

magnet

-

type

contact ignition

1.2

-

1.4

mm,

gap

0,4 mm

BOSCH W 5 AC

6 V/15 W

6 V/5 W

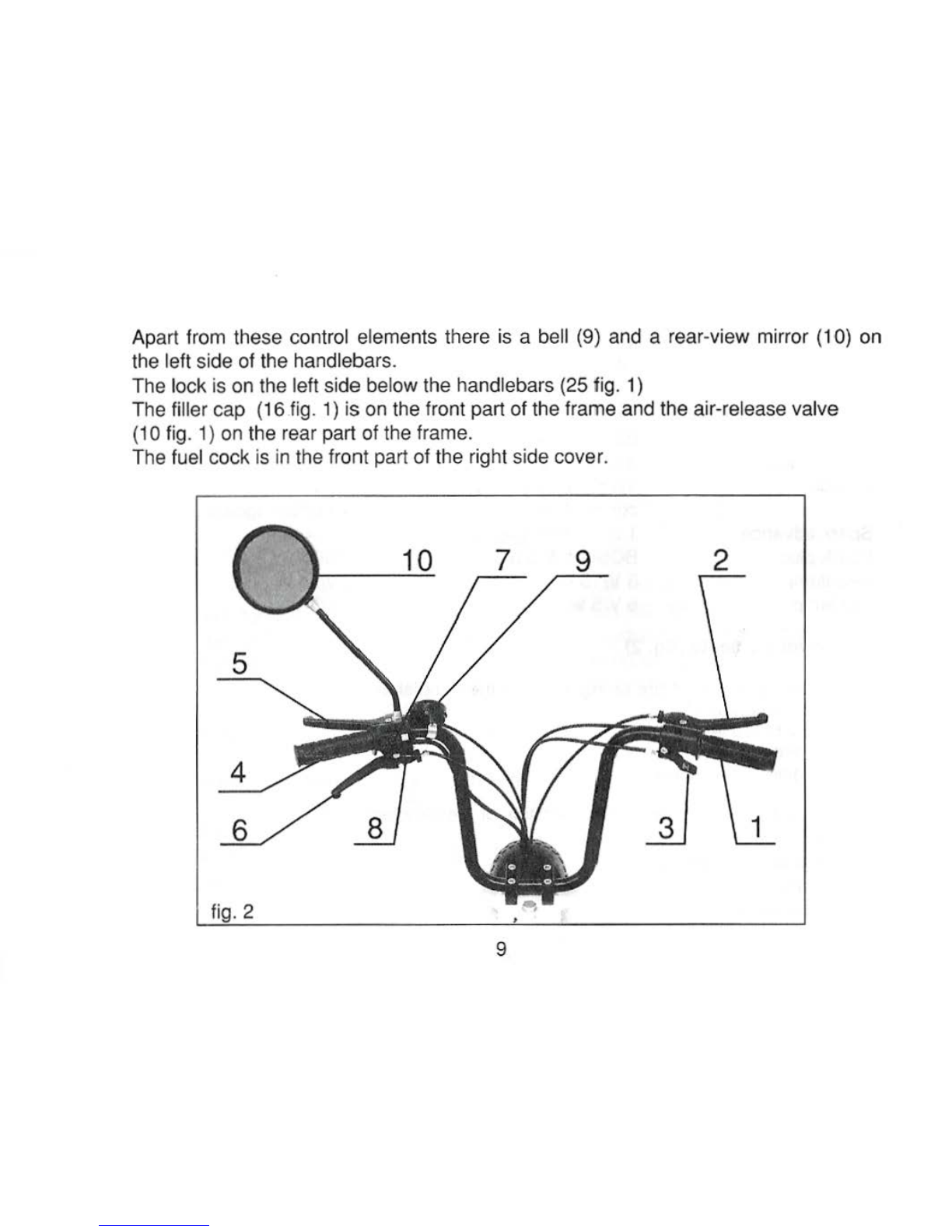

3. Control elements (fig. 2)

The following elements are on right side

of

the handlebar:

-throtle

co

ntrol (1)

-front br

ake

l

ever

(2)

-choke

(3)

-engine stop push button (8)

alternat

or

12 V/40 W

flywheel magnet-type

contactless ignition

1,2-1,4 mm

BOSCH

W5

AC

12 V/15 W

12

V/5

W

The

following elements are on the left side

of

the handlebar:

-firm

grip (4)

-rear brake lever (5)

- starting clutch lever (6)

-lights switch (7)

8

Apart from these control el

ements

there is a bell (9) and a rear-

view

mirror (1

0)

on

the left side of the handlebars.

The

lock

is

on the left side bel

ow

the handlebars (25 fig. 1)

The

filler

cap

{

16

fig. 1)

is

on the front part

of

the frame and the air-release

valve

(10 fig.

1)

on the rear part of the frame.

The fuel

cock

is in the front part

of

the right side cover.

9 2

5

4

8 3 1

fig. 2 •

9

4. Instructions for driving

Fill the tank with the gas-oil mixture befo

re

drivi

ng

as follows:

Unscrew the cap of the tank and release the air-release valve which

is

in

the upper

rear part of the frame. Fill t

he

tank up to the mark which is a wire sieve

in

the filler

neck. Close the air-release valve after refilling by tightening the screw and put on the

fi

ll

er

cap.

AT

TENT

I 0 N I The air-release valve can not be loosened after

fi

lling the tank. it

could cause fuel leaking through the ventilation hole of the filler cap. If it is not possi-

ble

to

fill the

ga

s-oil mixture automatically

at

the petrol station mix the fuel

in

a vessel

before refilling the

ta

nk.

Check

th

e following before

dr

iv

in

g:

-correct function of the brakes

- inflation pressure

- function of lights

-

ti

ghening of

th

e chain

Drive wi

th

the heal

ig

ht on according to the traffic r

eg

ul

ations.

10

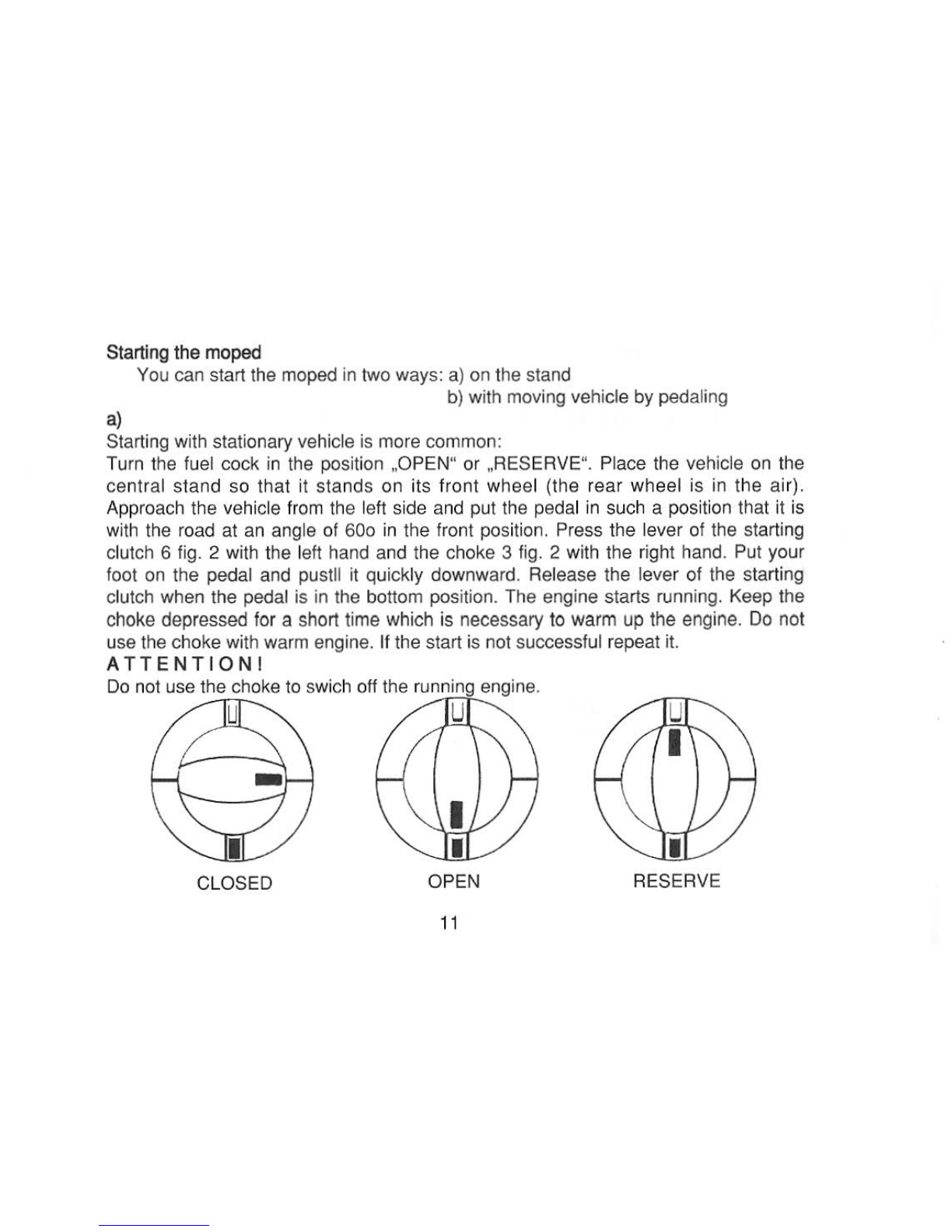

Starti

ng

the moped

You can start the moped

in

two ways: a)

on

the stand

b) with moving vehicle by pedaling

a)

Starting with stationary vehicle

is

more common:

Turn the fuel cock

in

the position ,OPEN" or ,RESERVE". Place the vehicle

on

the

central stand so that it stands on its front wheel (the rear wheel is

in

the air).

Approach t

he

vehicle fr

om

the left side and put the pedal in such a position that it is

with the road at

an

angle of 60o

in

the front posit

ion.

Press the lever of the starting

clutch 6 fig. 2 with the left hand and the choke 3 fig. 2 with the right hand. Put your

foot

on

the pedal and pustll it quickly downward. Release the lever of the starting

clutch when the pedal is in the bottom position. The engine starts runni

ng.

Keep the

choke depressed for a short time which is necessary to warm up the engine.

Do

not

use the choke with warm engine. If the start

is

not successful repeat it.

A T T E

NTI

O

N!

Do

not use the choke to swich off the r

un

n

ing

engine.

u u

CLOSED OP

EN

RESERVE

11

b)

Starting by pedaling

Put the fuel cock into the position ,OPEN" or ,RESERVE". Use the pedals to start

moving. When you reach a sufficient speed press the clutch lever with t

he

left hand

and the choke wi

th

the thumb of your right hand at the same time. Release both lev-

ers after the engine starts. Turn the twist grip

to

continue driving. By full turning of the

twistgrip the throttle of the carburettor opens fully and the vehicle reaches its maxi-

mum speed.

Do not start with moving vehicle if the weather conditions are bad (wet road, ice

etc.).

Stopping the engine

Lower the rotations of the engine, apply brakes and stop the vehicle.

The engine

is

idling. Press the engine cut-off 8 fig. 2 (red push button

on

the right

side of the handlebar) and the engine stops.

Breaking-in a

new

engine

Prepare the fuel mixture by mixing gas and oil

in

the ratio 1

:40

. Drive the first 500

km

with a maximal speed of 35 km/h.

5. Maintenance and adjustment

For cleaning the varnished and chromium plated vehicle parts use only water and

det

e

rg

e

nts.

After

washing

,

wipe

these

parts

dry.

Do

not

use

kerosene

and

other

sol-

vents when cleaning parts of plastics or rubber because they have detri

men

tal effect

on

such parts.

12

Take a short ride after washing the vehicle and dry the brakes by repeated short

breaking.

Exhaust silencer - it

is

almost not contaminated if you use the corrext gas-oil

mixture.

You

do not have to clean it after the fi

rst

5000

km.

It

is necessary to remove the

carbon deposi

ts

if the gas-oil ratio was wrong and after several years of driving.

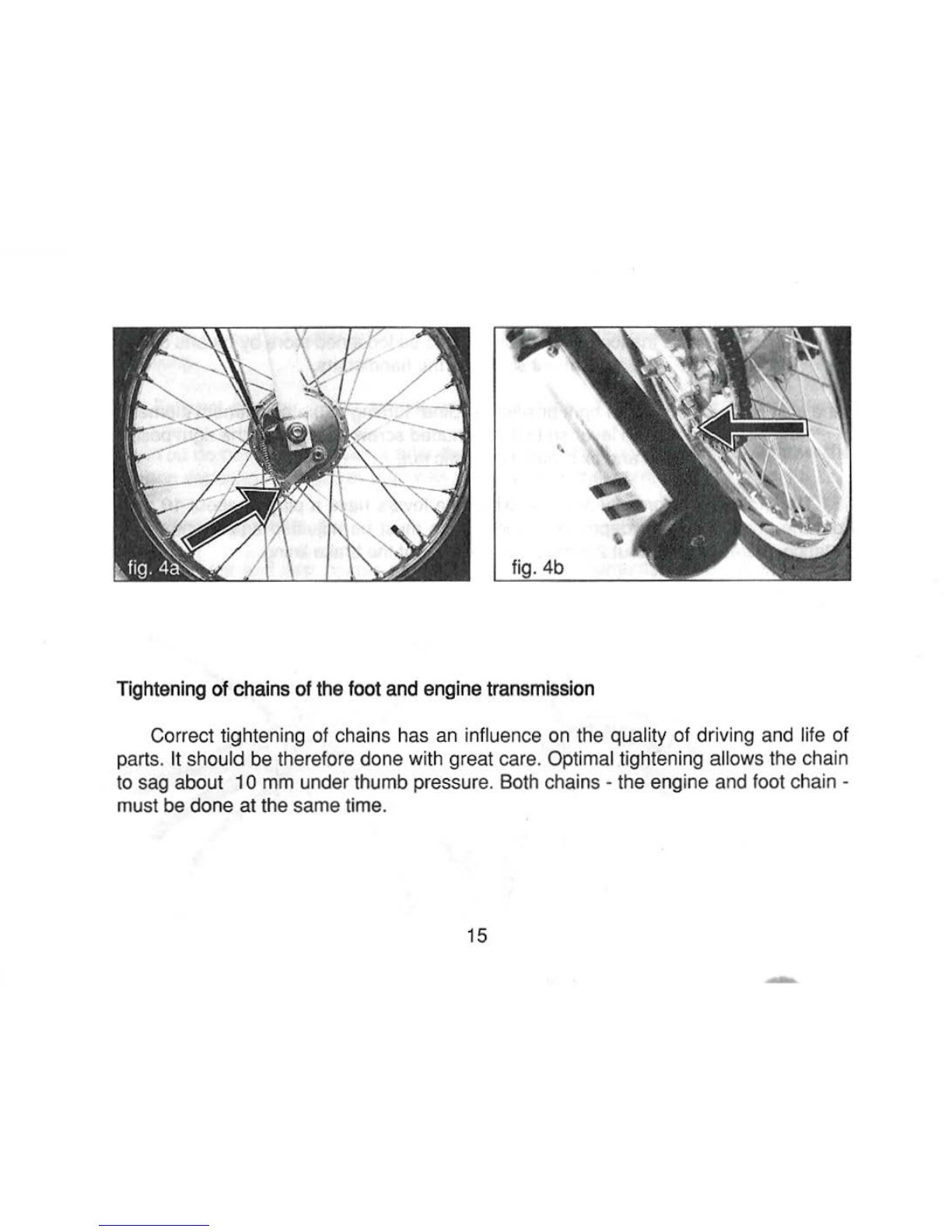

Adjustment

of

brakes

The front

and

rear brakes have two

ad

justment elements. Use the adjustment

elements at the end of the bowdens fig 4a, b for rough adjustment and the elements

on

the control levers fig. 3a, b for fine adjustment. Set the adjusting screw 1 fig. 3a, b

on

the handlebars into medium screwed position before rough adjustment.

Procedure: Put the brake lock into such a position that the jaws are fully open.

Loosen it slightly and fix it

in

th

is position by means of the adjustment element

(screw, nut). Press the brake lever.

13

If the play is too small: the lock of the brake has to be loosened more by means of

the adjustment screw on the handlebars.

If the play is too big: Find the right positi

on

by

,f

ine" turning of the adjustment element

on the lever so that the knurled screw determines the right posi

tion and fix

it

with the plastic nut.

The brakes are correctly adjusted when the levers have a play

of

about 10

mm

from the grip after being depressed. The brakes must be adjusted again when this

distance decreases to about 2

mm

due to the wear of the brake lining.

fig. 3a 1 fig. 3b

14

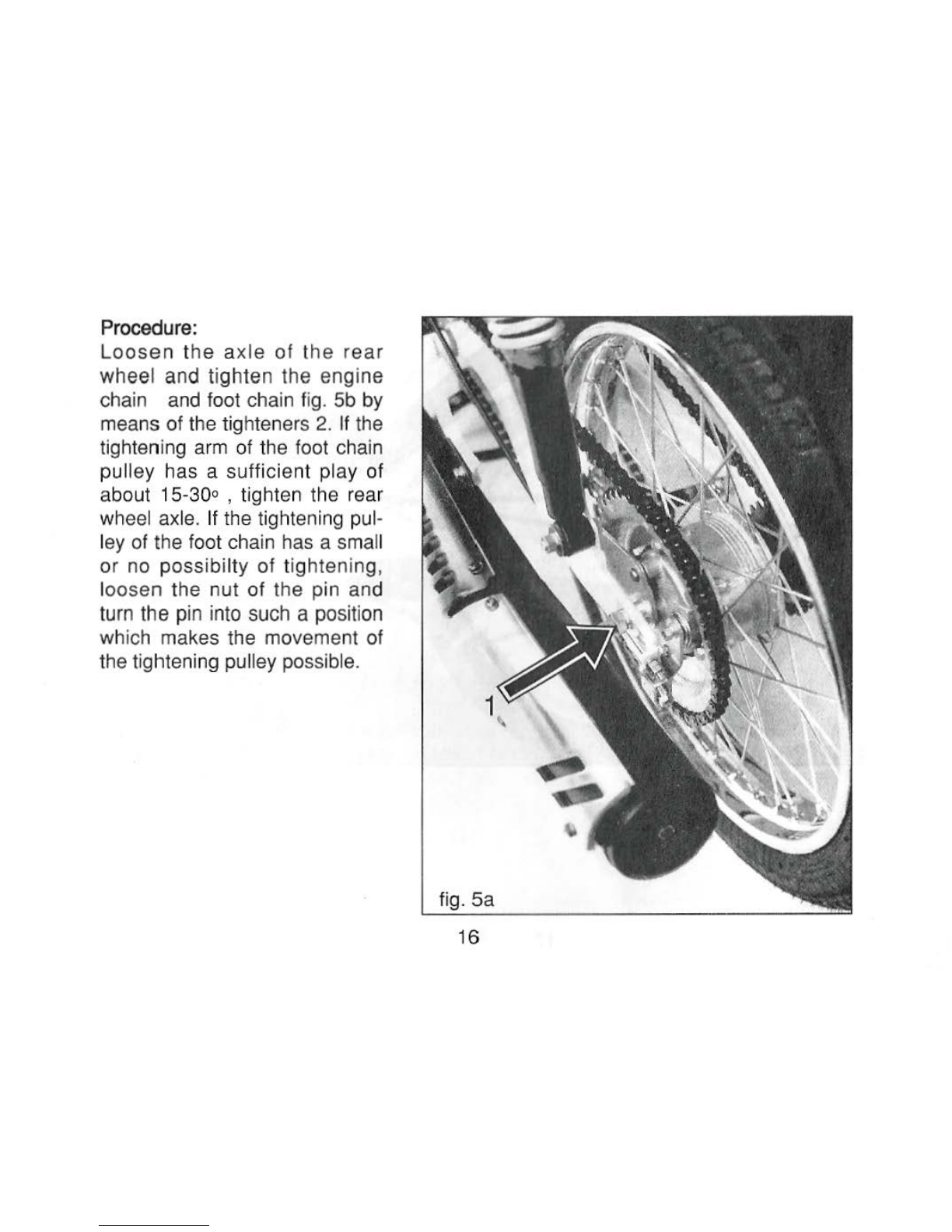

Tighte

ning

of

chains

of

th

efoot

and

eng

i

ne

tra

nsmi

ss

ion

Correct tightening

of

chains has an influence on the quality

of

driving and life

of

parts. It should be therefore done with great care. Optimal tightening allows the chain

to sag about

10

mm under thumb pressur

e.

Both chains -the engine and foot chain -

must be

done

at

the same time.

15 -

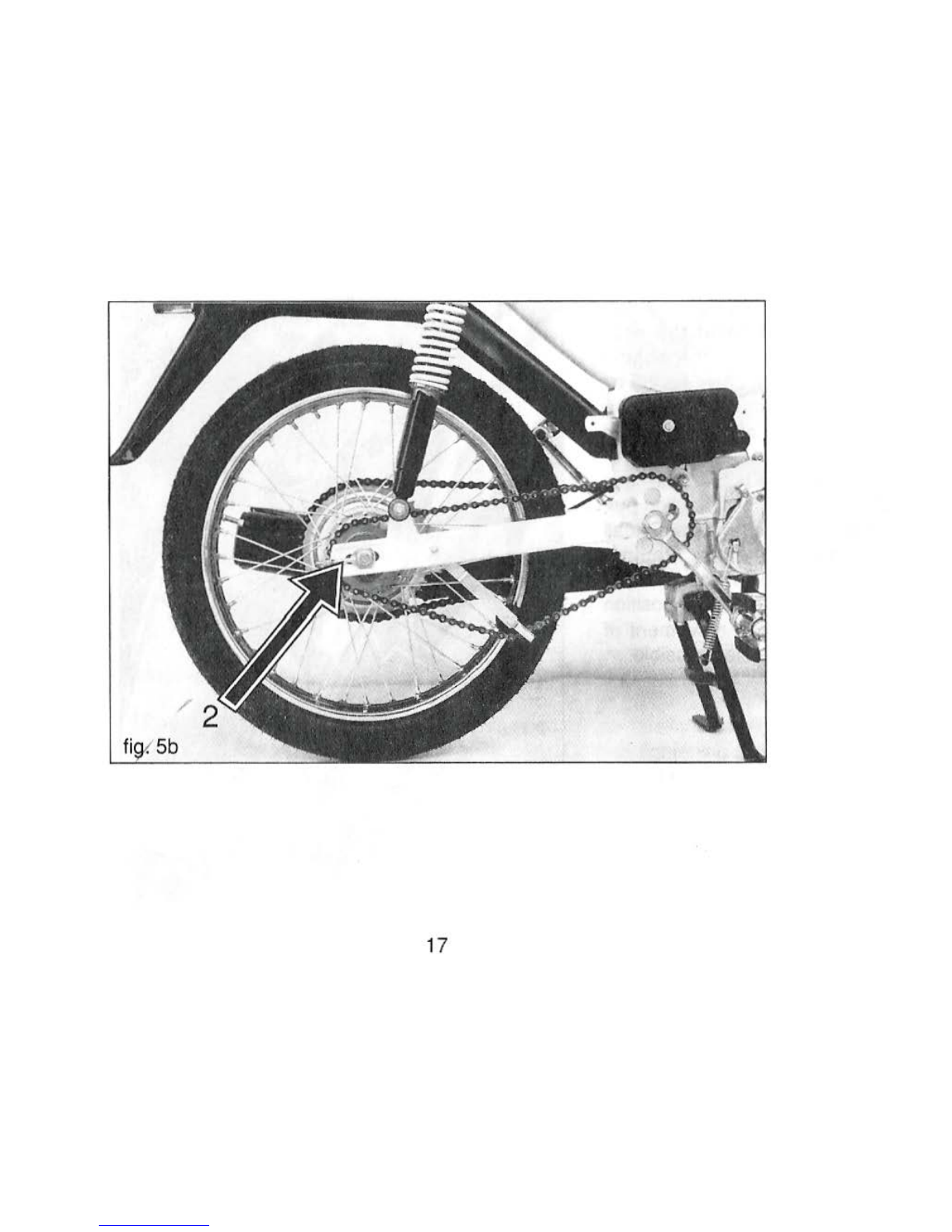

Procedure

:

Loosen

the axle of t

he

rear

wheel and tighten the engine

chain and foot chain fig.

5b

by

means of the tighteners

2.

If the

tighteni

ng

arm

of the foot chain

pulley has a sufficient play of

about 15-30o , tighten the

rear.

wh

ee

l axle. If the tightening pul-

ley of the foot chain has a small

or

no

possibilty of tightening,

loosen the nut of the pin

an

d

tu

rn

the pin into such a position

wh

ich makes t

he

movement of

the tightening pulley possible.

fig. 5a

16

17

Adjustment

of

the carburettor

The B

IN

G carburettor is adjusted by the manufacturer

to

give optimal parame-

ters. It

is

therefore undesirable to change the setting because it could.influence its

optimal setting.

If the carburettor

is

out of order it is recommended to have it repaired

in

an au-

thorized repair shop.

Oil change in gear-box:

Recommended oil

is

SHELL DONAX TA. Oil filling

is

done by producer for life

cycle of vehicle.

In

case of any other repairs where oil must be changed, contact your

dealer.

Adjustment

of

the ignition

Optimal ajdustment of t

he

ignition ensures optimal output of the engine. The ad-

justment has to be carri

ed

out with utmost care and accuracy and should be done

in

an authorized repair shop

18

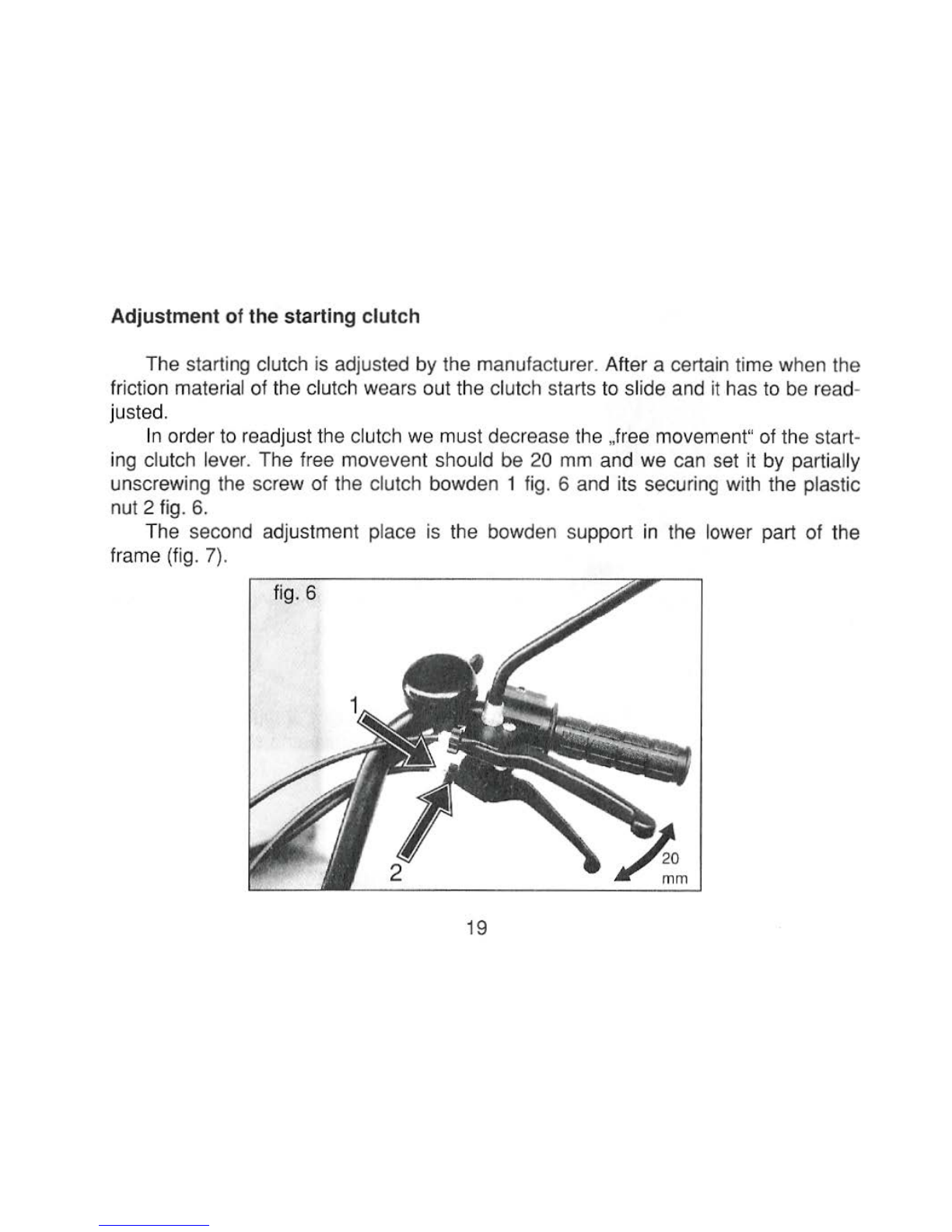

Adjustment of the starting clutch

The starting clutch is adjusted by the manufacturer. After a certain

ti

me

when the

friction material of the clutch wears out the clutch starts to slide and

it

has

to

be read-

justed.

In order to readjust the clutch we must decrease the ,free movement" of the sta

rt

-

ing clutch lever. The free movevent should be 20

mm

and we can set it by partially

unscrewing the screw of the clutch bowden 1 fig. 6 and its securing with the plastic

nut 2 fig. 6.

The second adjustment place is the bowden support

in

the

lo

wer part of the

frame (fig. 7).

fig. 6

19

Table of contents