7

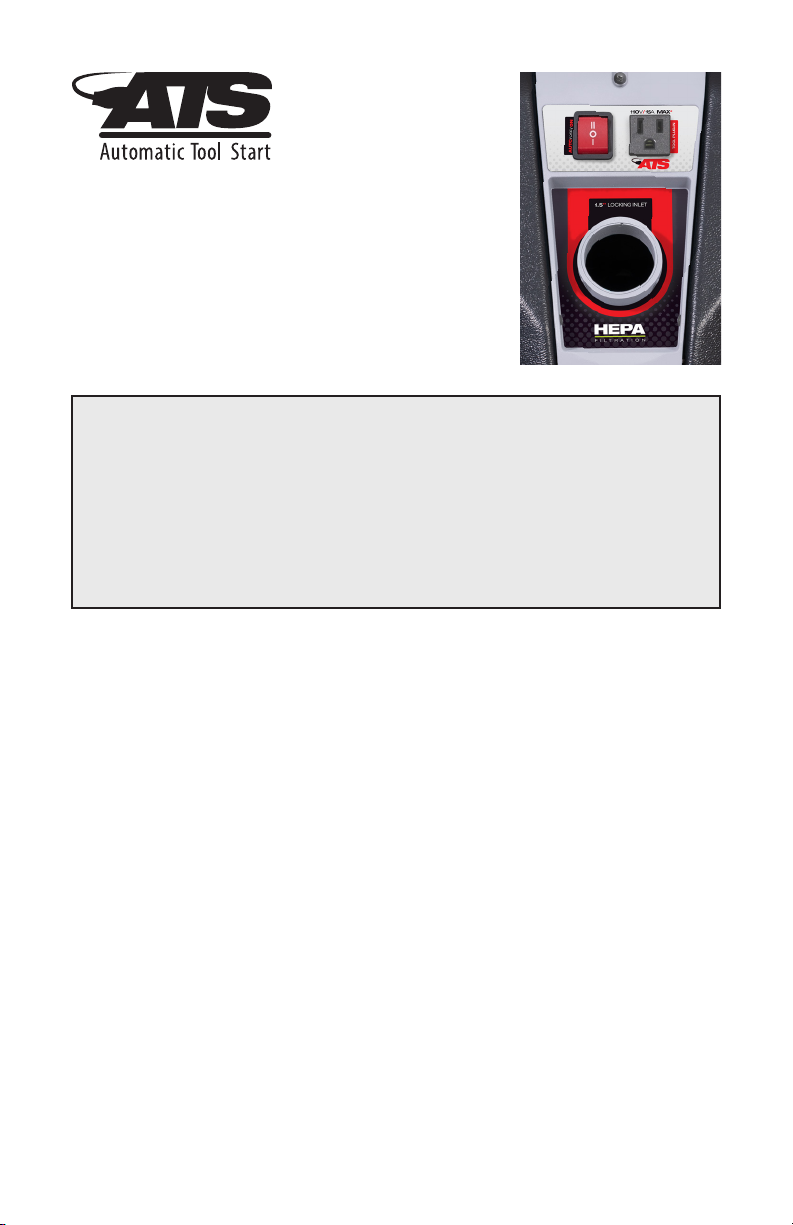

FILTER INSTALLATION & REPLACEMENT

The 552 comes with two Individuallytested HEPA Certied lters installed. The 552H has an additional HEPA

IEST RP CC007.3 lter installed. To replace twist on lters and ensure proper lter installation in the unit

follow instructions below.

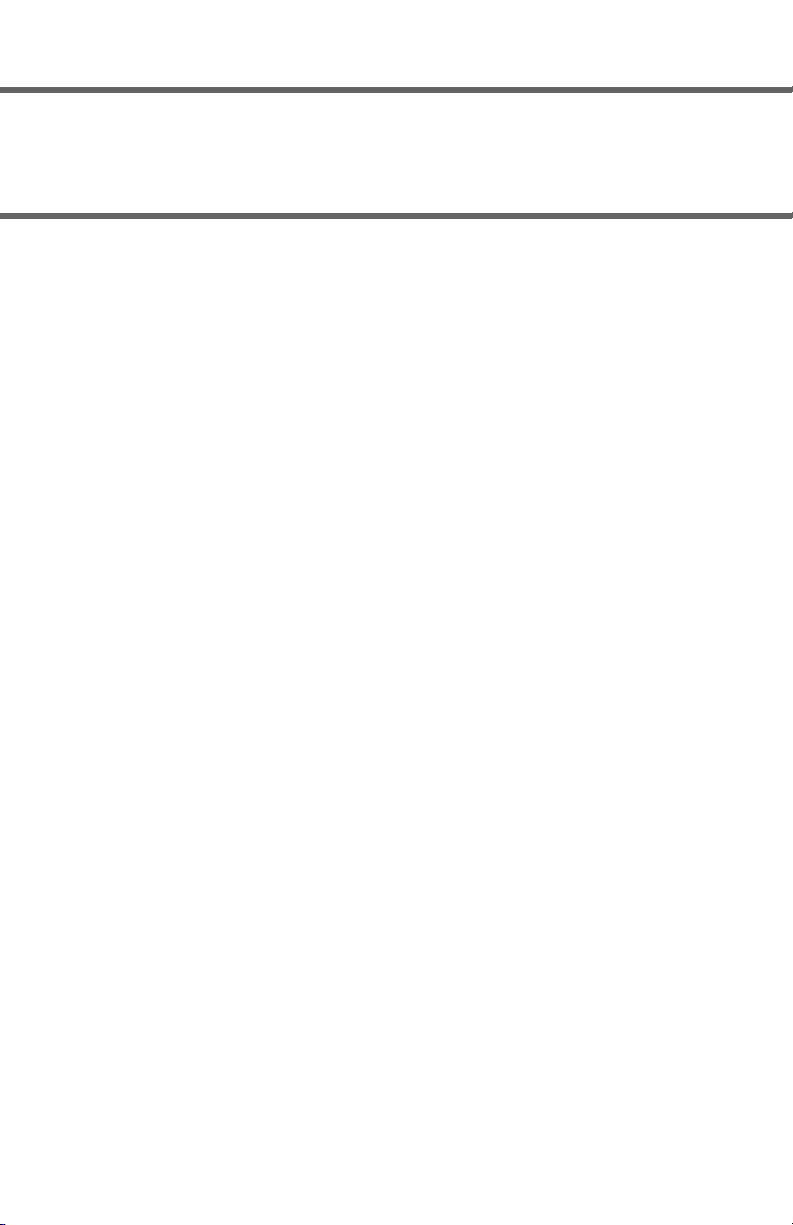

Figure 3

CAUTION:

Once you have installed the lters on the Pulse-Bac®, the lters should never

be removed unless they are to be replaced. Removing the lters after initial

installation can cause various problems if not reinstalled properly. Since

your new Pulse-Bac® cleans its lters automatically, you should never have

a reason to remove the lters other than for replacement. It is recommended

that lters be changed every 6-8 months when used daily.

If you need assistance or require additional information when installing the

lters, you can contact Pulse-Bac Vacuums Customer Services Department

at 866.954.9700 we will put you in contact with a technician that can help

you accomplish the installation and answer any questions you may have.

Step 1. If not already installed, install

the rubber seal (P/N #403245) onto

the the top of the Twist-on lter as

shown in Figure3 : Then twist the

lter Into the receiver under the head

assembly counter clock wise until

tight.

Step 2. Check to ensure that the lter

receiver is clean and void of any dust

or foreign material before screwing

your lter into place.

Step 3. Insert the lter into the lter

receiver and twist in a clockwise

direction until the lter just touches

the base, then turn the lter one

quarter turn to tightly secure it.

Once the lters have been installed,

the vacuum is ready to be put into

service. (The 552H’s third HEPA Filter

is located inside the vacuum unit. See

next page.)