Puhui MT-602 User manual

MT-602

User manual

Auto Chip Mounter

Taian Puhui Electric Technology Co., Ltd

Http://www.tech168.cn

MT-602 user manual

1/ 32

Instruction ofinstallation and commissioning

Introduce of machine

一、 machine parameters

Item

specification

product name

auto-mounter machine

product type

MT-602

mounting head

double mounting head

average speed

5000CPH

positioning accuracy

0. 025mm

net weight

151kg

applicable elements

0603-1206 SMD transistors, diodes, capacitors, resistors, chips, etc.

number of rack

56:8mm=50,12mm=4,16mm=2

Number of offline storage files

20

max size of circuit board

300mm×400mm

power supply

220V,50/60Hz,280W

vacuum gas source

-50Kpa,13L/min

operating system

Windows

installation dimension W×D×H

1396*761*480

Number of vacuum pump

2

Number of pump

1

malfunction detection

Suction leak detection, pressure detection

二、 appearance of the machine and basic structure

MT-602 user manual

2/ 32

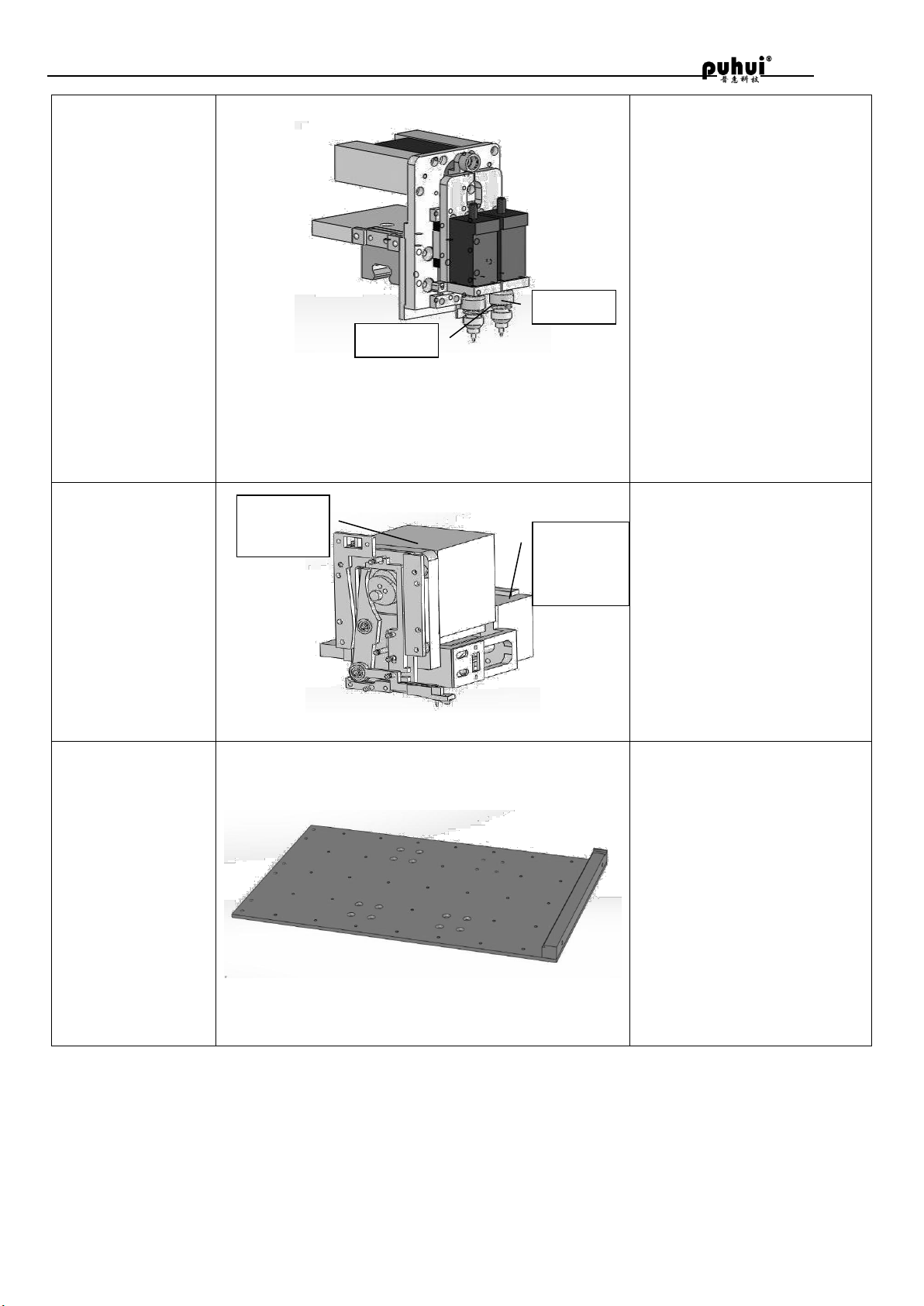

三、 Main Institutions

Y-axis motion

components

1, Y-axis plate

2, linear bearings supporting

base

3, linear bearings LM25UU

4, Y synchronous wheel

mounts

5, Y synchronous wheel

6, Y-axis motor mount

7, large X-axis belt fixed tooth

plate

8, shaft belt adjustment block

9, large X-axis belt adjustment

block briquetting

F608ZZ flange bearings

Emergency

stop switch

Suction

mechanism

Pusher

mechanism

Tray moving

mechanism

Feed tray

rack

Operation

panel

Y-axis motion

components

Power

switch

Take belt

mechanis

m

Rack shaft Motion

components

power

interface

USB

interface

MT-602 user manual

3/ 32

Suction

mechanism

1, the vacuum solenoid valve

2, linear slide MGN9C

3, Z-axis limit switch

4, pick-and-place the drive

motor Z

5, the rotary drive motor Q1,

Q2

6, a nozzle, the nozzle

assembly 2

7, Z-axis suction mounting

plate

8, Y-axis slide mechanism

connecting plate suction

9, Y-axis belt tensioning block

10, Y-axis belt tooth plate

11, motor angle slider stopper

Pusher

mechanism

1, the pusher motor

2, the pusher cam mechanism

component

3, T limit switch

4, the pusher pin

5, the pusher adjustment motor

6, pusher holder

7, pusher slider

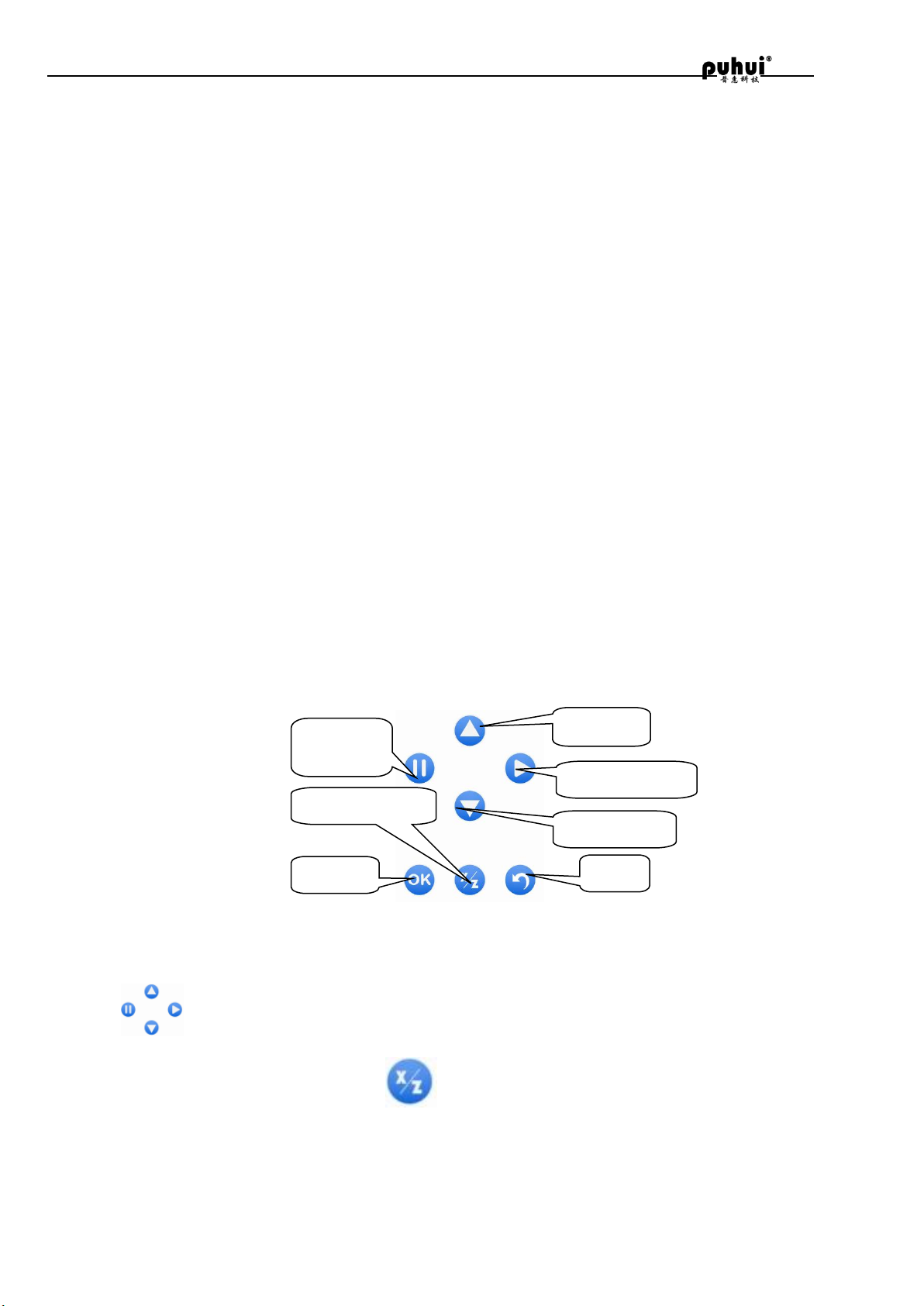

Tray moving

mechanism

1,470X300 tray

2, the slider tray

3, the tray belt fixing plate

4, linear slide SBR16UU

5, slider slider

6, the right tray stopper

7. Fixed slider block

Nozzle1

Nozzle2

2

Pusher

motor

Pusher

adjustment

motor

MT-602 user manual

4/ 32

Waste recovery

mechanism

1, closing with gear box

2, the take-up gear assembly

3, take-up motor

4, the take-up motor drive

circuit board

Feed tray

1, tray holder

2, pin for tray

3, waste recycling gear

4, the guide wheel

Rack

1、patch wedge

2、pressing reed

3、discharge pressure bar

Preparation and installation

1. Preparation and Precaution of installing

(1)Preparation of installing

1. Choose a flat ground to ensure that the machine level

2. Choose firm placement platform to ensure that the machine can not move.

3. Enough space for production operations.

4. Avoid hot and humid environment.

5. Check the power cable if there is breakage.

(2)Precaution for use

1. Electrical Considerations

Use a multimeter to check if the power supply voltage is correct and the connection is reliable.

Ensure that it is earth grounded safely.

Ensure that all hardware connections are secure.

2. Safety Precautions

Before moving the machine, turn the power off, unplug the power cord.

Pay attention to personal safety when transport.

Ensure there is no foreign matter inside of machine before electrifying.

MT-602 user manual

5/ 32

Before electrifying, manual confirmation of the agencies operating normally, without hindrance.

Press the red emergency stop switch, and the system power supply is disconnected when there is

emergency.

Installation of mounter

(1)Select the appropriate operating space for placing Mounter

(2)The SMT machine should be placed in a special support frame.

(3)The machine power should be accessed on the labeled INPUT socket.

Debugging Preparation

1. Safety tips of commissioning test

(1)All of components that are working should not be obstructed when operated.

(2)All of components that are working should not be pushed when stopped.

(3)Ensure that the terminal connection is well.

(4)Restart it after 20 seconds when cut off power.

(5)Press the red emergency stop switch and the system power supply is disconnected if there is emergency.

2. Introduce of operation panel

(1)Above panel

1. Emergency stop switch

Press this switch, power is cut off and all actions of mountor machine are stopped. Clockwise rotation,

button bounces and power is on, following that machine resets and each axis return to the original position.

(2)Main panel

1. LCD

2. Buttons

Description of function keys:

When the reference point to identify the state, it is used as the arrow key of mounting head to

control the moving of mounting head. When the reference point to identify the state, it is uesd for

controlling the nozzle’s up and down movement, while other states, functions as shown above picture.

(3)Side panels

1. Cooling fan outlet

2. Access outlet for main power

Cursor up

Back

Confirm

Mount Continue

Mount

pause

Cursor down

Tray in and oput

MT-602 user manual

6/ 32

3. Power switch

4. USB communication interface

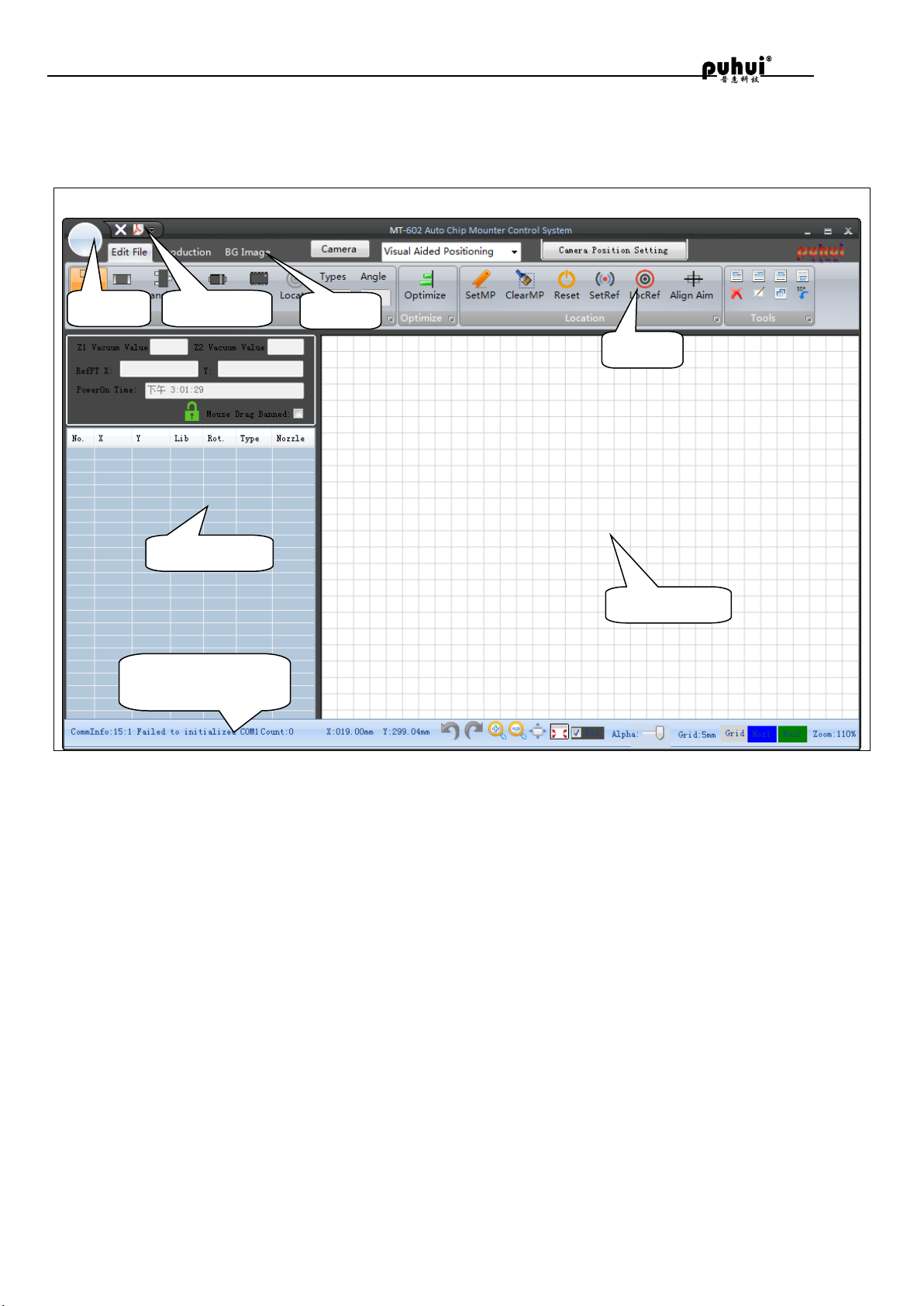

3. Introduce of software interface

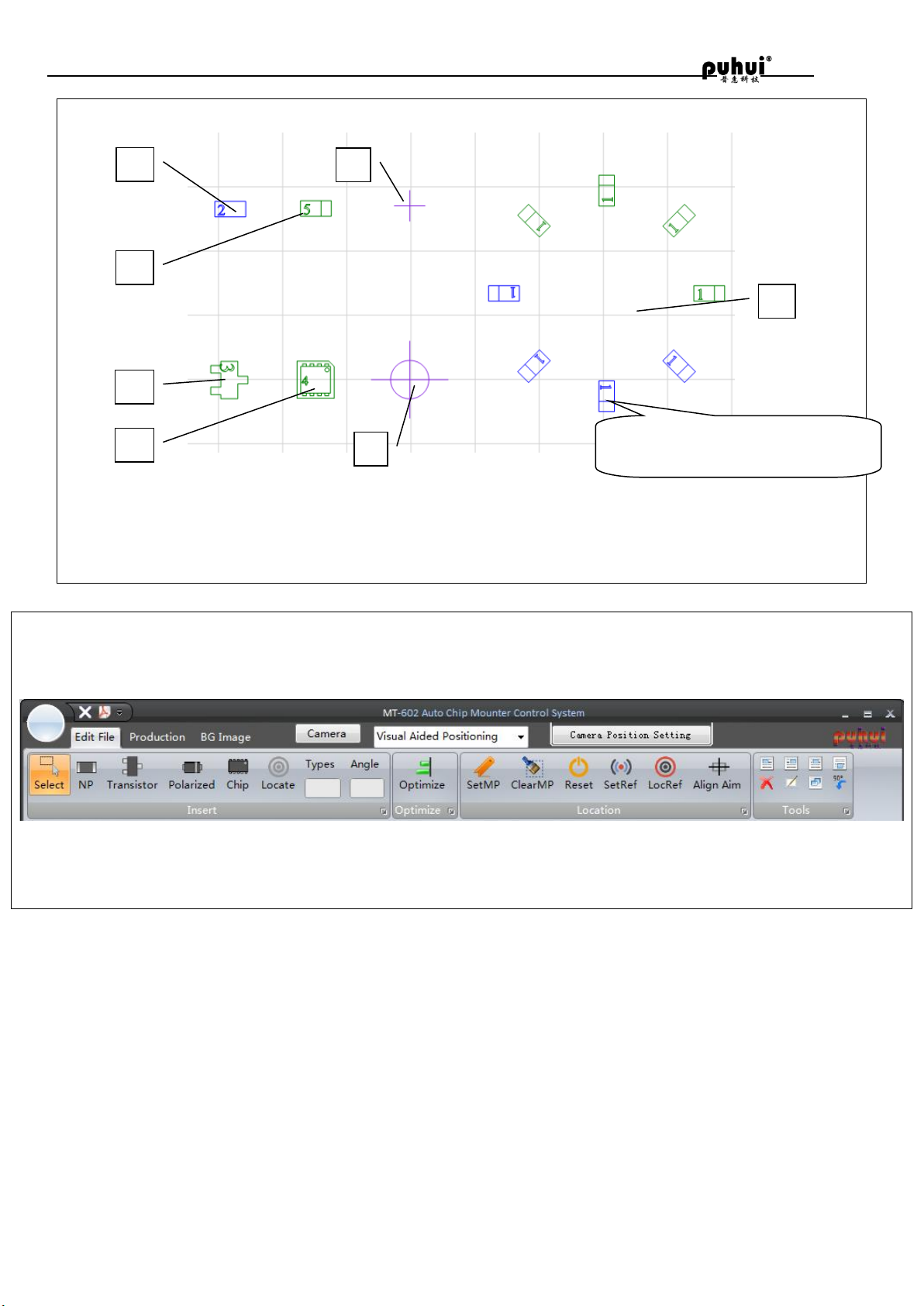

Main interface

Graphing area

Prompt area Status

information

Element list

Menu

Tab

Instructions

toolbar

MT-602 user manual

7/ 32

Graphical representation

1. No directional element graphical representation 2. Directional element graphical representation 3. Transistor

element 4. Graphical representation of chip components 5. Mark point marker graphic 6. Reference Point logo

graphic 7. Circular array

1

2

3

4

7

5

6

Blue elements using nozzle 1

Green software uses nozzle 2

MT-602 user manual

8/ 32

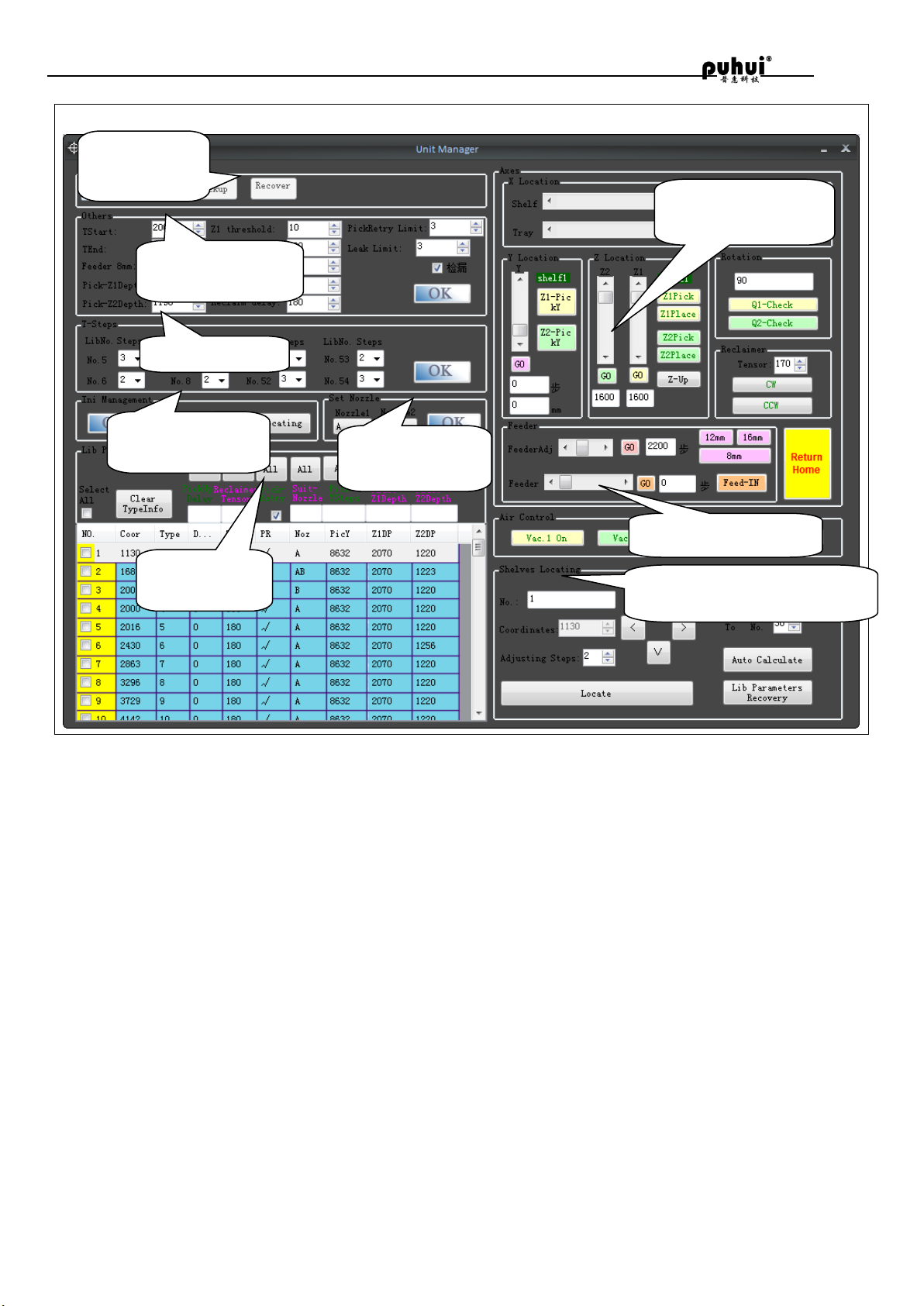

Parameter interface of equipment

Rack parameter

field

Backup and

recovery zone

Each axis positioning

zone

Rack coordinate adjustment

zone

Other parameters

zone

Pusher step zone

Pneumatic control zone

Rack management

zone

Current nozzle

settings area

MT-602 user manual

9/ 32

Interface of the device parameters

1. select all of rack 2. Empty rack model column 3. rack Number 4. device coordinates of rack 5. element

models of rack 6stay time on elements when picking element. 7. take-up tension of take-up belt 8. Whether

to check leak of rack element 9. The nozzle type that can be used on rack element. 10. device location

coordinates the feeder element Picking Y 11. Discharge depth of the rack-mount device application when the

nozzle 1, 12Discharge depth of the rack-mount device application when use nozzle 2, 13. Single rack selection

box

Blue area is

editable area

Gray areas is

non-editable

regions alone

yellow area is

current editing

area

2

1

3

5

4

6

7

8

9

10

11

12

Batch edit of

feeder parameters

13

MT-602 user manual

10 / 32

Paraments interface of the device

Rack coordinate coefficient correction: This

section generally do not need to change, but after

replacing a timing belt or adjust belt tightness

need to re-adjust

Mounter online port

selection

Communication baud rate

setting: Do not change this

MT-602 user manual

11 / 32

Operation instructions

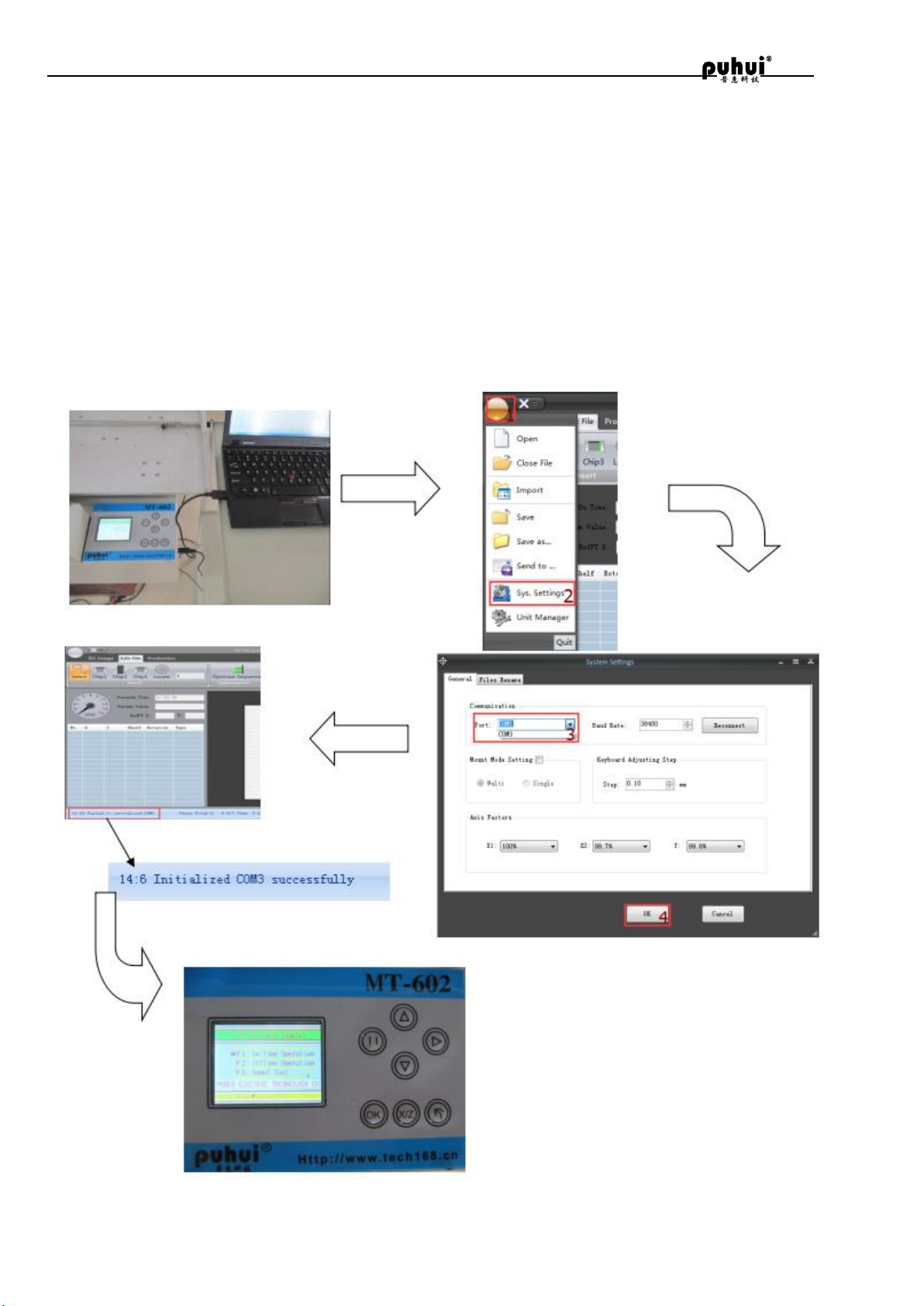

Operation 1 —— Connect with computer

一、Connect MT-602 with computer by using USB wire,open the control software, turn on the

power of MT-60.

二、Click “main menu” - “system parameter, you will see “system parameter setting dialog box”,

click serial port, you will see the current name of the serial port.

三、Select the serial port which match with USB wire.

四、Click OK, you will see the notice information in the bottom left corner of page。

五、At this time, Press “OK” at MT-602 operation panel, start to connect with computer, it connect

successfully when MT-60 operation page show “already connected with computer”

MT-602 user manual

12 / 32

Operation 2 —— Parameter Adjustment

1. Install Feeders

Feeders NO 1-10 suit for diode, triode with plastic feeders. 31-34 suit for

12mm components,35-36 suit for 16mm components. The others suit for 8mm components.

2. Entry formation of feeders

(1). Click Main menu - Unit manager, entry the information of feeders.

MT-602 user manual

13 / 32

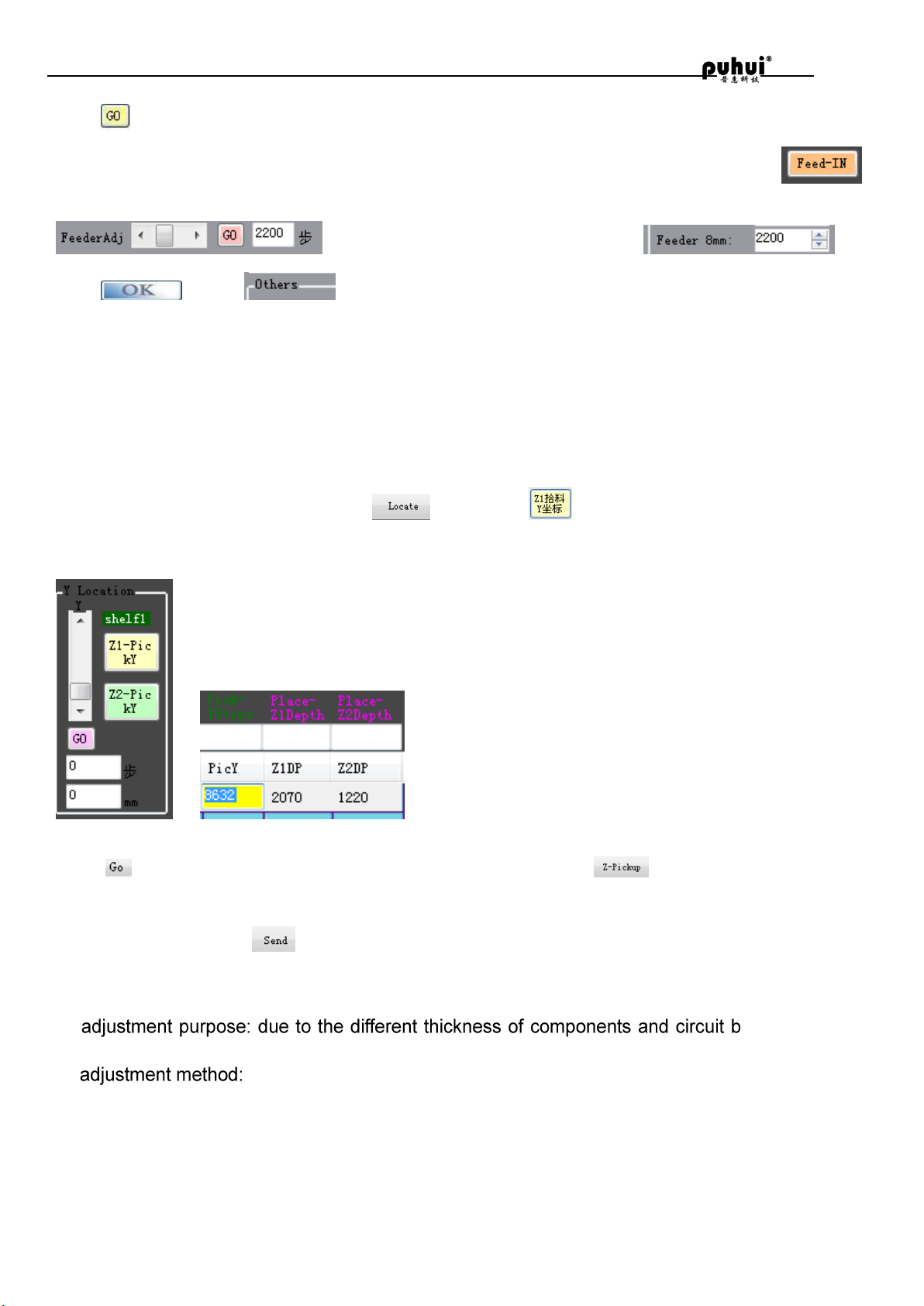

(2). Check feeders coordinate

Checking purpose: make nozzle locate in the middle of component between left and right.

Click “main menu” – “Unit manager”, click the number of checked feeder, click , the

nuzzle will move to the feeder, click and , check whether the nuzzle

locates in the middle of component. If not, click and , then click , click

again, the nuzzle wiil move the new coordinate, check again to confirm the position. Click

after adjusted.

(3). Check pick- Y steps

Checking purpose:make nozzle locate in the middle of component between before and after.

Select any a feeder number, click , then click to push a component, coil the skin

manually. Then copy the data of Y steps.

Click , the nuzzle will be moved over the component. Click , the nuzzle lands

on the component, check whether the nuzzle locates in the middle of component. Copy the

data to entry the pick Y steps. , click to save data.

MT-602 user manual

14 / 32

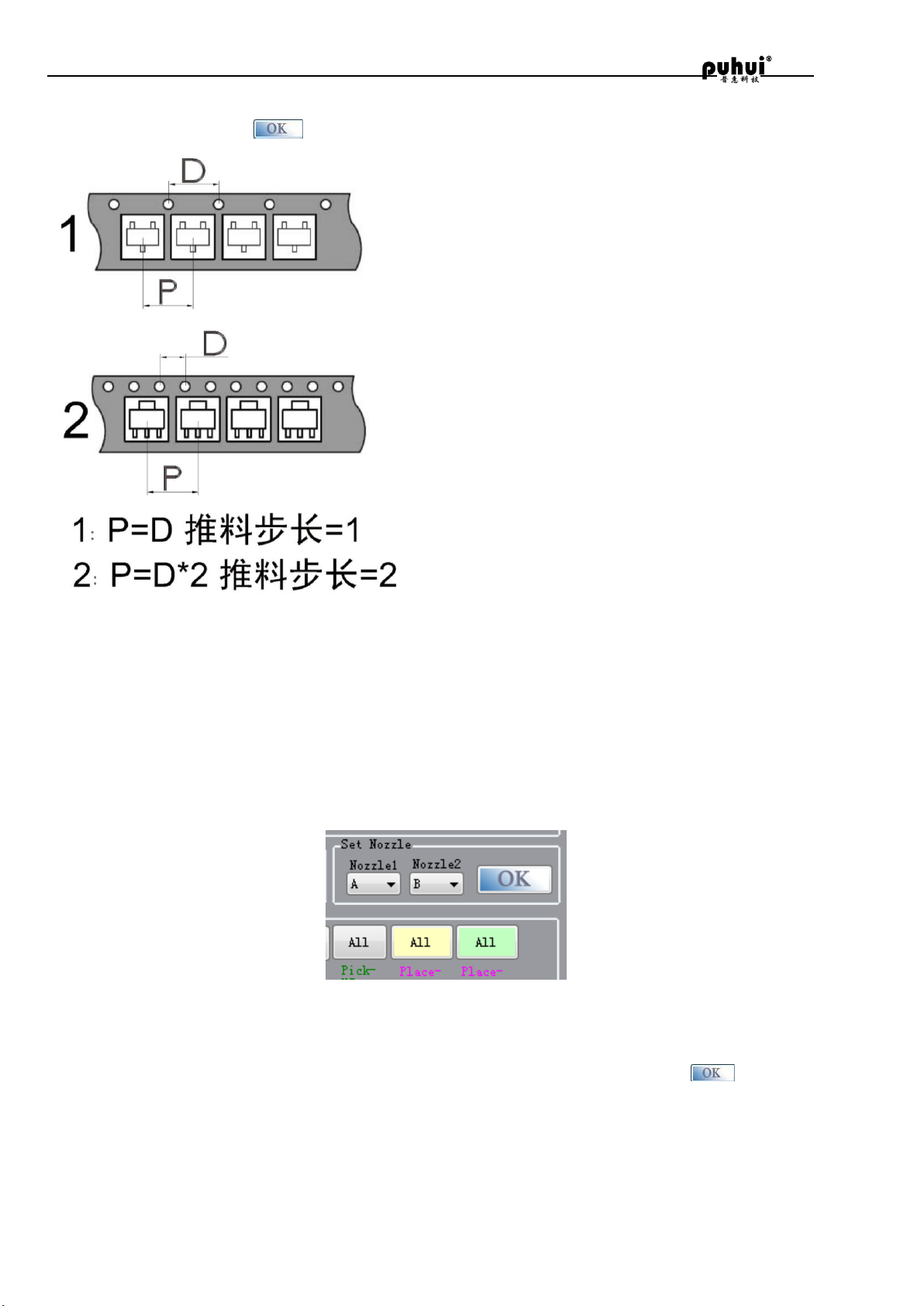

(4). In pushing step length, according to the no. 31 ~ 36 loading of material situation, set up

pushing step, click set after the completion of the pushing step to save data.

3. Suction nozzle setting

(1) The machine is equipped with five different specifications of the suction nozzle, specifications

and codes are: A inner diameter is 0. 6 mm, B inner diameter is 0. 8 mm, C inner diameter is 1. 2

mm, D inner diameter is 1. 5 mm, E inner diameter is 2. 5 mm. In order to realize the customer's

different specifications of the ideal of the patch SMT.

(2) Users choose to maximum meet all of the SMT components installed on the material shelf two

suction nozzle assembly requirements, installed on the suction nozzle 1, the suction nozzle 2.

(3) Click the main menu - equipment parameters - in the "current suction nozzle set" drop-down

menu Settings, such as, code-named B of suction nozzle is installed on the suction nozzle 1, as

shown below "suction nozzle 1" below the menu option "B", the same method for the suction nozzle

2 "Settings, set up is completed, click the current setting suction nozzle area save data.

(4) According to the material on the element size set the suction nozzle. Of no. 0603

components using A suction nozzle SMT, 0805 and 1206 components using A and B, suction

nozzle specifications for SMT, large size chip components suggest using D, E, suction nozzle for

SMT. All other components according to the size to choose suitable for placement of the suction

nozzle specifications.

MT-602 user manual

15 / 32

4. Parameter adjustment

(1) Coordinate correction and pick up material depth adjustment

▲ adjustment purpose: suction nozzle is located in the rack to head is the central element direction

and depth has the right to pick up.

▲adjustment method:

MT-602 user manual

16 / 32

(1) In turn, click on the main menu - equipment parameters, the material parameter selection a

marking bar, click , suction nozzle 1 will be shifted to the rack, click ,

near the suction nozzle to the material, click on the suction nozzle 1 to fall on the

components, observe whether suction nozzle 1 is located in the center position of the element left

and right. If there is deviation, according to the migration direction and distance, click or

adjust (click , rack position shift to the left, click , rack position moves to the right). Then

click on the suction nozzle 1 will be moved to the new coordinates, repeating

observation adjustment, until the suction nozzle 1 is the central element is located in the left and

right.

(2) Click or button, will change the selected material (position number increased to shift to

the left, position number reduced to moves to the right), click , suction nozzle to

the material. Repeat the first step of the operation, until all rack position adjustment.

3, click on the material management, to save parameters are adjusted to the MT - 602

hosts.

4, watch suction nozzle in the above check Z1 falls on components, whether to have enough buffer.

If need to adjust, click on the main menu - equipment parameters, fine-tuning area Z1

slider and Z1 slider below , click to view at this time whether there is enough to the suction

nozzle on the element of the buffer, adjust the appropriate after copying the value in the text box

below the Z1 notification to the text box at the back, the same method to adjust Z2

found material depth (note: Z2 to pick up the smaller depth, said the whereabouts of suction nozzle

Z2 depth, the greater the Z1 pick up material depth, the greater the said Z1 falling depth is larger).

5, If parameter tuning out, press , material parameters all returned to the factory

settings.

(1) The adjustment of pushing mechanism

First in the material parameters of the bar, choose a 8 mm rack, then click ,

suction nozzle will be shifted to the rack, click

and , when the element suction nozzle 1 is located in the center of the left and right

position, slide the slider and click , pushing electric opportunity

to the slider move in the direction of the translation, click at the ends of the slider and then

MT-602 user manual

17 / 32

click on pushing the motor position fine-tuning, when pushing motor to pushing needle at strip

pushing round hole left and right in the middle of the position, stop the adjustment, click

right now, to see whether the normal launch patch element, adjust the value

in ideal will be copied into the text box ,

click in the to save data.

(2) Check pick - Y steps

Checking purpose:make nozzle locate in the middle of component between before and after.

Select any a feeder number, click , then click to push a component, coil the skin

manually. Then copy the data of Y steps.

Click , the nuzzle will be moved over the component. Click , the nuzzle lands on the

component, check whether the nuzzle locates in the middle of component. Copy the data to entry

the pick Y steps. , click to save data.

(3) the feeding depth adjustment Feeding depth of ±10 will have obvious change oard thickness,

adjust the that suction nozzle feeding with appropriate flexibility.

1, 11 ~ 30 rack and 37 ~ 56 material feeding depth adjustment Will be pasted on the circuit board

fixed on the tray, Y axis adjustment slider, X axis, the slider, the suction nozzle above 1 to circuit

board. Adjust the Z1 slider, suction nozzle 1 after falling and circuit board, the distance between 1

after falling to suction nozzle, it is advisable to contact with the circuit board just. Copy Z1 slider

MT-602 user manual

18 / 32

below the values in the text box, paste into the text box below and select material

to full box full frame materials, click on the button , the material of the Z1 feeding depth are

set to the values in the text box. To adjust the feeding Z2 depth in the same way.

In the no. 2, 1 ~ 10 aircraft and 31 ~ 36 material feeding depth adjustment

Rack and 31 1 ~ 10 ~ 36 rack for components have different thickness difference is bigger, so I

need a single material. Will be pasted on the circuit board fixed on the tray, will adjust the rack

components placed on the circuit board, Y axis adjustment slider, X axis, the slider, the suction

nozzle above 1 to components. Adjust the Z1 slider, observe the suction nozzle 1 after falling and

the distance between components, with suction nozzle 1 after falling, and element just slightly

elastic contact is advisable. Copy Z1 slider below the values in the text box, paste to the material

parameters of the area to adjust the material feeding Z1 bar text box. The same method to adjust

the other rack and Z2 feeding depth.

3, the same method to adjust the feeding Z2 depth. All after the adjustment, click on OK and save

material in the material parameter bar parameters.

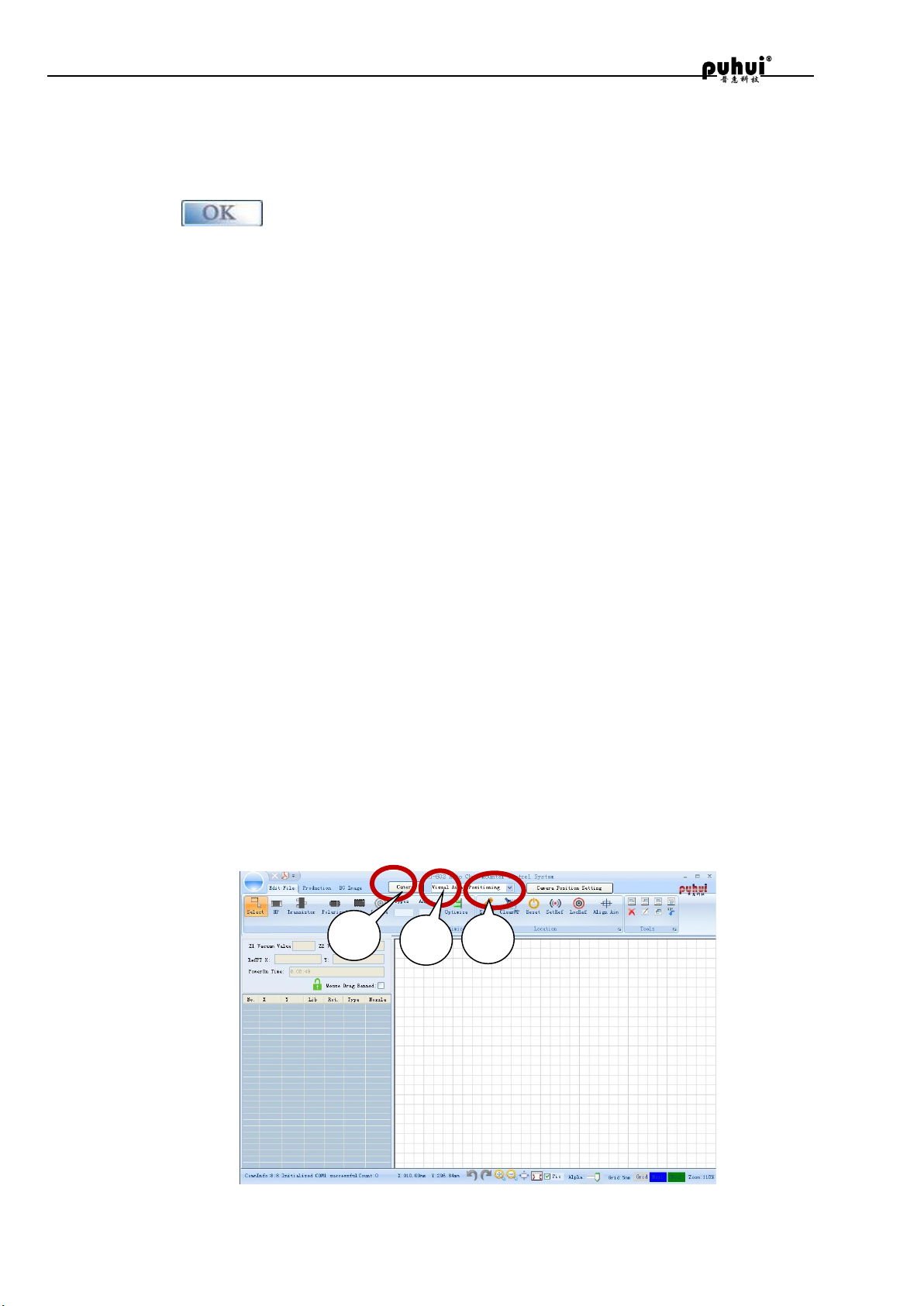

(4) Suction nozzle MARK point coordinate difference calculation:

poses:

Computing suction nozzle 2 relative to the suction nozzle 1 place in the X direction and Y direction

deviation, so as to determine the suction nozzle device coordinates of 2.

1, have a small flag stop right at the tray.

2, open the placement machine control software, click edit graphics - click on the "1" suction nozzle,

the mouse moved to the lower right graph area, the cursor into a black cross style.

3, move the mouse or press the direction key (keyboard to adjust the interval is inversely

proportional to the magnification of the canvas, canvas magnification, the greater the keyboard

adjustment interval is smaller, the adjustment precision is higher. Sliding the mouse wheel to

zoom the canvas size), and makes the suction nozzle 1 corresponding move over the tray. Press

the space bar, SMT machine suction nozzle 1 will fall, loosen the blank space key and suction

nozzle 1 is raised.

4, use the mouse or the direction key to adjust the suction nozzle position, until the suction nozzle 1

center is for us to do MARK, press the Enter key, the cursor position MARK will appear blue cross

point MARK. At this point, "suction nozzle 1" behind the two text box will show the MARK point

coordinate values.

5, click on the "suction nozzle 2", the choice we make marked as benchmark, use the mouse or the

direction key to adjust the suction nozzle position 2, until the suction nozzle 2 center right we do

MARK in the block center, press the Enter key, the cursor position MARK will appear blue cross

point MARK. At this point, "suction nozzle 2" behind the two text box will show the MARK point

marker coordinates, press the ESC key to exit the MARK point positioning, suction nozzle 1 and

suction nozzle 2 X and Y direction coordinate difference value is automatically calculated and

displayed on the back of the two text box, click the "OK", transferred to the SMT machine.

(5) other material parameter adjustment:

MT-602 user manual

19 / 32

1, components are required when increasing material delay.

2, components of material coated hard to tear apart, tension, increase recovery of coated strip

break easily, reduce the tension of recycling.

Enable/disable 3, leak detection function.

4, adjust, click on the rack to save administrative zones

MT-602 visual aids

Main interface

1

3

2

Table of contents

Popular Lathe manuals by other brands

Robust

Robust Sweet Sixteen owner's manual

Sherline Products

Sherline Products 4410 operating instructions

Teknatool

Teknatool nova Neptune DVR Operation manual

Rikon Power Tools

Rikon Power Tools 70-1824VSR Operator's manual

Teknatool

Teknatool NOVA DVR SATURN instruction manual

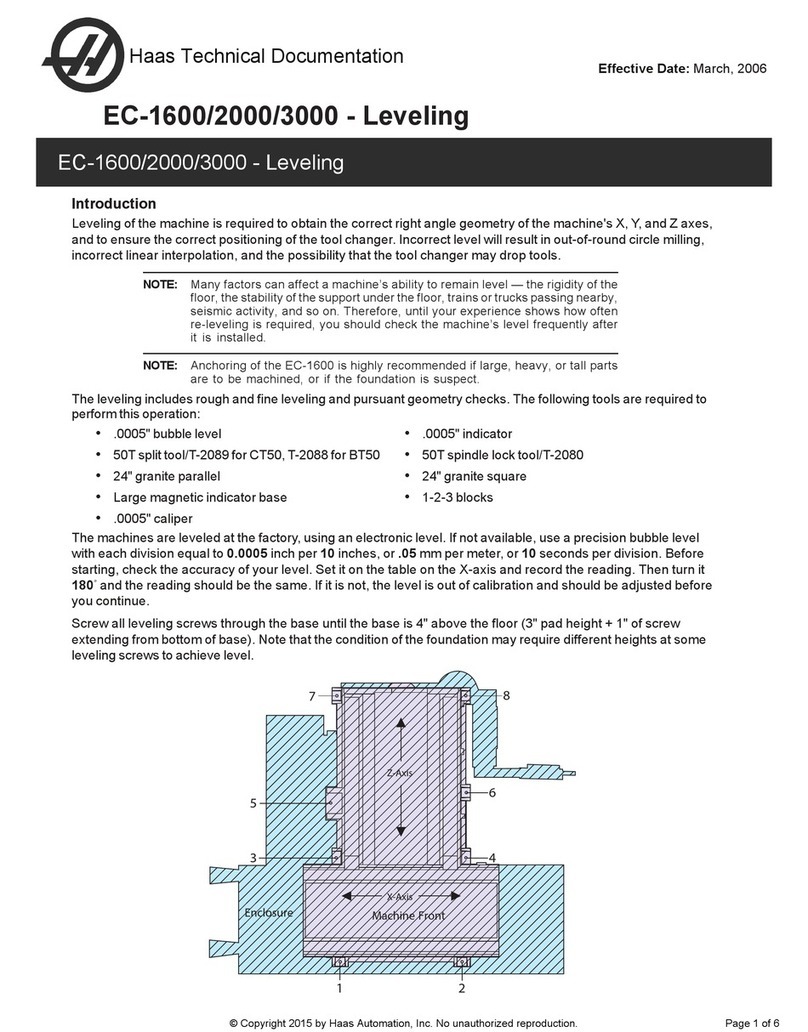

Haas

Haas EC-1600 Technical documentation