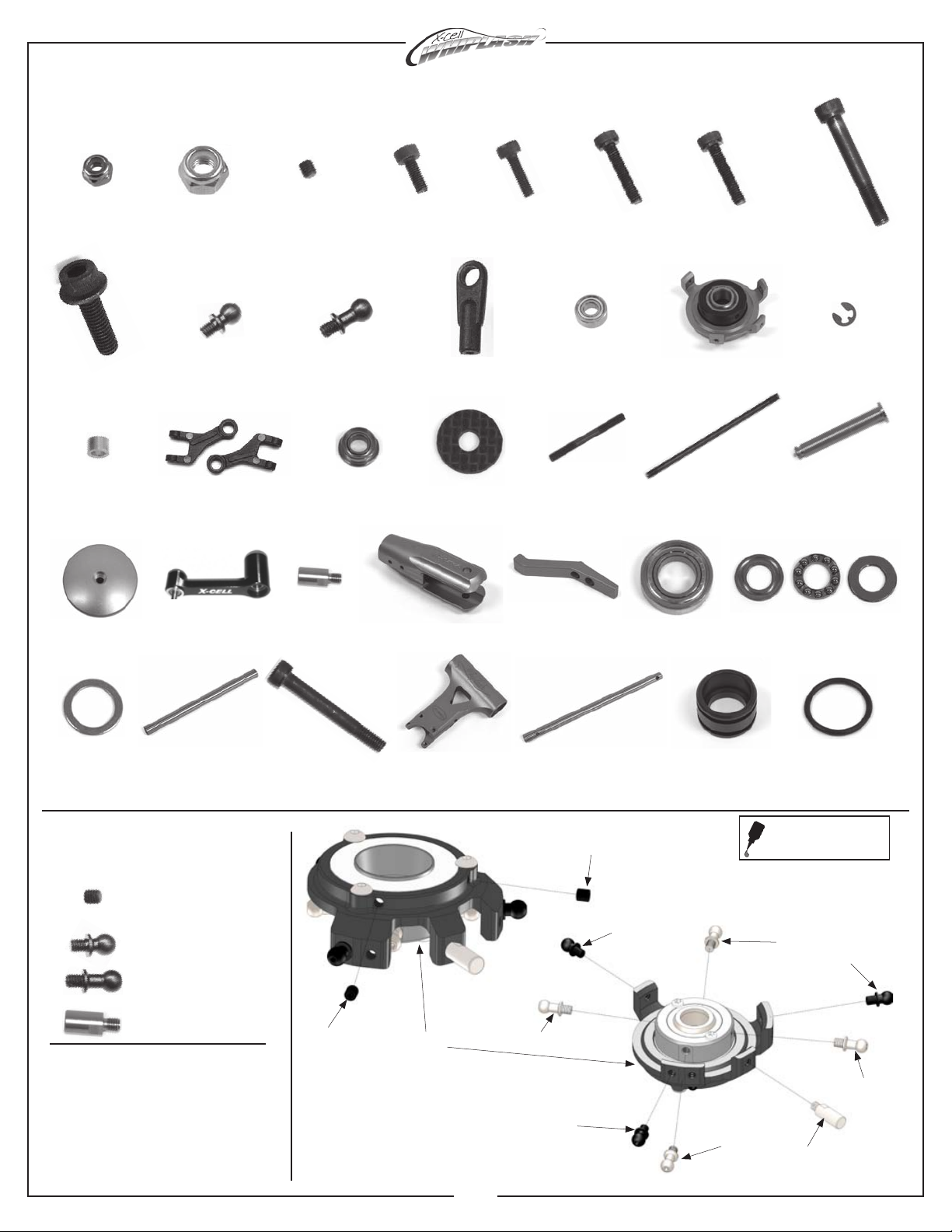

Bag Part No. Part Description Qty

3-A 128-57 3mm Tray Mount 6

3-A 131-52 Delrin Tray Mount 2

3-A 131-53 C/F Gyro Plate 2

3-A 135-55 C/F Angled Battery Tray 1

3-A 135-57 Spacer 1

3-A 135-383 Hopper Support 1 1

3-A 135-492 Hopper Support 2 1

3-Hardware 0032-2 M3x8 Tapping Screw 4

3-Hardware 0088-2 M3x6 Tapered Socket Bolt 14

3-Frames 135-487 C/F Left Frame - Turbine 1

3-Frames 135-488 C/F Right Frame - Turbine 1

3-Frames 135-115 C/F Bottom Plate 1

3-Hardware 0004 4mm Washer 10

3-Hardware 0032 2.9x9.5 Tapping Screw 4

3-Hardware 0060-1 M3x6 Socket Bolt 40

3-Hardware 0061 M3x8 Socket Bolt 40

3-Hardware 0063 M3x10 Socket Bolt 6

3-Hardware 0078-4 M4x8 Socket Bolt 6

3-Hardware 2700-01 3mm Blue Washer 35

3-B 128-58 Frame Spacer 6

3-B 128-90 Tank Plate Mounting Stud 4

3-B 131-46 P/A Servo Rail 2

3-B 131-47 C/F Servo Rail Spacer 2

3-B 131-186 C/F Anti-rotation Bracket 1

3-B 131-420 Mid Main Bearing Block 1

3-B 131-421 Upper Main Bearing Block 1

3-B 134-100 Engine Mount 1

3-B 135-104 T/R Drive Support 2

3-B 135-107 Rear Doubler 2

3-B 135-125 Front Canopy Spacer 2

3-B 135-429 C/F X-Brace 1

3-Hardware 0060-1 M3x6 Socket Bolt 4

3-Hardware 0063 M3x10 Socket Bolt 4

3-Hardware 0065 M3x12 Socket Bolt 4

3-C 0215 6mm Retaining Collar 1

3-C 127-86 Washer 2

3-C 131-3 Start Shaft w/Sleeve 1

3-C 131-117 Fan Hub 1

3-C 131-118 Shim Washer 1

3-C 131-119 Clutch 1

3-C 131-120 Fan 1

3-C 131-179 X-Block 1

3-C 131-411 Assembled Clutch Bell 1

3-C 135-101 Engine Support 4

3-C 135-103 Spacer 2

3-C 135-124 Turbine Mount 1

3-Hardware 0009 3mm Washer 4

3-Hardware 0051 M3x3 Socket Set Screw 2

3-Hardware 0064-3 M3x6 Button Head Socket 4

3-Hardware 0065 M3x12 Socket Bolt 2

3-Hardware 0069 M3x16 Socket Bolt 4

3-Hardware 0078-4 M4x8 Socket Bolt 2

Sensor Mount:

3-Hardware 0001 2mm Washer 4

3-Hardware 0016-2 4mm Safety Washer 4

3-Hardware 0018 2mm Lock Nut 2

3-Hardware 0049 M2x10 Socket Bolt 2

3-Hardware 0080 M4x14 Socket Bolt 2

3-Hardware 0081 M4x16 Socket Bolt 2

3-S 0818-3 Mounting Block 2

3-S 131-50 Elevator Servo Mount 2

3-S 131-148 C/F Servo Plates 14

S-Hardware 0017-2 2.5mm Hex Nut 5

S-Hardware 0059-1 M2.5x6 Socket Bolt 4

S-Hardware 0059-4 M2.5x12 Socket bolt 16

S-Hardware 0059-7 M2.5x20 Socket Bolt 4

S-Hardware 0116 M2.5 Threaded Steel Ball 5

Bag Part No. Part Description Qty

3-D 128-57 Spacer 1

3-D 128-58 Spacer 1

3-D 131-382 C/F Spacer 1

3-D 131-454 4mm Tray Mount 2

3-D 135-58 Spacer 1

3-D 135-380 White Strut II 2

3-D 135-382 C/F Strut Spacer 1

3-D 135-489 Lower Main Frame 2

3-D 135-490 C/F Frame Spacer R + L 2

3-D 135-491 C/F Washer 2

3-D 2500-39 Tuf-Strut II End Cap White 4

3-Hardware 0003 3mm Washer 4

3-Hardware 0058-1 M4x6 Socket Screw 4

3-Hardware 0064-3 M3x6 Button Head 6

3-Hardware 0073 M3x20 Socket Bolt 4

3-Hardware 0078-5 M4x10 Socket Bolt 4

3-E 0875-1 10mm Split Main Shaft Collar 2

3-E 131-424 Main Gear Hub 1

3-E 131-440 Lower Main Bearing Block 1

3-E 131-466 Auto Hub 1

3-E 131-469-1 Gear Support 1

3-E 131-470 70T Machined Crown Gear 1

3-E 132-117-B 124T Main Gear 1

3-Hardware 0021 4mm Lock Nut 1

3-Hardware 0059-2 M2.5x8 Socket Bolt 2

3-Hardware 0088 M3x8 Tapered Socket Bolt 8

3-Hardware 0088-3 M3x7 Tapered Socket Bolt 5

3-Hardware 0620-01 15x21x.10 Shim Washer 1

3-Hardware 0620-02 15x21x.20 Shim Washer 1

3-Hardware 0620-03 15x21x.30 Shim Washer 2

3-Hardware 131-202 Jesus Bolt OWB V2 1

3-E-1 106-22 Rubber Canopy Grommet 4

3-E-1 120-99 Canopy Knobs 2

3-E-1 128-59 M4 Front Boom Support Brace 1

3-E-1 131-153 C/F Canopy Breakaway Tabs 4

3-E-1 131-451 Rear Canopy Post 2

3-E-1 131-452 Canopy Post Splint 2

3-E-1 135-127 Boom Support Spacer 2

3-Hardware 0016-2 M4 External Serrated Lock Washer 2

3-Hardware 0015 2mm Hex Nut 1

3-Hardware 0081 M4x16 Socket Bolt 2

3-Hardware 0103 2mm Threaded Steel Ball 1

3-F 105-100 Fuel Line 9.5 cm 1

3-F 125-24 Fuel Filtered Pick-Up Magnet 1

3-F 128-92 Fuel Tank Plug 1

3-F 128-94 Fuel Nipple 1

3-F 131-138 Fuel Tank 1

3-F 131-144 Rubber Fuel Tank Mount 4

3-F 131-145 Tank Mounting Studs 2

3-F 131-146 C/F Fuel Tank Plate 2

3-F 135-133 Fanshroud R +L 2

3-Hardware 0011-5 Washer 1

3-Hardware 0014F 5mm Hex Nut - Fine Threaded 1

3-Hardware 0060-1 M3x6 Socket Bolt 4

3-Hardware 0061 M3x8 Socket Bolt 2

3-Hardware 0065 M3x12 Socket Bolt 4

3-G 0390 Wire Retainers 5

3-G 3200-30 20” Spiral Band for Wire and Cable 1

3-G 3200-46 1/2” Hook and Loop Tape 1

3-G 3200-48 20” 3/4 Hook and Loop Tape 1

3-G 3200-54 17” Adhesive Hook and Loop 1

BOX 135-252 Whiplash Canopy - Turbine 1

BOX 135-106 Hopper Tank 1

BOX 133-144 Skids

BOX 135-233 Whiplash Instruction Manual 1

BOX 3000-73 MA Towel 1

BOX 3700-160 Blade Holder 1

Bag 3 - Turbine Frame Assembly

8