PTI PX 300 User manual

Table of contents

Popular Toy manuals by other brands

Mega Bloks

Mega Bloks Nickelodeon Teenage Mutant Ninja Turtles Michelangelo Classic... manual

Fisher-Price

Fisher-Price J3987 instructions

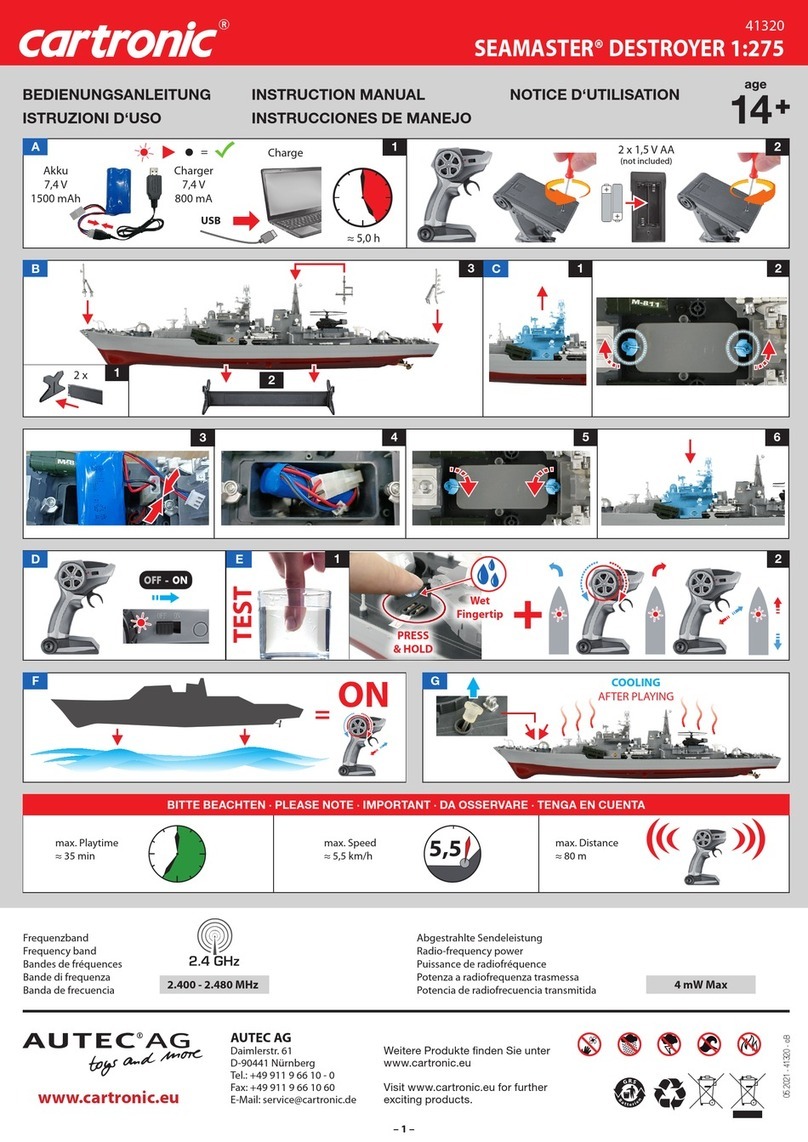

AUTEC

AUTEC Cartronic SEAMASTER DESTROYER instruction manual

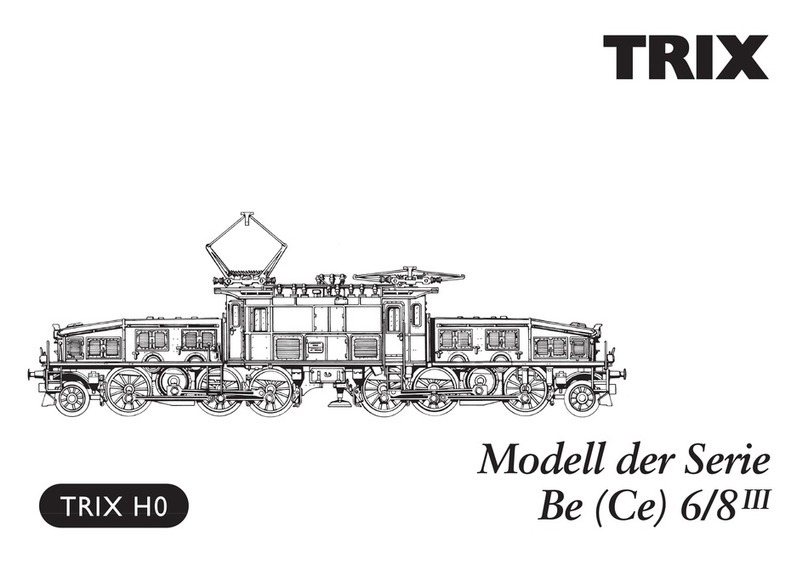

Trix

Trix Be 6/8III Series manual

ScaleTrains

ScaleTrains KIT CLASSICS HO SCALE CB&Q HAVELOCK SHOPS 52'6... manual

Nine Eagles

Nine Eagles SOLO PRO instruction manual

BLOTZ

BLOTZ B10-MW-112 instructions

LEGO

LEGO Town Plan 10184-1 Building instructions

Mattel

Mattel Monster High Create A Monster Design Lab instructions

Mattel

Mattel Polly Pocket GDK76 instructions

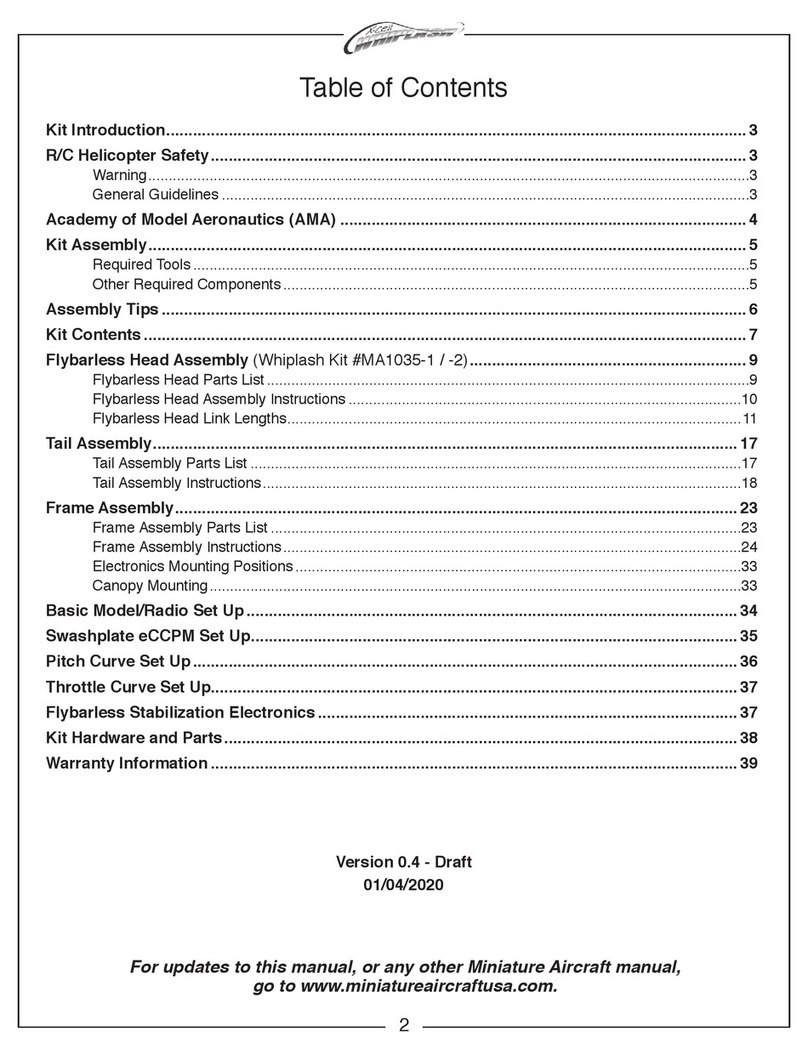

Miniature Aircraft USA

Miniature Aircraft USA X-Cell Whiplash Turbine manual

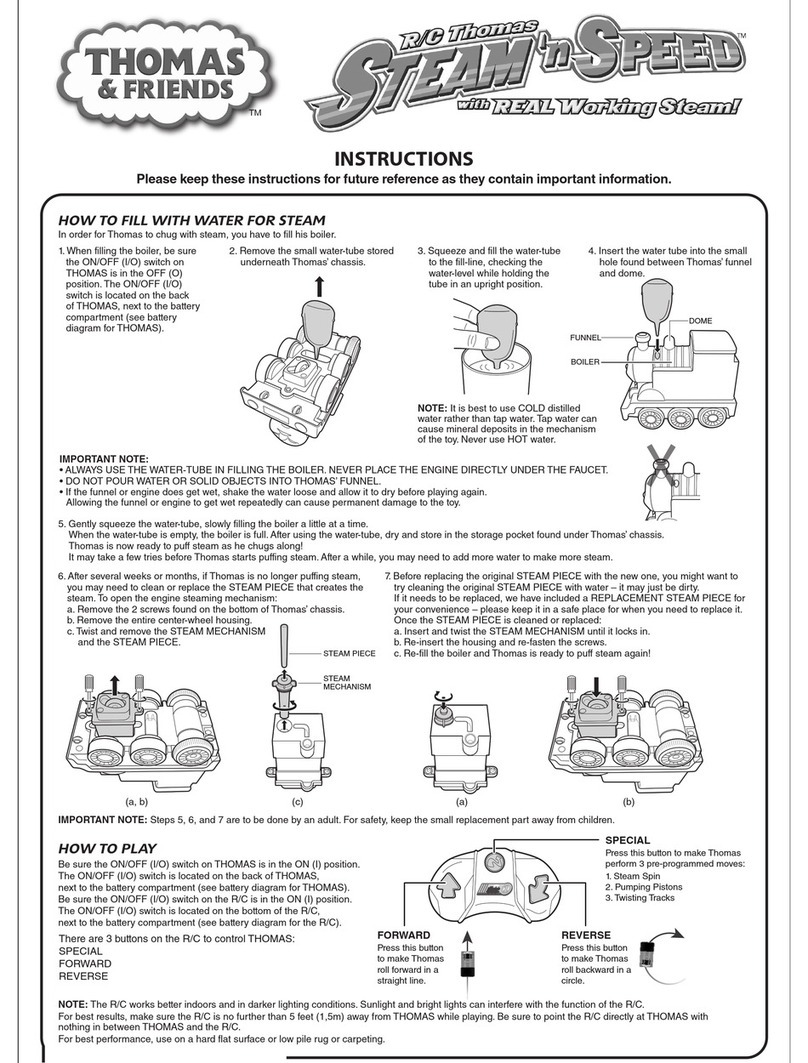

Fisher-Price

Fisher-Price Thomas & Friends R/C Thomas Steam'n Speed instructions

Fisher-Price

Fisher-Price Grow with me Kitchen J8226 instructions

Educational Insights

Educational Insights Artie 3000 user guide

REVELL

REVELL Dornier Do-28 D-2 SKYSERVANT Assembly manual

Mattel

Mattel Barbie FNY40 instructions

Fisher-Price

Fisher-Price 71664 instructions

Hasbro

Hasbro TransFormers Armada 7055 Assembly manual