PteroWorks 3D Mini Guppy User manual

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 1

Thank you for purchasing this 3D Guppy kit. It can be built in a day or two, or a few evenings. If you have built and

covered a wood model before you should have no trouble here, but please read the instructions thoroughly. Take your

time, be careful and have fun with the build. You will need thin and medium CA glue, 15 minute epoxy or aliphatic

wood glue, and sandpaper to assemble the airframe, and small spring clamps or clothespins will also be helpful. This

manual can be downloaded from the website (PteroWorks.com) as a PDF, and the pictures enlarged on your computer

for greater clarity.

The 3D Mini Guppy is easy to y with the control surfaces at low rates - it is very docile, but it is not a high-wing trainer

and requires some ying experience. At high rates the 3D Guppy is capable of many 3D maneuvers. The wing loading

is very low, and if set up properly there should be no surprises.

Specs:

wingspan: 28”

length: 21”

wing area: 140 square inches (0.97 ft2)

weight RTF: 7-8 oz. (with a 2s-3s 600 mah LiPoly battery)

wing loading: 8 oz/ft2

Included in this kit:

5 sheets of laser cut wood (all wood required), 28” x 36” rolled plans, 0.156” carbon wing spars, 2” steel wing joiner,

instructions.

Additional gear required: 24 mm 100 watt brushless motor with a kVa of around 1,500 rpm/v, 6 x 4 prop, 10 A ESC,

four micro servos (HS-45HB or equal), 6 channel receiver, and a 400-800 mah 2s-3s LiPoly battery.

Requires covering material (Ultracote or Oracover Lite recommended).

Instruction Manual for the PteroWorks 3D Mini Guppy

fly

o

u

t

s

i

d

e

o

f

t

he box

pt

e

r

o

d

a

c

t

yl

s

fo

a

m

p

l

a

n

e

s

ot

h

e

r

p

l

a

n

e

s

in

f

o

/

d

e

s

i

g

n

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 2

Body

1. Collect all parts for the body (g. A).

2. Assemble and glue inner frame skeleton

out of six ply pieces. Note doubler piece

at front-bottom. Check t of tabs and

sand if necessary before gluing (g. B).

3. Check t of skeleton frame with left body

side, ensuring all tabs t into their proper

slots, and glue in place (g. C).

4. Check t of right body side and glue in

place (g. D).

5. Check t then glue rudder post to

rear body sides. Note rudder post is

sandwiched in-between body sides. Be

sure body is square and straight before

gluing. Small clamps can help to set

alignment before gluing, and a scrap of

1/8” balsa can be used to align stabilizer slots (g. E).

6. Slide “backbone” into open top of body, check t,

sand if necessary and glue in place. Small clamps

can help ensure a solid bond (g. F).

7. Check t then glue top head piece. Sand if necessary

for a good t (g. G).

8. Check t then glue lower tail stiffener pieces. Sand if

necessary for a good t (g. H).

A

B

C

D

E

H

G

F

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 3

9. Glue two belly

plate doubler

pieces to inside of

belly plate (g. I).

10. Check t then

glue belly plate to

bottom of body

assembly (g. J).

11. Assemble lower

battery hatch

parts, checking position and t of latch

pieces before gluing (gs. K, L).

12. Sand body until pretty!

Wing

13. Collect all wing parts and lightly sand any laser

burn off all parts (g. M).

14. Cut two main carbon wing spars (0.156”

diameter) to 12.5” length each.

15. Glue two sets of identical inner (root) ribs (the

3/16” balsa ones) together, and sand an angle

into inner side surface (where it will mate with the

body) to match body angle. Note orientation of

ribs - the extension tab at the trailing edge is on

I J

K

M

N O P

L

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 4

the bottom of the wing. Test t the rib assembly to the body

with a carbon wing spar (g. N, O, P).

16. Fit all ribs to the leading edge piece. Sand ribs if necessary for

a good t of the tabs into the slots. Do not glue yet (g. Q).

17. Carefully run carbon wing spar through holes in ribs and into

notch on leading edge piece. Do not glue yet (g. R, S).

18. Fit and glue trailing edge pieces to rib ends, and the leading

edge piece at the tip (g.T).

19. Place wing assemblies on a at surface and ensure there

is no twist or warp in wing and glue all joints. Note: wing

design will favor a slight amount of wash-out at the wing tips

to increase stability of wing. Note again orientation of ribs -

the extension tab at the trailing edge is on the bottom of the

wing.

20. Carefully sand trailing edge to match the prole of the ribs.

21. Carefully sand ailerons to match wing ribs and taper down

toward their trailing edges.

Tail

22. Carefully sand rudder and horizontal stabilizer/elevator

pieces for a nice aerodynamic shape. Do not glue in control

horns yet (g. U). Note: shorter control horns are meant

for the tail surfaces (elevator and rudder).

Q

R

T

U

S

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 5

Covering and Assembly

23. Cover all parts before nal assembly. Ultracote/Oracover Lite

is recommended, but any good lightweight covering will work.

When covering the wing halves ensure there is no twist or warp.

Use a heat gun or covering iron to carefully remove any twist or

warp after covering (g. V, W).

24. Tape the control surfaces (ailerons, rudder and elevator) to the

wing halves and stabilizers with 1/2” clear tape. Glue control

horns into slots. Aileron horns should be on bottom side and

elevator horn should be on top. Rudder horn should be on side

opposite elevator horn. Use short horns for elevator/rudder.

25. Glue the horizontal stab to the body, ensuring it is square to the

vertical rudder and wing. Sand if necessary to ensure a good t.

26. Install the motor, ensuring there is clearance with the body sides

and lower battery hatch. Wires should run through the vent hole

in the rewall, and speed control will need to be attached to

wires on inside of body.

27. Install the elevator and rudder servos into the rear of the body,

and aileron servos into rectangle holes in body. Note orientation in

picture. Glue in place with CA or use screws (g. X).

28. Glue 2” steel wing joiner half way into one side of the wing spar.

Sand steel rst to get a good bond with CA (g. Y).

29. The wing can be left un-glued if you wish it to be removable, but

for increased strength the wings should be glued to the body.

30. Install receiver in main hatch area above wing and test t the

battery, which should lay on the belly plate doubler. Use a 2S-3S

LiPoly 400 - 800 mah.

31. Attach control rods to servo horns and control surfaces. Use

Z-bend .040 piano wire for ailerons and .050 carbon rods with

.040 piano wire glued to each end (g. Z).

32. Check Center of Gravity against the plans and ensure you are

within 1/8”. Position the battery to adjust the C/G, and mark the

battery’s position. Use velcro to hold the battery in place.

33. Program radio and adjust control surface throws. High rates:

Elevator should be about 5/8” up and down; ailerons should be

3/4” up and 3/4” down. Rudder throw should be about 1” left and

right. Low rates should be 60%-70% of high rates. Exponential is

recommended.

34. Always perform a radio check before ying the 3D Guppy. Use

low rated for first flight! The Guppy is designed to take off with

a gentle toss of your hand and belly land on grass. Spoilerons

(raised ailerons) can be programmed for shorter landings.

Experiment at a safe height!

35. Have fun!

V

W

X

Y

Z

Copyright © 2012 Ron Marston all rights reserved rev. D 7/12 6

Table of contents

Popular Toy manuals by other brands

Lionel

Lionel Madison TrainSounds Baggage Car owner's manual

Kyosho

Kyosho Gee Bee Z 40 instruction manual

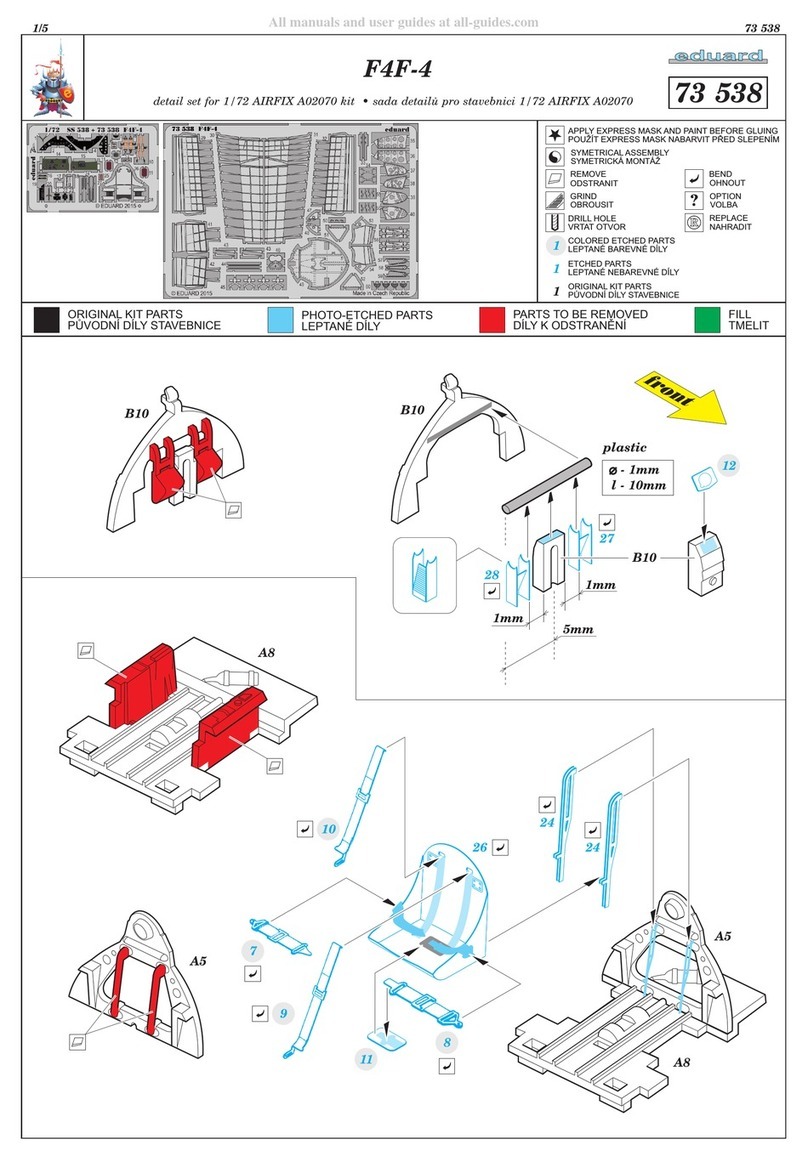

Eduard

Eduard 648520 quick guide

Eduard

Eduard F4F-4 Wildcat 1/48 quick start guide

MGA Entertainment

MGA Entertainment Gel-a-Peel Fashion Maker manual

Eduard

Eduard F-100F air brake Assembly instructions

Carrera

Carrera GO RALLY HEROES Assembly and operating instructions

LEXIBOOK

LEXIBOOK Barbie RPB011 instruction manual

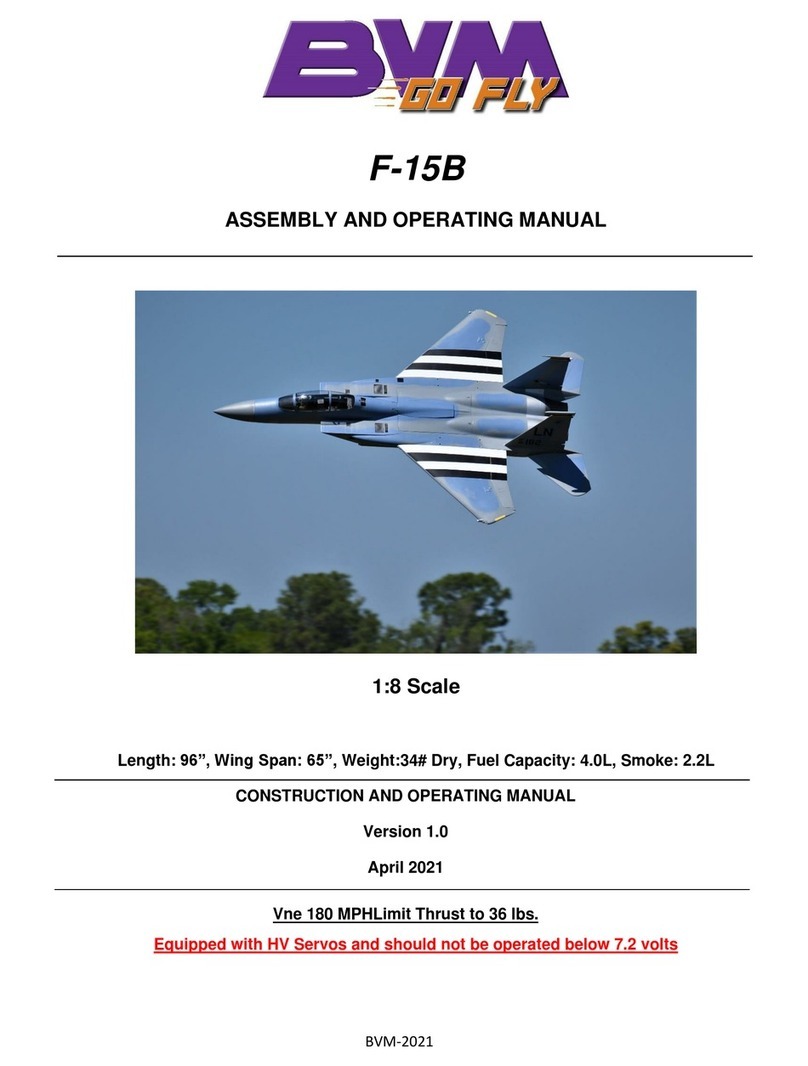

BVM

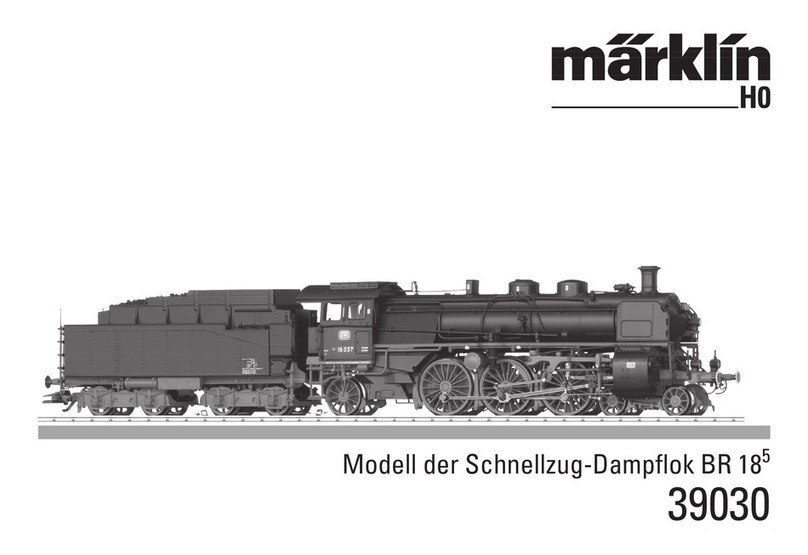

BVM F-15B Assembly and operating manual

Eduard

Eduard Tiger I Ausf. E early quick start guide

Viessmann

Viessmann 5020 Operation manual

Enabling Devices

Enabling Devices Funtastic user guide